Method for synchronously removing shell and peel of Chinese chestnut through microwaves

A chestnut and microwave technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems affecting the quality and productivity of chestnuts, high microwave heating efficiency, and fast heating speed, so as to avoid ripening and cracking, maintain color and luster, and shell high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

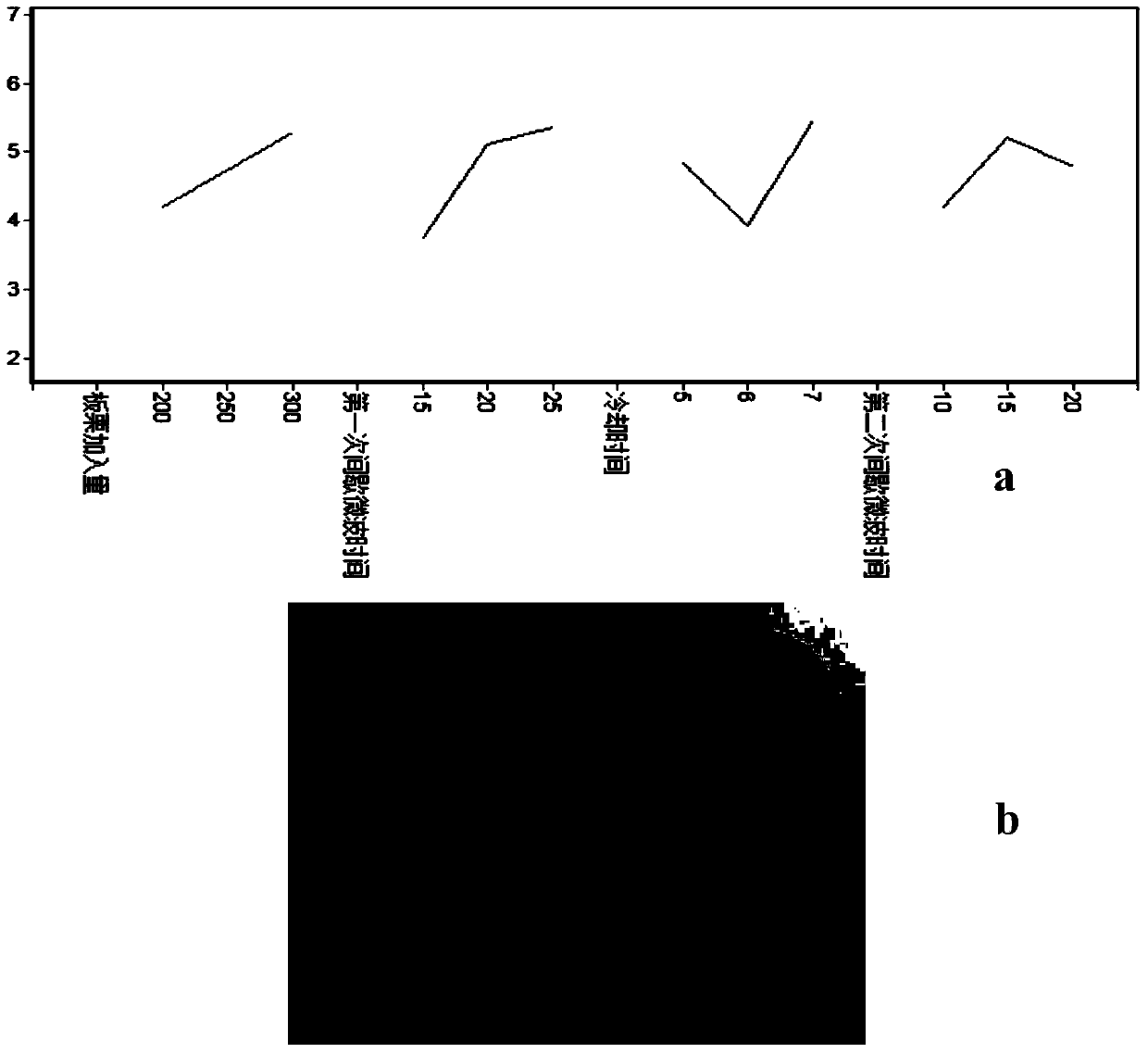

[0039] Embodiment 1 Large chestnut microwave synchronous shelling and peeling

[0040] In this embodiment, the microwave power is 800W, and two intermittent microwave treatments are performed, and the intermittent time in each intermittent microwave treatment is uniformly 5s, specifically:

[0041] (1) Take 200-300g of large chestnuts (equivalent to a microwave irradiation power density of about 2.6-4.0W / 1g chestnut), and cut the chestnut shell into a "V" shape;

[0042] (2) The first microwave treatment (the first intermittent microwave): first microwave irradiation for 15-25s, intermittent for 5s, and then microwave irradiation for 15-25s;

[0043] (3) Cooling: Cooling treatment for 5-7 minutes;

[0044](4) Second microwave treatment (second intermittent microwave): first microwave irradiation for 10-20s, intermittent for 5s, and then microwave irradiation for 10-20s;

[0045] (5) Remove the shell and inner skin to obtain chestnut kernels.

[0046] Orthogonal test design ...

Embodiment 2

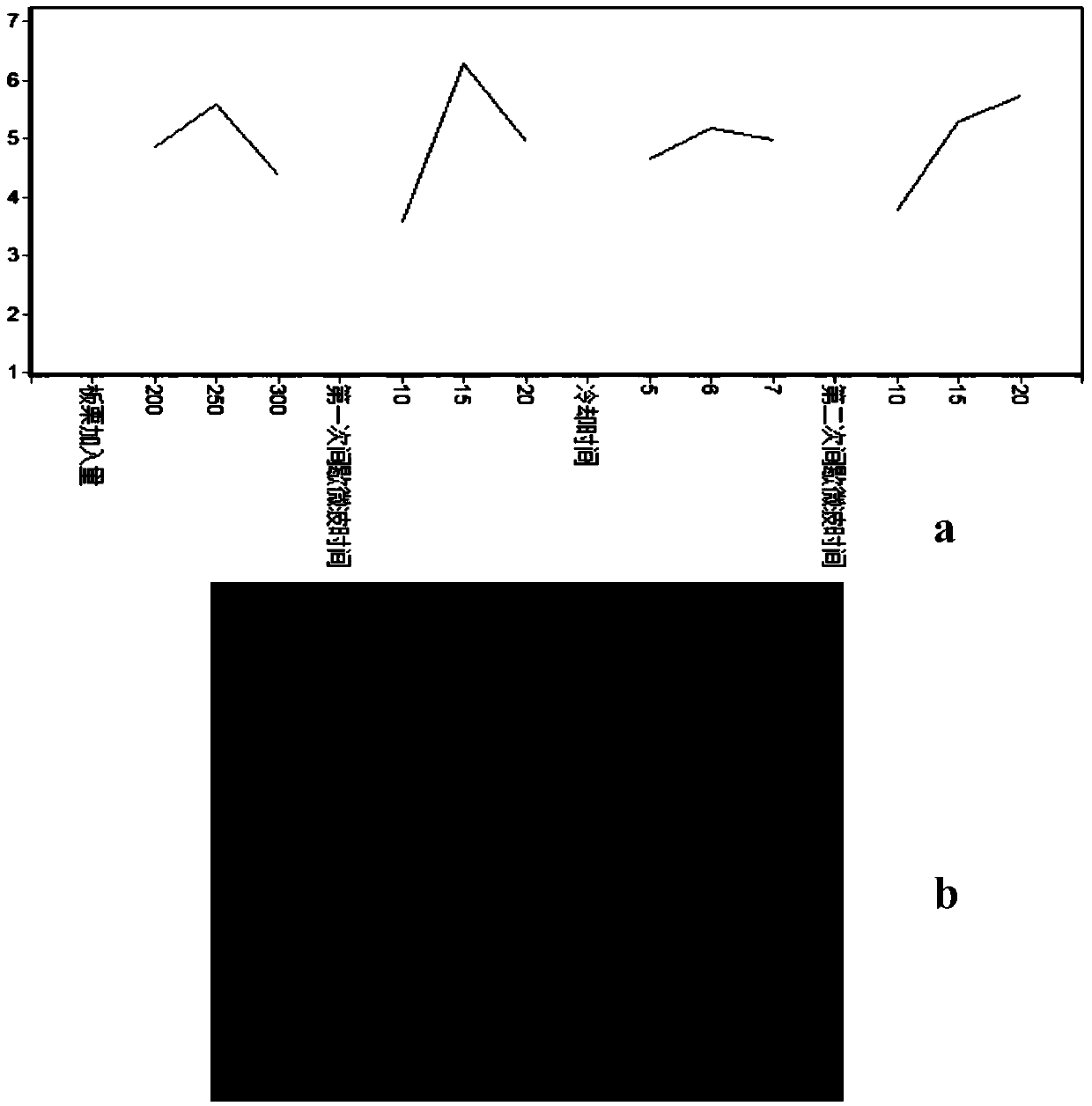

[0066] Chestnut microwave synchronous shelling and peeling in embodiment 2

[0067] In this embodiment, the microwave power is 800W, and two intermittent microwave treatments are performed, and the intermittent time in each intermittent microwave treatment is uniformly 5s, specifically:

[0068] (1) Take 200-300g of Chinese chestnuts (equivalent to about 2.6-4.0W / 1g of chestnuts with microwave irradiation power density), and cut the chestnut shell into a "V" shape;

[0069] (2) The first microwave treatment (the first intermittent microwave): first microwave irradiation for 10-20s, intermittent for 5s, and then microwave irradiation for 10-20s;

[0070] (3) Cooling: Cooling treatment for 5-7 minutes;

[0071] (4) Second microwave treatment (second intermittent microwave): first microwave irradiation for 10-20s, intermittent for 5s, and then microwave irradiation for 10-20s;

[0072] (5) Remove the shell and inner skin to obtain chestnut kernels.

[0073] Orthogonal test des...

Embodiment 3

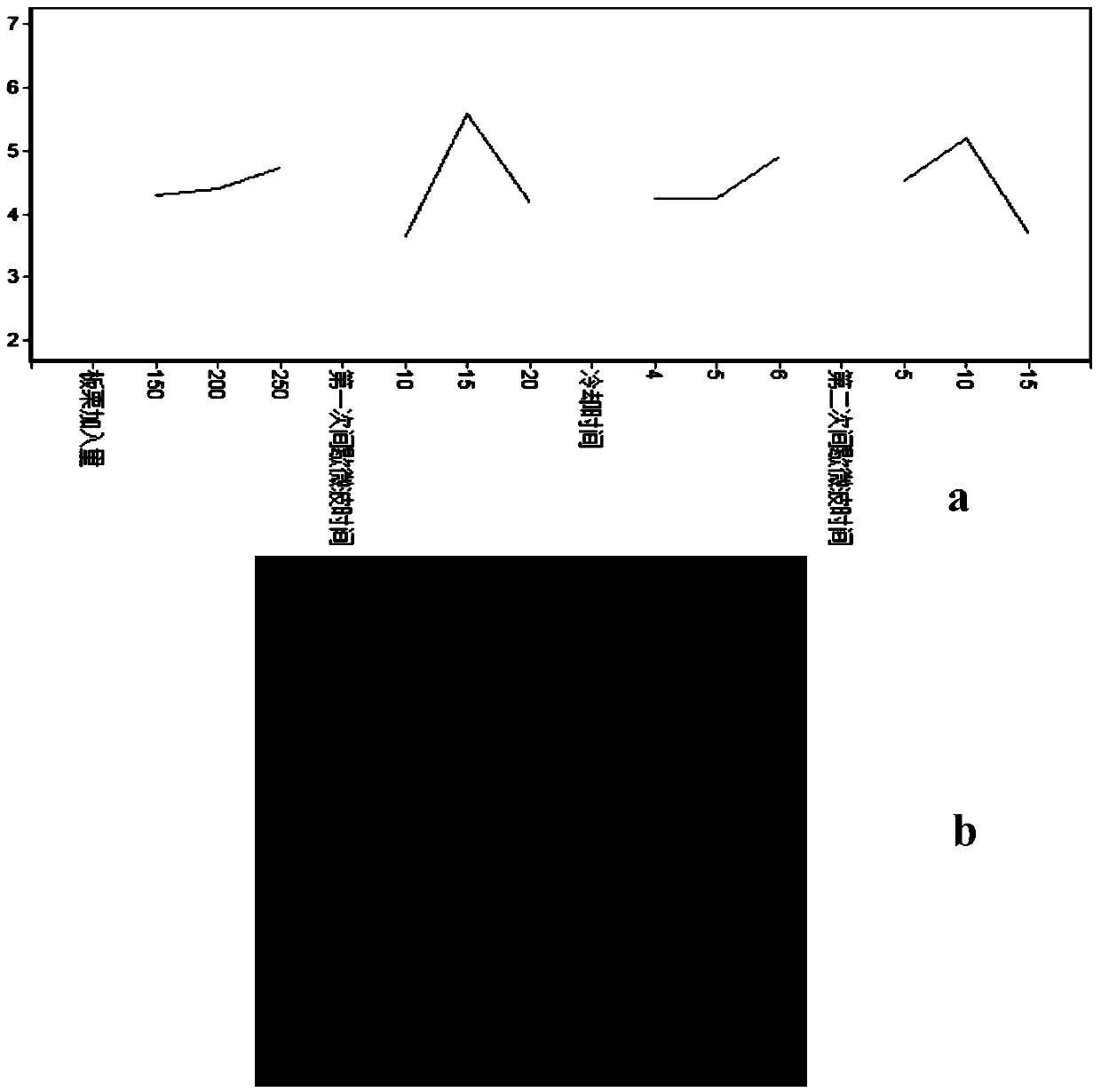

[0092] Example 3 Microwave Synchronous Shelling and Peeling of Small Chestnuts

[0093] In this embodiment, the microwave power is 800W, and two intermittent microwave treatments are performed, and the intermittent time in each intermittent microwave treatment is uniformly 5s, specifically:

[0094] (1) Take 150-250g of small chestnuts (equivalent to a microwave irradiation power density of about 3.2-5.4W / 1g chestnut), and cut the chestnut shell into a "V" shape;

[0095] (2) The first microwave treatment (the first intermittent microwave): first microwave irradiation for 10-20s, intermittent for 5s, and then microwave irradiation for 10-20s;

[0096] (3) Cooling: Cooling treatment for 4-6 minutes;

[0097] (4) The second microwave treatment (the second intermittent microwave): first microwave irradiation for 5-15s, intermittent for 5s, and then microwave irradiation for 5-15s;

[0098] (5) Remove the shell and inner skin to obtain chestnut kernels.

[0099] Orthogonal test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

| Radial size | aaaaa | aaaaa |

| Radial size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com