Synthetic process of compound superhard material

A synthesis process, a technology for superhard materials, applied in the process of applying ultra-high pressure, the method of chemically changing substances by using atmospheric pressure, chemical instruments and methods, etc. and other problems, to achieve the effect that the thermal stability parameters are not much different, the amount of metal dialysis is reduced, and the wear ratio is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The assembled cemented carbide and diamond are placed in the pyrophyllite body, placed in the six top hammers of the six-sided top hydraulic press, first pressurized to 10MPa, and heated to 700℃~800℃ by electric heating to the heating hammer. For 30 seconds, pressurize to 90MPa, heat up to 1400℃~1700℃, after reaching the rated time (5~15 minutes) set by the synthesis process, stop heating, reduce the pressure to zero, and take out the synthesized product.

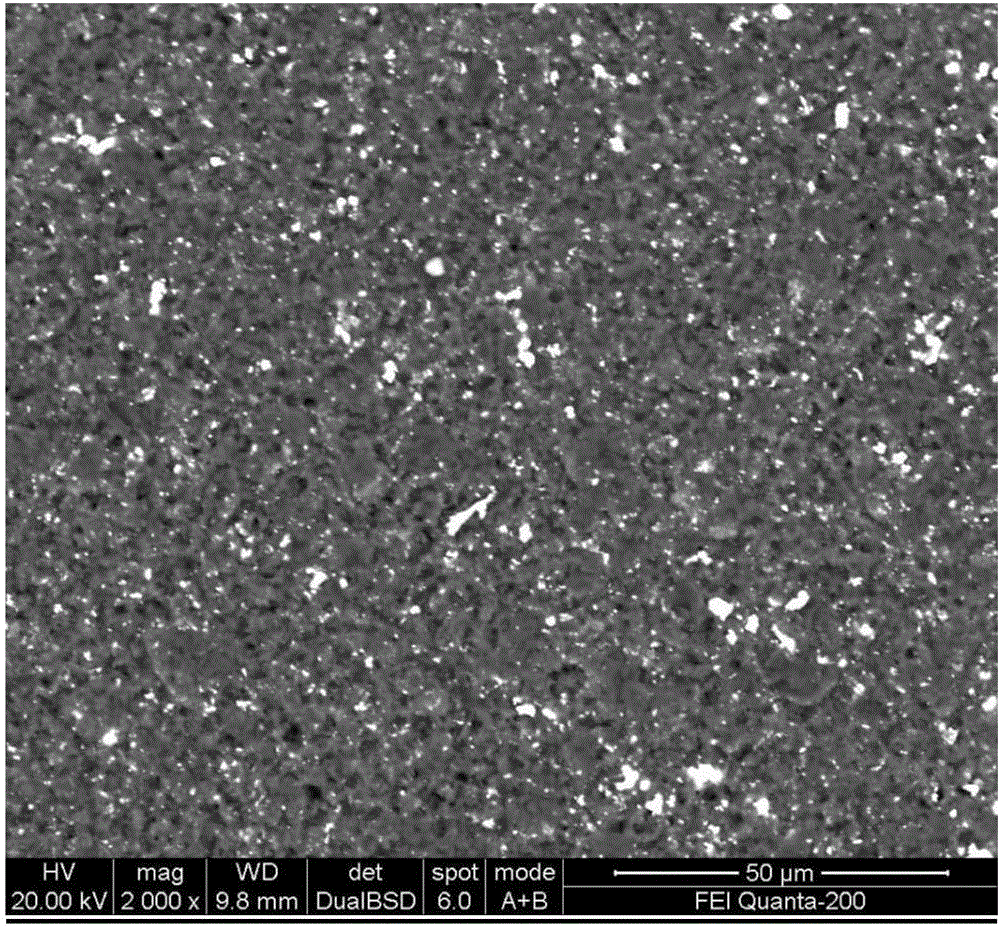

[0032] The metal content of the superhard material in traditional craft products is 9% to 20%;

[0033] In the product obtained by the above process, the metal content in the superhard material is 1.05% to 5.06%.

[0034] And the thermal stability of the obtained product is improved to some extent, and the difference between the thermal stability parameters before and after welding of the product is 6%.

Embodiment 2

[0036] The assembled cemented carbide and diamond are placed in the pyrophyllite body, and placed in the six top hammers of the six-sided top hydraulic press. When the pressure is first to 10MPa, the heating hammer is heated to 700℃~800℃ by electric heating. The time is 30 seconds, pressurized to 90 MPa, heated to 1400 ℃ ~ 1700 ℃, after reaching the rated time (5 ~ 15 minutes) set by the synthesis process, further pressure is applied on the hammer surfaces of the two heating hammers to make it more The pressure on the hammer surface of the heating hammer is 11% higher. After reaching the rated time (3-5 minutes) set by the synthesis process, the heating is stopped, the pressure is reduced to zero, and the synthesized product is taken out.

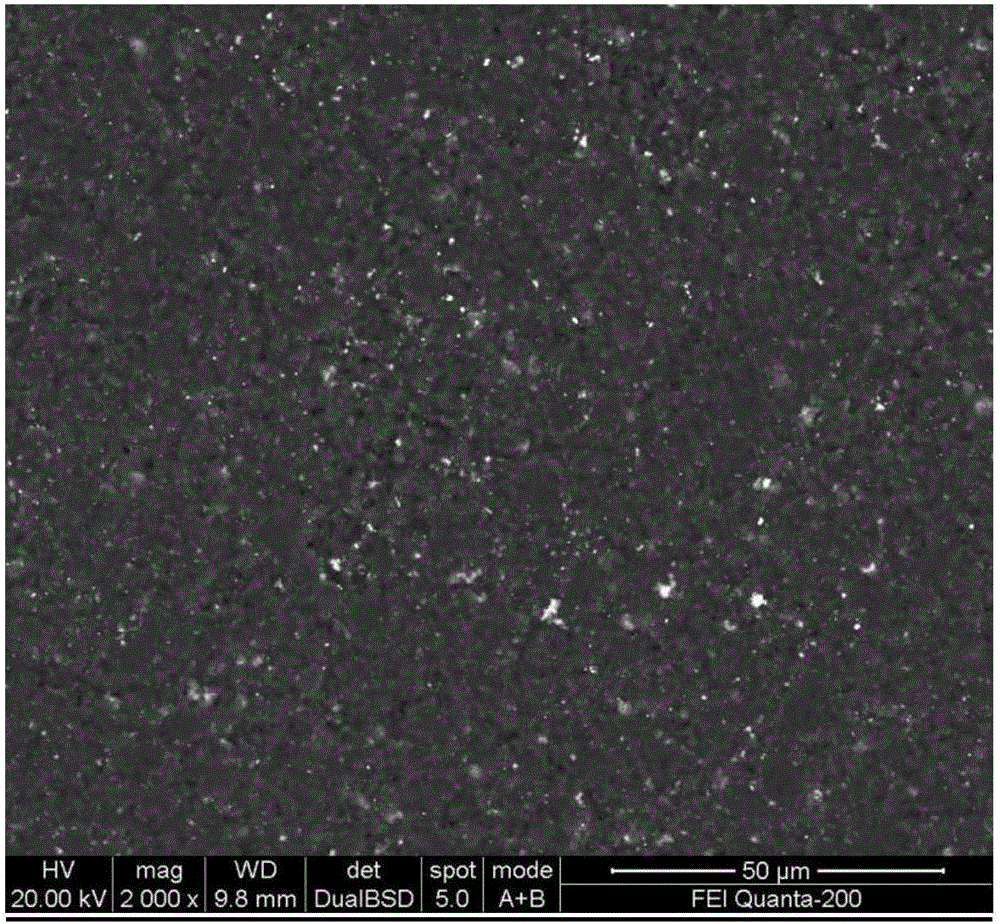

[0037] The metal content of superhard materials in traditional craft products is 9% to 20%;

[0038] The metal content of the superhard material in the product obtained by the above process is only 3.14%.

[0039] The difference between th...

Embodiment 3

[0041] The assembled cemented carbide and diamond are placed in the pyrophyllite body, and placed in the six top hammers of the six-sided top hydraulic press. When the pressure is first to 10MPa, the temperature is raised to 700℃~800℃, and the heating time is 30 seconds. Press to 90MPa, heat up to 1400℃~1700℃, and after reaching the rated time set by the synthesis process, apply further pressure on the two heated hammer surfaces to make it 19% higher than the pressure on the four non-heated hammer surfaces. After reaching the rated time set by the synthesis process, the heating is stopped, the pressure is reduced to zero, and the synthesized product is taken out.

[0042] The metal content of the composite working layer in traditional craft products is 9% to 20%;

[0043] The metal content in the superhard material in the product obtained by the above process is only 2.01%.

[0044] The difference between the thermal stability parameters of the product before and after weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com