Maturation device and polymer preparation system for chemical flooding oil recovery

A chemical flooding and polymer technology, applied in the direction of chemical/physical processes, chemical instruments and methods, mixers, etc., can solve the problems of reducing the viscosity of polymer solutions, clogging of screens or porous materials, shear degradation, etc., to achieve improved Dissolution speed, reduced investment and floor area, and the effect of preventing shear degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

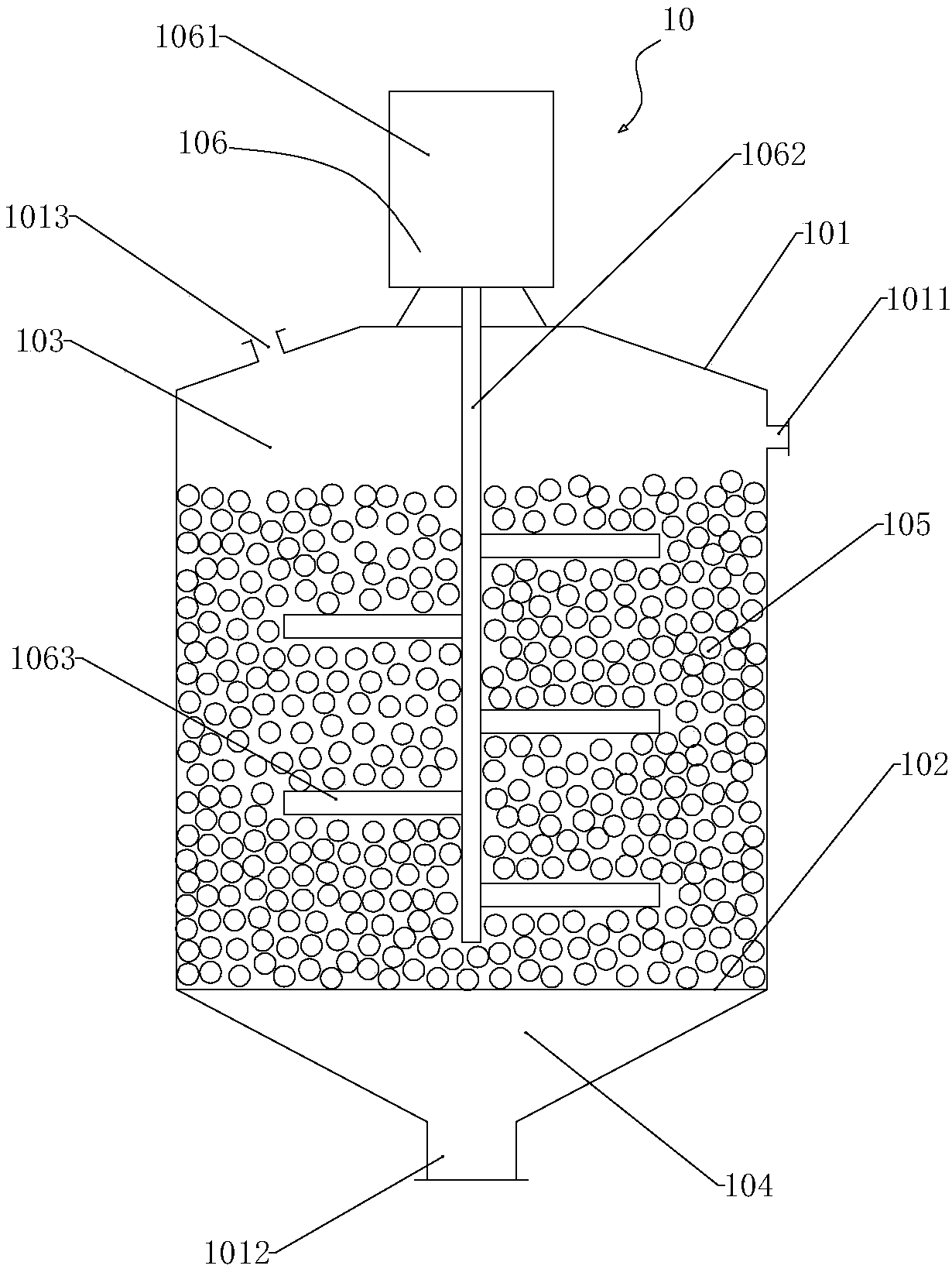

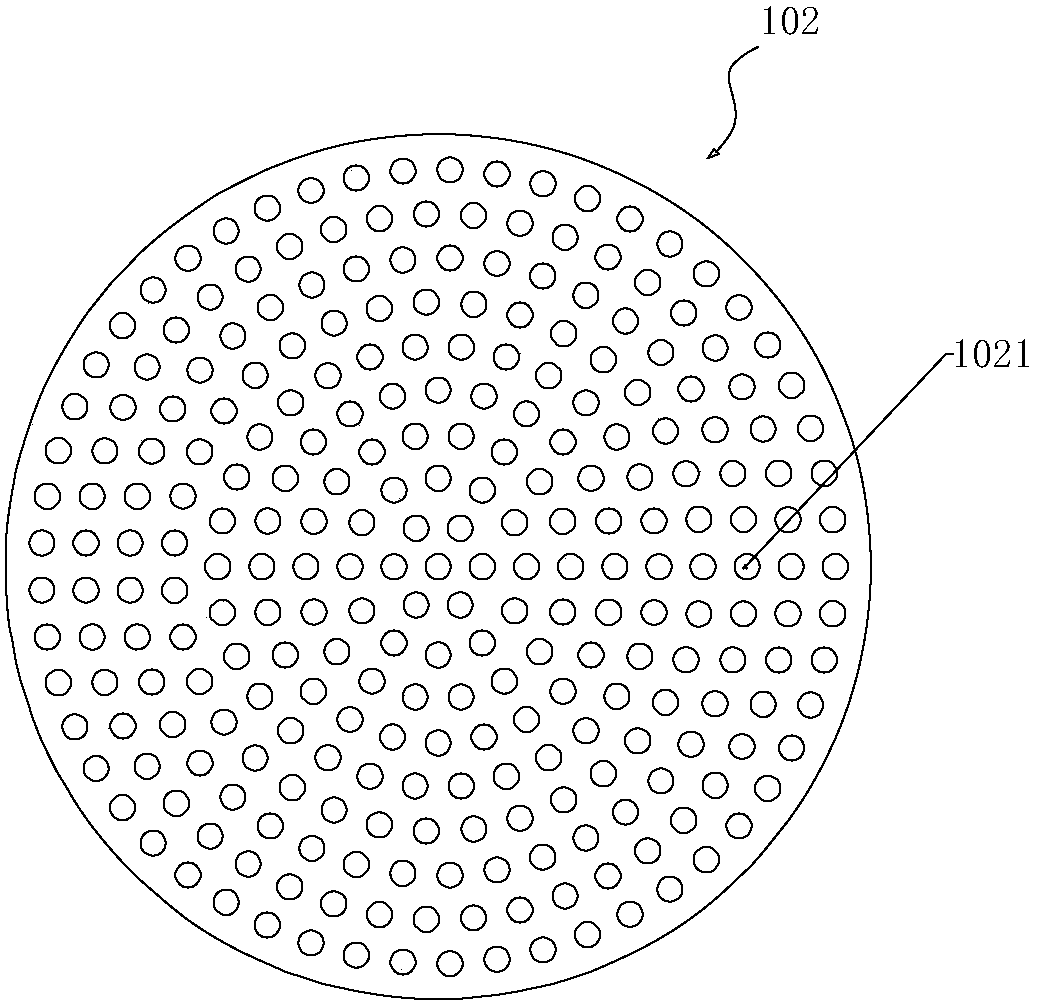

[0053] see figure 1 , the present invention provides a curing device 10 for chemical flooding oil recovery, the curing device 10 for chemical flooding oil recovery has a tank body 101, the tank body 101 is vertically arranged, and the tank body 101 is equipped with There is a support plate 102, the support plate 102 is horizontally arranged in the tank body 101, the periphery of the support plate 102 is welded and fixed with the inner wall of the tank body 101, and the interior of the tank body 101 is divided into The upper cavity 103 and the lower cavity 104; the position of the support plate 102 in the tank body 101 is relatively close to the bottom of the tank body 101, so that the upper cavity 103 has a larger space, and the lower cavity 104 has a larger space. smaller. The upper cavity 103 is the main working cavity. The upper cavity 103 is provided with particle fillers 105 and a first agitator 106. The particle fillers 105 fill most of the space in the upper cavity 10...

Embodiment 2

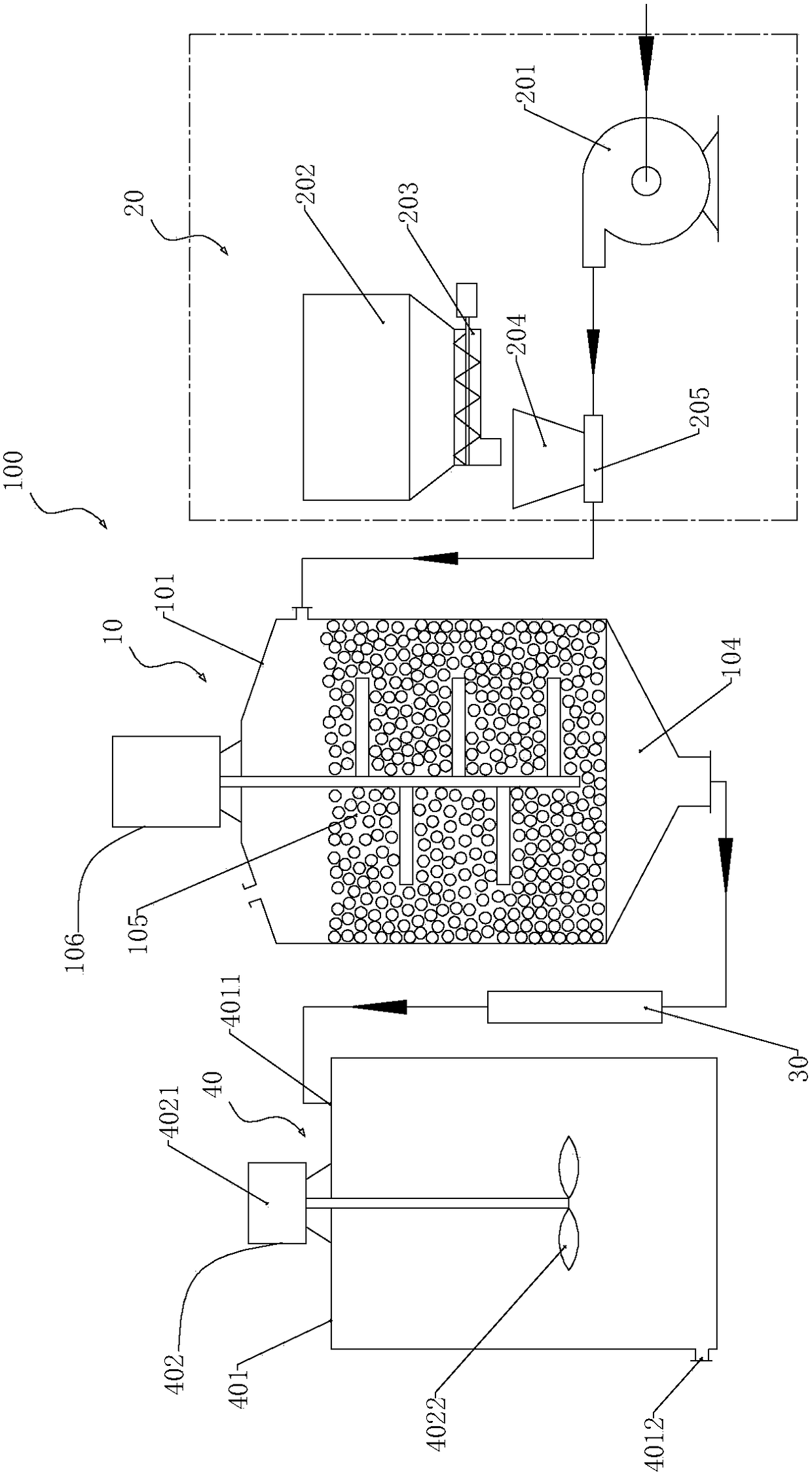

[0060] see figure 2 As shown, the present invention also provides a polymer preparation system 100 for chemical flooding oil recovery, the polymer preparation system 100 for chemical flooding oil recovery includes the aging method for chemical flooding oil recovery described in Embodiment 1 The device 10, wherein the liquid inlet 1011 of the curing device 10 is connected to the polymer dispersing and dissolving device 20 through a pipeline; the liquid outlet 1012 of the curing device 10 is connected to the liquid inlet of the screw pump 30 through a pipeline, and the screw The liquid outlet of the pump 30 is connected to the stirring and dissolving device 40 through a pipeline.

[0061] Since the polymer preparation system 100 adopts the curing device 10 described in the first embodiment, the stirring effect is improved, and the curing speed of the polymer is accelerated. It can be used for a certain period of time after aging in the tank. The structure is simple and the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com