Platinum-based intermetallic nanocrystal with ordered structure and preparation and application thereof

A technology with ordered structure and nanocrystals, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of nanoparticle agglomeration, low catalyst activity, high preparation cost, etc., achieve reduced agglomeration, high catalytic ability, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

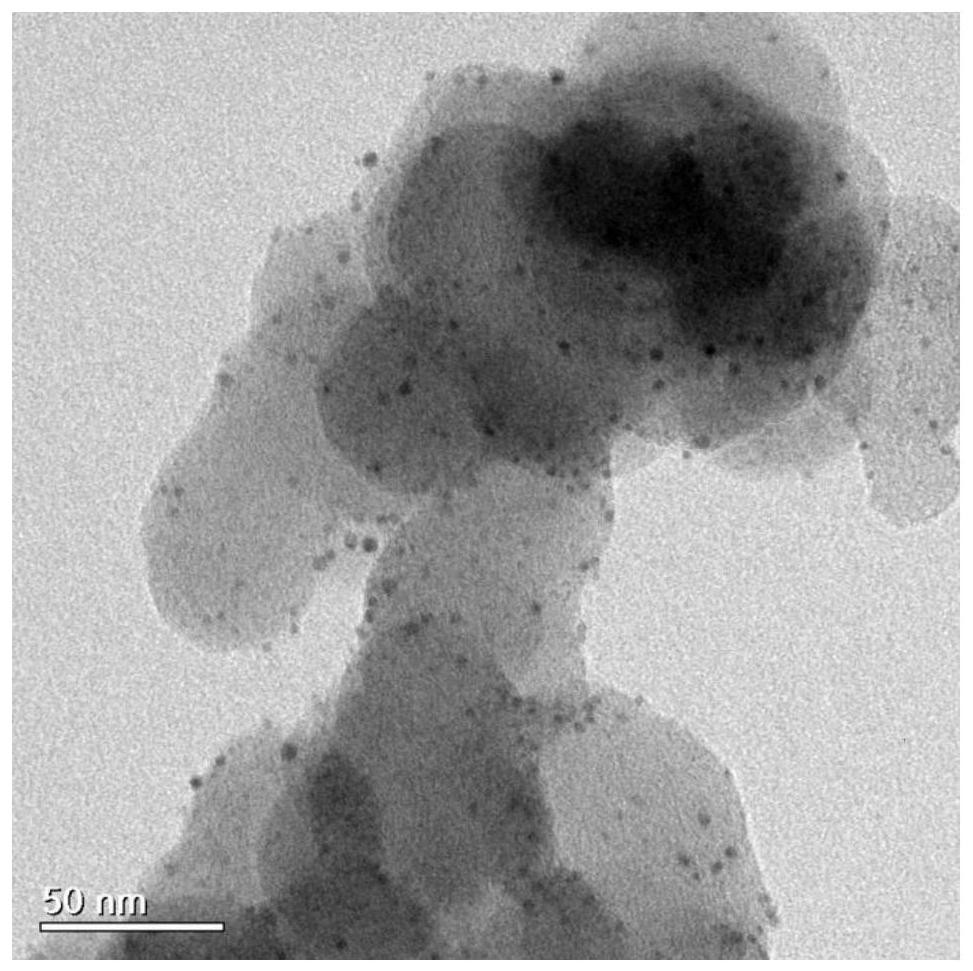

[0035] The embodiment of the present invention provides a simple and environmentally friendly method for preparing a platinum-based intermetallic nanocrystalline oxygen reduction catalyst with a completely ordered structure. The preparation process is as follows: figure 1 As shown, it specifically includes the following steps:

[0036] (1) ultrasonically disperse the carbon powder into the polyol solution to obtain a carbon powder dispersion with a concentration of 0.5 to 5 mg / mL, and dissolve the platinum salt in deionized water to obtain a platinum salt solution with a concentration of 5 to 50 mg / mL, Measure the platinum solution and carbon dispersion according to a certain platinum / carbon ratio, weigh the surfactant according to a certain ratio of surfactant / platinum substance, and stir at 100°C to 130°C under the condition of condensation and reflux React for 0.5 to 1 hour to obtain a carbon-supported platinum nanoparticle solution;

[0037] (2) After dissolving the trans...

Embodiment 1

[0042] (1) Dissolve 1g of chloroplatinic acid in 100mL of deionized aqueous solution to make a platinum salt solution with a concentration of 10mg / mL, take 16mg of carbon powder and disperse it in 8mL of ethylene glycol solution, add 1mL of platinum salt solution, and add 1.6g Polyvinylpyrrolidone (molecular weight 8000), ultrasonically mixed uniformly; under the condition of condensation and reflux, stirred and reacted at 130°C for 1 hour to obtain a carbon-supported platinum nanoparticle solution;

[0043] (2) Weigh 100 mg of zinc acetate powder, dissolve it in 1 mL of deionized water, slowly add the zinc acetate solution into the carbon-supported platinum nanoparticles solution, and stir evenly with ultrasonic;

[0044] (3) Under the condition of condensation and reflux, the solution is heated and reacted, stirred and reacted at 130°C for 1 hour, the transition metal salt is hydrolyzed on the surface of carbon-supported platinum to obtain an oxide coating layer, and after ce...

Embodiment 2

[0048] (1) Take 1g of chloroplatinic acid and dissolve it in 20mL of deionized aqueous solution to make a platinum salt solution with a concentration of 50mg / mL, take 40mg of carbon powder and disperse it in 8mL of 2-propylene glycol alcohol solution, add 1mL of platinum salt solution, and add 80mg of poly Vinylpyrrolidone (molecular weight 8000), ultrasonically mixed uniformly; under the condition of condensation and reflux, stirred and reacted at 130°C for 2 hours to obtain a carbon-supported platinum nanoparticle solution;

[0049] (2) Weigh 200 mg of ferric chloride powder, dissolve it in 1 mL of deionized water, slowly add the ferric chloride solution into the carbon-supported platinum nanoparticle solution, and stir evenly with ultrasonic;

[0050] (3) Under the condition of condensation and reflux, the solution is heated and reacted, stirred and reacted at 130°C for 1 hour, ferric chloride is hydrolyzed on the surface of carbon-supported platinum to obtain an oxide coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com