Carbon fiber-coated manganese oxide-carbon composite material with egg yolk shell structure as well as preparation method and application thereof

A carbon composite material, egg yolk shell technology, applied in structural parts, electrochemical generators, electrical components, etc., can solve the problems of easy collapse and agglomeration of electrode material structure, rapid decrease in specific capacity, rupture of active materials, etc. Good, prolong battery life, reduce the effect of volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

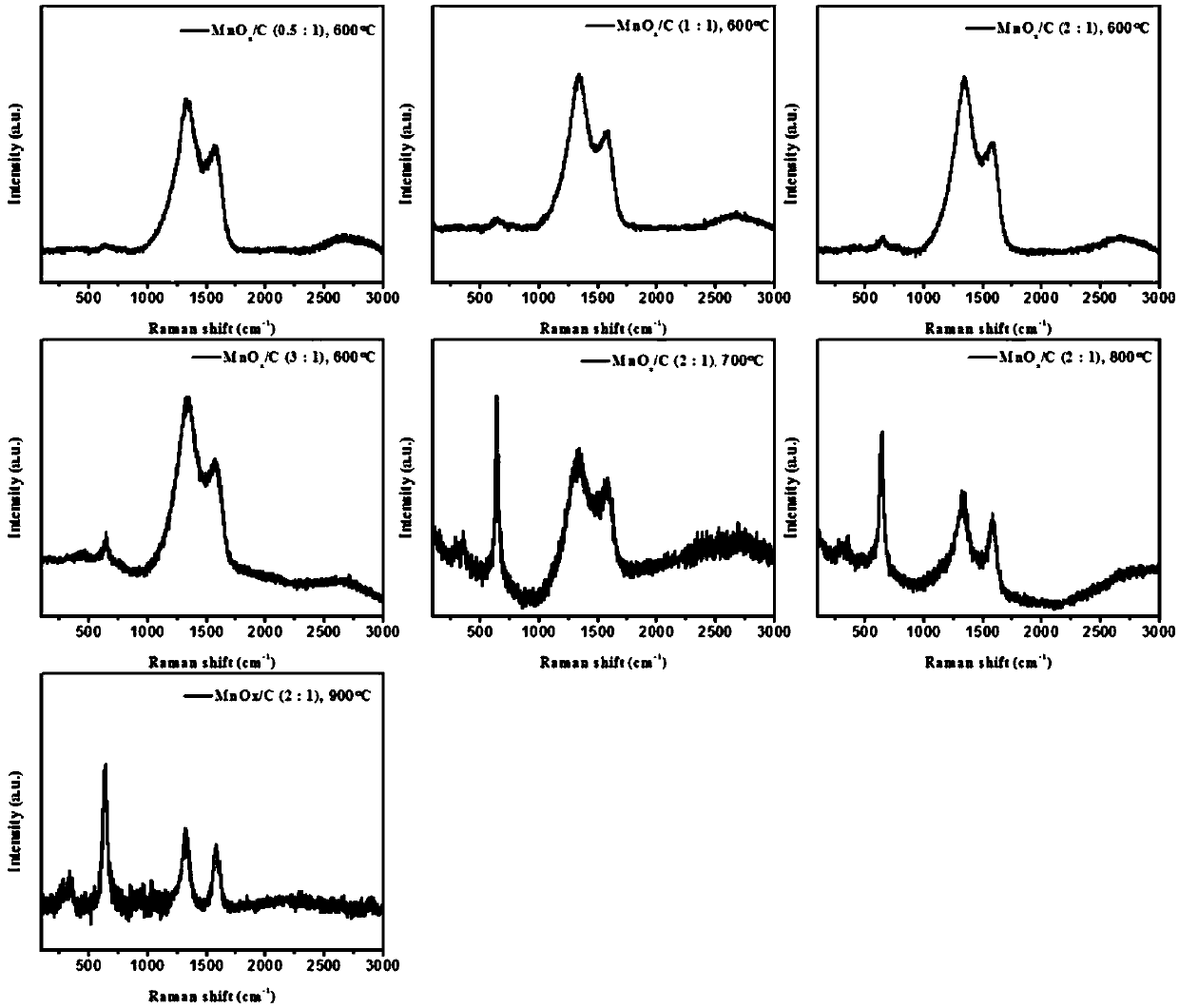

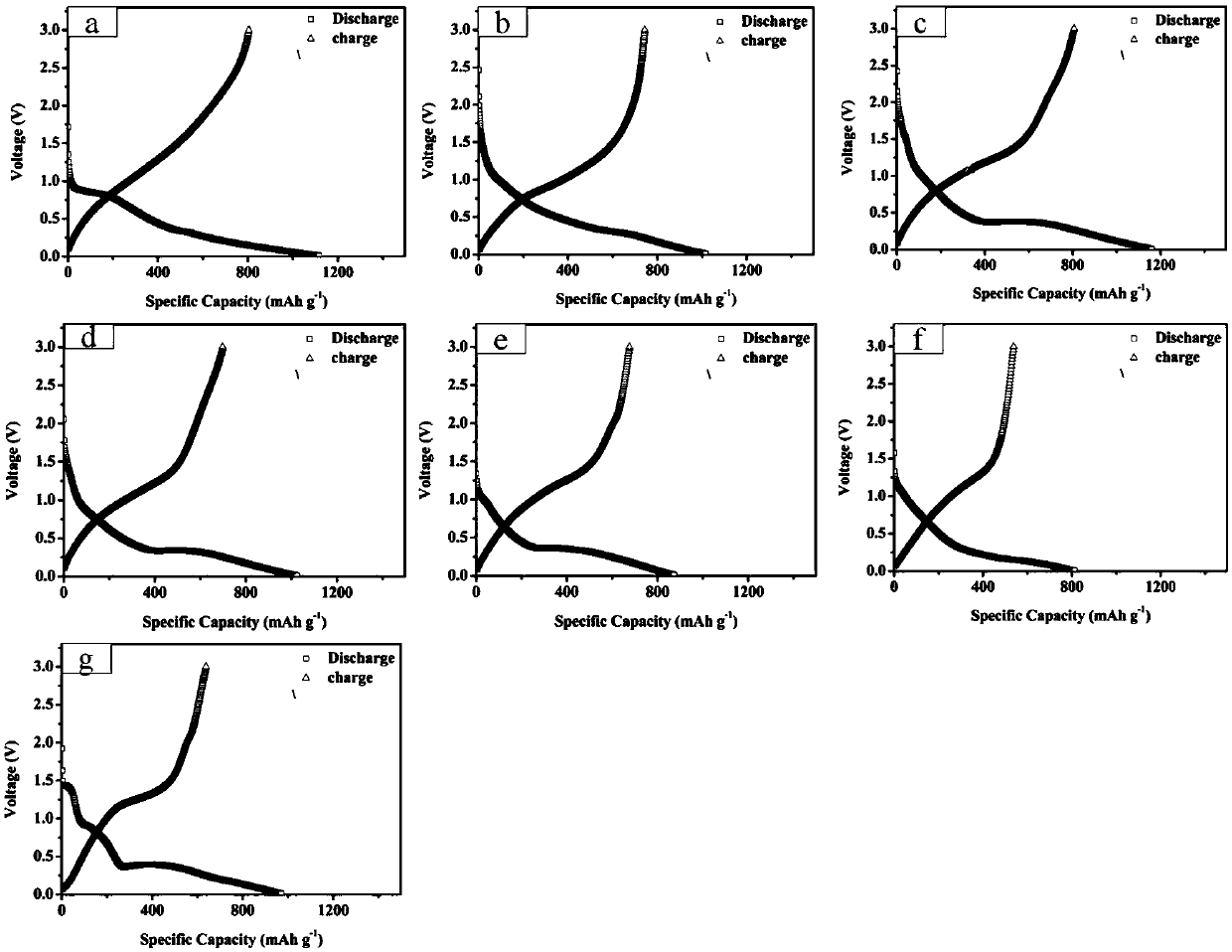

Embodiment 1

[0032] Take 0.1875g of manganese nitrate tetrahydrate, dissolve it in 50mL of ethanol, and configure it as solution A; then take 0.0875g of trimesic acid, dissolve it in 30mL of ethanol, and configure it as solution B. Solution B was added to solution A and stirred for 20 minutes. The obtained mixed solution was placed in a 100 mL reaction kettle, and then the reaction kettle was put into a constant temperature drying oven, and kept at 160° C. for 24 hours. After the reaction is completed, the solution in the reactor is centrifuged to obtain metal organic framework powder.

[0033] 0.5 g of polyacrylonitrile was dissolved in 9.75 g of N,N-dimethylformamide, 0.25 g of metal-organic framework powder was dispersed in the above solution, and stirred for 12 h to obtain a suspension. Next, the above suspension was transferred into a 10 mL syringe, and electrospinning was performed at a voltage of 17 KV at a propulsion rate of 13 μL / min. Move the spun film into a muffle furnace, ra...

Embodiment 2

[0035] Take 0.1875g of manganese nitrate tetrahydrate, dissolve it in 50mL of ethanol, and configure it as solution A; then take 0.0875g of trimesic acid, dissolve it in 30mL of ethanol, and configure it as solution B. Solution B was added to solution A and stirred for 20 minutes. The obtained mixed solution was placed in a 100 mL reaction kettle, and then the reaction kettle was put into a constant temperature drying oven, and kept at 160° C. for 24 hours. After the reaction is completed, the solution in the reactor is centrifuged to obtain metal organic framework powder.

[0036] 0.5 g of polyacrylonitrile was dissolved in 9.75 g of N,N-dimethylformamide, 0.5 g of metal-organic framework powder was dispersed in the above solution, and stirred for 12 h to obtain a suspension. Next, the above suspension was transferred into a 10 mL syringe, and electrospinning was performed at a voltage of 17 KV at a propulsion rate of 13 μL / min. Move the spun film into a muffle furnace, rai...

Embodiment 3

[0038] Take 0.1875g of manganese nitrate tetrahydrate, dissolve it in 50mL of ethanol, and configure it as solution A; then take 0.0875g of trimesic acid, dissolve it in 30mL of ethanol, and configure it as solution B. Solution B was added to solution A and stirred for 20 minutes. The obtained mixed solution was placed in a 100 mL reaction kettle, and then the reaction kettle was put into a constant temperature drying oven, and kept at 160° C. for 24 hours. After the reaction is completed, the solution in the reactor is centrifuged to obtain metal organic framework powder.

[0039] 0.5 g of polyacrylonitrile was dissolved in 9.75 g of N,N-dimethylformamide, 1.0 g of metal-organic framework powder was dispersed in the above solution, and stirred for 12 h to obtain a suspension. Next, the above suspension was transferred into a 10 mL syringe, and electrospinning was performed at a voltage of 17 KV at a propulsion rate of 13 μL / min. Move the spun film into a muffle furnace, rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com