Hyaluronic acid-based modified gliadin nanoparticles as well as preparation method and application thereof

A gliadin and nanoparticle technology, applied in the directions of pharmaceutical formulations, organic active ingredients, cosmetic preparations, etc., can solve problems such as application limitations, multiple emulsion thermodynamic instability, etc., achieve simple preparation methods, improve bioavailability, Enhanced solubility and emulsifying properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] One aspect of the embodiments of the present invention provides a method for preparing hyaluronic acid-based modified gliadin nanoparticles, which includes:

[0030] The first mixed reaction system containing gliadin, EGCG, sodium hydroxide, ethanol and water was reacted at 25°C for 24h to obtain a gliadin-EGCG covalent complex, and then the gliadin-EGCG covalent complex was made to The second mixed reaction system of the valence complex, sodium carbonate, ethanol and water was reacted at 25°C for 4 hours to obtain hollow gliadin-EGCG nanoparticles;

[0031] The third mixed reaction system comprising hyaluronic acid, 1,3-carbodiimide, dimethylaminopyridine, DMSO and water was activated at 25° C. for 1 h, and then EGCG was added to the third mixed reaction system, and the React at 60-65°C for 4 hours to obtain a hyaluronic acid-EGCG covalent complex;

[0032] And, the fourth mixed reaction system comprising the hollow gliadin-EGCG nanoparticles, hyaluronic acid-EGCG cov...

Embodiment 1

[0103] (1) Preparation of hollow gliadin-EGCG nanoparticles

[0104] Dissolve gliadin and EGCG in 80% (v / v) ethanol solution respectively, adjust the pH value to 9.0 with 0.1 mol / L sodium hydroxide solution after mixing, and react with continuous stirring at 25°C for 24h, After the reaction was completed, the obtained mixed solution was ultrasonically dialyzed in a water bath for 24 hours, during which the dialysate was replaced 8 times to remove free EGCG, and finally the solution was freeze-dried to obtain a gliadin-EGCG covalent complex;

[0105]Dissolve 2g of gliadin-EGCG covalent complex in 100mL ethanol solution (volume fraction 80%), and stir at 800rpm for 2h, let it stand until completely dissolved, and simultaneously mix 2wt% sodium carbonate aqueous solution and absolute ethanol by Mix uniformly at a volume ratio of 3:7 to form an ethanol suspension of sodium carbonate, and mix the above suspension with a gliadin-EGCG covalent complex solution at a volume ratio of 1:...

Embodiment 2

[0116] (1) Preparation of hollow gliadin-EGCG nanoparticles

[0117] Dissolve gliadin and EGCG in 80% (v / v) ethanol solution respectively, adjust the pH value to 9.0 with 0.1 mol / L sodium hydroxide solution after mixing, and react with continuous stirring at 25°C for 24h, After the reaction was completed, the obtained mixed solution was ultrasonically dialyzed in a water bath for 24 hours, during which the dialysate was replaced 8 times to remove free EGCG, and finally the solution was freeze-dried to obtain a gliadin-EGCG covalent complex;

[0118] Dissolve 2g of gliadin-EGCG covalent complex in 100mL ethanol solution (volume fraction 80%), and stir at 800rpm for 2h, let it stand until completely dissolved, and simultaneously mix 2wt% sodium carbonate aqueous solution and absolute ethanol by Mix uniformly at a volume ratio of 3:7 to form an ethanol suspension of sodium carbonate, and mix the above suspension with a gliadin-EGCG covalent complex solution at a volume ratio of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

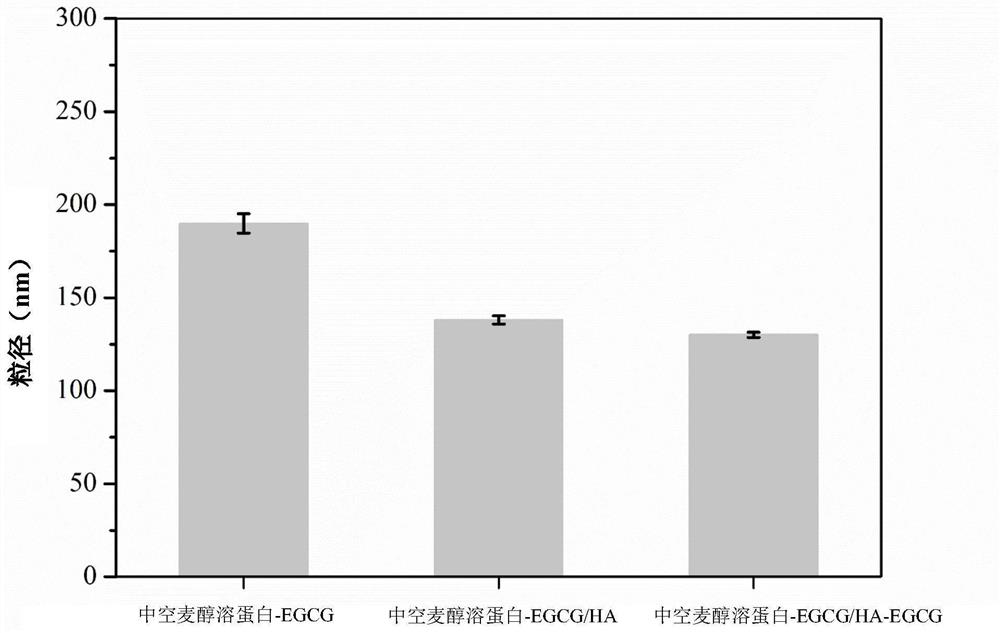

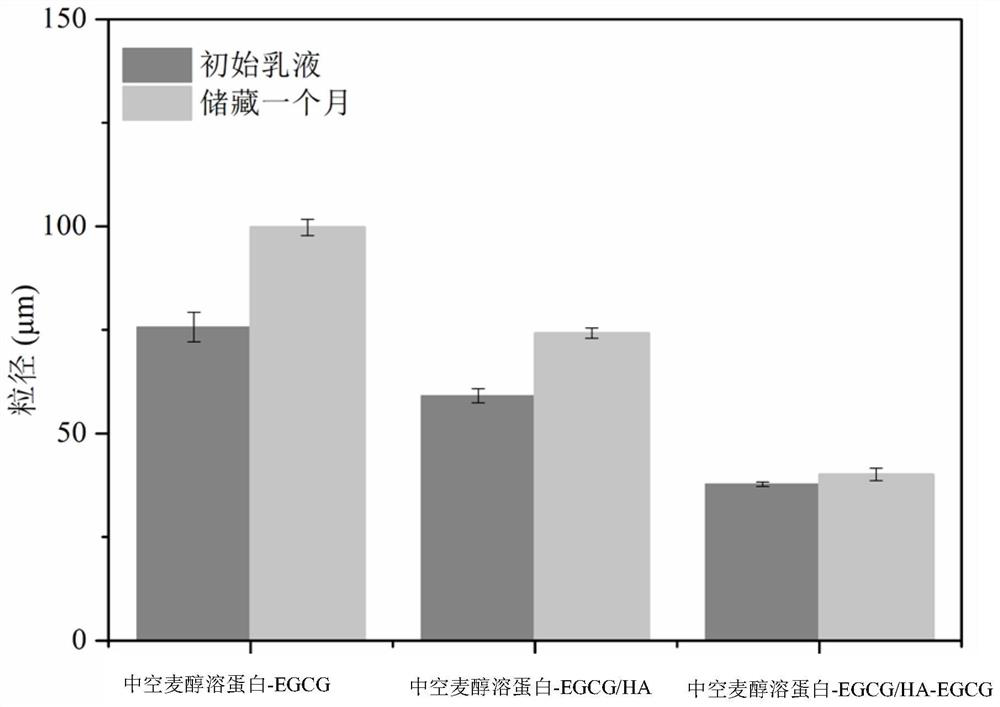

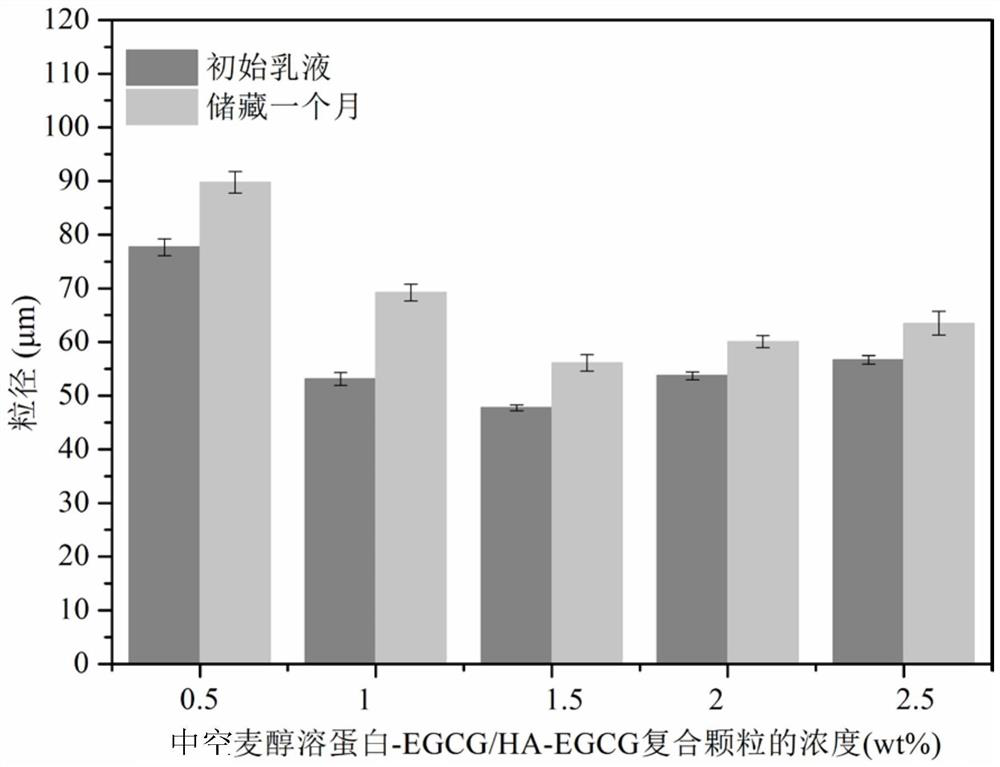

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com