High-performance composite pressure transmission component and preparation method thereof

A high-performance, component technology, applied in the methods of using atmospheric pressure to chemically change substances, chemical instruments and methods, and ultra-high pressure processes, etc., can solve problems such as large pressure loss and weakening, and achieve pressure transfer efficiency. High, reduce flow deformation, save practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

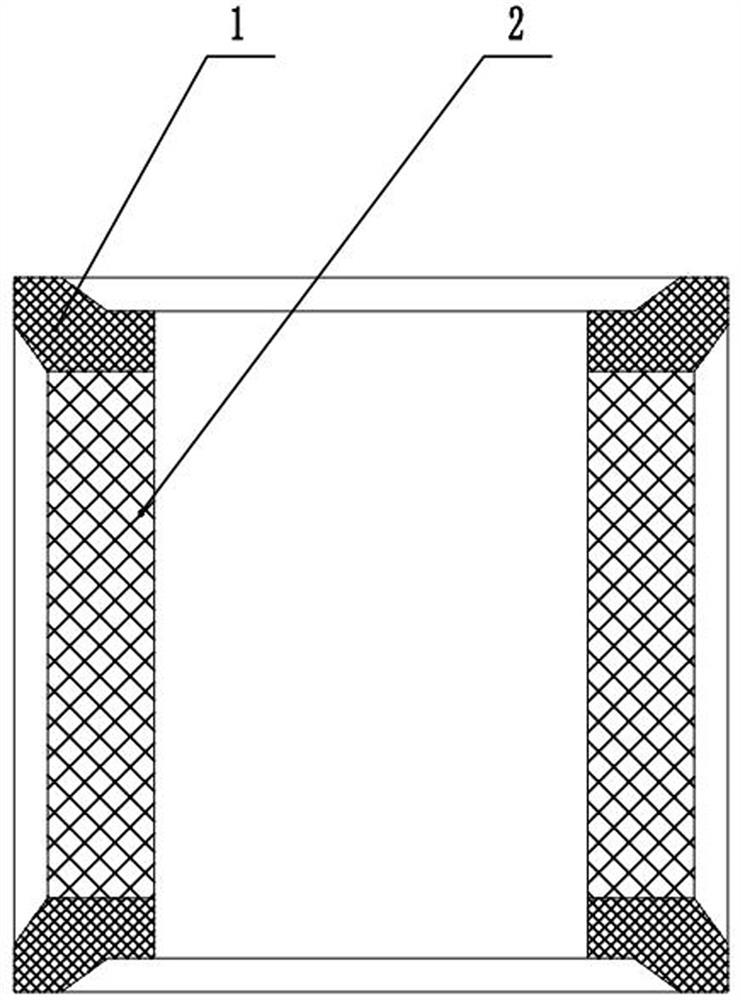

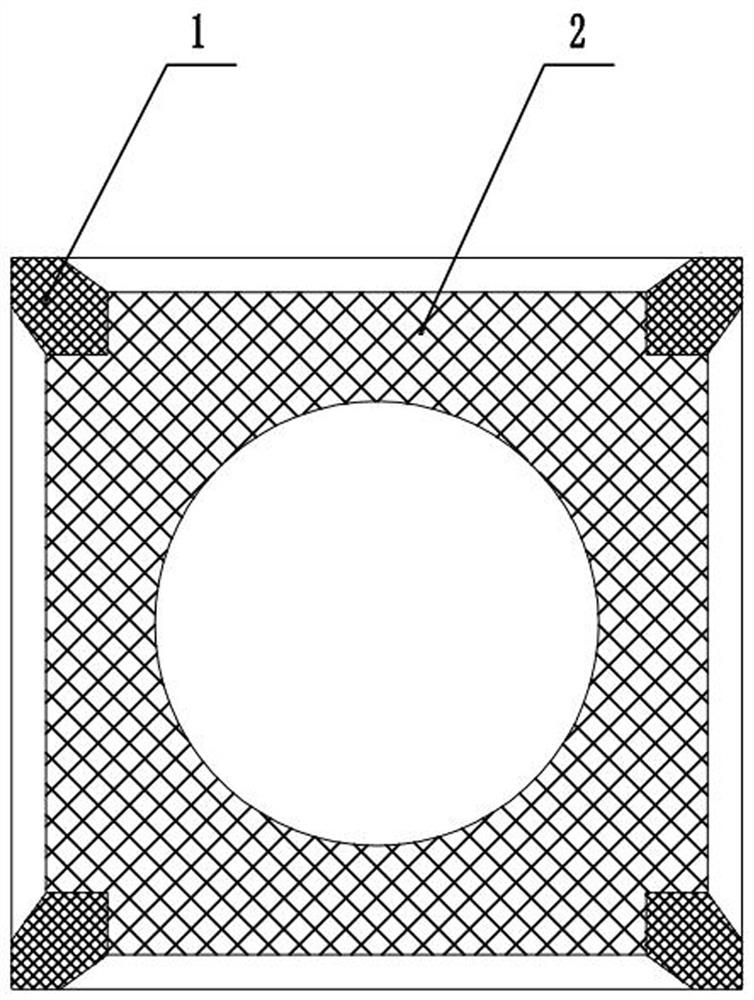

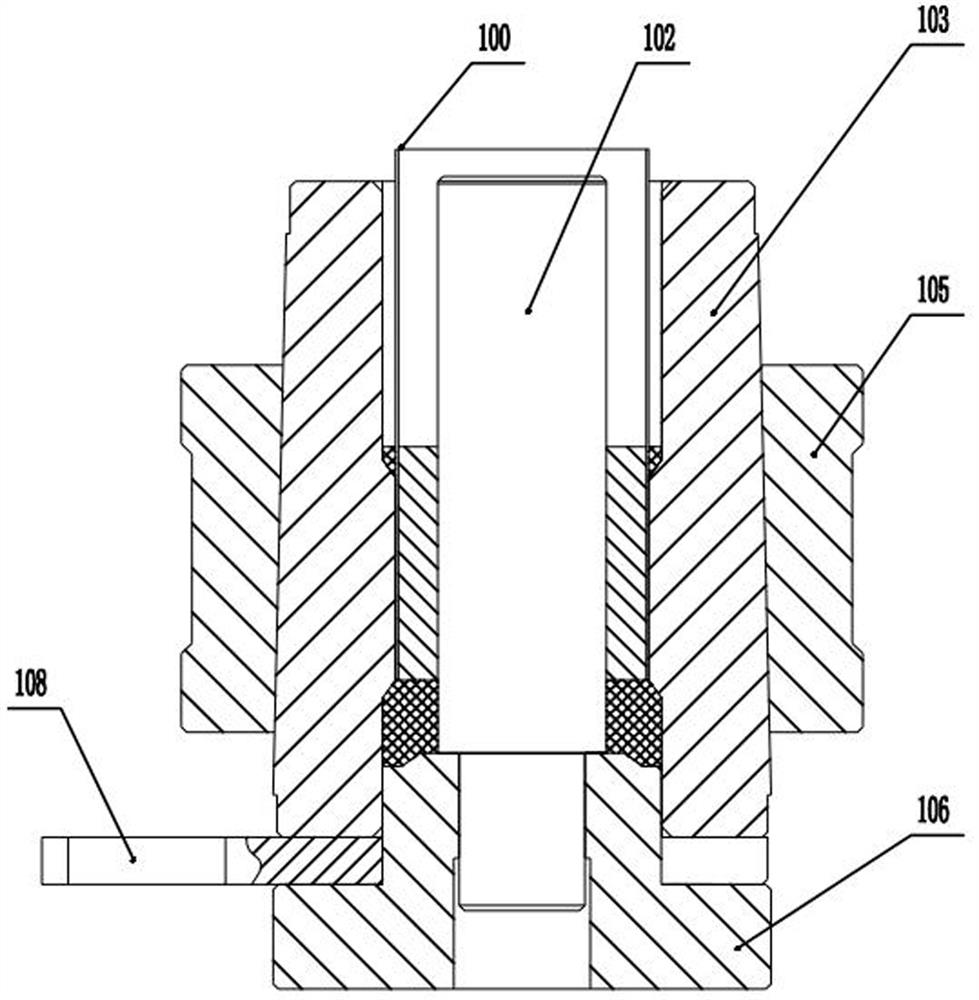

[0051] Such as Figure 1 to Figure 2 As shown, a high-performance composite pressure transmission part, the high-performance composite pressure transmission part is hollow, and a synthetic chamber is formed in the middle of the high-performance composite pressure transmission part, and the synthetic chamber penetrates up and down;

[0052] The cross-section of the synthesis cavity is circular;

[0053] The high-performance composite pressure transmission component includes a cubic pressure transmission medium 2, and a sealing frame 1 sleeved outside the pressure transmission medium 2; the sealing frame 1 is a cubic frame structure, and each frame of the sealing frame 1 All are attached to the side wall of the pressure transmission medium 2;

[0054] The frame on the six sides of the sealing frame 1 is provided with a notch that is recessed toward the geometric center of the sealing frame 1, and the notch extends to each side of the pressure transmission medium 2, that is, the...

preparation Embodiment 1

[0060] A method for preparing the high-performance composite pressure transmission part described in Example 1, the specific steps are as follows:

[0061] 1) Magnetic separation: Put the yellow pyrophyllite powder used in the raw material of the pressure transmission medium 2 on a CFLJ12-Ⅲ type magnetic separator for magnetic separation, and select the raw materials whose magnetic properties are less than 3000 Gauss for later use;

[0062] 2) Mixing: Weigh the raw materials of the pressure transmission medium 2 and the sealing frame 1 respectively in proportion, and mix the materials of the pressure transmission medium 2 and the sealing frame 1 respectively on the horizontal ribbon mixer, and use clockwise Alternate counterclockwise operation, clockwise rotation speed is 45r / min, clockwise operation time is 5min, counterclockwise rotation speed is 40r / min, counterclockwise operation time is 3min, alternate interval standby time is 1min, The total mixing time is 40 minutes, an...

Embodiment 3

[0077] A high-performance composite pressure transmission component, the structure of the high-performance composite pressure transmission component in Example 3 is the same as that in Example 1, the difference lies in the composition and dosage of each component are different, specifically:

[0078] Groove depth is 3mm;

[0079] The pressure transmission medium 2 is composed of the following raw materials in percentage by weight: 49% of quartz powder, 23% of talc powder, 12% of magnesium oxide powder, 8% of aluminum oxide powder, 1% of samarium oxide powder, 1% of mica powder and Sodium silicate is 6%;

[0080] The sealing frame 1 is composed of the following raw materials in weight percentage: 94% of yellow pyrophyllite powder, 1% of iron oxide powder and 5% of sodium silicate.

[0081] The particle size of the quartz powder is 120 mesh, the particle size of the talc powder, magnesium oxide powder, aluminum oxide powder and samarium oxide powder is 200 mesh, and the mica po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com