Epoxiconazole water suspension agent and preparation method thereof

A technology of epoxiconazole water and suspending agent, which is applied in botany equipment and methods, biocides, disinfectants, etc., can solve the problems of poor stability, more foam, and poor automatic dispersibility, and achieve high stability and high suspension rate , the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

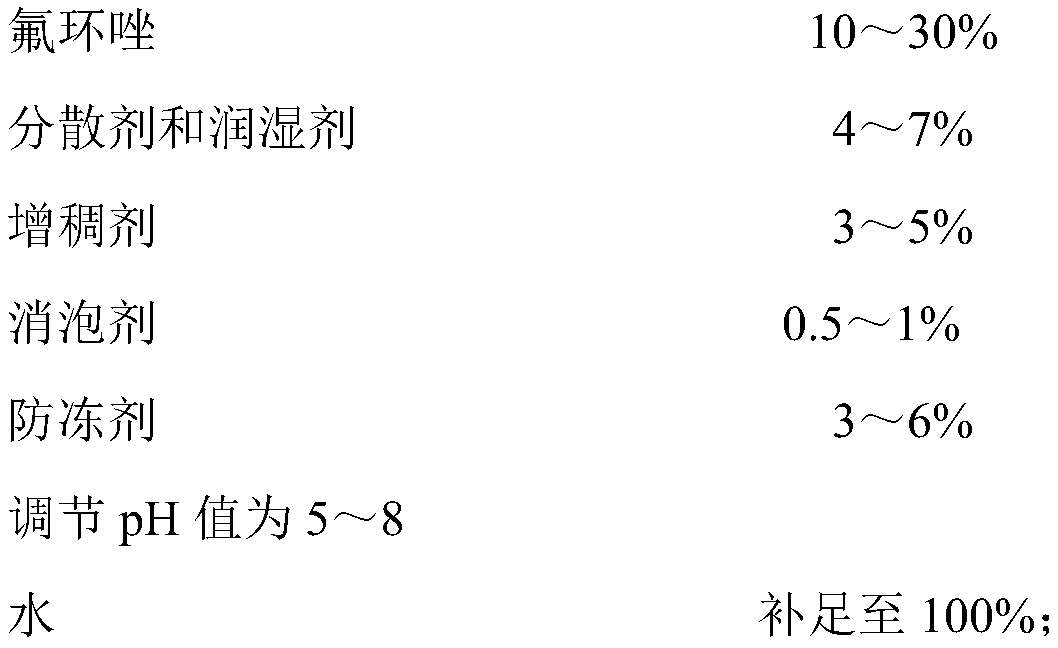

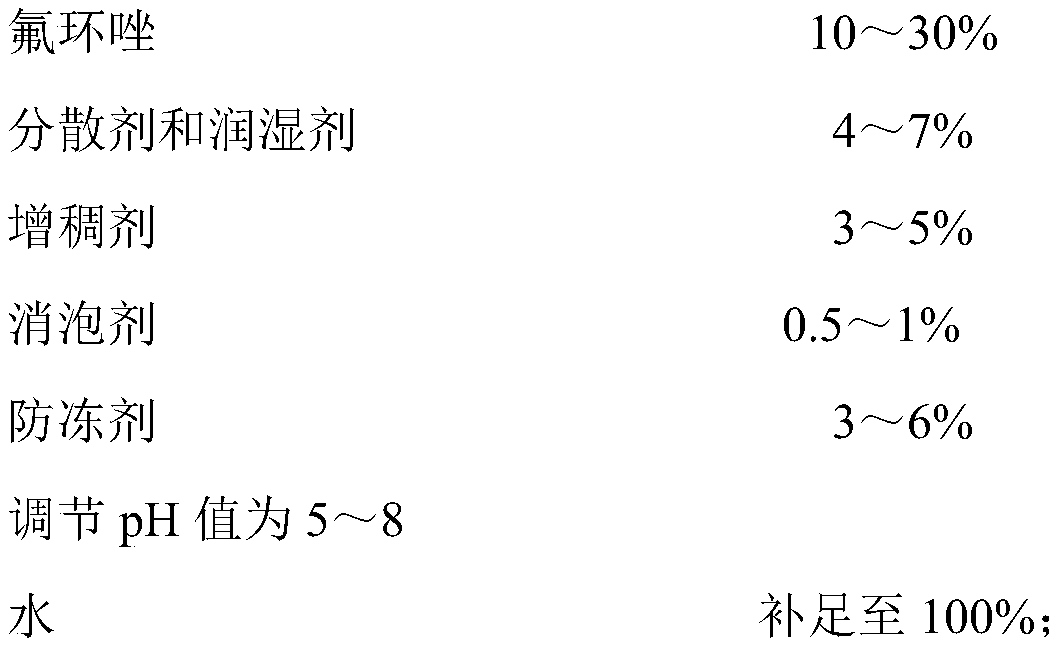

[0029] The preparation of embodiment 1 10% tricyclazole aqueous suspension concentrate

[0030] The content of each component (by weight) is 10% of the original drug of epoxiconazole, 3% of tristyrylphenol polyoxyethylene ether sulfate dispersant (Shanghai Shida Polymer Material Co., Ltd.), polymer EO-PO block Copolymer dispersant 1% (Shanghai Shida Polymer Material Co., Ltd.), thickener xanthan gum XG (2%) 3%, defoamer silicone 0.5%, ethylene glycol 3% (Aladdin Reagent Shanghai Co., Ltd. company), adjust the pH value to 7-8 with triethanolamine. Add deionized water to l00%.

[0031] In the first step, add tristyrylphenol polyoxyethylene ether sulfate dispersant, polymer EO-PO block copolymer dispersant, ethylene glycol, and silicone defoamer to deionized water and mix well, then add fluorine Cycloconazole raw material and zirconia beads of equal quality are sand-milled at a speed of 1200in, the sand-milling temperature is controlled below 40°C, and the sand-milling is stopp...

Embodiment 2

[0036] Embodiment 2 Preparation of 20% epoxiconazole aqueous suspension

[0037] The content of each component (by weight) is 20% of the original drug of epoxiconazole, 4% of tristyrylphenol polyoxyethylene ether sulfate (Shanghai Shida Polymer Material Co., Ltd.); alkylphenol polyoxyethylene ether 2 %; Thickener sodium carboxymethyl cellulose 4%, antifoaming agent silicone compound 0.5%, antifreeze agent glycerin 4% (Aladdin Reagent Shanghai Co., Ltd.), adjust the pH value to 7-8 with ammonia water. Add deionized water to l00%. The specific preparation is carried out according to Example 1.

[0038] Main technical indicators: the average particle size before thermal storage is 2.62μm, and after thermal storage is 3.04μm; both before and after thermal storage are white homogeneous liquid, with a limited content of 20%; before thermal storage, the suspension rate is 96.24%, after thermal storage is 95.13%. It shows that the thermal storage stability is qualified.

[0039] E...

Embodiment 3

[0040]Embodiment 3 Preparation of 30% epoxiconazole aqueous suspension

[0041] The content of each component (by weight) is 30% of the original drug of epoxiconazole, 5% of tristyrylphenol polyoxyethylene ether sulfate dispersant (Shanghai Shida Polymer Material Co., Ltd.); styrylphenol polyoxypropylene Ether 2% (Shanghai is a large polymer material Co., Ltd.); thickener magnesium aluminum silicate 5%, Cl0-20 saturated fatty acid compound 1%, antifreeze agent polyethylene glycol and ethylene glycol 6% (Aladdin reagent Shanghai Co., Ltd.), adjust the pH value to 7-8 with sodium hydroxide. Add deionized water to l00%. The specific preparation is carried out according to Example 1.

[0042] Main technical indicators: the average particle size before thermal storage is 2.83μm, and after thermal storage is 3.26μm; both before and after thermal storage are white homogeneous liquids, with a limited content of 30%; before thermal storage, the suspension rate is 95.48%, after therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com