Apple low-temperature storage method

An apple, low temperature technology, applied in the field of fruit and vegetable preservation, to achieve the effect of apple quality optimization and good regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

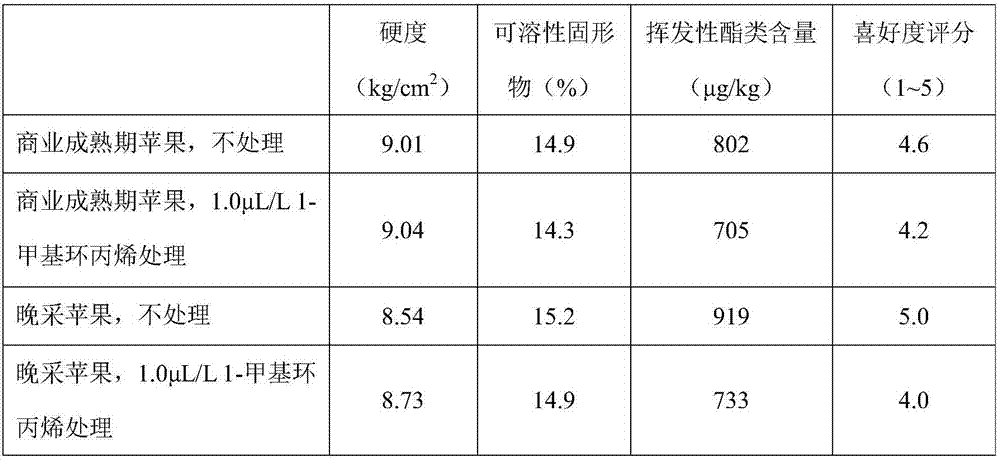

[0057] Embodiment 1: Different ripeness and processing apple quality in 60 days after harvesting

[0058] 1) Harvest apples at the commercial ripening stage of Fuji apples and 12 days after the commercial ripening stage of Fuji apples (late harvesting) to obtain commercial ripening apples and late harvesting apples, and pre-cool after removing diseased and defective fruits;

[0059] 2) Put the above apples into fruit baskets, stack them in a pre-cooling room at 0-1°C, and pre-cool them for 3 days. During the pre-cooling process, some apples will not be treated, and some apples will be treated with 1.0 μL / L 1-methylcyclopropene. The time is 24 hours, and the processing method is that the apples are fumigated with 1-methylcyclopropene in a closed plastic tent in a pre-cooling room.

[0060] 3) After the pre-cooling and processing, the apples are put into storage for refrigeration; the temperature of the refrigerator is -1-1°C, and the humidity is not lower than 90%.

[0061] 4)...

Embodiment 2

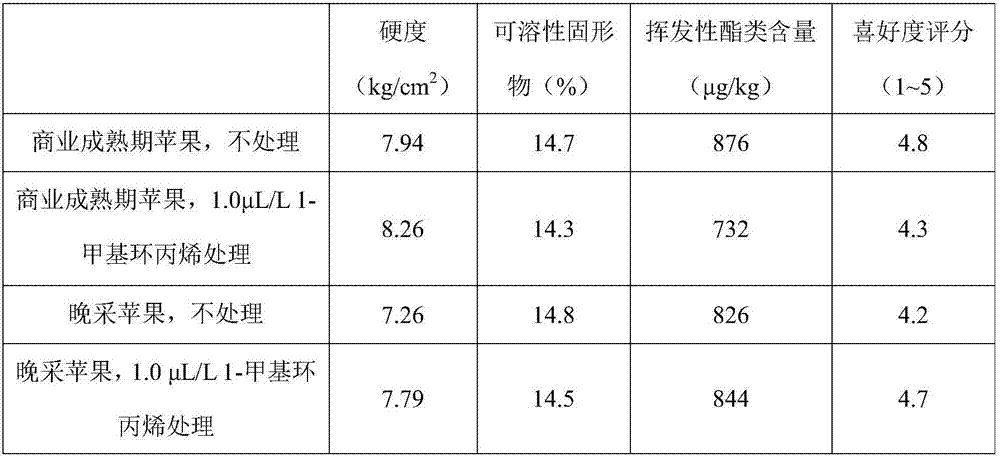

[0065] Embodiment 2: different ripeness and processing apple quality in 120 days after harvesting

[0066] 1) Harvest apples at the commercial ripening stage of Fuji apples and 10 days after the commercial ripening stage of Fuji apples (late harvesting) to obtain commercial ripening apples and late harvesting apples, and pre-cool after removing diseased and defective fruits;

[0067] 2) Put the above apples into fruit baskets, loosely stack them in the pre-cooling room at 0-1°C, and pre-cool them for 3 days. During the pre-cooling process, some apples will not be treated, and some apples will be treated with 1.0 μL / L 1-methylcyclopropene. The processing time is 24 hours, and the processing method is that the apples are fumigated with 1-methylcyclopropene in a closed plastic tent in a pre-cooling room.

[0068] 3) After the pre-cooling and treatment, the apples are stored in a refrigerator; the temperature of the refrigerator is -1-1°C, and the humidity is not lower than 90%. ...

Embodiment 3

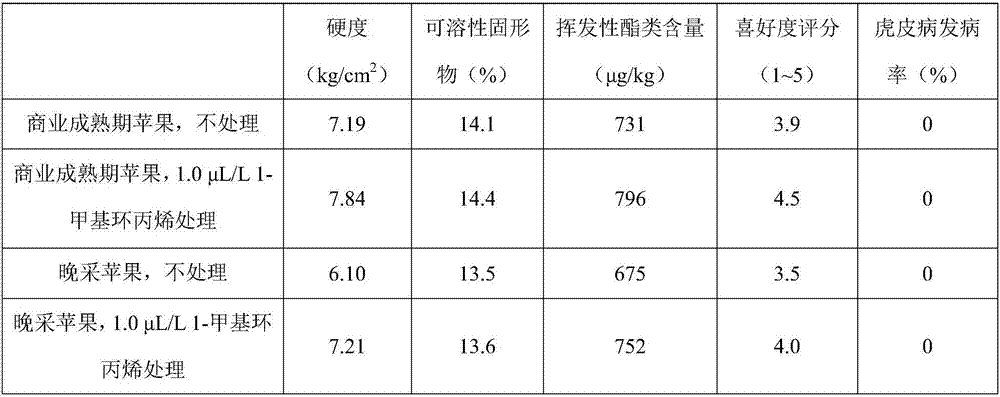

[0073] Embodiment 3: Different ripeness and processing apple quality in 180 days after harvesting

[0074] 1) Harvest apples at the commercial ripening stage of Fuji apples and 10 days after the commercial ripening stage of Fuji apples (late harvesting) to obtain commercial ripening apples and late harvesting apples, and pre-cool after removing diseased and defective fruits;

[0075] 2) Put the above apples into fruit baskets, stack them in a pre-cooling room at 0-1°C, and pre-cool them for 3 days. During the pre-cooling process, some apples will not be treated, and some apples will be treated with 1.0 μL / L 1-methylcyclopropene. For 24 hours, the processing method is that the apples are fumigated with 1-methylcyclopropene in a closed plastic tent in the pre-cooling room.

[0076] 3) After the pre-cooling and treatment, the apples are stored in a refrigerator; the temperature of the refrigerator is -1-1°C, and the humidity is not lower than 90%.

[0077] 4) The quality indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com