Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Increase wear ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometal bonding agent and polycrystal CBN (cubic boron nitride) composite sheet made by using same

InactiveCN102794448AGood sintering promotion effectIncrease the volume ratioAl powderAlloy substrate

The invention relates to a nanometal bonding agent. The bonding agent consists of the following raw materials in percentage by weight: 35-40% of TiN powder, 20-25% of TiC powder, 15-20% of Si3N4 powder, 15-20% of Co powder and 10-20% of Al powder. The invention also discloses a polycrystal CBN (cubic boron nitride) composite sheet made by using the nanometal bonding agent. The polycrystal CBN composite sheet comprises a CBN polycrystal layer and a hard alloy substrate, wherein the CBN polycrystal layer consists of the following raw materials in percentage by weight: 55-95% of CBN powder and 5-45% of nanometal bonding agent. In the polycrystal CBN composite sheet provided by the invention, by adopting the nanometal bonding agent in the formula of polycrystal layer, the technical bottleneck in high impact toughness and high bending strength of a PCBN composite sheet is broken, the impact resistance of a tool is enhanced, and the service life of the tool is prolonged.

Owner:ZHONGNAN DIAMOND CO LTD

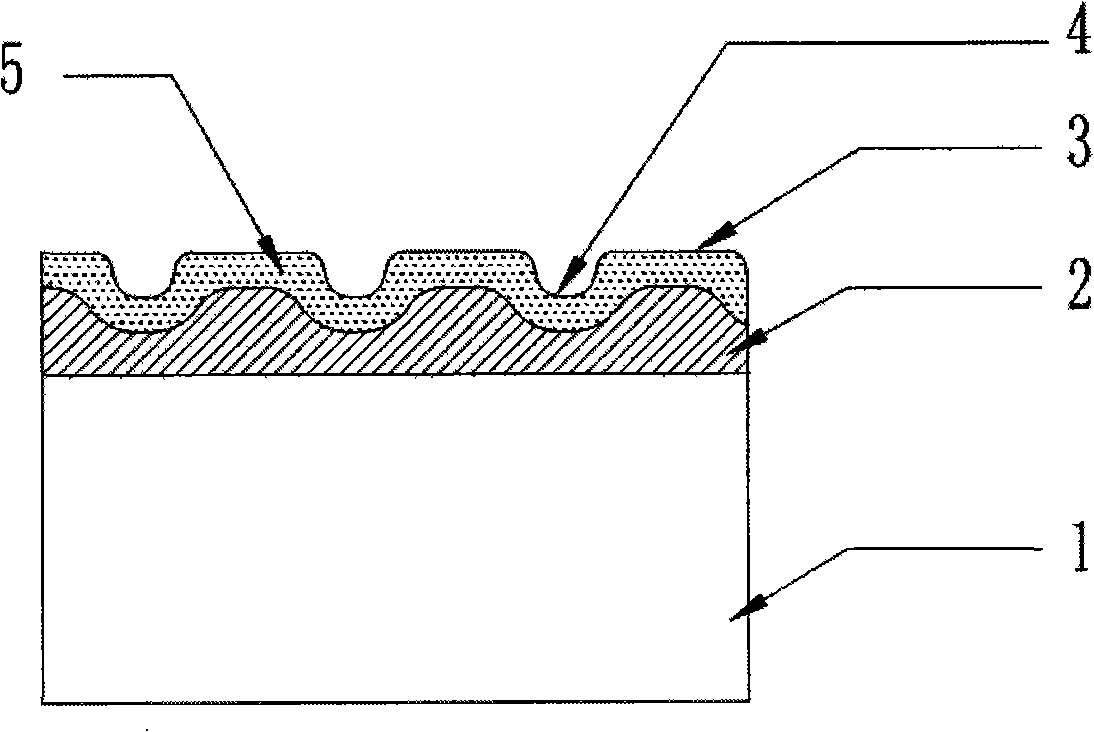

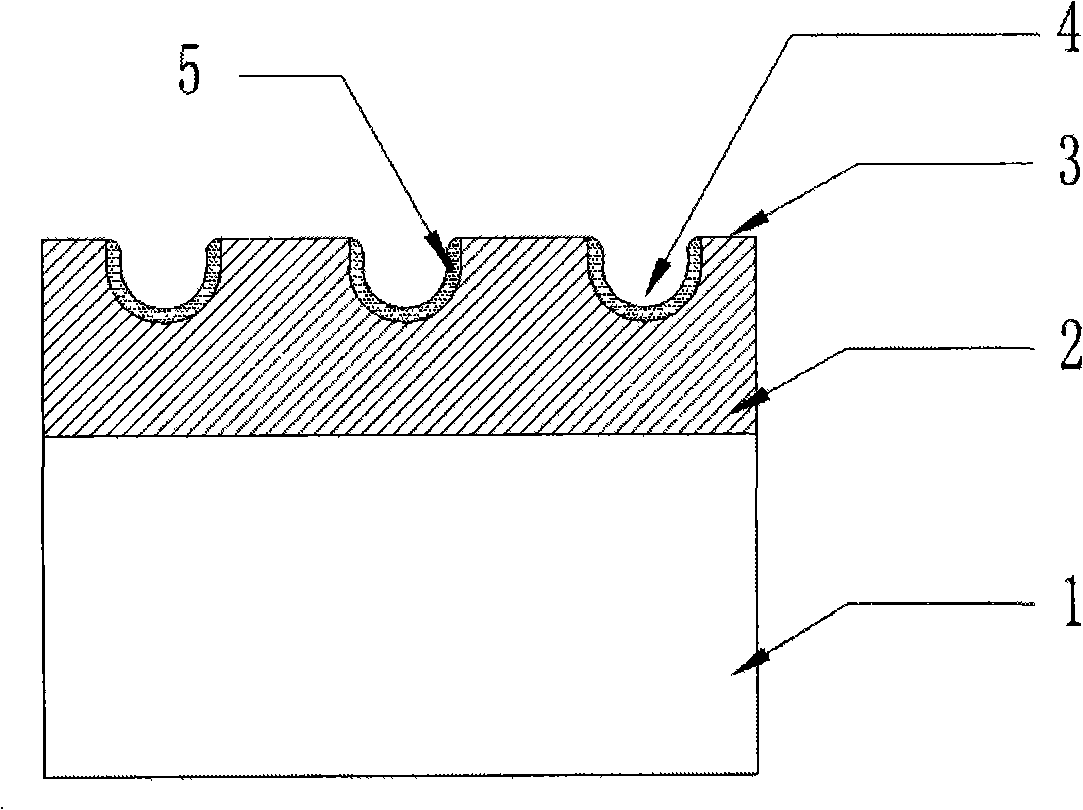

Polycrystal diamond hard alloy complex sheet of surface groove with lack Co area

The invention discloses a carbide composite tablet of polycrystalline diamond with Co deficient areas and a grooved surface, which includes a carbide layer and a polycrystalline diamond layer; the carbide layer consists of a carbide (usually adopting tungsten carbide: WC) and a bonding agent (usually adopting Co), and a polycrystalline diamond layer consists of a diamond and a catalytic binder (usually adopting Co). The surface of the diamond is engraved with grooves, wherein, the engraved grooves divide the diamond layer into a plurality of platforms. Through the process of removing Co, Co deficient areas are formed on the engraved grooves or the platforms of the polycrystalline diamond layer or on both. The carbide composite tablet of polycrystalline diamond of the invention is increased by 1-2 times in abrasion ratio; under the same size of impact force, the break-off area of the diamond layer can be reduced by 50 to 80 percent, and the composite tablet of the invention can greatly improve the use temperature of carbide composite tablet of polycrystalline diamond, and the use temperature can be improved to at least 100 DEG C, thus enlarging the scope of use temperature and enabling the composite tablet to be used under higher abrasion speed.

Owner:河南四方超硬材料有限公司

Formula of elastic grinding piece and machining method thereof

ActiveCN106392921AGood flexibilityImprove polishing effectAbrasion apparatusGrinding devicesGas phasePotassium

The invention discloses a formula of an elastic grinding piece. The formula comprises a fine material layer and a thick material layer compounded up and down; the thick material layer comprises the raw materials of SG abrasives, high-temperature calcined corundum, white corundum, liquid phenolic resins, liquid butyronitrile rubber, powder-shaped phenolic resins, decolored and dewaxed lac powder, diamond powder, nanoscale gas-phase silicon dioxide, magnesium oxide powder, titanium white powder and phthalein green; and the fine layer material comprises the raw materials of corundum, white corundum, liquid phenolic resins, liquid butyronitrile rubber, powder-shaped phenolic resins, decolored and dewaxed lac powder, potassium fluoborate, nanoscale gas-phase silicon dioxide, magnesium oxide powder, titanium white powder and phthalein green. The prepared elastic grinding piece needs no flexible bending and softening, is excellent in polishing hand feel, breaks no edges, is high in durability, is excellent in flexibility, can reach the biggest bending angle of 52 degrees, is high in adaptability, can satisfy the demands on such precise machining as finish grinding and polishing in the bearing industry, and is high in surface precision of machined workpieces.

Owner:东莞市金利威磨料磨具有限公司

Super-hard grinding tool of inorganic and organic composite binder and preparation method of super-hard grinding tool

ActiveCN104669128AGood mechanical propertiesGood grindingAbrasion apparatusGrinding devicesHot pressingCalcium Binder

The invention discloses a super-hard grinding tool of an inorganic and organic composite binder and a preparation method of the super-hard grinding tool. The super-hard grinding tool is characterized by being prepared by the following materials in percentage by volume: 10%-30% of super-hard grinding material, 30%-50% of thermosetting resin powder, 8%-12% of phosphate binder, 10%-29% of curing agent and 10%-29% of filler. The preparation method comprises the following steps of carrying out hot press molding after the composite binder and the grinding material are uniformly mixed, and then curing to obtain the super-hard grinding tool of the composite binder. Compared with a super-hard grinding tool of a resin binder, the super-hard grinding tool prepared by the preparation method has higher strength and higher heat resistance, and meanwhile, the super-hard grinding machine has good grinding performance.

Owner:珠海泰达砂轮有限公司

Polycrystalline diamond cubic boron nitride composite sheet and preparation method thereof

ActiveCN111057925AHigh bonding densityIncrease bond densityTransportation and packagingMetal-working apparatusPolycrystalline diamondAlloy substrate

The invention provides a polycrystalline diamond cubic boron nitride composite sheet. The polycrystalline diamond cubic boron nitride composite sheet comprises a hard alloy substrate, a polycrystalline diamond composite layer, a polycrystalline cubic boron nitride composite layer and a hard alloy protective layer which are sequentially arranged from bottom to top, wherein the polycrystalline diamond composite layer is composed of diamond micro powder and a nano metal binding agent, and the polycrystalline cubic boron nitride composite layer is composed of cubic boron nitride micro powder and ametal ceramic bonding agent. The invention further provides a method for preparing the polycrystalline diamond cubic boron nitride composite sheet. The method comprises the following steps that the diamond micro powder and the nano metal bonding agent are used for preparing a diamond bonding agent mixture; the cubic boron nitride micro powder and the metal ceramic bonding agent are used for preparing a cubic boron nitride bonding agent mixture; the hard alloy substrate is put into a tantalum cup, and the diamond bonding agent mixture and the cubic boron nitride binding agent mixture are sequentially poured into the tantalum cup; and the hard alloy protective layer is put into the tantalum cup, then vacuum heat treatment is carried out, and then high-temperature high-pressure sintering treatment is carried out. The composite sheet has high impact toughness and high strength.

Owner:FUNIK ULTRAHARD MATERIAL

High-performance diamond saw blade and preparation method thereof

ActiveCN109175388AHigh hardnessImprove impact toughnessMetal sawing tool makingMetal sawing toolsIron powderBoron carbide

The invention discloses a high-performance diamond saw blade and a preparation method thereof. A tool bit of the high-performance diamond saw blade comprises a first cutting area and a second cuttingarea. The first cutting area comprises, by weight part, 8-14 parts of polycrystalline diamond particles, 48-55 parts of iron powder, 25-32 parts of copper powder, 4-6 parts of zinc powder, 2-3 parts of tin powder, 1.5-2.5 parts of nickel powder, 2-3 parts of cobalt powder, 1.5-2 parts of manganese powder, 2.5-5 parts of tungsten carbide and titanium carbide mixture powder and 0.4-0.7 part of lanthanum pentanickel powder. The second cutting area comprises, by weight part, 10-16 parts of polycrystalline diamond and boron carbide mixture particles, 45-50 parts of iron powder, 27-33 parts of copper powder, 4-6 parts of zinc powder, 2-3 parts of tin powder, 1.5-2.5 parts of nickel powder, 2-3 parts of cobalt powder, 1.5-2 parts of manganese powder, 2.5-4 parts of titanium carbide powder and 0.4-0.7 part of lanthanum pentanickel powder. The high-performance diamond saw blade is excellent in comprehensive performance.

Owner:泉州市华兴超硬工具有限公司

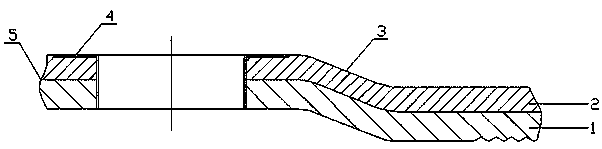

Alloy drill bit for mining

The invention belongs to the technical field of machining, and discloses a mining drill bit comprising a tool bit and a base body. The tool bit comprises, by weight, 100-120 parts of nickel powder, 85-90 parts of barium titanate powder, 70-75 parts of tungsten powder, 69-72 parts of silicon nitride powder, 65-68 parts of chromium carbide powder, 50-55 parts of alumina powder, 45-48 parts of chromium powder, 30-32 parts of copper powder, 25-28 parts of tungsten carbide powder, 20-22 parts of titanium carbide powder, 5-8 parts of water glass and 2-3 parts of silica gel. The invention further discloses a drill bit matrix. The drill bit has good bending strength, impact toughness and abrasive ratio.

Owner:宽城铧尖金矿有限公司

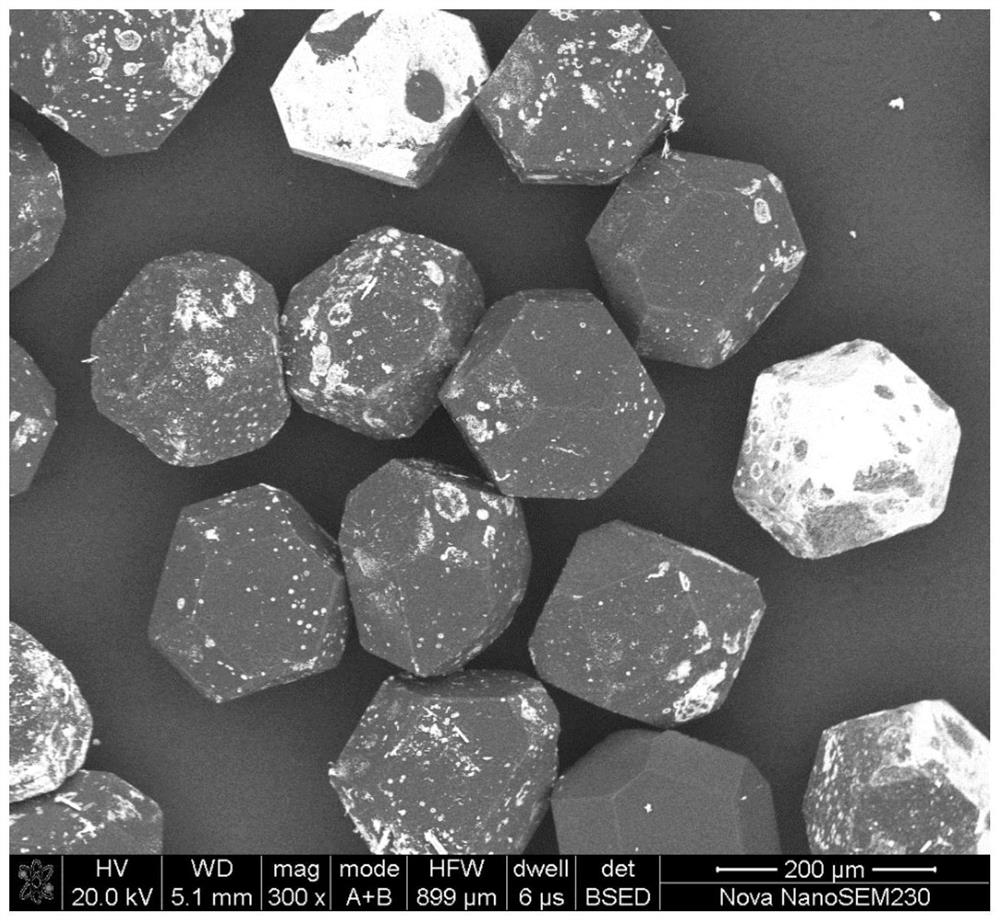

Method for processing drilling hexagonal polycrystalline diamond

InactiveCN101954261AImprove thermal stabilityHigh impact strengthUltra-high pressure processesPolycrystalline diamondMixed materials

The invention discloses a method for processing drilling hexagonal polycrystalline diamond. The processing method of the invention comprises the following steps of: adding a certain amount of boron into basic raw materials including diamond powder, silicon and metal nickel; blending the raw materials including the diamond powder, the silicon and the nickel with the boron and adding the mixed materials into a carbon synthesizing mold; putting the carbon synthesizing mold into a vacuum furnace for heating under vacuum; placing the semi-finished product after the vacuum heating into a diamond hexagonal heading press for high-temperature and high-pressure synthesizing; and relieving pressure after the high-temperature and high-pressure synthesizing to obtain the product of drilling hexagonal polycrystalline diamond TSP of the invention. The polycrystalline diamond TSP prepared by the technical scheme of the invention has relatively high thermal stability, relatively high impact resistance and high wear resistance and can meet the requirements of complicated substrate drilling completely; and the qualification rate of the product is as high as over 88 percent.

Owner:ZHENGZHOU SANHE DIAMOND

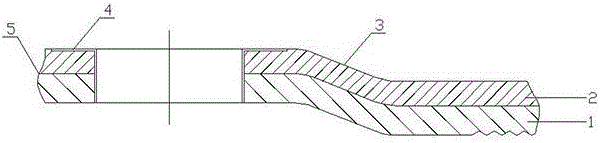

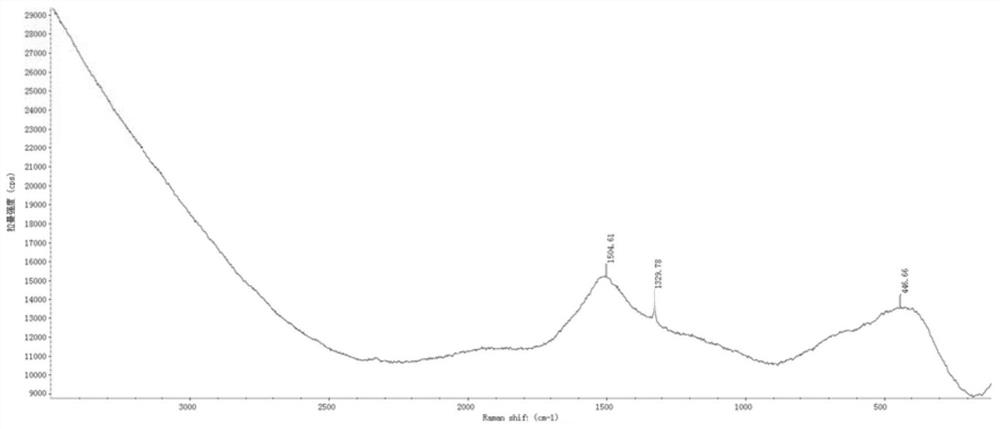

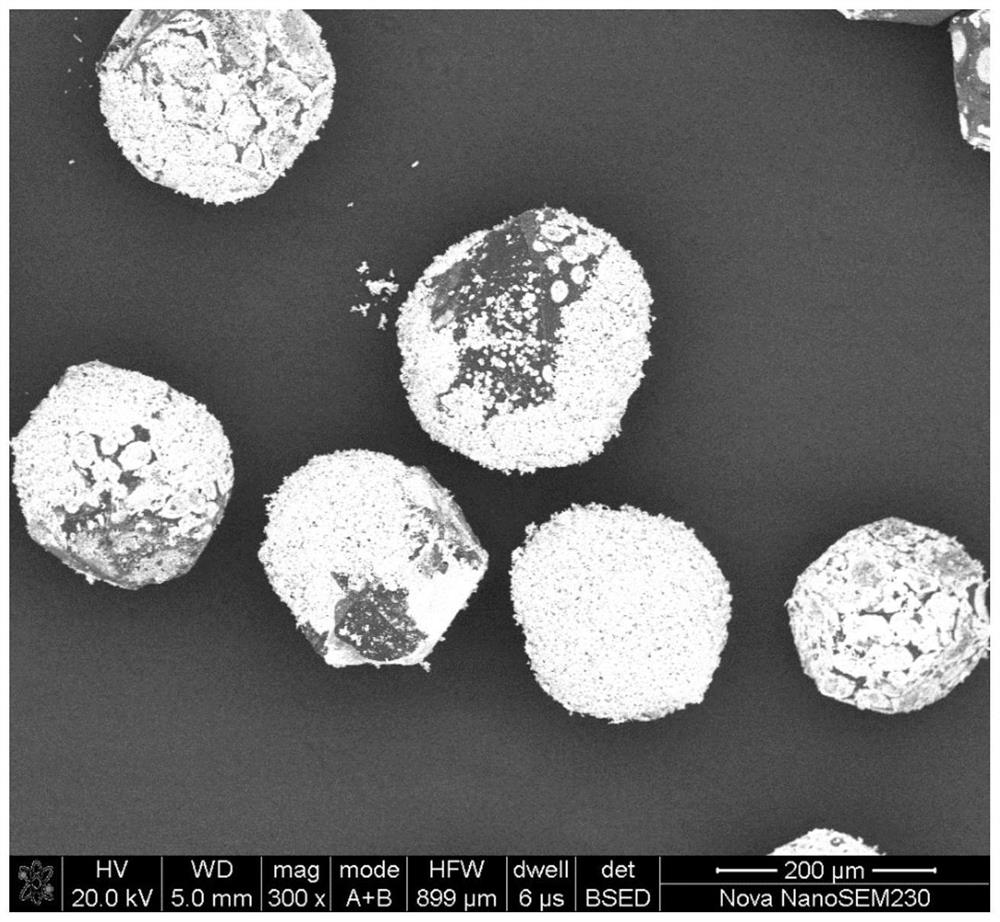

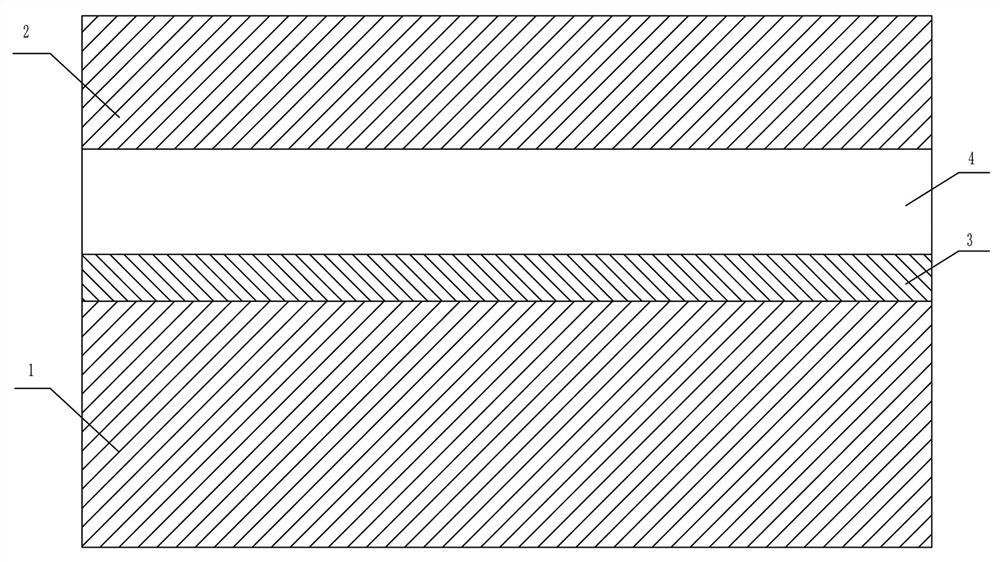

Diamond composite material, as well as preparation method and application thereof

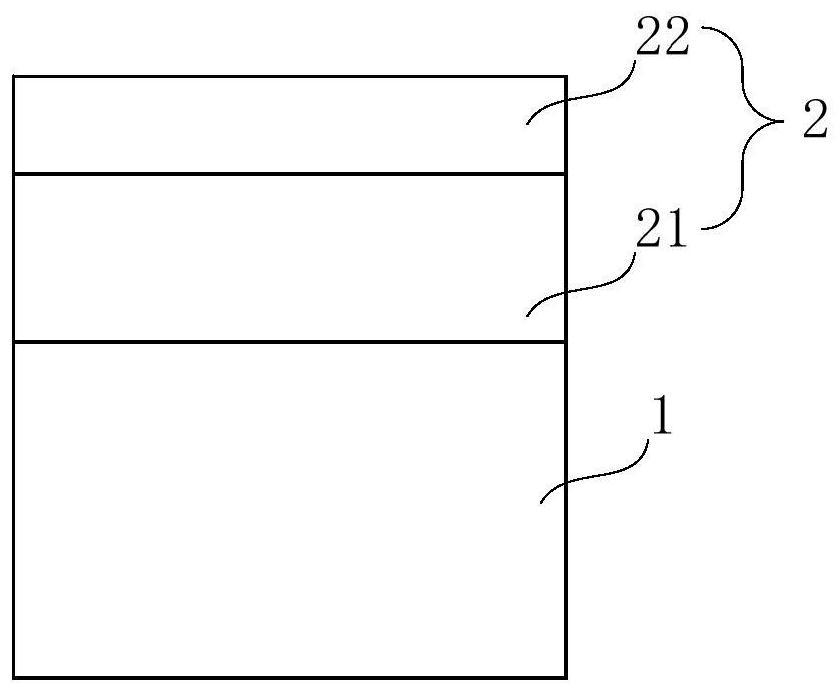

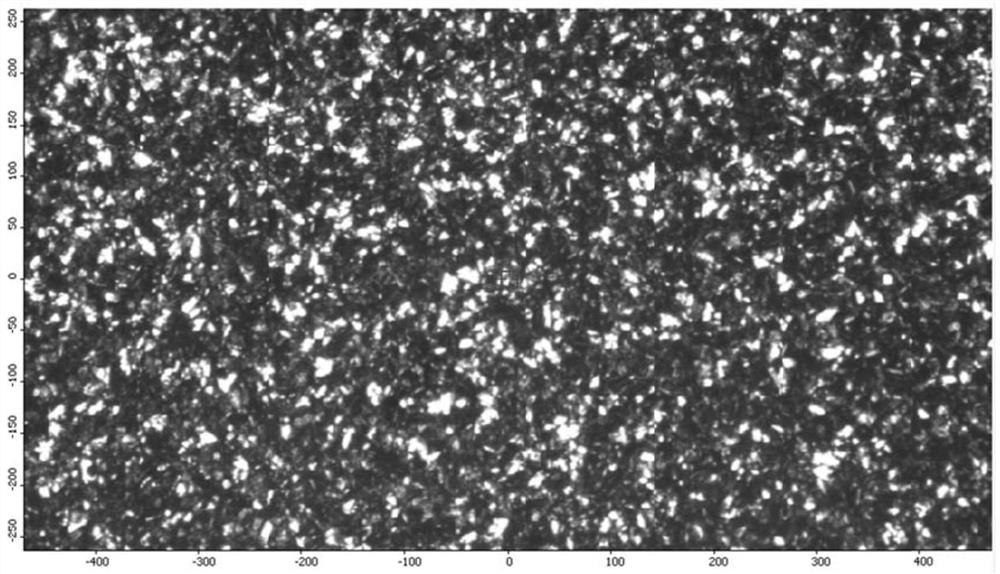

ActiveCN111809162AIncrease wear ratioExtended use timeChemical vapor deposition coatingPolycrystalline diamondChemical vapor deposition

The invention provides a diamond composite material, as well as a preparation method and application thereof. The diamond composite material comprises a CVD diamond layer and a polycrystalline diamondcomposite layer, wherein the polycrystalline diamond composite layer comprises a polycrystalline diamond layer and a hard alloy layer; the polycrystalline diamond layer is arranged between the CVD diamond layer and the hard alloy layer; and from one side close to the CVD diamond layer to one side close to the hard alloy layer, the metal contents in the polycrystalline diamond layer are increasedprogressively. The preparation method of the diamond composite material comprises the following steps of (1) polishing and cleaning the polycrystalline diamond layer in the polycrystalline diamond composite layer, and obtaining a pretreated polycrystalline diamond composite layer; (2) placing the pretreated polycrystalline diamond composite layer into microwave plasma chemical vapor deposition equipment, and carrying out corrosion; and (3) stopping feeding oxygen, and then feeding mixed gas to carry out chemical vapor deposition on the polycrystalline diamond layer. According to the diamond composite material, as well as the preparation method and the application thereof provided by the invention, the diamond composite material has low wear resistance ratio and long service time, and the occurrence probability of layer-to-layer stripping is low.

Owner:CR GEMS SUPERABRASIVES

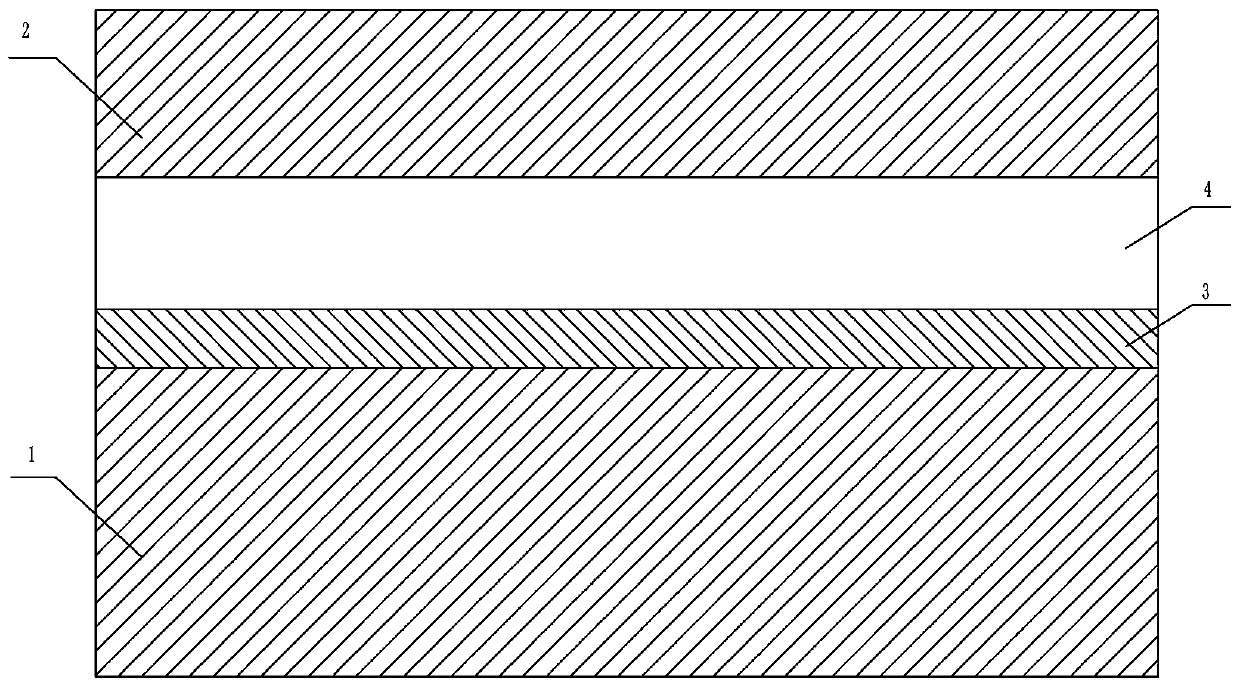

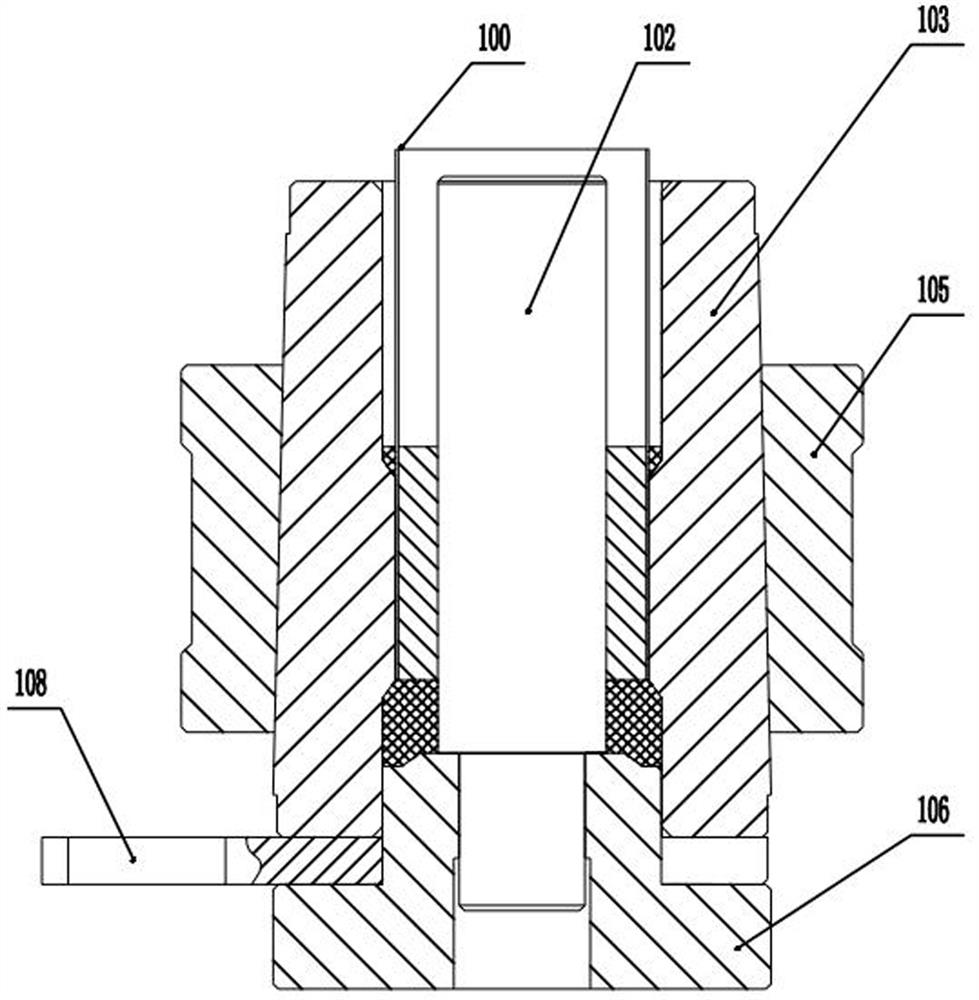

High-performance composite pressure transmission component and preparation method thereof

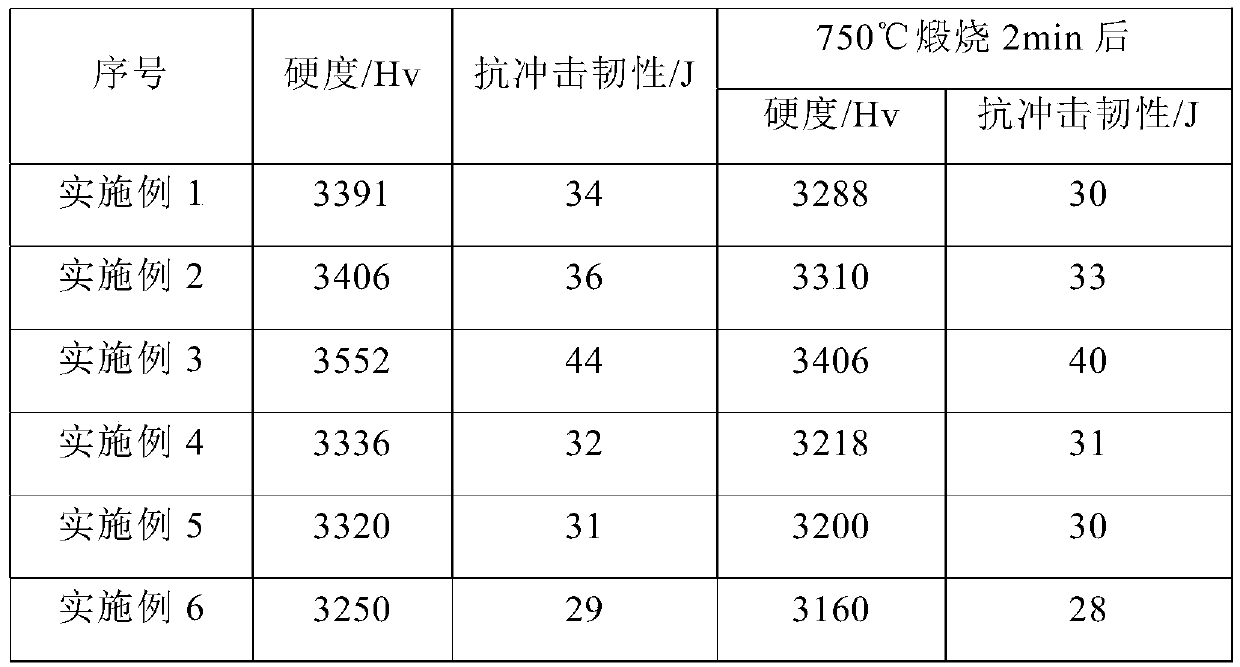

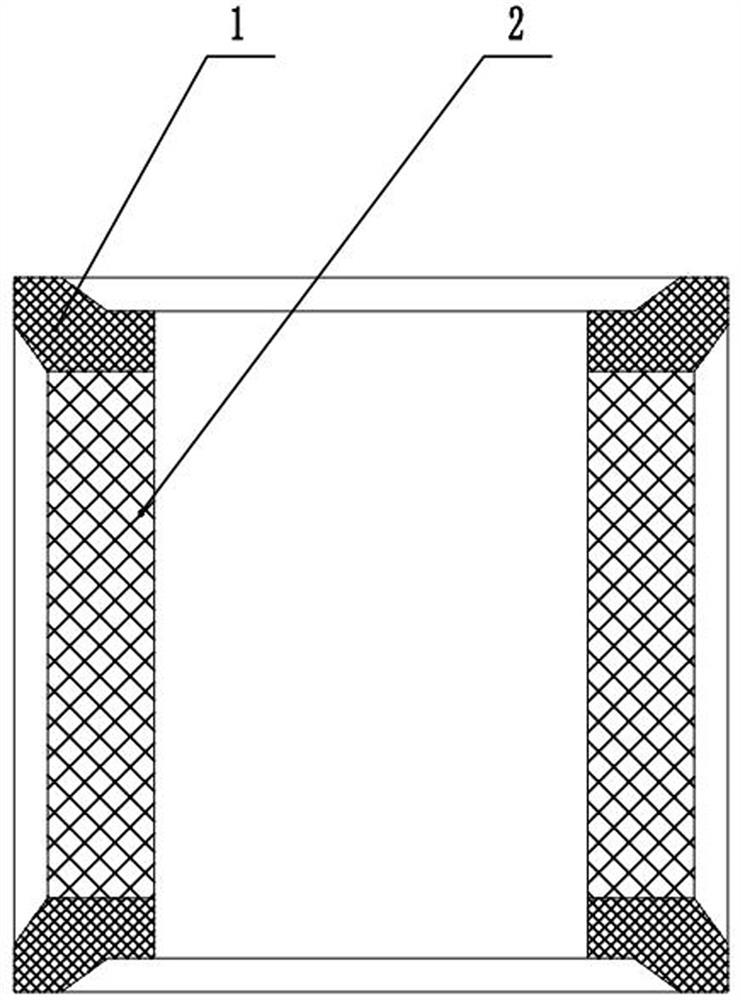

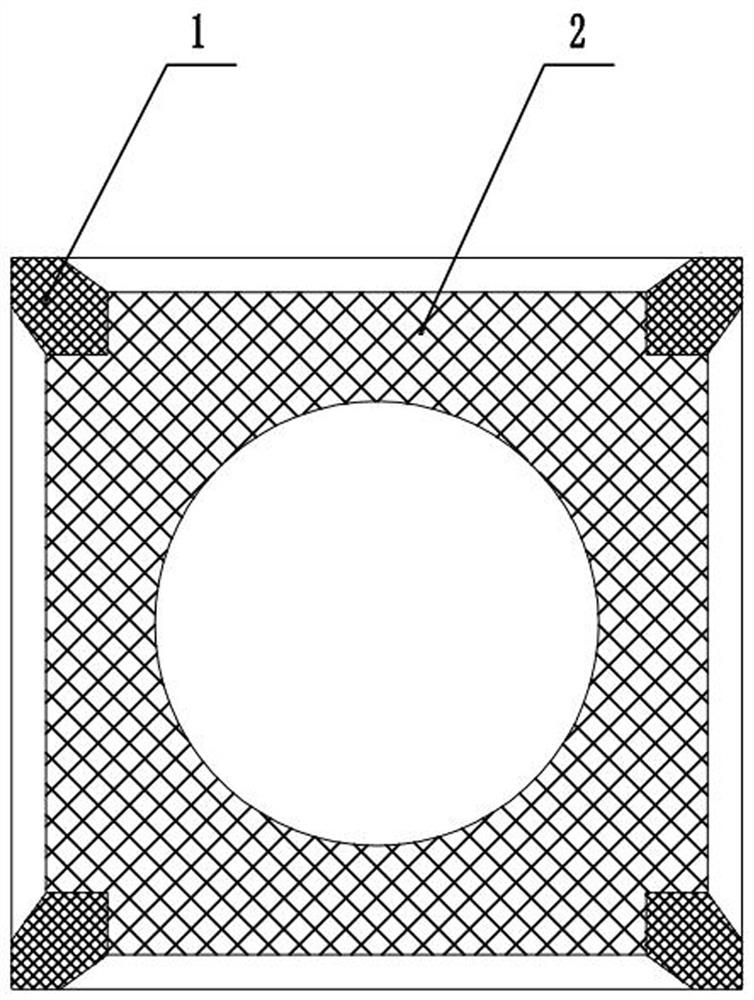

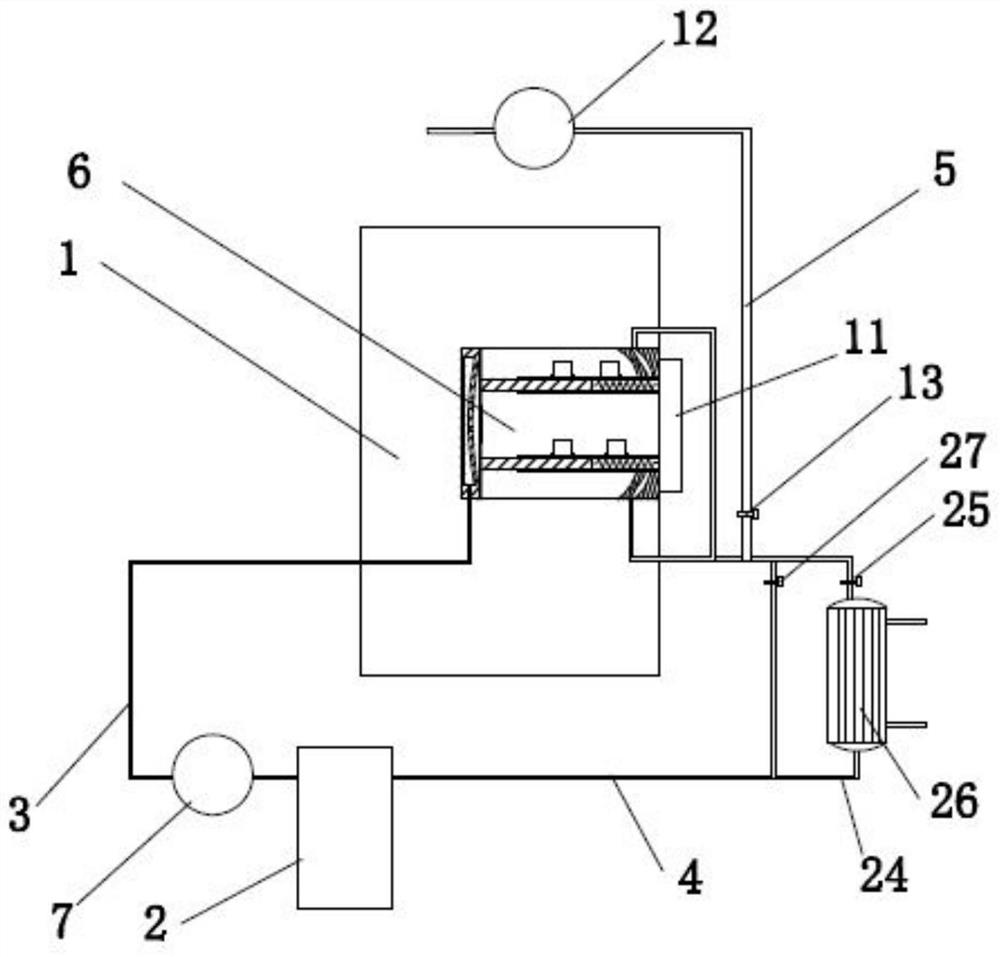

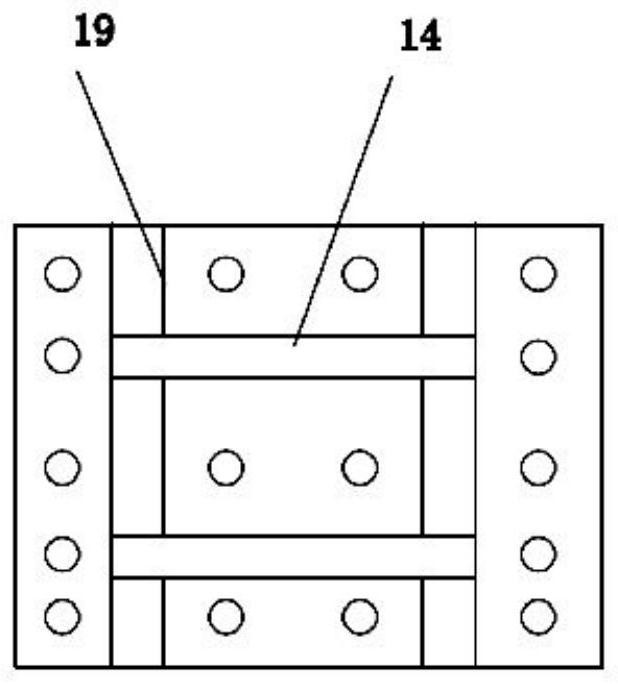

PendingCN113856558AHigh pressure transmission efficiencyReduce flow deformationUltra-high pressure processesSuperhard materialInternal pressure

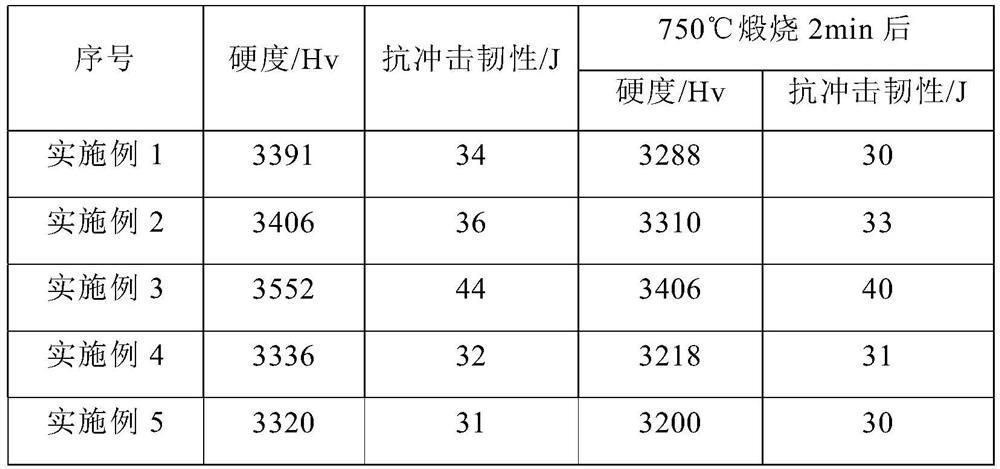

The invention belongs to the technical field of superhard material manufacturing, and particularly relates to a high-performance composite pressure transmission component and a preparation method thereof. The high-performance composite pressure transmitting component comprises a cubic pressure transmitting medium and a sealing square frame arranged outside the pressure transmitting medium in a sleeving mode. The sealing square frame is of a cubic frame structure, and each frame of the sealing square frame is attached to the side wall of the pressure transmitting medium. According to the present invention, the wear resistance test and the impact toughness test are performed on the polycrystalline diamond compact prepared by using the high-performance composite pressure transmission component, and the test results show that the wear resistance and the impact toughness of the polycrystalline diamond compact prepared by using the high-performance composite pressure transmission component are improved; it is shown that the polycrystalline diamond compact prepared by adopting the high-performance composite pressure transmission component has high mechanical performance and good thermal performance, and meanwhile the problem that the internal pressure cannot be effectively improved when an existing pyrophyllite pressure transmission component is used is solved.

Owner:ZHONGNAN DIAMOND CO LTD

Diamond grinding wheel with resin binder

Disclosed is a diamond grinding wheel with resin binder. High-thermal-conductivity rigid and crispy material which is phosphotungstic bronze alloy powder is used as filler for the grinding wheel. According to a formula of the grinding wheel, volume ratio of the phosphotungstic bronze alloy powder is 5%-25%, volume ratio of diamond is 5%-37.5%, volume ratio of resin binder is 10%-70%, volume ratio of chromic oxide is 0-15%, and volume ratio of zinc oxide is 0-15%. Without changing the prior art, the phosphotungstic bronze alloy powder is used as the filler for improving service performance of the diamond grinding wheel with resin binder. The diamond grinding wheel is fine in self-sharpening and high in sharpening degree, and abrasive ratio is increased greatly. Coarseness of the surface of a grinding piece is reduced, which corresponds with the trend that modern machining industry increasingly requires high precision.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD +1

Cutter head tire casing for mining bit

The invention belongs to the technical field of mechanical processing, and discloses a mining bit. The mining bit consists of a cutter head and a basal body, wherein the cutter body is prepared from the following components: 100-120 parts of nickel powder, 85-90 parts of barium titanate powder, 70-75 parts of tungsten powder , 69-72 parts of silicon nitride powder, 65-68 parts of chrome carbide powder, 50-55 parts of aluminum oxide powder, 45-48 parts of chromium powder, 30-32 parts of copper powder, 25-28 parts of tungsten carbide powder, 20-22 parts of titanium carbide powder, 5-8 parts of water glass and 2-3 parts of silica gel. The invention further discloses a bit tire casing. The bit prepared from the tire casing disclosed by the invention has the advantages of better bending strength, better impact toughness and higher wearing ratio.

Owner:CANGSHAN DELI GYPSUM

A wear-resistant multi-principal alloy-diamond composite material and its preparation method and application

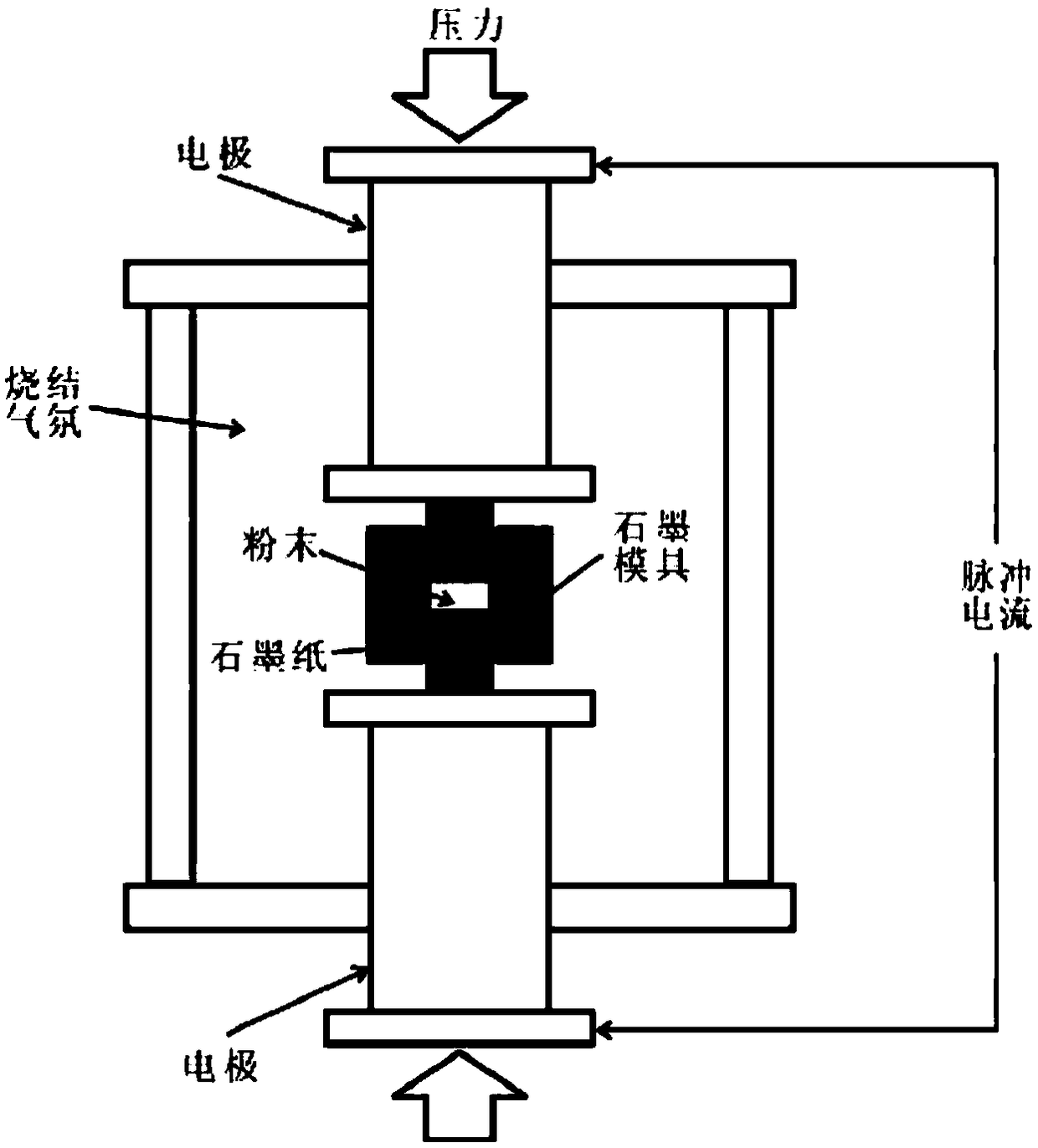

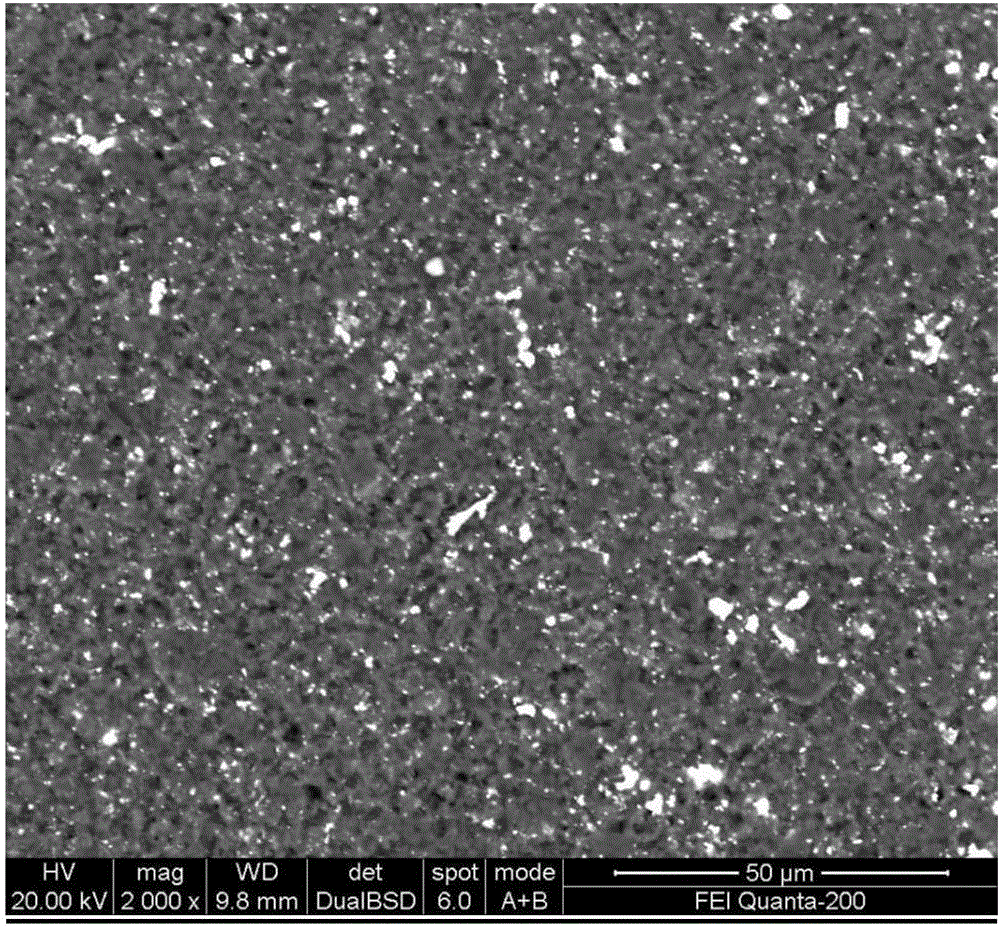

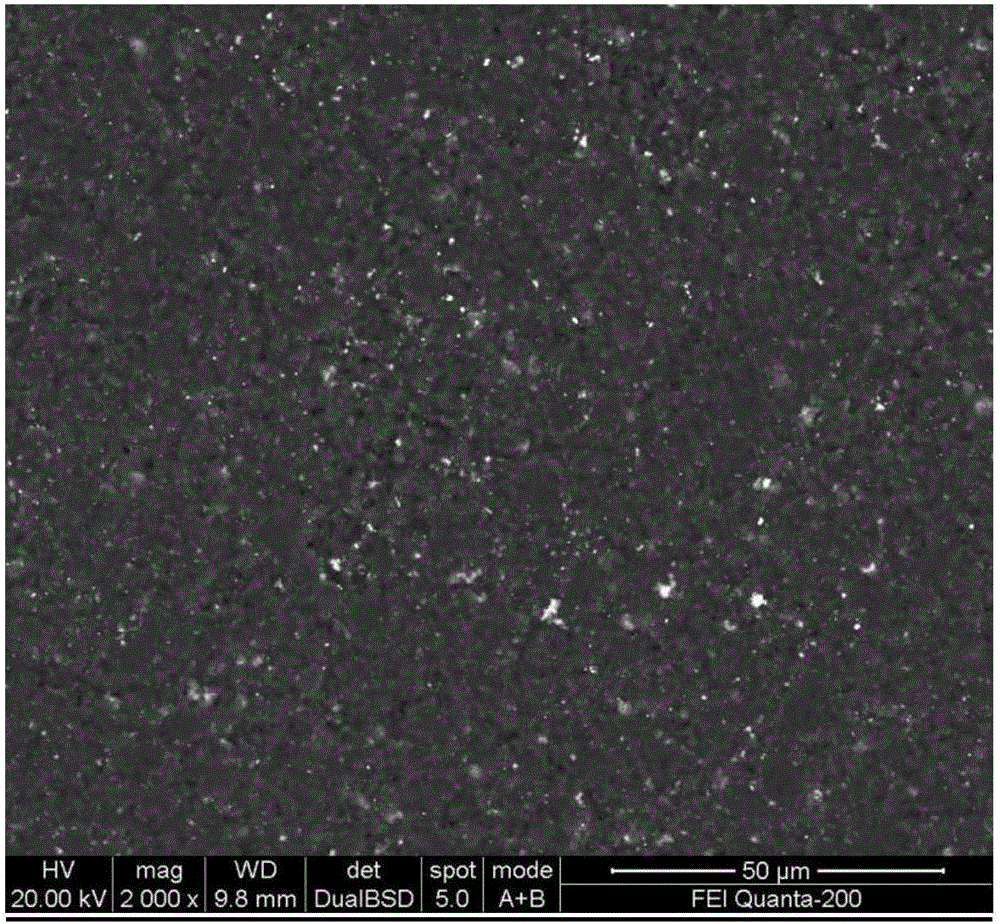

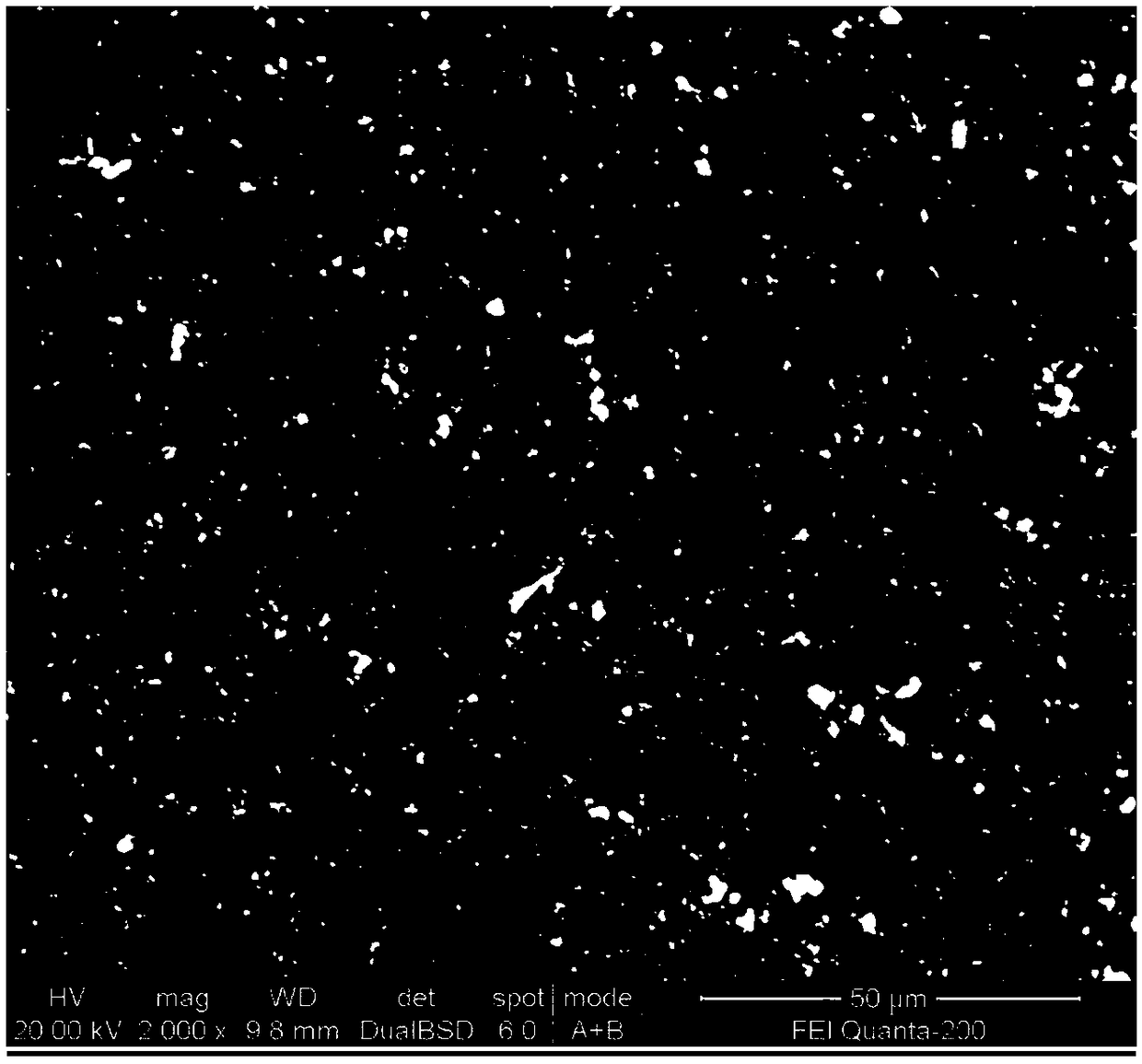

The invention belongs to the field of preparation of composite materials, and in particular relates to a multi-principal alloy-diamond composite material and its preparation method and application. The raw materials of the composite material include 80-95vol.% binder phase powder and 5-20vol% diamond. The binder phase powder used is composed of Cu, Ni, Co, Cr in atomic ratio (20-40):(20-30):(20-30):(10-20). The preparation method is as follows: after fully mixing the bonding phase powder and the diamond powder, the spark plasma sintering process is used to sinter at 800-1000°C to obtain the product. The material has good interfacial bonding, diamond stability, and friction and wear properties. The multi-principal element alloy-diamond composite material designed and prepared by the present invention can be used to prepare grinding diamond-like tools such as diamond grinding discs and diamond grinding wheels.

Owner:CENT SOUTH UNIV

Preparation process for artificial diamond sintered body

ActiveCN109317662APreparation pressure reductionShorten production timeTransportation and packagingMetal-working apparatusSilicon alloyHigh pressure

The invention discloses a preparation process for an artificial diamond sintered body. The preparation process comprises the steps of screening, proportioning and purifying of diamond micro-powder, germanium-silicon alloy film deposition, bonding agent proportioning, ionized plasma sintering and the like. The high-temperature and high-pressure requirements in an existing preparation technology areeffectively reduced, the preparation duration is shortened, the preparation efficiency of the artificial diamond sintered body is improved, the preparation energy consumption is reduced, the hardnessand the abrasiveness ratio of the sintered product are greatly improved, and the product quality is improved.

Owner:ANHUI YAZHU DIAMOND

Synthetic process of compound superhard material

ActiveCN106622032AReduced amount of metal dialysisLittle thermal stability parameterUltra-high pressure processesSuperhard materialCemented carbide

The invention discloses a synthetic process of a compound superhard material. The synthetic process comprises the following steps: (1) putting an assembled hard alloy and a superhard material into a pyrophyllite body, putting the pyrophyllite body into a cubic press, pressurizing the pyrophyllite body to 8MPa-10MPa, and heating to 700-800 DEG C; and (2) further pressurizing the pyrophyllite body to 90MPa-100MPa, and heating to 1400-1700 DEG C. By virtue of the synthetic process, the dialysis of hard alloy elements in the compounding process of the superhard material can be reduced, the metal content in the superhard material can be reduced, the yield of the superhard material can be increased, the thermal stability of the superhard material can be improved, and the abrasive ratio can be increased.

Owner:湖南泰鼎新材料有限责任公司

CBN (cubic boron nitride) polycrystalline sintered compact made by using nano-metal additives and method for manufacturing CBN polycrystalline sintered compact

InactiveCN104962769AHigh pressure and high temperature field stabilityWill not be pollutedAl powderMetallurgy

The invention discloses CBN (cubic boron nitride) polycrystalline sintered compact made by using nano-metal additives and a method for manufacturing the CBN polycrystalline sintered compact, and belongs to the technical field of cubic boron nitride tool materials. The nano-metal additives comprise, by weight, 25-45% of TiN powder, 20-25% of TaC powder, 10-15% of AlB<2> powder, 15-20% of Co powder and 10-15% of Al powder. Formulas of the CBN polycrystalline sintered compact made by using the nano-metal additives are reasonably arranged and selected by the aid of nano-technologies, and accordingly technical bottleneck in the aspects of high toughness and high abrasion resistance of existing CBN polycrystalline sintered compact can be broken through. Compared with the existing CBN polycrystalline sintered compact, the CBN polycrystalline sintered compact made by using the nano-metal additives and the method have the advantages that the abrasion ratio can be increased and is 6000-7000 from the original 3500-5000; the micro-hardness HV (Vickers hardness) of working layers can be increased and is 5000-7000 from the original 2000-5000, and the bending strength can be increased and is 750-850MPa from the original 300-600MPa.

Owner:ZHONGNAN DIAMOND CO LTD

A Superhard Abrasive Tool with Inorganic and Organic Composite Binder

ActiveCN104669128BImprove mechanical propertiesImprove grinding effectAbrasion apparatusGrinding devicesHeat resistanceCalcium Binder

The invention discloses a super-hard grinding tool of an inorganic and organic composite binder and a preparation method of the super-hard grinding tool. The super-hard grinding tool is characterized by being prepared by the following materials in percentage by volume: 10%-30% of super-hard grinding material, 30%-50% of thermosetting resin powder, 8%-12% of phosphate binder, 10%-29% of curing agent and 10%-29% of filler. The preparation method comprises the following steps of carrying out hot press molding after the composite binder and the grinding material are uniformly mixed, and then curing to obtain the super-hard grinding tool of the composite binder. Compared with a super-hard grinding tool of a resin binder, the super-hard grinding tool prepared by the preparation method has higher strength and higher heat resistance, and meanwhile, the super-hard grinding machine has good grinding performance.

Owner:珠海泰达砂轮有限公司

A Synthetic Process of Composite Superhard Material

ActiveCN106622032BReduced amount of metal dialysisLittle thermal stability parameterUltra-high pressure processesSuperhard materialCemented carbide

The invention discloses a synthetic process of a compound superhard material. The synthetic process comprises the following steps: (1) putting an assembled hard alloy and a superhard material into a pyrophyllite body, putting the pyrophyllite body into a cubic press, pressurizing the pyrophyllite body to 8MPa-10MPa, and heating to 700-800 DEG C; and (2) further pressurizing the pyrophyllite body to 90MPa-100MPa, and heating to 1400-1700 DEG C. By virtue of the synthetic process, the dialysis of hard alloy elements in the compounding process of the superhard material can be reduced, the metal content in the superhard material can be reduced, the yield of the superhard material can be increased, the thermal stability of the superhard material can be improved, and the abrasive ratio can be increased.

Owner:湖南泰鼎新材料有限责任公司

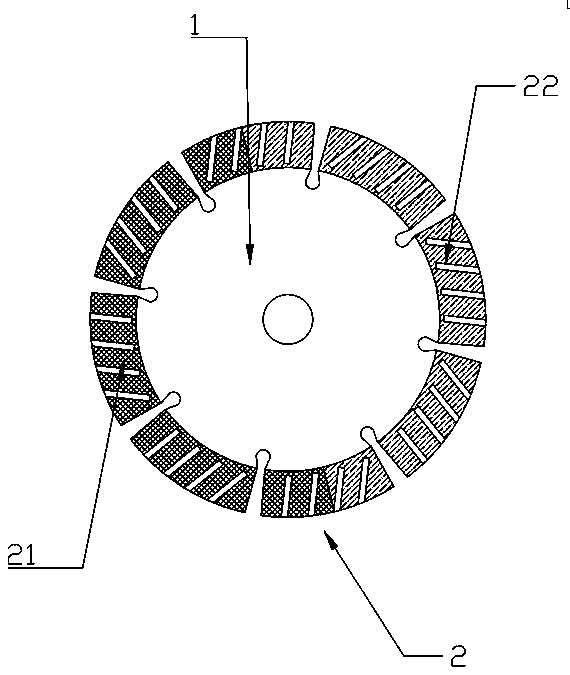

A kind of diamond saw blade and preparation method thereof

ActiveCN109175388BHigh hardnessImprove impact toughnessMetal sawing tool makingMetal sawing toolsIron powderPolycrystalline diamond

The invention discloses a diamond saw blade and a preparation method thereof. The cutter head includes a first cutting area and a second cutting area; the first cutting area includes the following raw materials in parts by weight: 8-14 parts of polycrystalline diamond particles, iron powder 48-55 parts, copper powder 25-32 parts, zinc powder 4-6 parts, tin powder 2-3 parts, nickel powder 1.5-2.5 parts, cobalt powder 2-3 parts, manganese powder 1.5-2 parts, tungsten carbide and 2.5-5 parts of titanium carbide mixture powder, 0.4-0.7 part of lanthanum nickel five powder; the second cutting zone includes the following raw materials by weight: 10-16 parts of polycrystalline diamond and boron carbide mixture particles, 45-50 parts of iron powder, copper 27-33 parts of powder, 4-6 parts of zinc powder, 2-3 parts of tin powder, 1.5-2.5 parts of nickel powder, 2-3 parts of cobalt powder, 1.5-2 parts of manganese powder, 2.5-4 parts of titanium carbide powder, lanthanum 0.4 to 0.7 parts of nickel five powder. The diamond saw blade of the invention has excellent comprehensive performance.

Owner:泉州市华兴超硬工具有限公司

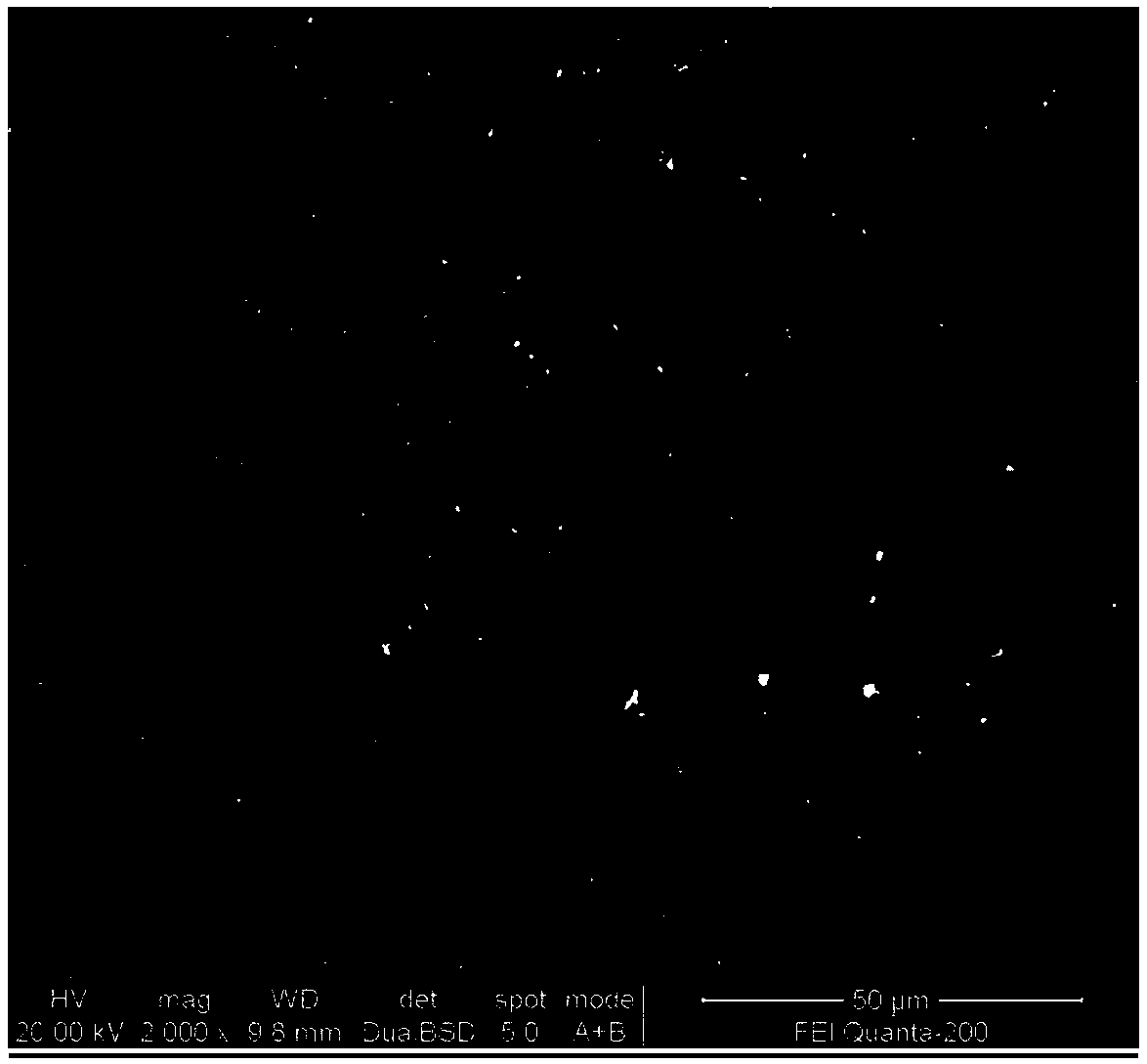

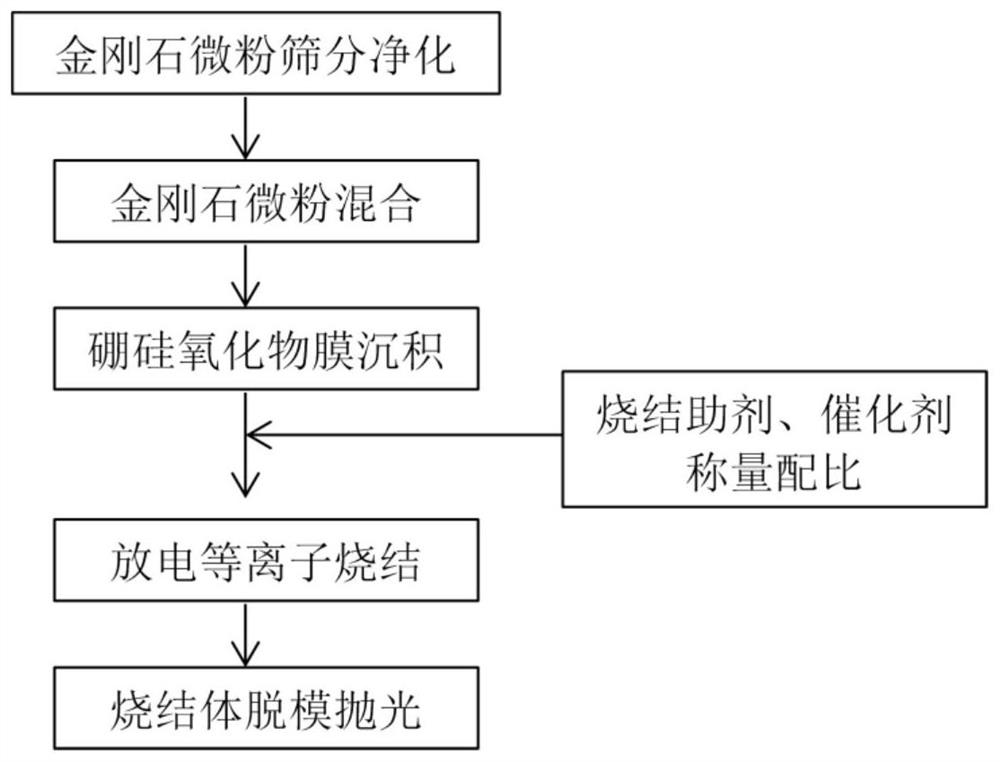

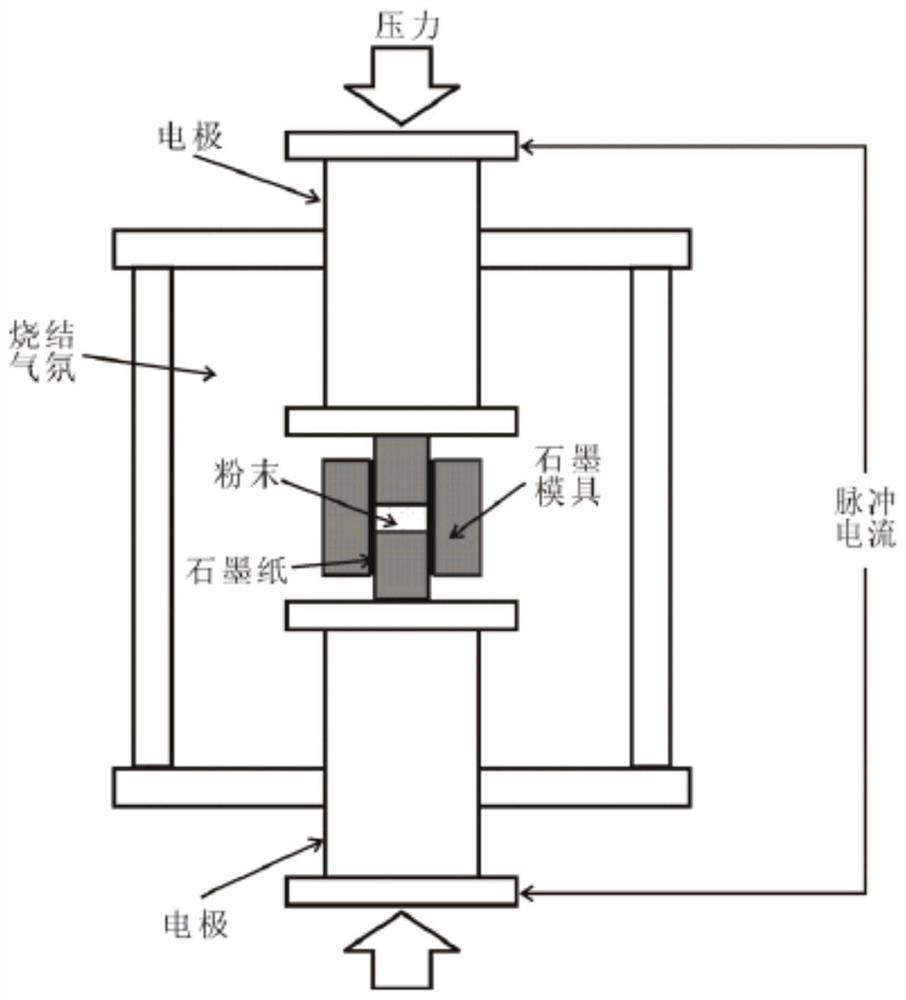

An improved preparation process of synthetic diamond sintered body

ActiveCN109465456BPreparation pressure reductionShorten production timeChemical vapor deposition coatingSilicon oxideSynthetic diamond

A process for preparing an improved synthetic diamond sintered body includes such steps as screening, matching, and purification on diamond micro powder, deposition of a boron silicon oxide film, binder matching, ionizing plasma sintering, etc. The invention effectively reduces the requirement of high temperature and high pressure in the prior preparation technology, shortens the preparation time,improves the preparation efficiency of the synthetic diamond sintered body, reduces the preparation energy consumption, greatly improves the hardness and the wear ratio of the sintered product, and improves the quality of the product.

Owner:ANHUI YAZHU DIAMOND

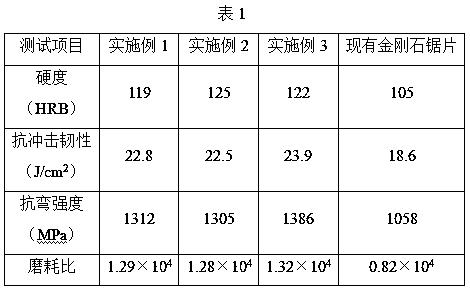

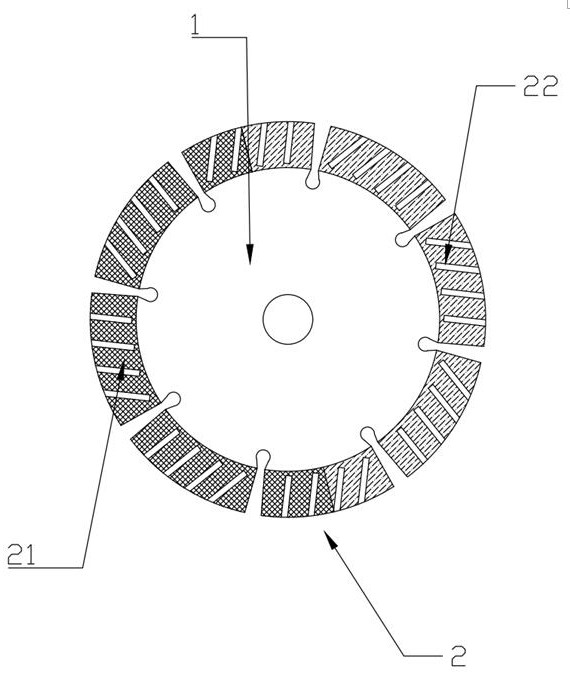

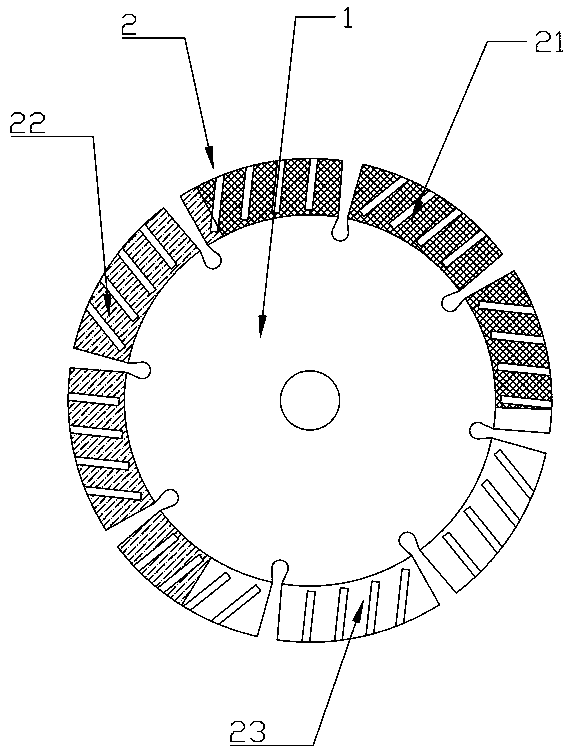

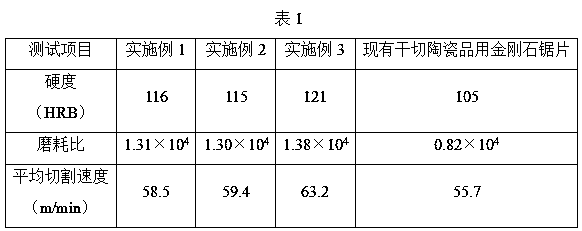

A kind of diamond saw blade for dry cutting ceramics and preparation method thereof

ActiveCN109176903BFlat cutting surfaceImprove cutting efficiencyStone-like material working toolsTool bitDiamond blade

The invention discloses a diamond saw blade for dry-cutting of ceramic and a preparation method of the diamond saw blade. The diamond saw blade for dry-cutting of ceramic comprises a base body and a cutter bit; and the cutter bit comprises a first cutting zone, a second cutting zone and a third cutting zone. The diamond saw blade for dry-cutting of ceramic is divided into the first cutting zone, the second cutting zone and the third cutting zone, by selecting raw material compositions of the first cutting zone, the second cutting zone and the third cutting zone of the cutting bit carefully andoptimizing the contents of all raw materials, the diamond saw blade for dry-cutting of ceramic has good mechanical properties such as hardness and cutter bit abrasive ratio, during cutting, the cut surface of cut ceramic can be smoother, the cutting efficiency is high, edge breakage is not prone to occurring, and the diamond saw blade has broad application prospects.

Owner:泉州市华兴超硬工具有限公司

A kind of formula of elastic grinding disc and its processing method

ActiveCN106392921BIncrease wear ratioHigh hardnessAbrasion apparatusGrinding devicesGas phasePotassium

The invention discloses a formula of an elastic grinding piece. The formula comprises a fine material layer and a thick material layer compounded up and down; the thick material layer comprises the raw materials of SG abrasives, high-temperature calcined corundum, white corundum, liquid phenolic resins, liquid butyronitrile rubber, powder-shaped phenolic resins, decolored and dewaxed lac powder, diamond powder, nanoscale gas-phase silicon dioxide, magnesium oxide powder, titanium white powder and phthalein green; and the fine layer material comprises the raw materials of corundum, white corundum, liquid phenolic resins, liquid butyronitrile rubber, powder-shaped phenolic resins, decolored and dewaxed lac powder, potassium fluoborate, nanoscale gas-phase silicon dioxide, magnesium oxide powder, titanium white powder and phthalein green. The prepared elastic grinding piece needs no flexible bending and softening, is excellent in polishing hand feel, breaks no edges, is high in durability, is excellent in flexibility, can reach the biggest bending angle of 52 degrees, is high in adaptability, can satisfy the demands on such precise machining as finish grinding and polishing in the bearing industry, and is high in surface precision of machined workpieces.

Owner:东莞市金利威磨料磨具有限公司

Alloy drill bit for mining

The invention belongs to the technical field of machining, and discloses a mining drill bit comprising a tool bit and a base body. The tool bit comprises, by weight, 100-120 parts of nickel powder, 85-90 parts of barium titanate powder, 70-75 parts of tungsten powder, 69-72 parts of silicon nitride powder, 65-68 parts of chromium carbide powder, 50-55 parts of alumina powder, 45-48 parts of chromium powder, 30-32 parts of copper powder, 25-28 parts of tungsten carbide powder, 20-22 parts of titanium carbide powder, 5-8 parts of water glass and 2-3 parts of silica gel. The invention further discloses a drill bit matrix. The drill bit has good bending strength, impact toughness and abrasive ratio.

Owner:宽城铧尖金矿有限公司

Polycrystalline diamond cubic boron nitride composite sheet and preparation method thereof

ActiveCN111057925BHigh bonding densityIncrease bond densityTransportation and packagingMetal-working apparatusBoridePolycrystalline diamond

The invention provides a polycrystalline diamond cubic boron nitride composite sheet, which includes a cemented carbide substrate, a polycrystalline diamond composite layer, a polycrystalline cubic boron nitride composite layer and a hard alloy protective layer arranged sequentially from bottom to top; The polycrystalline diamond composite layer is composed of diamond micropowder and nano metal bonding agent, and the polycrystalline cubic boron nitride composite layer is composed of cubic boron nitride micropowder and metal ceramic bonding agent. The present invention also provides a method for preparing the polycrystalline diamond cubic boron nitride composite sheet, using diamond micropowder and nano-metal binder to prepare diamond bond mixture; using cubic boron nitride micropowder and cermet bond to prepare cubic nitride Boron binder mixture; put the cemented carbide substrate into the tantalum cup, pour the diamond bond mixture and the cubic boron nitride binder mixture in turn; and put the cemented carbide protective layer, and then carry out high temperature after vacuum heat treatment High pressure sintering. The composite sheet has high impact toughness and strength.

Owner:FUNIK ULTRAHARD MATERIAL

Method for machining elliptic polycrystalline diamond for drilling

InactiveCN101940894BImprove thermal stabilityHigh impact strengthUltra-high pressure processesPolycrystalline diamondUltimate tensile strength

The invention provides a method for machining an elliptic polycrystalline diamond for drilling. The machining method comprises the following steps of: adding a certain amount of boron into diamond powder, silicon and metallic nickel serving as basic raw materials and mixing; adding the mixture into a carbon synthetic mold; putting the synthetic mold into a vacuum furnace; heating the synthetic mold in vacuum; putting semi-finished products heated in the vacuum into a diamond hexahedron press for high temperature and high pressure synthesis; and releasing the pressure after the high temperature and high pressure synthesis to obtain a product of the invention, namely the elliptic polycrystalline diamond TSP for drilling. The polycrystalline diamond TSP prepared by the technical scheme has the advantages of higher thermal stability, higher anti-impact strength, higher abrasion resistance, capability of meeting the requirement of complicated bottom layer drilling, and over 85 percent of high product yield.

Owner:ZHENGZHOU SANHE DIAMOND

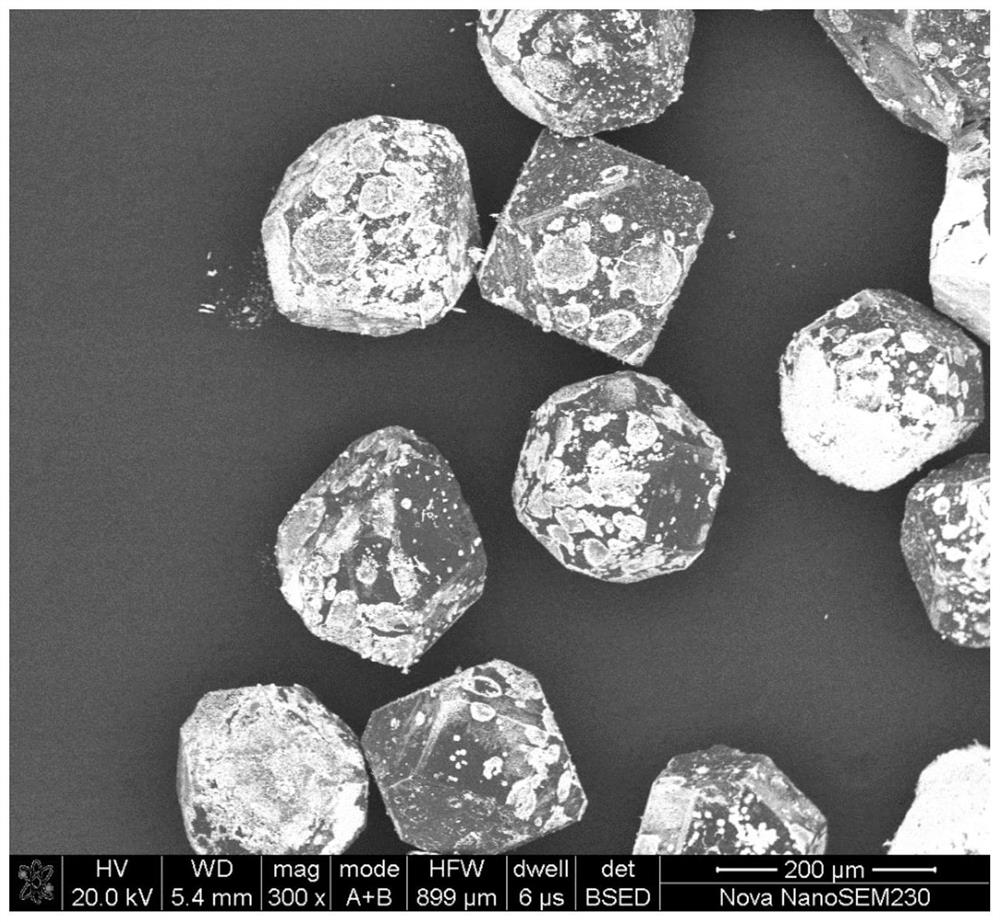

Preparation process of polycrystalline diamond composite sheet with mixed particle size

The preparation process of a polycrystalline diamond composite sheet with a mixed particle size provided by the present invention comprises the following steps: 1) preparation of a hard alloy part; 2) preparation of a composite transition layer; 3) selection of spherical micron diamond, which includes a particle size of The first diamond powder of ~7 microns, the second diamond powder of 15-19 microns, the third diamond powder of 25-27 microns and the fourth diamond powder of 35-39 microns, the first diamond powder , the second diamond micropowder, the third diamond micropowder and the fourth diamond micropowder are mixed and ball-milled with the bonding agent; dried under the protection of an inert gas and pressed into a polychip. The invention improves the proportion of the polycrystalline diamond, which greatly improves the abrasion ratio, impact toughness and Knoop microhardness of the polycrystalline diamond composite sheet with mixed particle size.

Owner:JINHUA ZHONGYE SUPERHARD MATERIALS CO LTD

A kind of elastic grinding plate and its preparation method

The invention belongs to the technical field of resin grinding wheels, and particularly relates to an elastic abrasive disc and a preparing method thereof. The elastic abrasive disc comprises, by weight, 25-35 parts of white corundum 80#, 20-40 parts of green silicon carbide 100#, 20-40 parts of ceramic corundum 100#, 20-25 parts of phenolic resin powder, 8-12 parts of phenolic resin liquid, 8-12 parts of potassium fluoroaluminate, 3-5 parts of modified nitrile rubber powder and 1-3 parts of iron oxide red. A toughening agent is added in the phenolic resin powder so that the elastic abrasive disc can have certain toughness, and a hardening curve for abrasive disc manufacturing is set more easily; the solid content of the phenolic resin liquid is high, and accordingly the abrasion resistance and cutting efficiency are improved; through adding of the modified nitrile rubber powder, the made elastic abrasive disc does not need to be bent or smoothened, the polishing and grinding feeling is good, durability is high, flexibility is good, and the requirements for machining of glass stone, hard alloys and the like can be met.

Owner:珠海泰达砂轮有限公司

A method for coating boron carbide on diamond surface

The invention discloses a method for plating boron carbide on a diamond surface. The method comprises the following steps: boriding on the diamond particle surface under the conditions that the vacuum degree is less than 100 Pascal, the temperature is preserved to 300 DEG C for 30 minutes and the temperature is preserved to 1200 DEG C for 3-12 hours, thereby plating a boron carbide film on the diamond surface. According to the diamond of which the surface is plated with the boron carbide film prepared by the invention, the binding force between a metal matrix and the diamond can be improved, the erosion resistance of the diamond to oxygen, iron, nickel and cobalt can be greatly improved, and the phenomena such as oxidation and graphitization of the diamond in the process of preparing a diamond-impregnated drill bit can be effectively avoided, so that the diamond inlaid into the metal matrix is complete in appearance, clear in edges and stable in performance. Therefore, the abrasive ratio of the manufactured appliances is greatly improved, and the service life is obviously prolonged.

Owner:JILIN UNIV

Nanometal bonding agent and polycrystal CBN (cubic boron nitride) composite sheet made by using same

InactiveCN102794448BGood sintering promotion effectIncrease the volume ratioAl powderAlloy substrate

The invention relates to a nanometal bonding agent. The bonding agent consists of the following raw materials in percentage by weight: 35-40% of TiN powder, 20-25% of TiC powder, 15-20% of Si3N4 powder, 15-20% of Co powder and 10-20% of Al powder. The invention also discloses a polycrystal CBN (cubic boron nitride) composite sheet made by using the nanometal bonding agent. The polycrystal CBN composite sheet comprises a CBN polycrystal layer and a hard alloy substrate, wherein the CBN polycrystal layer consists of the following raw materials in percentage by weight: 55-95% of CBN powder and 5-45% of nanometal bonding agent. In the polycrystal CBN composite sheet provided by the invention, by adopting the nanometal bonding agent in the formula of polycrystal layer, the technical bottleneck in high impact toughness and high bending strength of a PCBN composite sheet is broken, the impact resistance of a tool is enhanced, and the service life of the tool is prolonged.

Owner:ZHONGNAN DIAMOND CO LTD

Method for processing drilling hexagonal polycrystalline diamond

InactiveCN101954261BImprove thermal stabilityHigh impact strengthUltra-high pressure processesPolycrystalline diamondMixed materials

The invention discloses a method for processing drilling hexagonal polycrystalline diamond. The processing method of the invention comprises the following steps of: adding a certain amount of boron into basic raw materials including diamond powder, silicon and metal nickel; blending the raw materials including the diamond powder, the silicon and the nickel with the boron and adding the mixed materials into a carbon synthesizing mold; putting the carbon synthesizing mold into a vacuum furnace for heating under vacuum; placing the semi-finished product after the vacuum heating into a diamond hexagonal heading press for high-temperature and high-pressure synthesizing; and relieving pressure after the high-temperature and high-pressure synthesizing to obtain the product of drilling hexagonal polycrystalline diamond TSP of the invention. The polycrystalline diamond TSP prepared by the technical scheme of the invention has relatively high thermal stability, relatively high impact resistanceand high wear resistance and can meet the requirements of complicated substrate drilling completely; and the qualification rate of the product is as high as over 88 percent.

Owner:ZHENGZHOU SANHE DIAMOND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com