Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Improve uneven thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

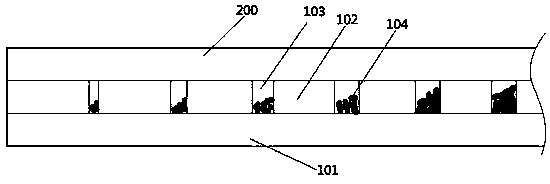

Substrate and liquid crystal display panel comprising substrate

ActiveCN107085324ANo backflow to the display areaImprove uneven thicknessNon-linear opticsLiquid-crystal displayEngineering

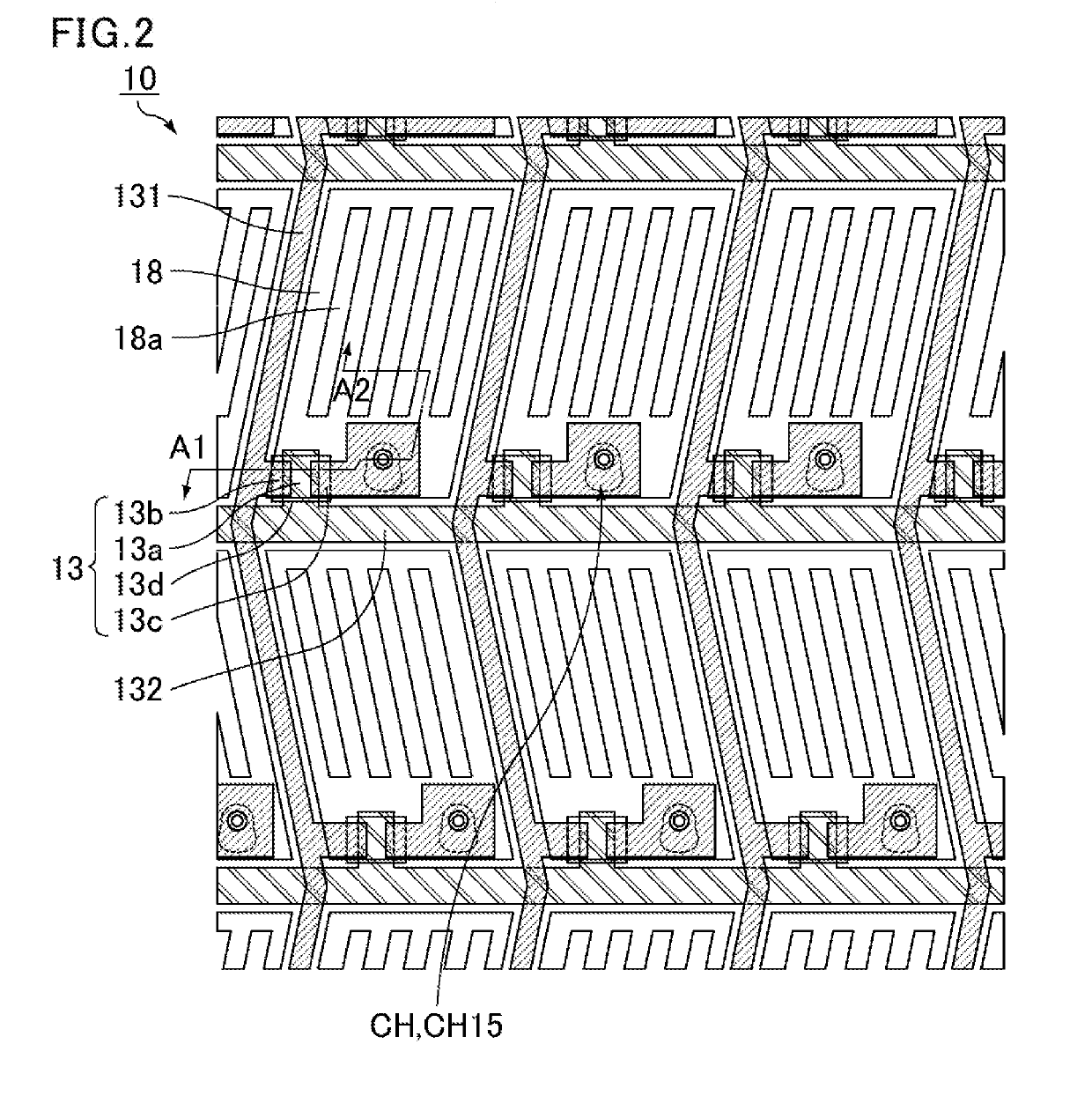

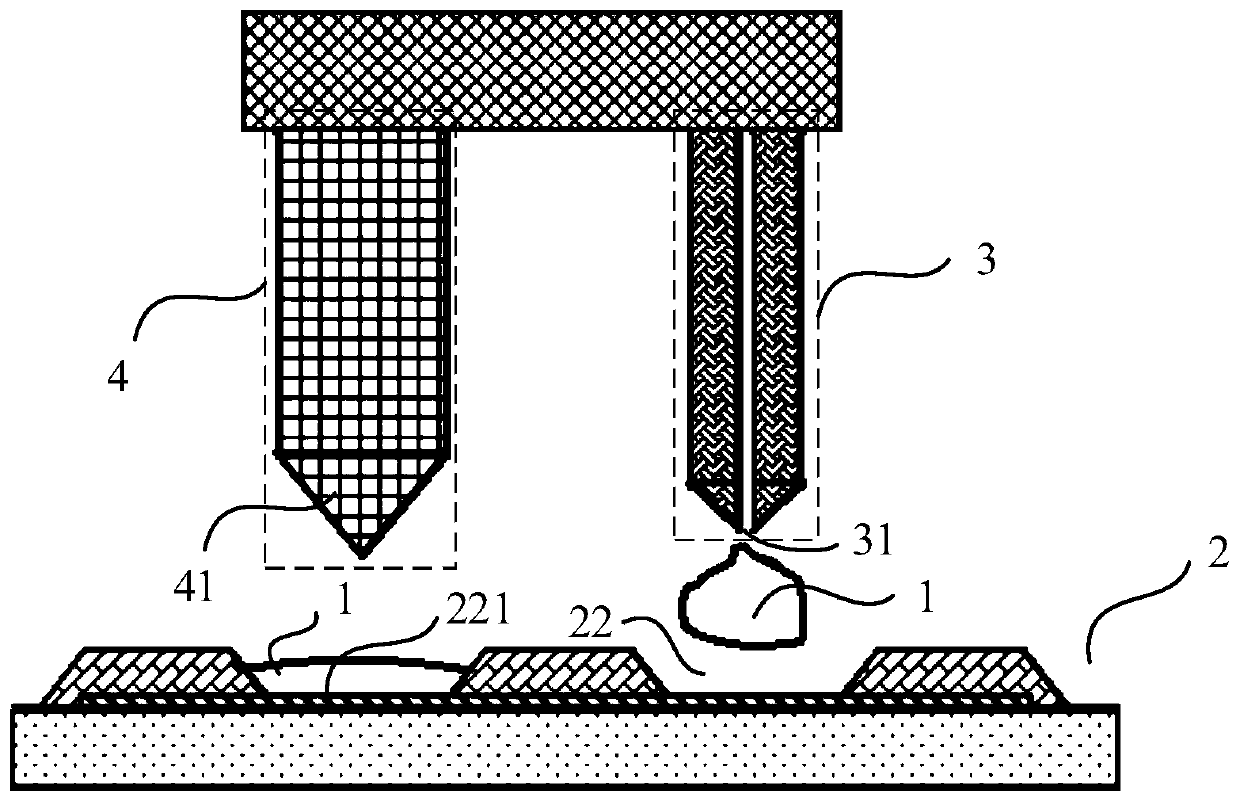

The application discloses a substrate and a liquid crystal display panel comprising the substrate. The substrate includes a display region and a non-display region surrounding the display region; the substrate includes a lining substrate and a first insulating layer disposed over the lining substrate; the first insulating layer covers the display region and at least part of the non-display region; in the non-display region, the first insulating layer is provided with a first groove; the first groove comprises a first sub-groove and a plurality of second sub-grooves communicated with the first sub-groove; the second sub-grooves are located between the first sub-groove and the display area, and the extending direction of the first sub-groove and the extending direction of the second sub-groove are perpendicular to each other. According to the scheme, the phenomenon of the uneven thickness of an alignment film in the display region due to the accumulation of the alignment liquid in the non-display region is improved, so that the incidence rate of unhealthy phenomenon including the uneven brightness of the liquid crystal display panel of the substrate is reduced.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

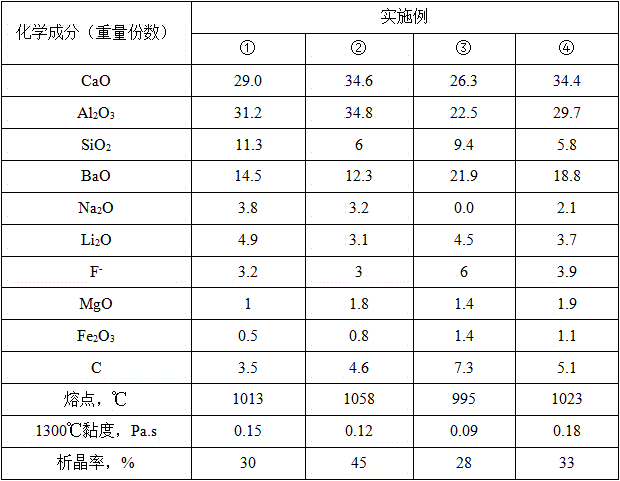

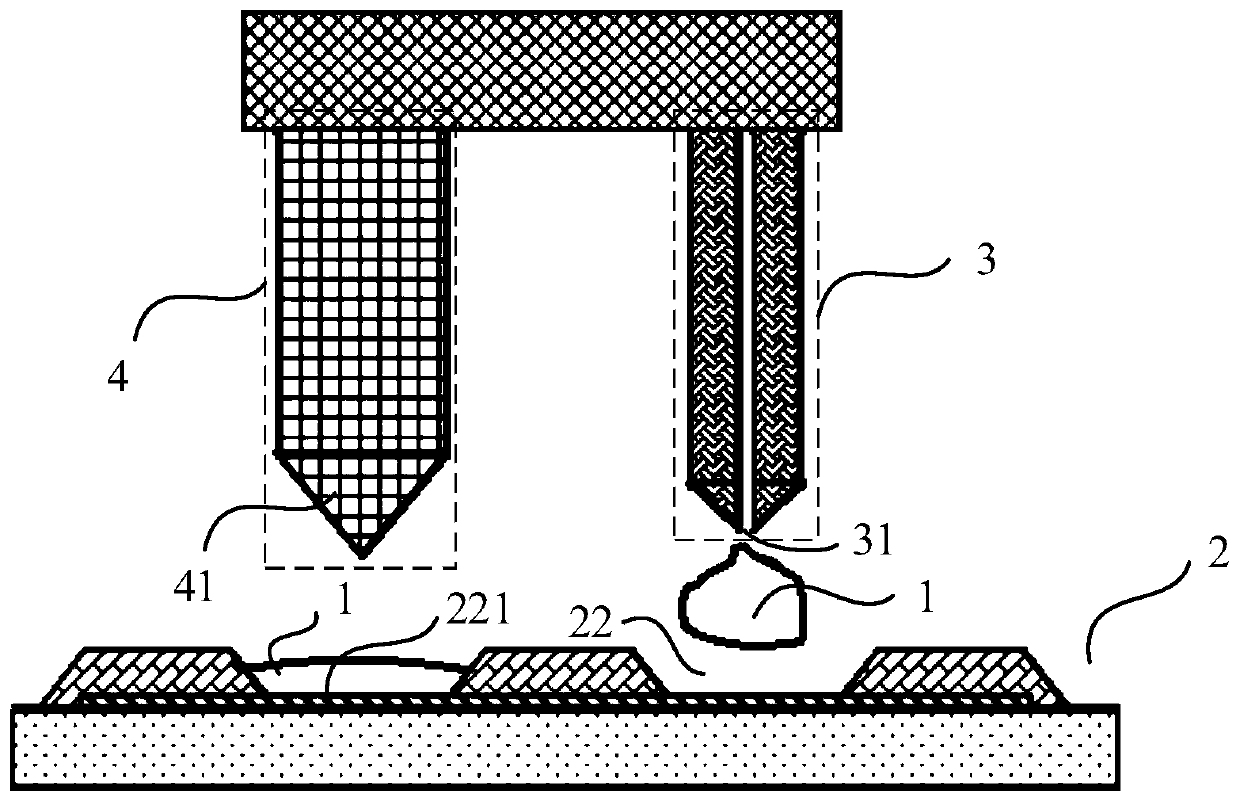

Crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of crystallizer covering slag

The invention provides a crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of the crystallizer covering slag. The covering slag is prepared from the following components in parts by weight: 20-38 parts of CaO, 20-35 parts of Al2O3, 5-18 parts of SiO2, 10-22 parts of BaO, 2-7 parts of Li2O, 5-12 parts of F<->, 1-4 parts of MgO, 2-8 parts of C and Fe2O3 which is less than or equal to 2 parts. According to the preparation method disclosed by the invention, wollastonite, limestone, quartz sand, fluorite, bauxite, barium carbonate, magnesia, soda, lithium carbonate and carbonaceous materials are used as raw materials, and the covering slag is prepared through the following steps of: calculating of consumption, melting, smashing, fine grinding, drying and granulation. The covering slag disclosed by the invention has the characteristics of being low in reactivity and good in property stability, the lubrication and the thermal transmission of casting blanks can be effectively coordinated and controlled, the smooth performing of the continuous casting process of the high-manganese high-aluminum steel can be guaranteed, high-manganese high-aluminum steel continuous casting blanks with excellent surface quality are cast, and multi-heat continuous casting can be realized.

Owner:CHONGQING UNIV

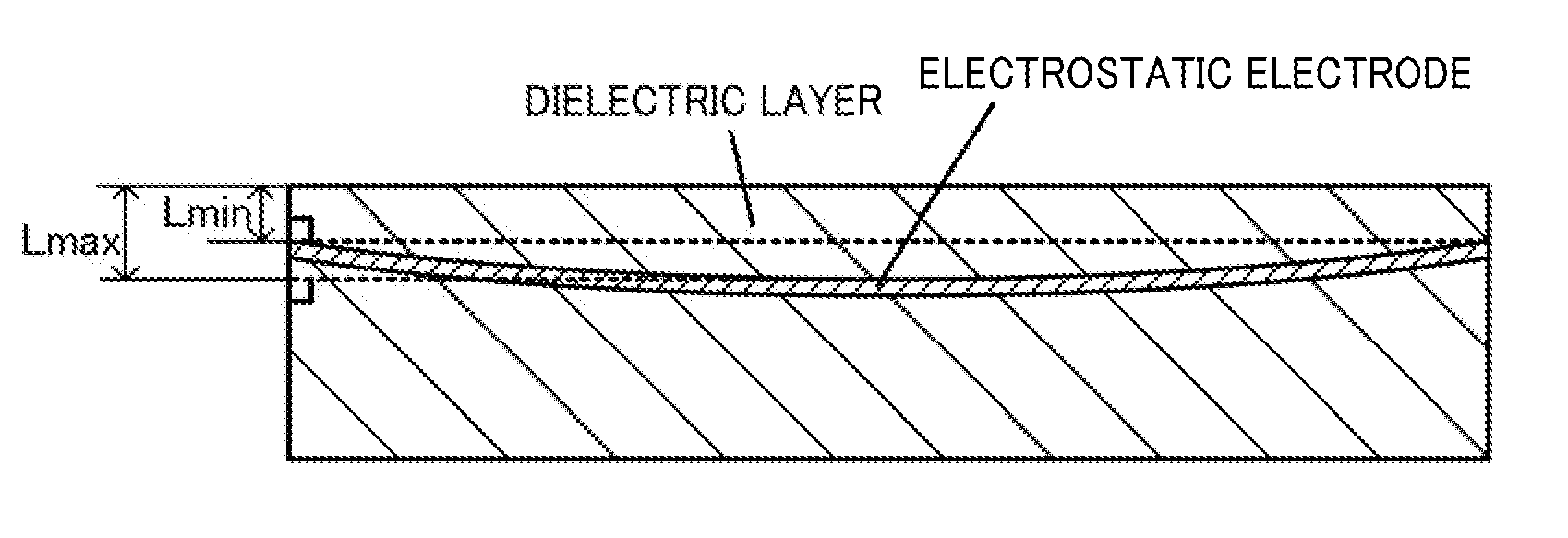

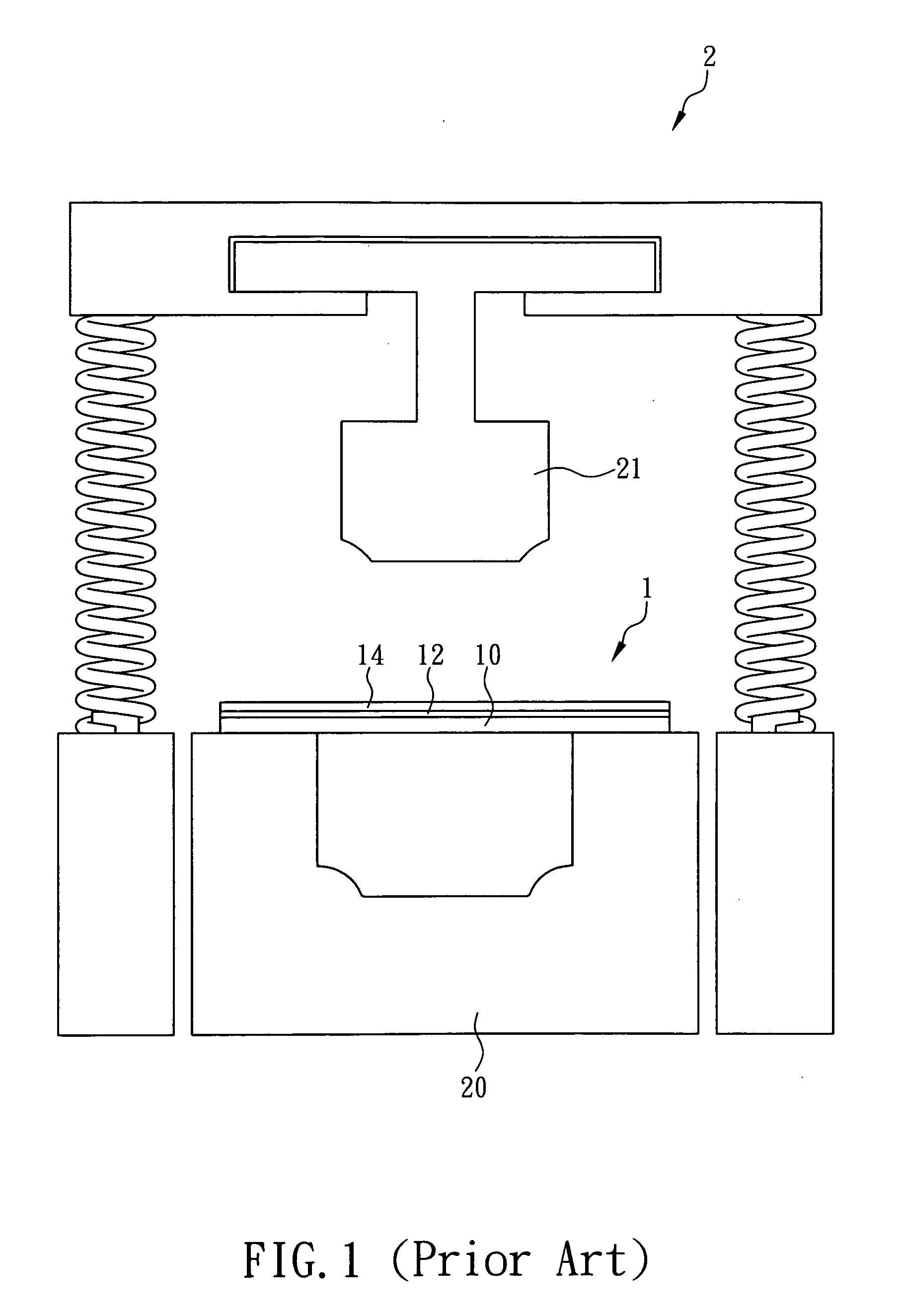

Method for producing electrostatic chuck and electrostatic chuck

ActiveUS20120248716A1Suppress generation of particleIncrease breakdown voltageSleeve/socket jointsSemiconductor/solid-state device manufacturingSolventHot press

A method for producing an electrostatic chuck includes the steps of (a) placing a ceramic slurry in a molding die, the ceramic slurry containing a ceramic powder, a solvent, a dispersing agent, and a gelling agent, gelatinizing the ceramic slurry in the molding die, and removing the molding die to obtain first and second ceramic molded bodies; (b) drying, debinding, and calcining the first and second molded bodies to obtain first and second ceramic calcined bodies; (c) printing an electrostatic electrode paste on a surface of one of the first and second ceramic calcined bodies to form an electrostatic electrode while assuming the first ceramic calcined body is to form a dielectric layer of an electrostatic chuck; and (d) superposing the first and second ceramic calcined bodies on each other to sandwich the electrostatic electrode and subjecting the first and second calcined bodies to hot-press firing.

Owner:NGK INSULATORS LTD

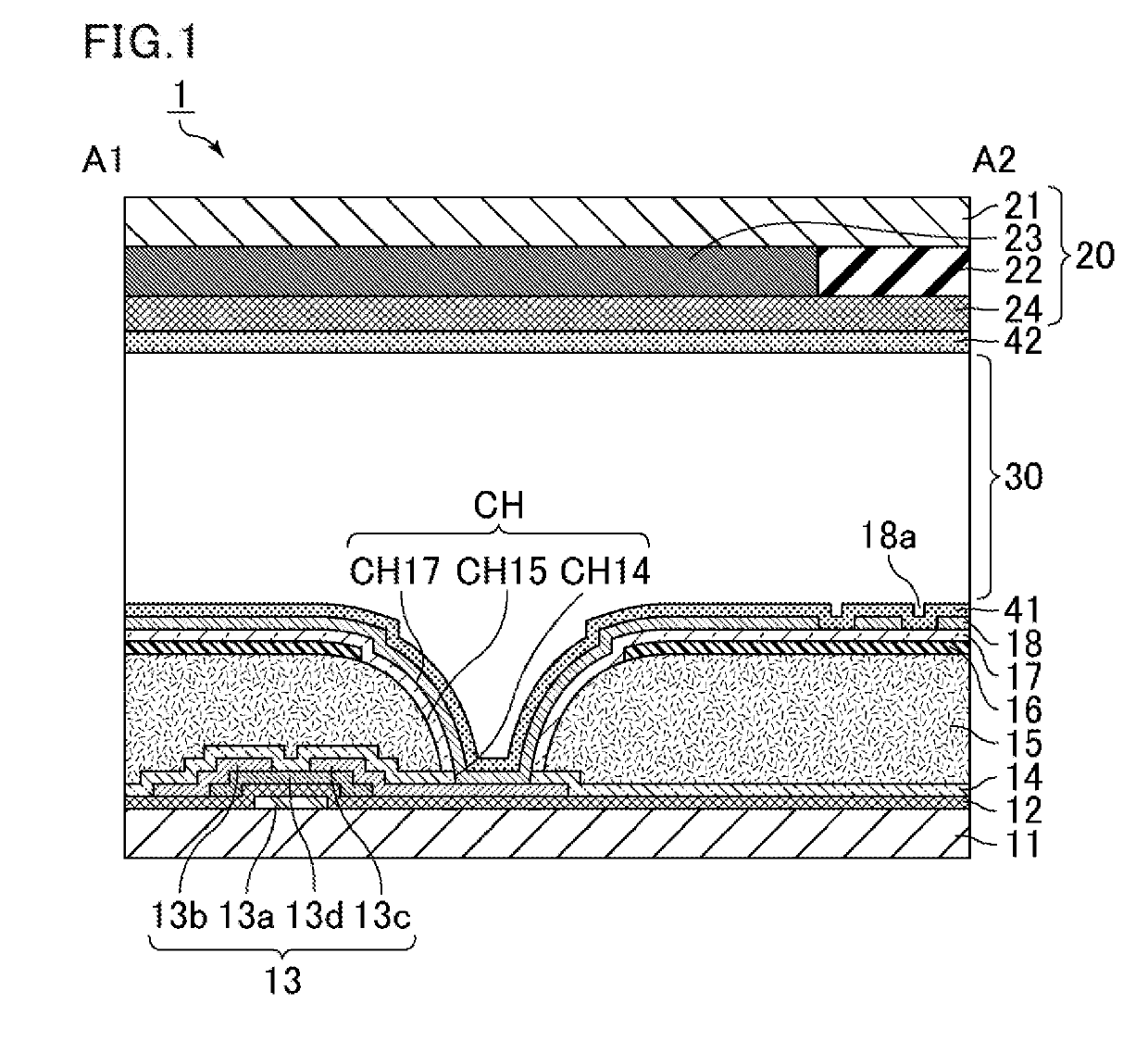

Mask plate and preparation method thereof

ActiveCN108193191AExtended service lifeQuality improvementLiquid/solution decomposition chemical coatingChemical vapor deposition coatingSurface roughnessEngineering

The invention provides a mask plate and a preparation method thereof. The mask plate comprises a mask plate mother board and a protection layer, wherein the protection layer is arranged on at least one surface of the mask plate mother board, and the protection layer is used for protecting the mask plate mother board and or a substrate in direct contact with the mask plate from being not damaged. Therefore, the mask plate can have a small surface roughness by arranging the protection layer, and the substrate which is in direct contact with the mask plate can be prevented from being scratched; the protection layer can also prevent the mask plate mother board from static electricity, and the phenomenon that the thickness of a thin film at the edge of the mask plate is not uniform caused by burning of the substrate and the edge of the mask plate are avoided; and the corrosion resistance of the mask plate can be improved, and the service life of the mask plate can be prolonged.

Owner:BOE TECH GRP CO LTD +1

Method and device for improving non-uniform thickness in blade-feeding position during multi-line cutting of silicon chip

InactiveCN102241081AImprove uneven thicknessConsistent parallelismWorking accessoriesFine working devicesPhysicsSilicon chip

Owner:浙江光益硅业科技有限公司

Method for preparing zeolite membrane through thermal inversion of xerogel

InactiveCN1600688AImprove defectsStable supportCrystalline aluminosilicate zeolitesCeramicMaterials science

The invention relates to a kind of zeolite film prepn, method. The characteristics are: to compound sol according to mole matching ratio of Na2O:SiO2:Al2O3:H2O, to coat sol layer on supporting body of a-Al2O3 ceramics etc., it is conversed to dry sol layer, then is put into stainless steel pressure pot with polytetrafluorine lining to be soaked by water heat treatment solution compounded at same time, the pot is closed in temp, 80-200 deg.C, keeping the temp, for 24-48 hours, then taking out, washing, drying and inreasing and reducing temp, in program to obtain zeolite film.

Owner:DALIAN UNIV OF TECH

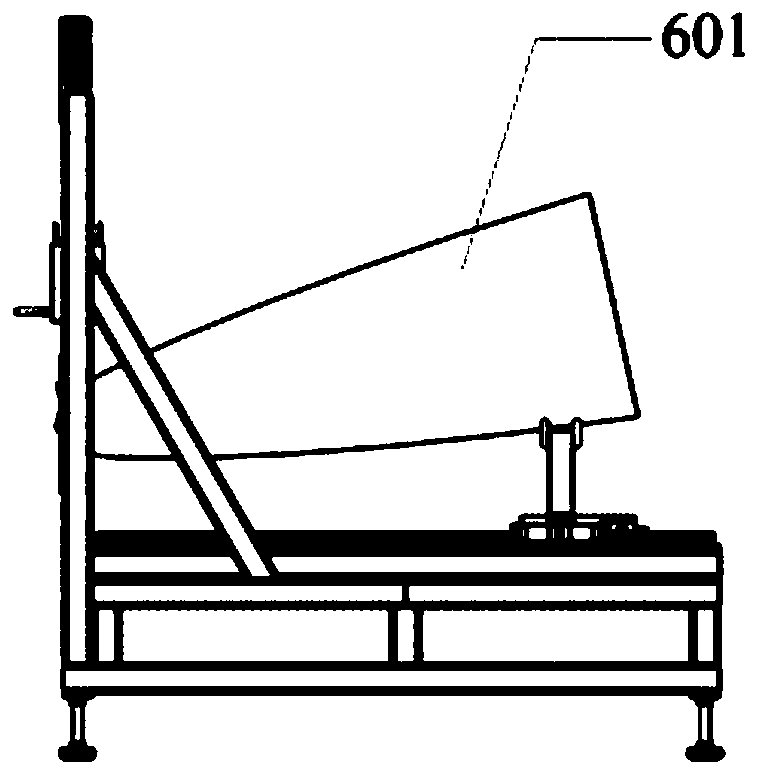

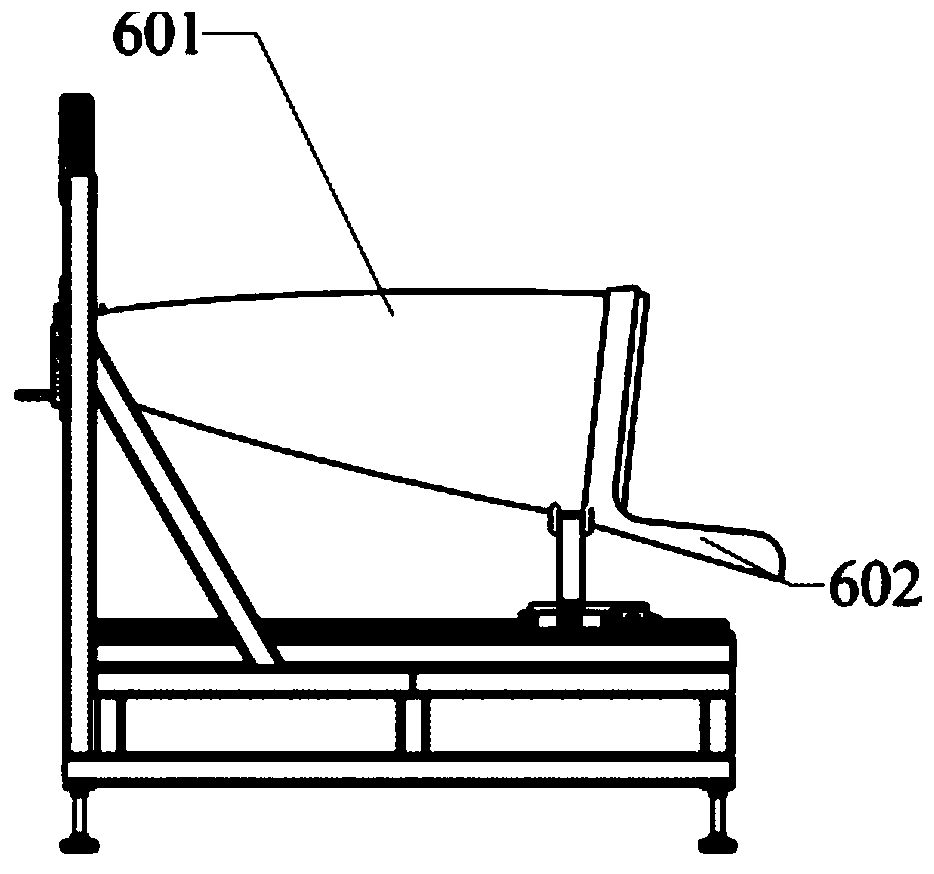

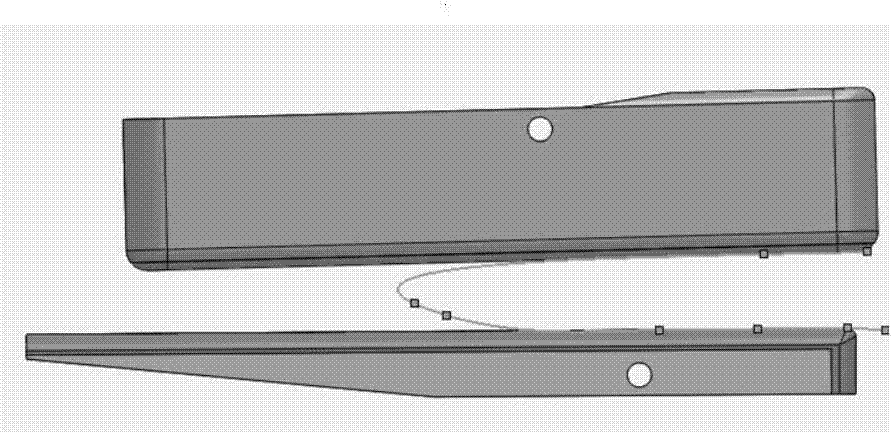

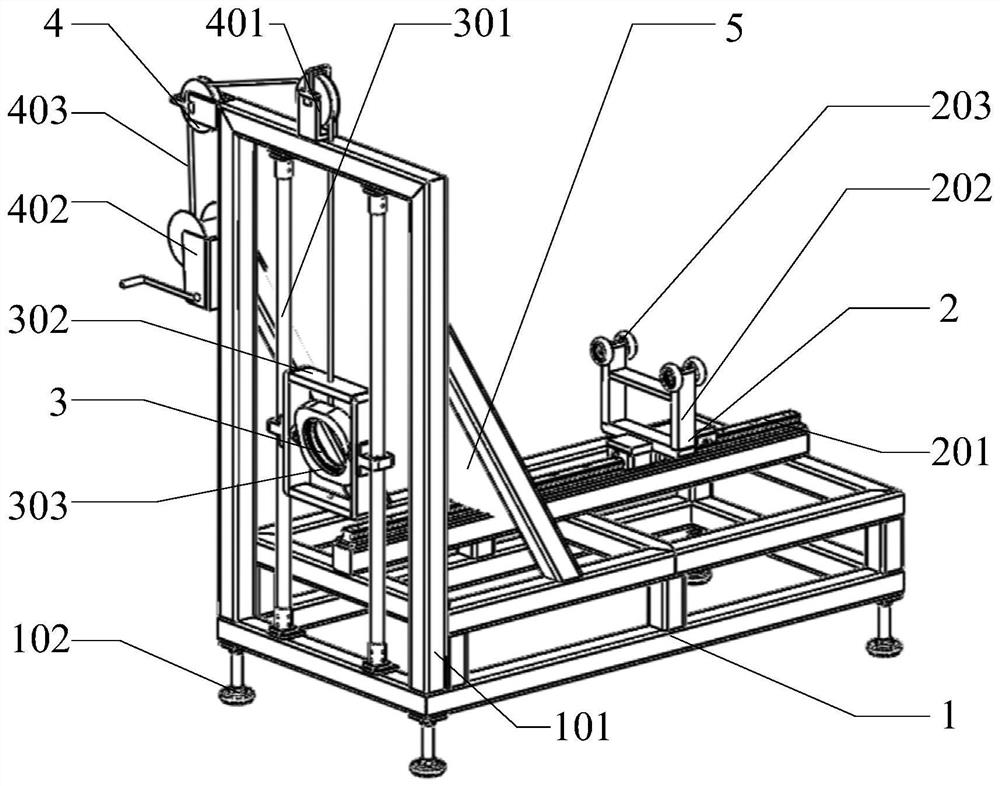

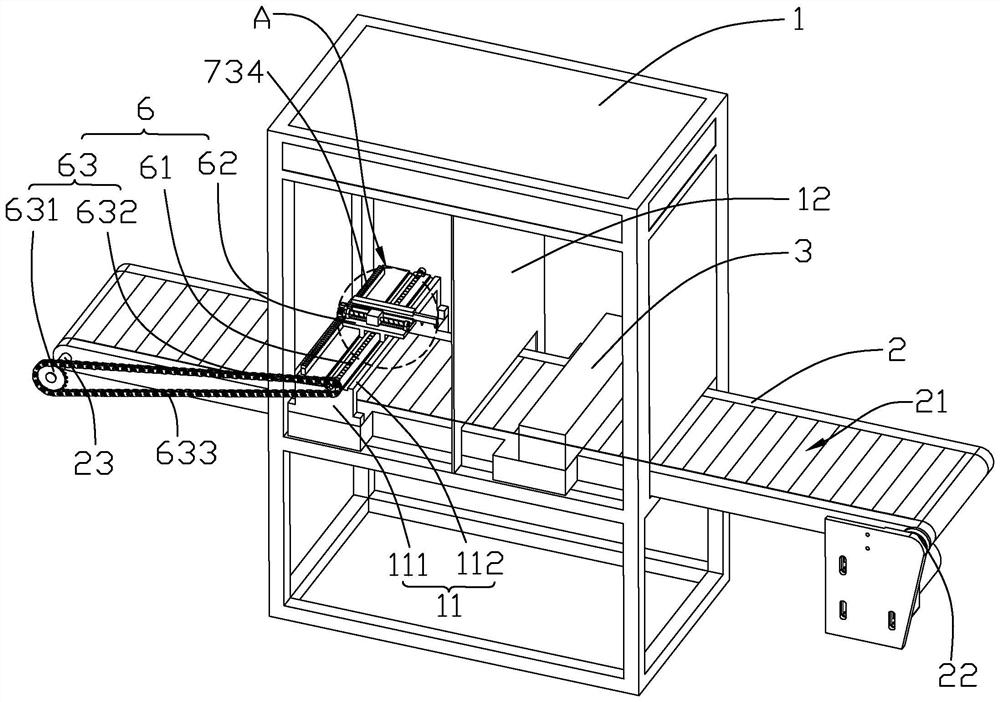

Support tool structure for painting inner wall of gyration shell

ActiveCN110180721AImprove painting efficiencyReduce labor intensitySpraying apparatusSupport pointInner wall zone

The invention discloses a support tool structure for painting the inner wall of a gyration shell. The support tool structure for painting the inner wall of the gyration shell comprises a support frame, a horizontal guiding support structure, a vertical guiding support structure and a lifting assembly. The support frame is of an L shape as a whole and comprises a base and a vertical frame arrangedon one side of the base. The horizontal guiding support structure is arranged on the base, the rear end of the gyration shell can be supported by the horizontal guiding support structure, and supporting points can translate along the horizontal direction to adapt to gyration shells of different length and diameters through the horizontal guiding support structure. The vertical guiding support structure is arranged on the vertical frame, the front end of the gyration shell can be supported by the vertical guiding support structure, and the supporting points can translate in the vertical direction through the vertical guiding support structure so that the tilting angle of the gyration shell can be adjusted. The lifting assembly is arranged on the vertical frame and used for driving the vertical guiding support structure to move in the vertical direction. By means of the support tool structure for painting the inner wall of the gyration shell, it is guaranteed that the tilting angle of axis of the gyration shell in the painting process does not change, the problem that inner wall paint film thickness is uneven is solved, and in addition, the distance from the cut-off line of paint film to the rear end face of the gyration shell is consistent.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

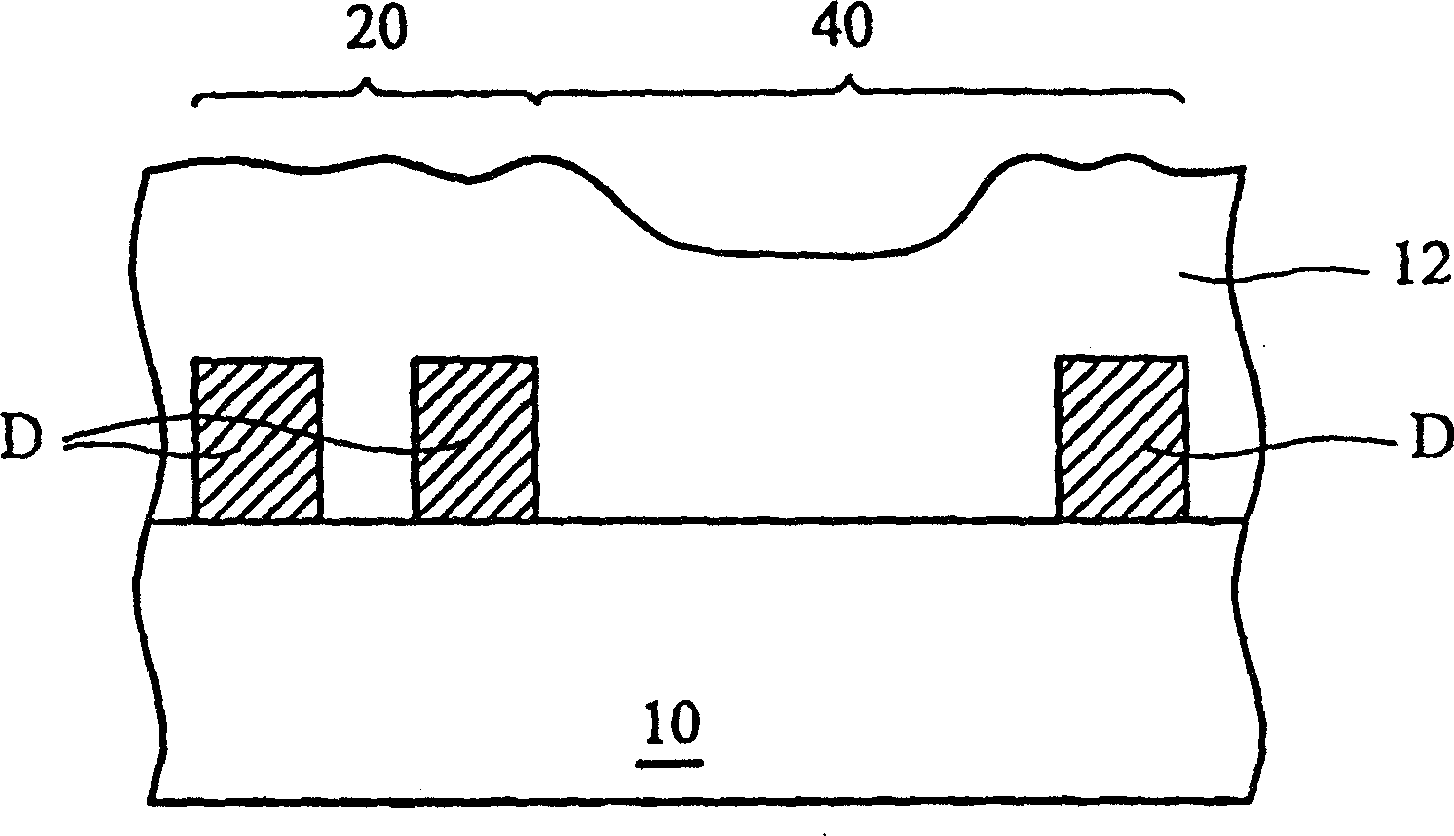

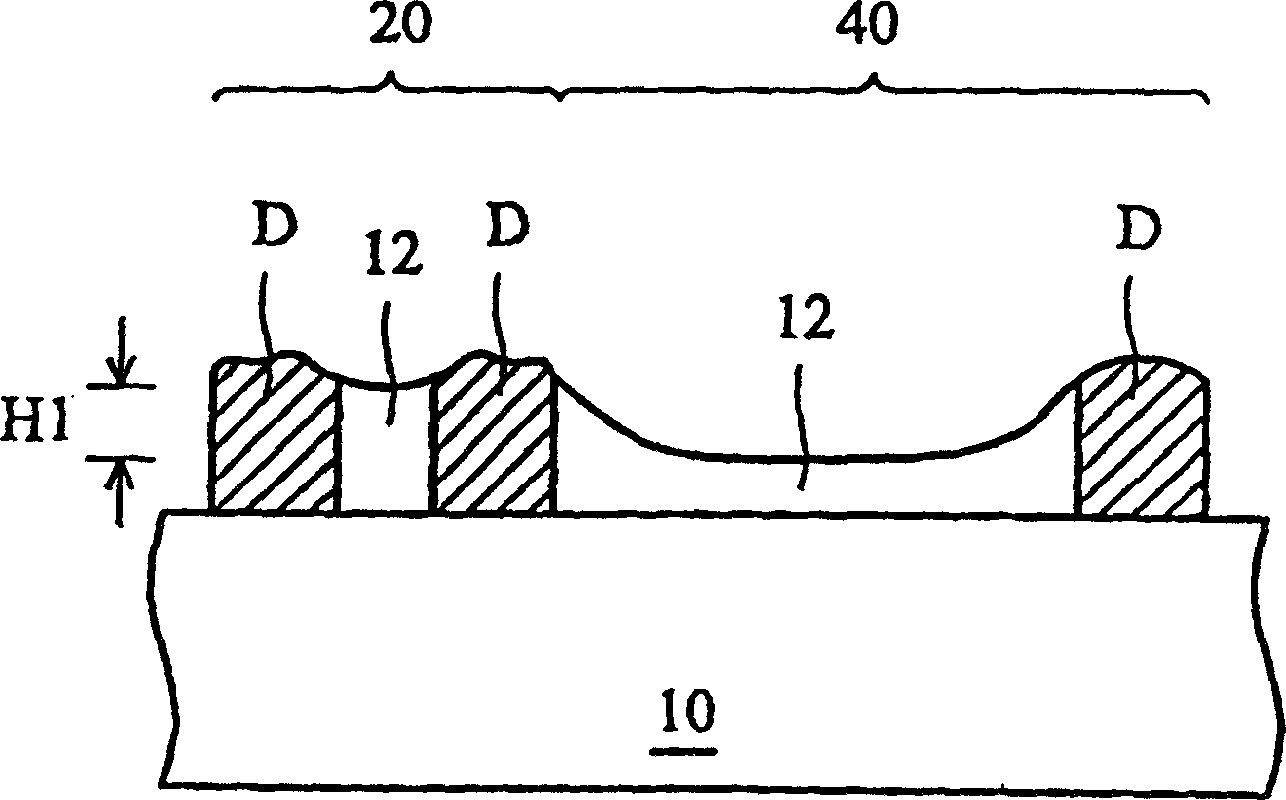

Dielectric layer reetching method

InactiveCN1238886CFrom erosionImprove uneven thicknessSemiconductor/solid-state device manufacturingElectrical conductorInter layer

The invention method is suitable to working procedure for evening inter layer dielectric (ILD) and inter metal dielectric (IMD) in flow for manufacturing semiconductor parts so as to improve the issue of inconsistence dielectric thickness after chemically machinery grinding. The method includes following steps. A semiconductor substrate possessing multiple components or patternized metal conducting wire is provided. A dielectric layer is formed to cover components or metal conducting wires uniformly. Etch back procedure is carried out by using technology of reactivity ion etching (RIE) with etching gas containing C5H3, CHF3 and Ar. The said etching procedure is stopped on the components or patternized metal conducting wire in order to form an even dielectric layer between components and wires.

Owner:NAN YA TECH

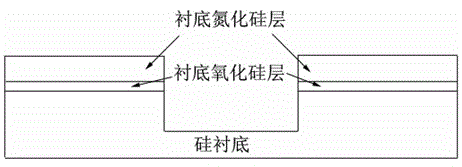

Method for controlling uniformity of substrate oxide layer in manufacture procedure of shallow-channel insulation layer

ActiveCN102945830AImprove uneven thicknessReduce manufacturing costSemiconductor/solid-state device manufacturingInsulation layerDevice material

The invention discloses a method for controlling uniformity of a substrate oxide layer in a manufacture procedure of a shallow-channel insulation layer, which belongs to the technical field of technology of CMOS (complementary metal oxide semiconductor) semiconductor devices. The steps of the method are as follows: growing one more layer of thin film layer while growing a substrate silicon oxide layer, removing a substrate silicon nitride layer, measuring the thickness of the substrate silicon oxide layer after removing the substrate silicon nitride layer, taking the thickness as a front value, simultaneously setting a target value which is the thickness value of the substrate silicon oxide layer under an ideal condition, setting a modification value for the substrate silicon oxide layer in each batch, wherein the value range of the modification value is the difference range of the front value and the target value, and modifying and etching the substrate silicon oxide layer according to the modification value. The method adopting the technical scheme has the benefits that the problem of non-uniform thickness of the substrate oxide layers is improved, the manufacture cost of the semiconductor technology is saved, and the production-manufacturing time of a product is shortened.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

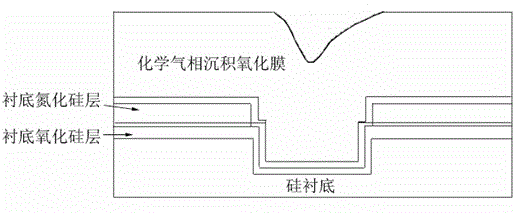

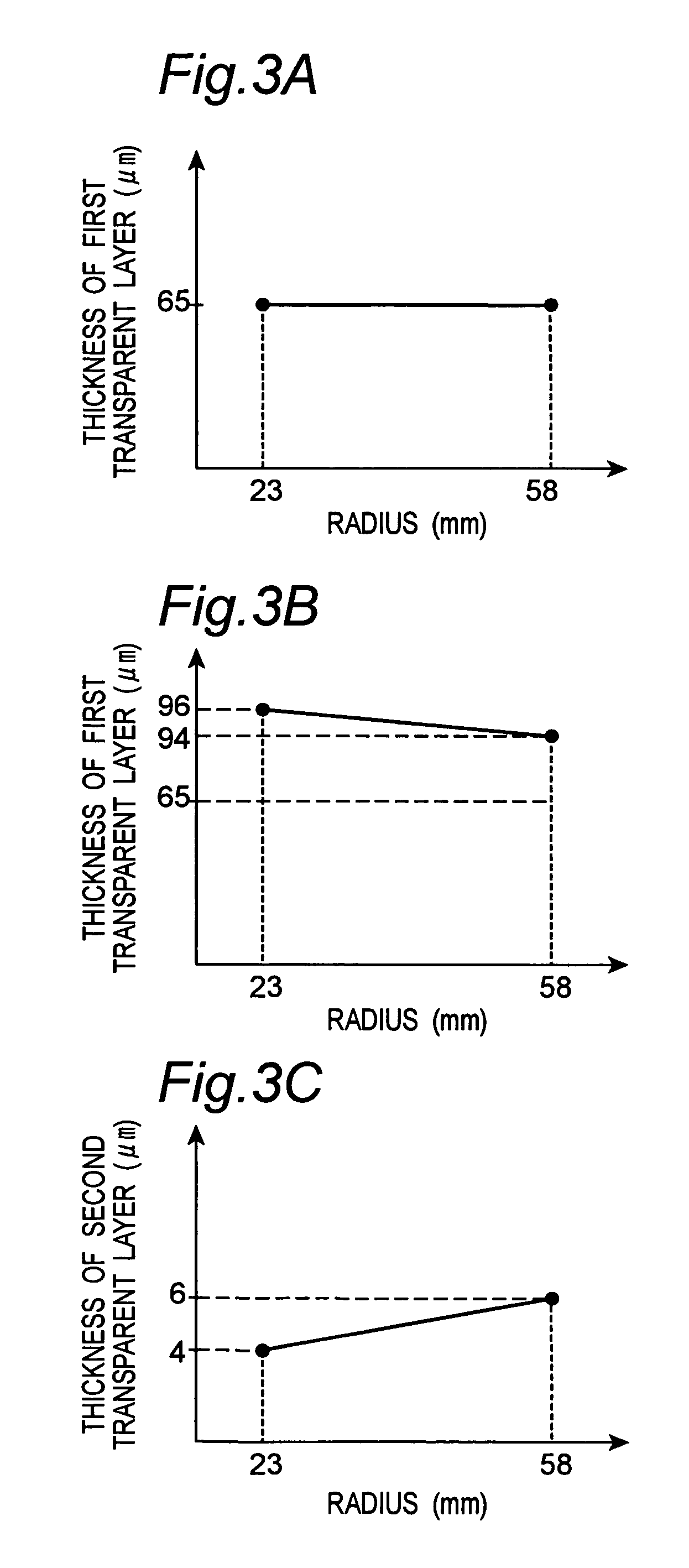

Manufacturing method of optical information recording medium

ActiveUS7820234B2Easy to recordGood reproducing characteristicPretreated surfacesRecord information storageRecording layerTotal thickness

A method of manufacturing an optical information recording medium to / from which signals can optically be recorded and reproduced. The recording medium includes a signal substrate (100), a signal recording layer (110), and a transparent cover layer (125) having a first transparent layer (115) and a second transparent layer (120), which is harder than the first transparent layer (115). Signals can be recorded and reproduced to and from the recording medium by a light transmitted to the signal recording layer through the transparent cover layer (125). The first transparent layer is formed so as to have a first predetermined distribution of thickness. The second transparent layer is formed so as to have a second predetermined distribution of thickness to make the total thickness of the transparent cover layer (125) uniform. The first transparent layer (115) may be made of a plurality of thin laminated transparent layers.

Owner:PANASONIC CORP

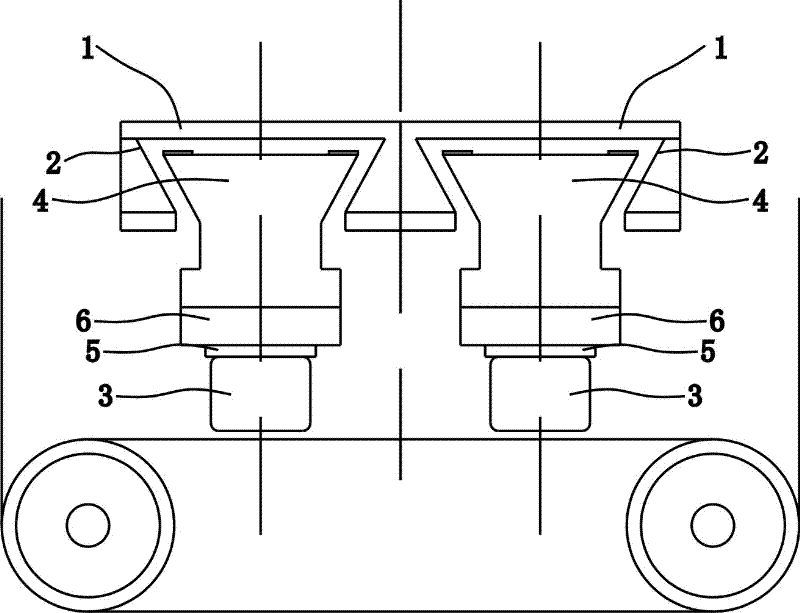

Movable support assembly, mammary radiography machine and mammary radiography machine pressing method

ActiveCN106963404AImprove uneven thicknessImprove stressPatient positioning for diagnosticsMammographyImaging qualityEngineering

The embodiment of the invention provides a movable support assembly, a mammary radiography machine and a mammary radiography machine pressing method. The movable support assembly comprises a movable support plate and a support rail, wherein a revolving shaft is arranged on the support rail, the movable support plate is movably connected to the support rail through the revolving shaft, and the movable support plate can move up and down through the revolving shaft; the back end of the support rail is connected to a fixed portion, the fixed portion comprises a force application part, and the force application part is used for applying downward force to the movable support plate so that the movable support plate can be upwarped relative to the horizontal direction in the initial state. According to the embodiment of the invention, the oppressing and releasing effect can be effectively improved, the comfort of patients is improved, the phenomenon that the examined body is extruded in oppressing is effectively improved, and the quality of imaging is improved.

Owner:NEUSOFT MEDICAL SYST CO LTD

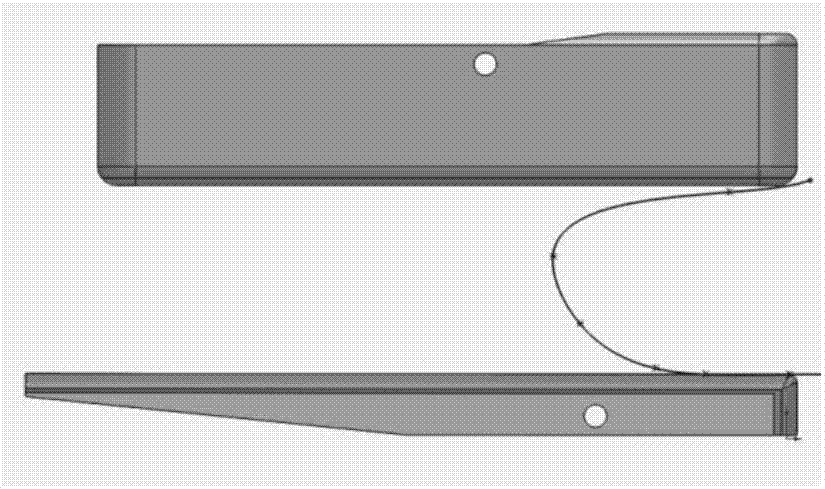

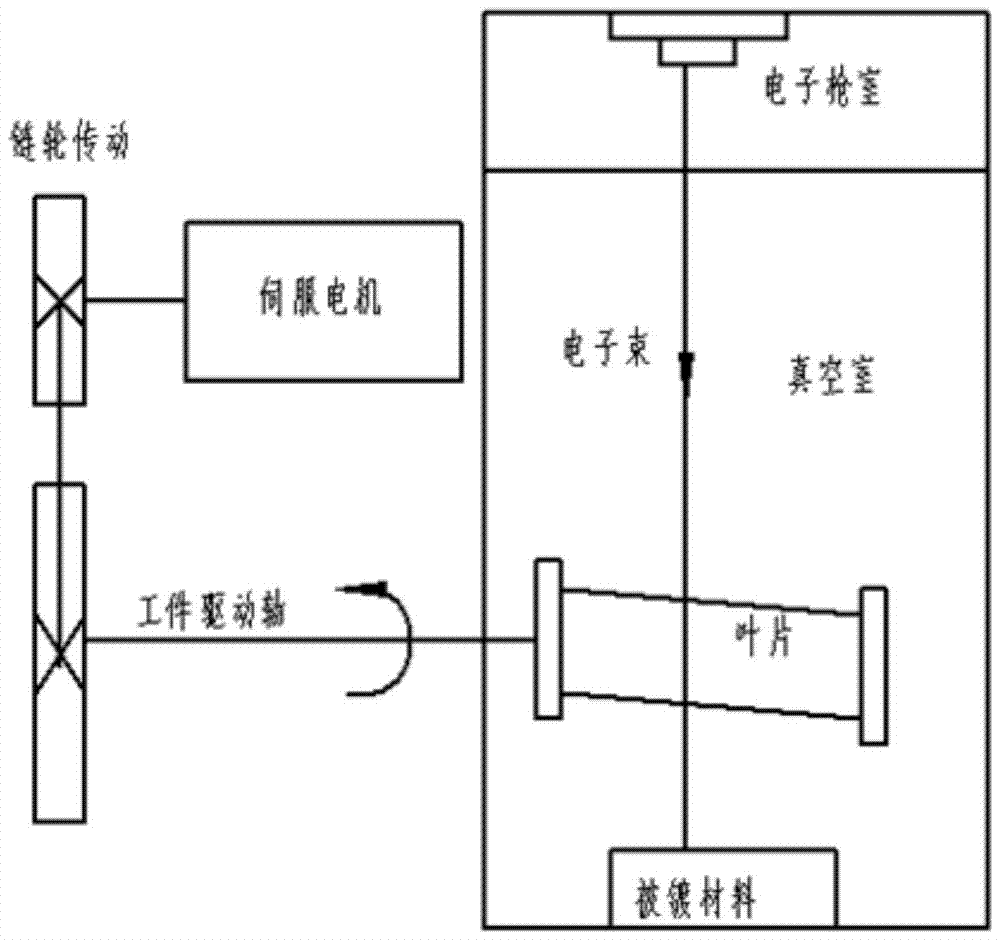

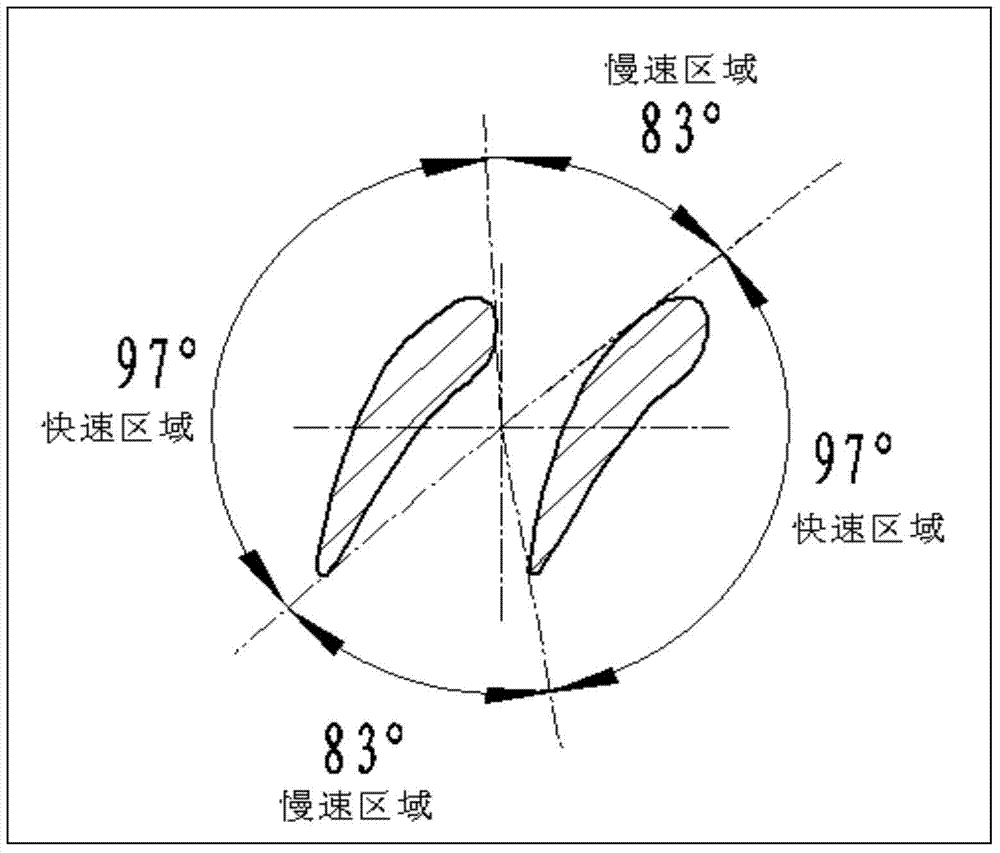

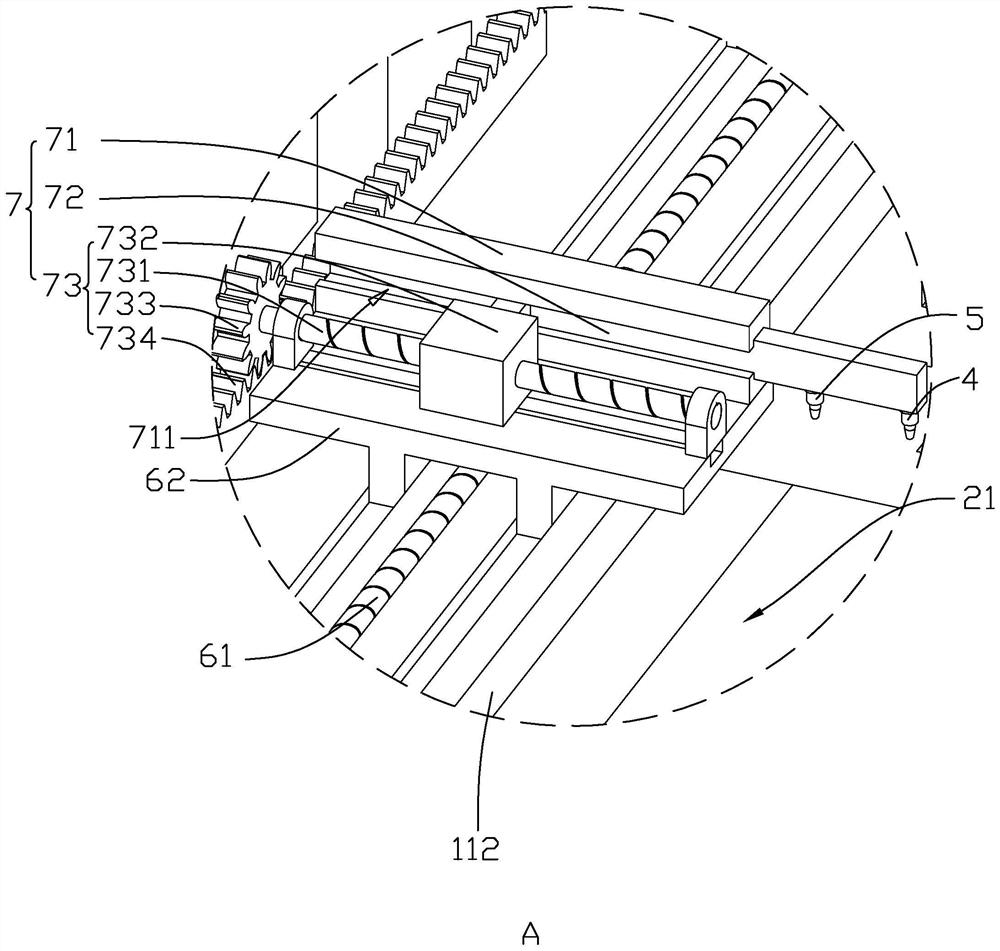

Constant-angle speed changing device applied to vapor-phase deposition of coating of blade and control method

The invention discloses a constant-angle speed changing device applied to vapor-phase deposition of a coating of a blade and a control method. The constant-angle speed changing device comprises a servo motor driving circuit, an additional control circuit and a cam; the cam is capable of changing the rotation speed of a blade-rotating servo driving motor, so that the rotation speed of the blade is related to the rotation angle of the blade; when the shielded surface of the blade rotates to the position which directly faces an ionic group, the rotation speed of the blade is reduced; the time for forming the coating by the ionic group is prolonged, so that the thickness of the coating is more uniform. In addition, the constant-angle speed changing device is capable of depositing the area, with unequal thickness requirement, of the blade surface coating; the residence time in the area with relatively high thickness is long; the residence time of the area with relatively low thickness is short; meanwhile, the device is used for depositing and processing the surface coatings of a turbine working blade and a turbine guide blade; the device is also applicable to the deposition coatings of multi-layer (2-5 layers) guide blades. The device is capable of depositing and processing multiple coating systems such as MCrAlY coatings, YSZ coatings, Al2O3 coatings and TiN coatings.

Owner:AECC AVIATION POWER CO LTD

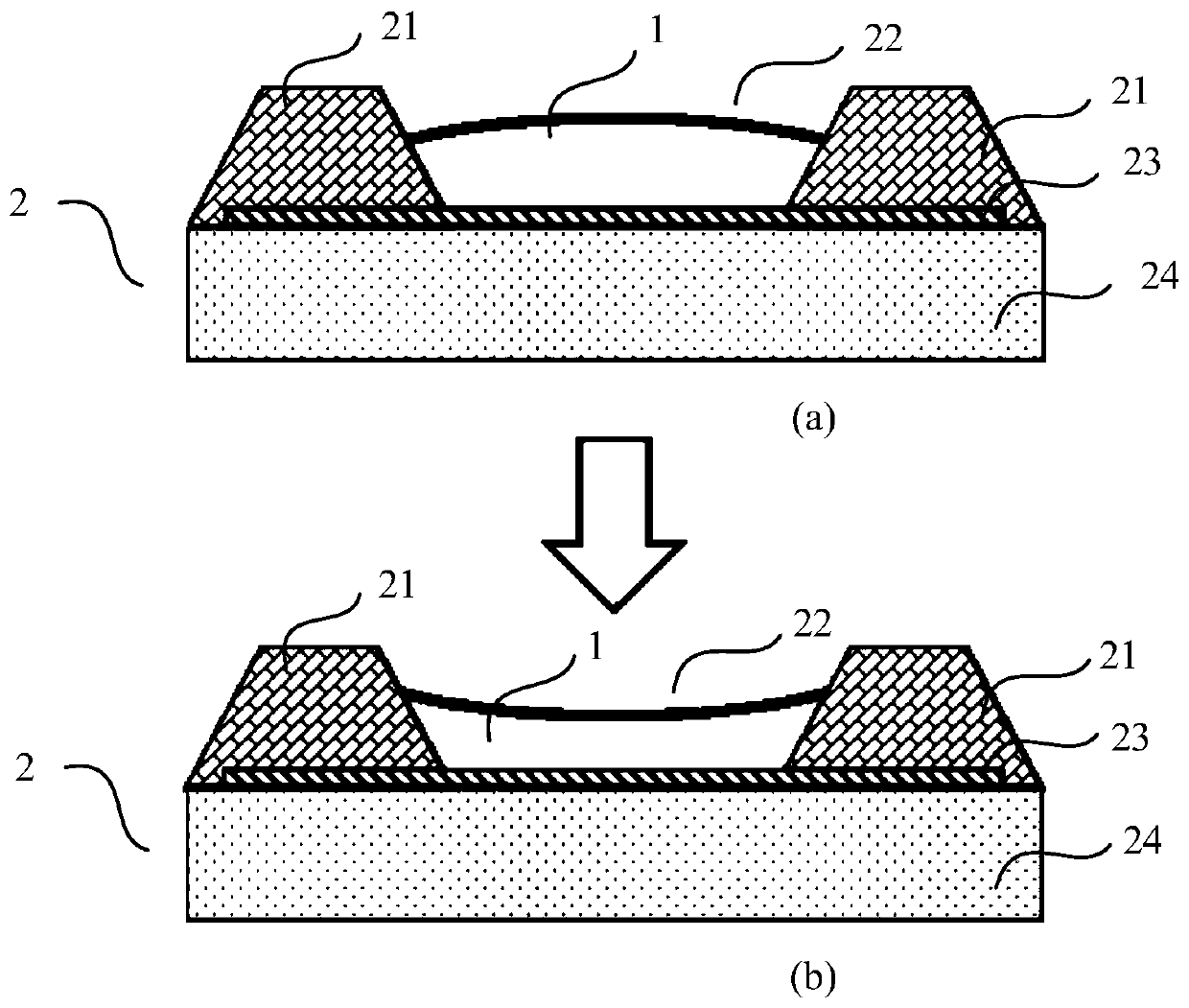

Graphic substrate, epitaxial wafer, manufacturing method, storage medium and LED chip

ActiveCN110190163AImprove uneven thicknessImprove wavelength uniformitySemiconductor devicesEpitaxial materialEngineering

The invention relates to a graphic substrate, an epitaxial wafer, a manufacturing method, a storage medium and an LED chip. The graphic substrate is applied to a Micro LED, and the body is provided with at least one accommodating groove for accommodating at least a portion of the epitaxial material dropped in the epitaxial process. The graphic substrate is advantaged in that at least a portion ofthe excess epitaxial material generated during high-speed rotational molding of the epitaxial layer in an MOCVD furnace can be dropped into the accommodating groove without remaining on the epitaxiallayer, a problem of uneven thickness of the epitaxial layer is ameliorated, wavelength uniformity is improved, and a problem of wavelength non-uniformity is at least solved.

Owner:KONKA GROUP

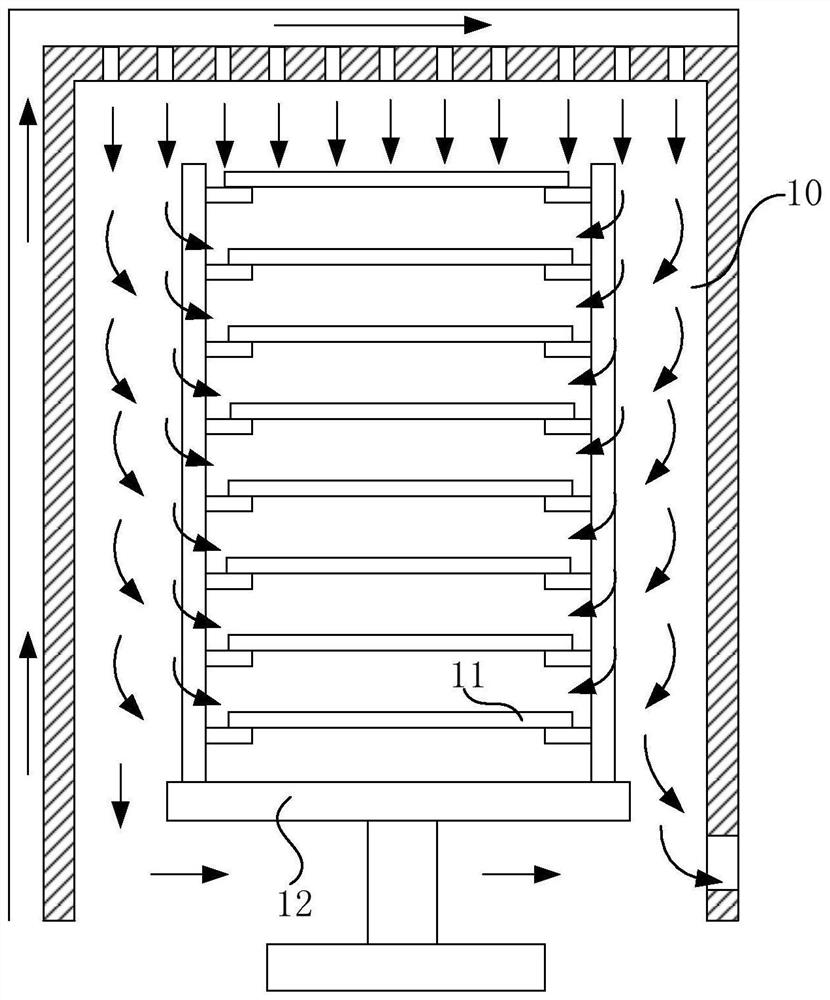

Diffusion furnace

ActiveCN114369813AAvoid differences in reactive gas concentrationsAvoid uneven thicknessFinal product manufactureSemiconductor/solid-state device manufacturingWaferAcute angle

The present invention provides a diffusion furnace, comprising: a reaction chamber extending along a first direction, the reaction chamber having an exhaust end, a plurality of wafers capable of being sequentially arranged along the first direction, the surfaces of the wafers extending along a second direction, the second direction being perpendicular to the first direction or forming an acute angle with the first direction; the gas pipelines penetrate through the side wall of the reaction chamber so as to introduce external reaction gas into the reaction chamber, the gas channels are distributed from the exhaust end in the first direction, and an acute included angle is formed between the axis of each gas channel and the second direction. The reaction gas sprayed from the gas channel can directly reach the center of the wafer through the inclined design of the gas channel, so that the problem that the two sides are thick and the middle is thin in the deposition process is solved, due to the exhaust effect of the exhaust end, the reaction gas reaches the middle of the wafer and diffuses towards the two sides, meanwhile, diffusion of the gas is accelerated through rotation of the wafer boat, and the deposition efficiency is improved. Therefore, the thickness of the film layer deposited at the center and the edge of the surface of the single wafer is more uniform, and the product yield is improved.

Owner:CHANGXIN MEMORY TECH INC

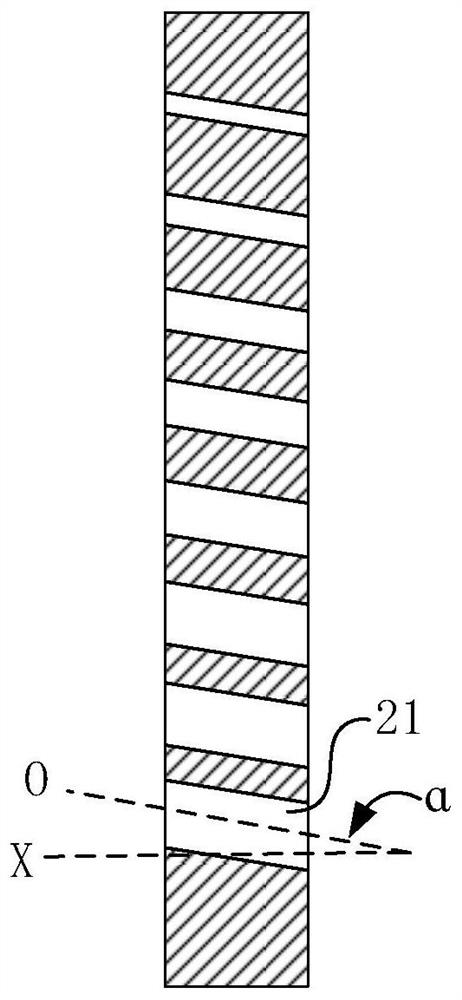

Method for preparing HA-containing biological composite film layer through ultrasonic-assisted titanium alloy micro-arc oxidation hydro-thermal treatment

PendingCN114032598ASmall apertureImprove corrosion resistanceCellsSurface reaction electrolytic coatingElectrolytic agentMicro arc oxidation

The invention discloses a preparation method of an HA biological composite film layer through ultrasonic and micro-arc oxidation titanium alloy surface hydro-thermal treatment. The method comprises the following steps: immersing a pretreated titanium alloy as an anode into a biological electrolyte, taking a stainless steel sheet as a cathode, carrying out micro-arc oxidation by using a direct-current pulse power supply and the optimized biological electrolyte, preparing a biological ceramic membrane layer, cleaning a sample, and drying the cleaned sample; and then placing the dried sample in a liner of a hydrothermal reaction kettle, dissolving NaOH into deionized water, adjusting the pH value, pouring the hydrothermal solution into the liner of the reaction kettle, and finally carrying out heat preservation treatment. The biological membrane layer obtained by combining ultrasonic synergistic micro-arc oxidation and hydrothermal treatment has high wear resistance and corrosion resistance of a micro-arc oxidation membrane layer and excellent biological activity of hydroxyapatite, and meanwhile, the ultrasonic synergism has an improvement effect on the thickness, element distribution and the like of the micro-arc oxidation membrane, so that the generation of hydroxyapatite can be promoted; and the morphology and distribution of hydroxyapatite are homogenized.

Owner:江苏通和生物医药科技有限公司

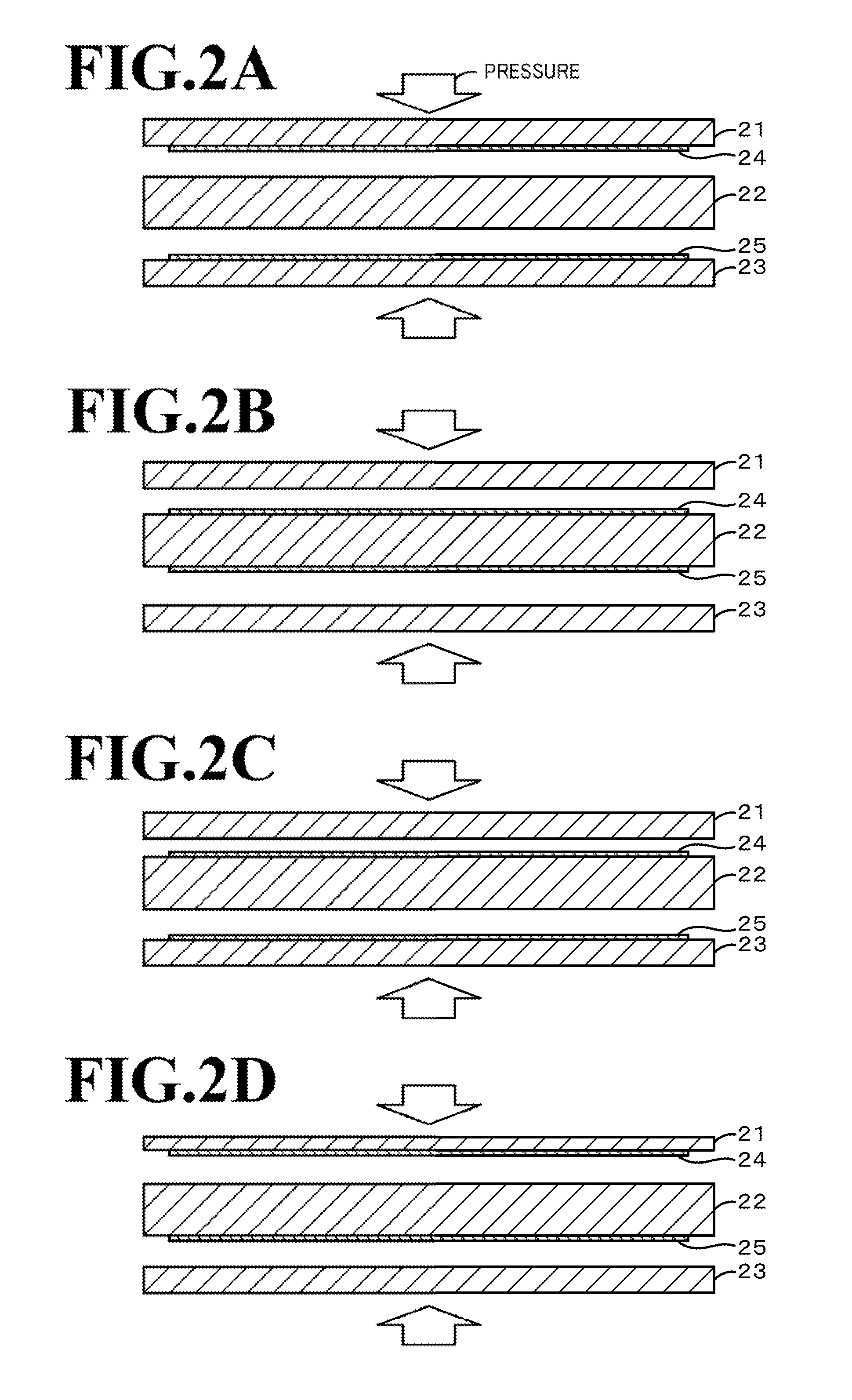

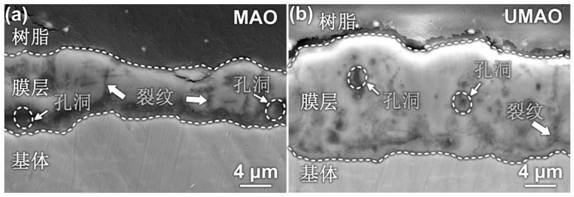

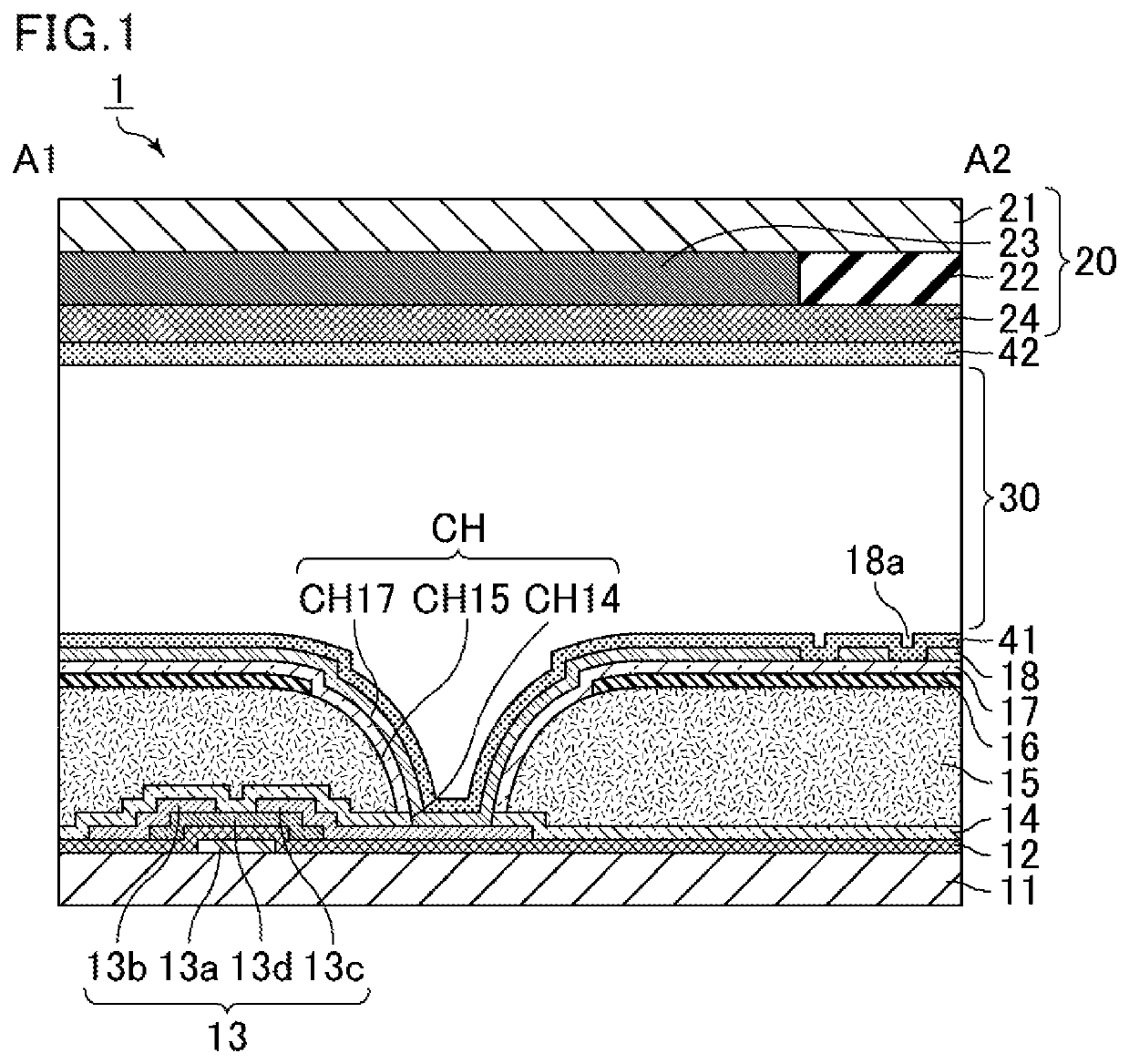

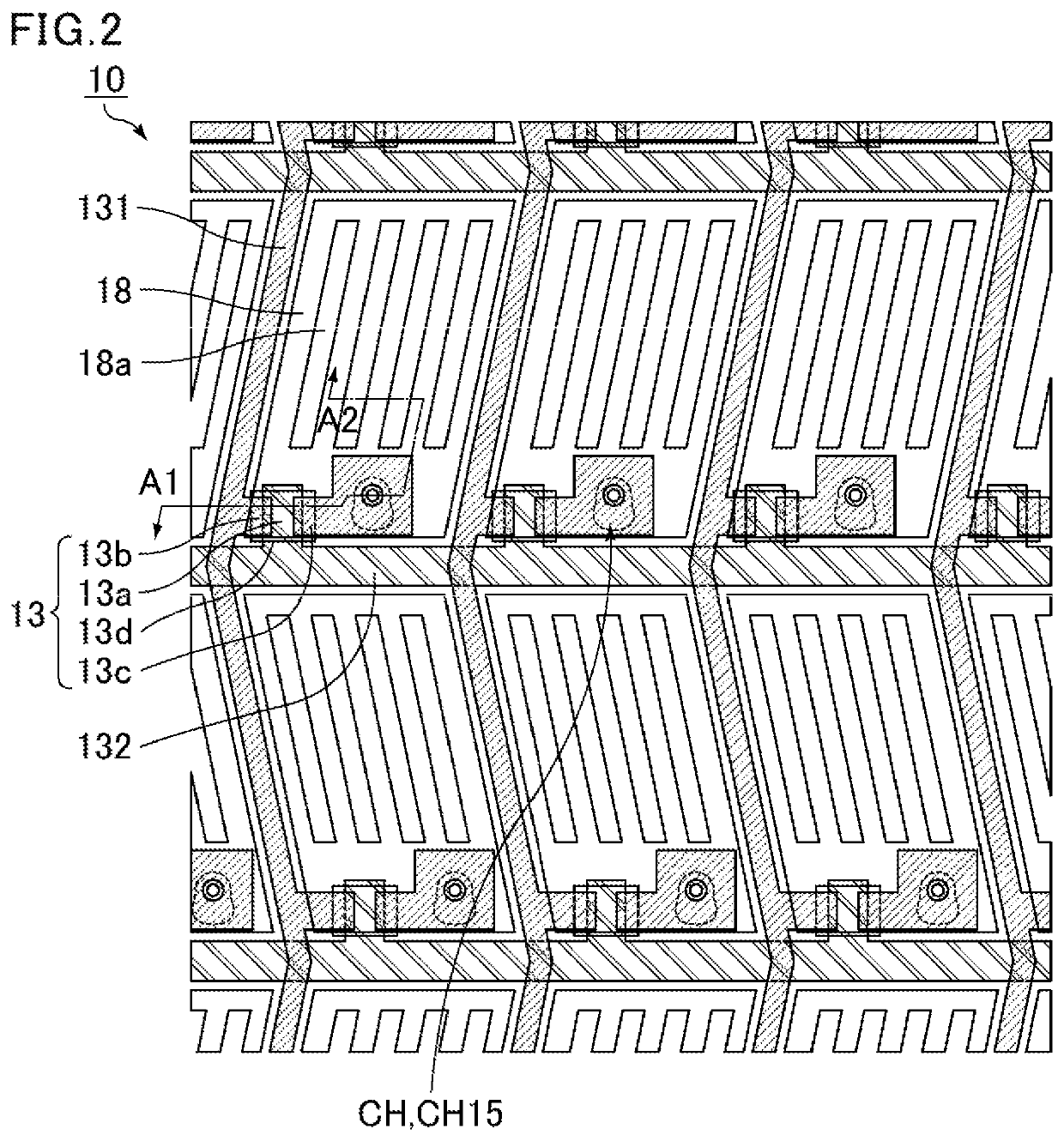

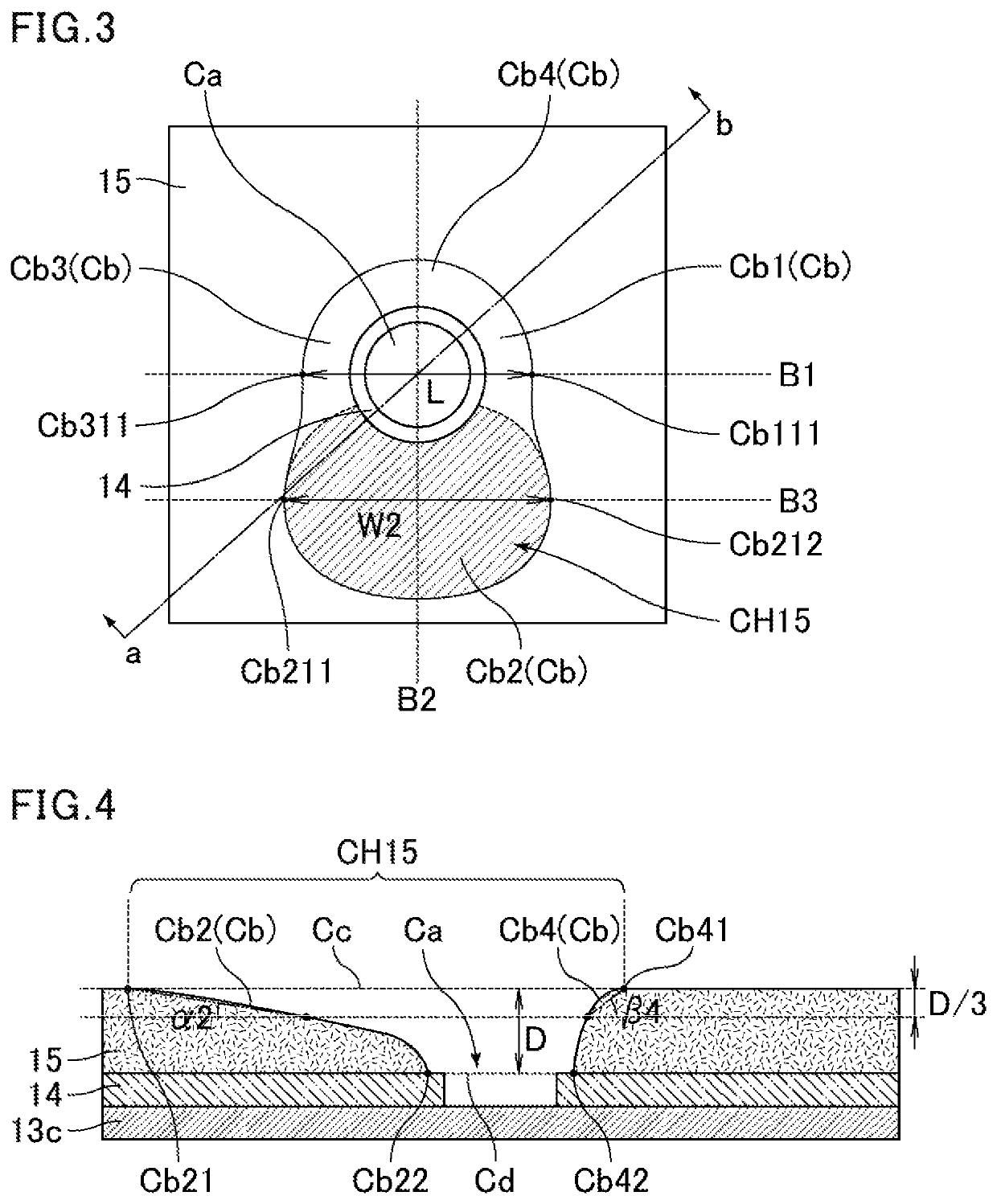

Liquid crystal display device and method of producing liquid crystal display device

ActiveUS20190302552A1Thickness unevenness is suppressedSmall sizeNon-linear opticsLiquid-crystal displayEngineering

The liquid crystal display device according to the present invention includes: a thin-film transistor substrate, wherein the thin-film transistor substrate includes an organic insulating film disposed on a drain electrode and provided with a contact hole, the contact hole includes first, second, third, and fourth side wall portions in the given order, an inclination of an upper portion of the second side wall portion is gentler than an inclination of an upper portion of each of the first and third side wall portions, and the contact hole satisfies W2>L, wherein L is a distance from an upper end of the first side wall portion to an upper end of the third side wall portion on a first straight line, and W2 is a maximum distance between one and another upper end of the second side wall portion on a third straight line parallel to the first straight line.

Owner:SHARP KK

Lamp shape structure

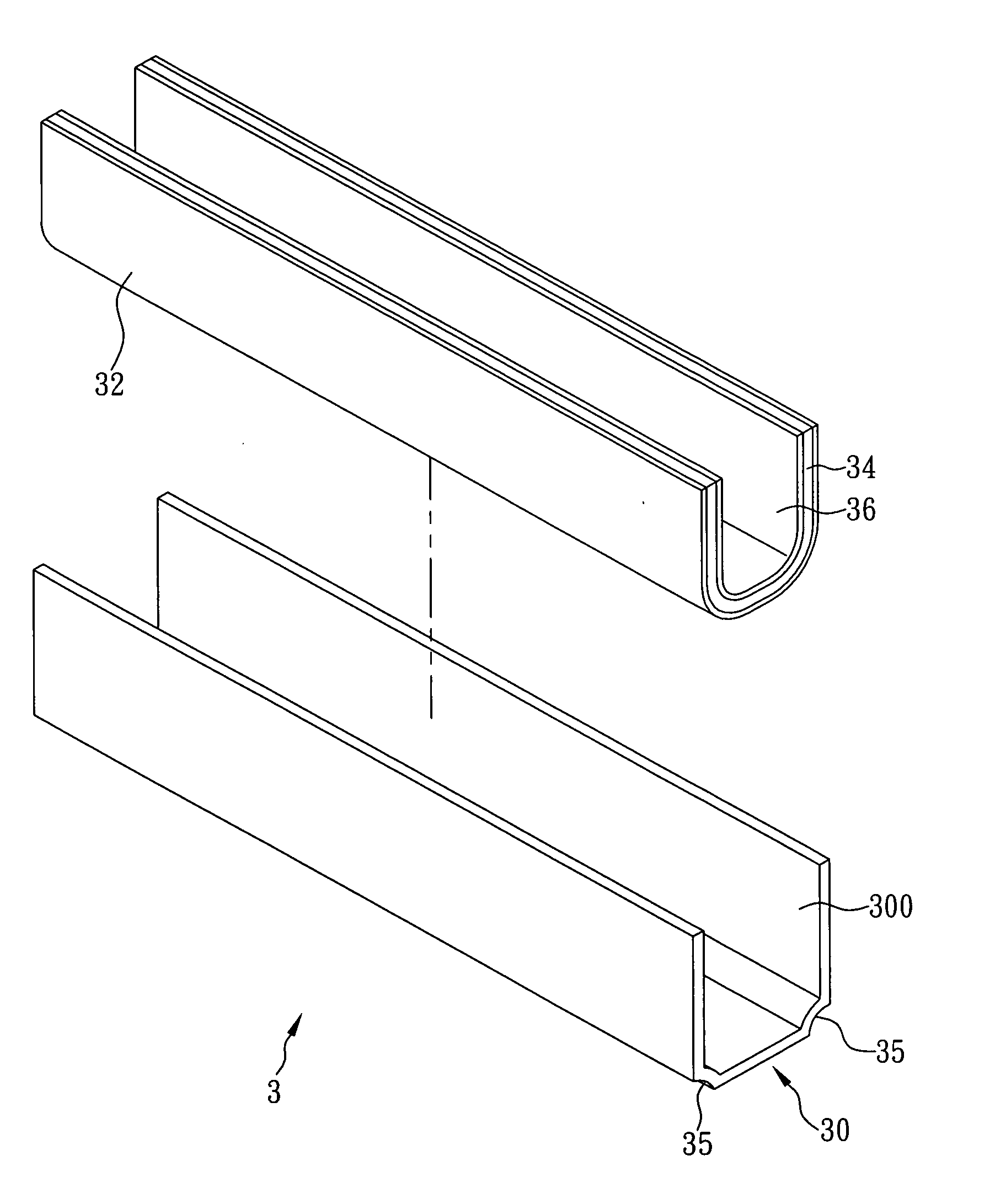

InactiveUS20100067239A1Affecting reflecting efficiency of adverselySmall thicknessNon-linear opticsReflectorsLiquid-crystal displayEngineering

A lamp shade structure applied to a liquid crystal display backlight module includes a metal hood, an adhesive layer and a reflective sheet, wherein the metal hood is formed by bending a metal sheet into a cross-sectional shape and has a containing space formed at an internal side of the metal hood, the cross-section of the reflective sheet is in an arc shape, and a side of the reflective sheet is attached to the containing space through the adhesive layer. Since the cross-section of the reflective sheet is in an arc shape, therefore the present invention can improve the reflecting efficiency of the lamp shade structure effectively.

Owner:KOCAM INT

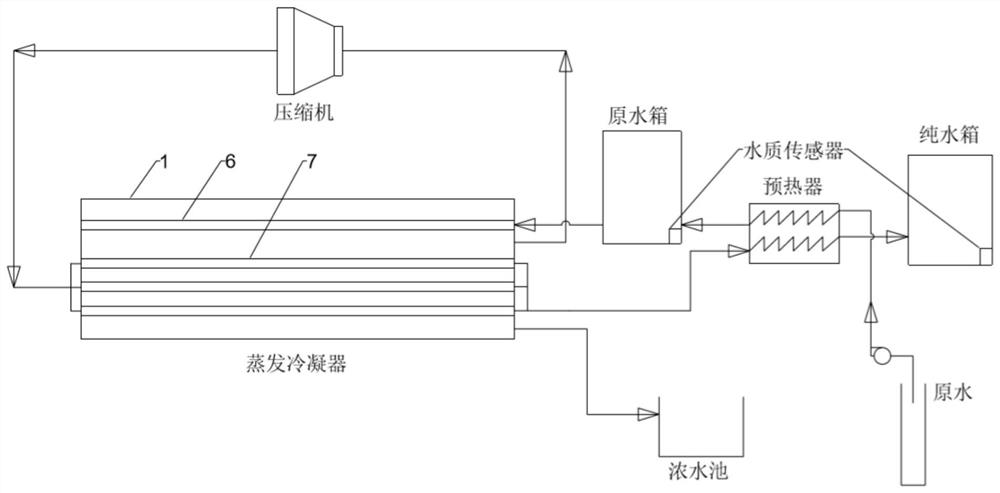

An all-glass tube mvc low-solubility sewage evaporation condensation purification system

ActiveCN111792684BClear distributionTo play the case of uneven thicknessWater/sewage treatment by heatingWater/sewage treatment apparatusSewagePurified water

Owner:SOUTHEAST UNIV

A fixed angle speed change device and control method for blade vapor deposition coating

The invention discloses a constant-angle speed changing device applied to vapor-phase deposition of a coating of a blade and a control method. The constant-angle speed changing device comprises a servo motor driving circuit, an additional control circuit and a cam; the cam is capable of changing the rotation speed of a blade-rotating servo driving motor, so that the rotation speed of the blade is related to the rotation angle of the blade; when the shielded surface of the blade rotates to the position which directly faces an ionic group, the rotation speed of the blade is reduced; the time for forming the coating by the ionic group is prolonged, so that the thickness of the coating is more uniform. In addition, the constant-angle speed changing device is capable of depositing the area, with unequal thickness requirement, of the blade surface coating; the residence time in the area with relatively high thickness is long; the residence time of the area with relatively low thickness is short; meanwhile, the device is used for depositing and processing the surface coatings of a turbine working blade and a turbine guide blade; the device is also applicable to the deposition coatings of multi-layer (2-5 layers) guide blades. The device is capable of depositing and processing multiple coating systems such as MCrAlY coatings, YSZ coatings, Al2O3 coatings and TiN coatings.

Owner:AECC AVIATION POWER CO LTD

A supporting tooling structure for painting the inner wall of a rotary housing

ActiveCN110180721BImprove painting efficiencyReduce labor intensitySpraying apparatusBraced frameSupport point

The invention discloses a support tool structure for painting the inner wall of a gyration shell. The support tool structure for painting the inner wall of the gyration shell comprises a support frame, a horizontal guiding support structure, a vertical guiding support structure and a lifting assembly. The support frame is of an L shape as a whole and comprises a base and a vertical frame arrangedon one side of the base. The horizontal guiding support structure is arranged on the base, the rear end of the gyration shell can be supported by the horizontal guiding support structure, and supporting points can translate along the horizontal direction to adapt to gyration shells of different length and diameters through the horizontal guiding support structure. The vertical guiding support structure is arranged on the vertical frame, the front end of the gyration shell can be supported by the vertical guiding support structure, and the supporting points can translate in the vertical direction through the vertical guiding support structure so that the tilting angle of the gyration shell can be adjusted. The lifting assembly is arranged on the vertical frame and used for driving the vertical guiding support structure to move in the vertical direction. By means of the support tool structure for painting the inner wall of the gyration shell, it is guaranteed that the tilting angle of axis of the gyration shell in the painting process does not change, the problem that inner wall paint film thickness is uneven is solved, and in addition, the distance from the cut-off line of paint film to the rear end face of the gyration shell is consistent.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

Inkjet printing device and inkjet printing method

ActiveCN110406266AImprove uneven thicknessMitigation of flow over edge areasPrintingEdge regionPrinting ink

The invention provides an inkjet printing device and an inkjet printing method, and relates to the technical field of display. The inkjet printing device is used for spraying printing ink to a targetsubstrate and comprises an inkjet assembly and a heating assembly, wherein the inkjet assembly comprises a nozzle for spraying the printing ink; the heating assembly comprises an emitting nozzle for emitting heat source beams; and the heat source beams are used for heating the printing ink on the target substrate, and energy density of each heat source beam is decreased progressively from center to the periphery on the cross section of the heat source beam. According to the embodiment, the energy density of each heat source beam is decreased progressively from center to the periphery on the cross section of the heat source beam, so that the increase speed of the solidification rate of the intermediate region of the printing ink in accommodating holes is higher than that of the solidification rate of the edge region, and the printing ink flowing from the intermediate region to the edge region can be reduced.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Method for preparing blackening coating agent for metal surface treatment

ActiveCN104213115AImprove compactnessImprove stabilityMetallic material coating processesThermal stabilitySodium nitrite

The invention discloses a method for preparing a blackening coating agent for metal surface treatment. The method comprises the steps that (A) sodium nitrite and copper sulfate are weighed according to the proportion and are dissolved into deionized water; (B) disodium nucleotide, hydroxymethyl cellulose, sodium polyacrylate, poly alkylene glycol, methylparaben and complexing agents are added into an obtained solution, heating is carried out, and stirring is carried out for 20 minutes; (C) the solution in the step (B) is cooled to 25 DEG C, thickening agents and defoaming agents are added into the solution, and stirring is carried out for 15 minutes; (D) intensive mixing and even dispersion are carried out, a 200-mesh bag type filter is adopted to filter the solution, the filtered liquid is the coating agent, and components are weighed by mass. The prepared blackening coating agent can obviously enhance the compactness and firmness of the coating, the problem that the thickness of the coating is uneven is effectively solved, and the blackening coating agent prepared through the method is good in heat stability, innocuous, easily degradable, free of pollution to the environment, and wide in application range.

Owner:湖南锦络电子股份有限公司

Inkjet printing device and inkjet printing method

ActiveCN110406266BImprove uneven thicknessMitigation of flow over edge areasPrintingEngineeringPrinting ink

The invention provides an inkjet printing device and an inkjet printing method, and relates to the technical field of display. The inkjet printing device is used for spraying printing ink to a targetsubstrate and comprises an inkjet assembly and a heating assembly, wherein the inkjet assembly comprises a nozzle for spraying the printing ink; the heating assembly comprises an emitting nozzle for emitting heat source beams; and the heat source beams are used for heating the printing ink on the target substrate, and energy density of each heat source beam is decreased progressively from center to the periphery on the cross section of the heat source beam. According to the embodiment, the energy density of each heat source beam is decreased progressively from center to the periphery on the cross section of the heat source beam, so that the increase speed of the solidification rate of the intermediate region of the printing ink in accommodating holes is higher than that of the solidification rate of the edge region, and the printing ink flowing from the intermediate region to the edge region can be reduced.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Preparation method of ultra-pure, ultra-thick and compact aluminum film

ActiveCN114481067AHigh purityImprove compactnessVacuum evaporation coatingSputtering coatingAlloyAluminum coating

The invention relates to a preparation method of an ultra-pure, ultra-thick and compact aluminum film, which adopts a magnetron sputtering technology and an ion intervention (ion plating) mode to form an ultra-thick aluminum film (or aluminum coating) with the thickness of more than 50 microns on the surface of a metal (or alloy material), the porosity of the film layer is less than 1%, the purity of the film layer is more than 99%, and the thickness of the film layer is more than 50 microns. And good interface bonding force with a to-be-plated workpiece is achieved. The method can be used for decoration of parts in the fields of 3C and the like, and surface treatment of metal (or alloy) parts in the fields of semiconductor equipment, integrated circuit equipment and the like.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

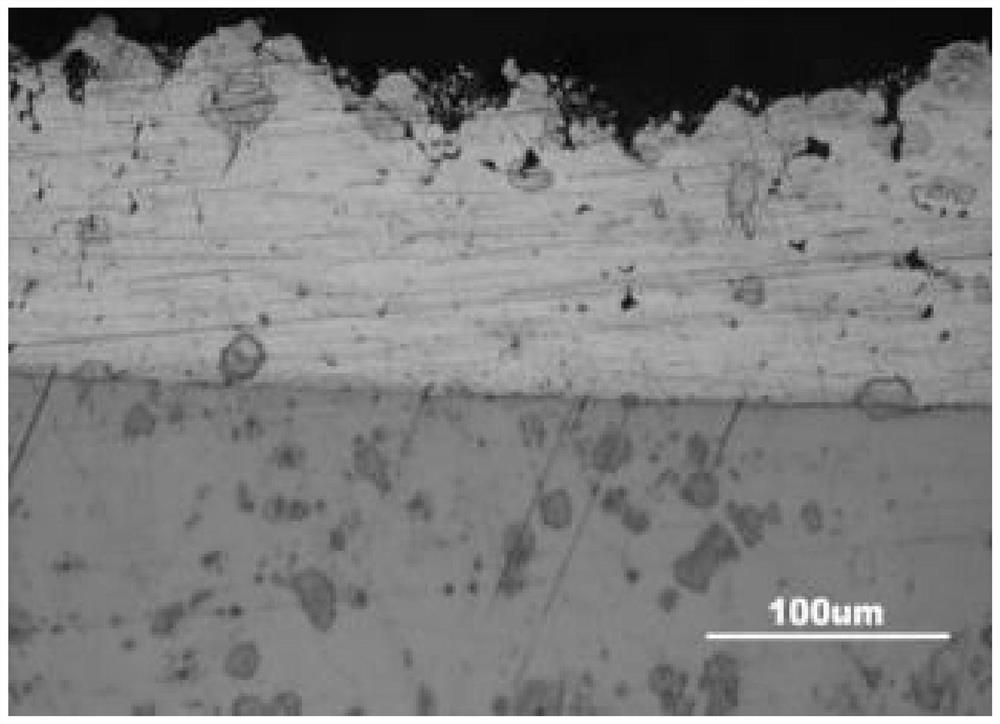

Patch pressurizing device and method for sensor

ActiveCN112525063AImprove productivityGuaranteed stabilityElectrical/magnetic solid deformation measurementPressure transmissionEngineering

The invention discloses a patch pressurizing device and method for a sensor. The device comprises a pressure transmission plate, a spring, a guide rod, a fixed base, a positioning plate and a nut, a threaded hole is formed in the fixed base, through holes are formed in the pressure transmission plate and the positioning plate, and the guide rod sequentially penetrates through the threaded hole ofthe fixed base, the through hole of the pressure transmission plate and the through hole of the positioning plate and is fixed by the nut; a patch area of the sensor is clamped between the pressure transmission plate and the positioning plate; and the spring is arranged between the pressure transmission plate and the fixed base. The method comprises the following steps: step 1, fixing the sensor on the positioning plate, and fixing the patch area of the sensor on the pressurizing surface of the positioning plate; 2, screwing the guide rod in the threaded hole in the fixed base, and sequentially arranging the spring, the pressure transmission plate, the positioning plate and the nut on the guide rod to be fixed; and 3, compressing the patch pressurizing spring, generating a gap between thenut and the upper surface of the positioning plate, and tightening the nut to perform pressurizing compensation after the pressurizing force value is stable.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

Liquid crystal display device and method of producing liquid crystal display device

ActiveUS10642117B2Ink consumption amount is smallEasy inflowNon-linear opticsCrystallographyLiquid-crystal display

The liquid crystal display device according to the present invention includes: a thin-film transistor substrate, wherein the thin-film transistor substrate includes an organic insulating film disposed on a drain electrode and provided with a contact hole, the contact hole includes first, second, third, and fourth side wall portions in the given order, an inclination of an upper portion of the second side wall portion is gentler than an inclination of an upper portion of each of the first and third side wall portions, and the contact hole satisfies W2>L, wherein L is a distance from an upper end of the first side wall portion to an upper end of the third side wall portion on a first straight line, and W2 is a maximum distance between one and another upper end of the second side wall portion on a third straight line parallel to the first straight line.

Owner:SHARP KK

Method for preparing zeolite membrane through thermal inversion of xerogel

InactiveCN1264750CImprove defectsStable supportCrystalline aluminosilicate zeolitesCeramicMaterials science

The invention relates to a kind of zeolite film prepn, method. The characteristics are: to compound sol according to mole matching ratio of Na2O:SiO2:Al2O3:H2O, to coat sol layer on supporting body of a-Al2O3 ceramics etc., it is conversed to dry sol layer, then is put into stainless steel pressure pot with polytetrafluorine lining to be soaked by water heat treatment solution compounded at same time, the pot is closed in temp, 80-200 deg.C, keeping the temp, for 24-48 hours, then taking out, washing, drying and inreasing and reducing temp, in program to obtain zeolite film.

Owner:DALIAN UNIV OF TECH

Multi-point plasma spraying coating machine

PendingCN114849933AImprove uneven material thicknessDrive compactSpraying apparatusPhysicsEngineering

The multi-point type plasma spraying coating machine comprises a machine shell, a conveying belt, a first spraying gun and a second spraying gun, the conveying belt is arranged in the machine shell in a penetrating mode, and the top face of the conveying belt is divided into a plurality of spraying areas with the same width in the direction perpendicular to the moving direction of the conveying belt; the connecting line direction of the first spray gun and the second spray gun is the same as the moving direction of the conveying belt; a driving mechanism used for driving the first spray gun and the second spray gun to move back and forth in the length direction of the spraying area is installed in the machine shell, and a reciprocating mechanism used for driving the first spray gun and the second spray gun to move in the moving direction of the conveying belt is installed in the machine shell. The movement speed of the first spray gun and the second spray gun in the length direction of the conveying belt is the same as that of the conveying belt, the first spray gun and the second spray gun spray corresponding spraying areas, and meanwhile the conveying belt advances by one spraying area. The method has the effect of improving the non-uniform thickness of the glass panel.

Owner:SHENZHEN DECHENGDA PHOTOELECTRIC MATERIAL CO LTD

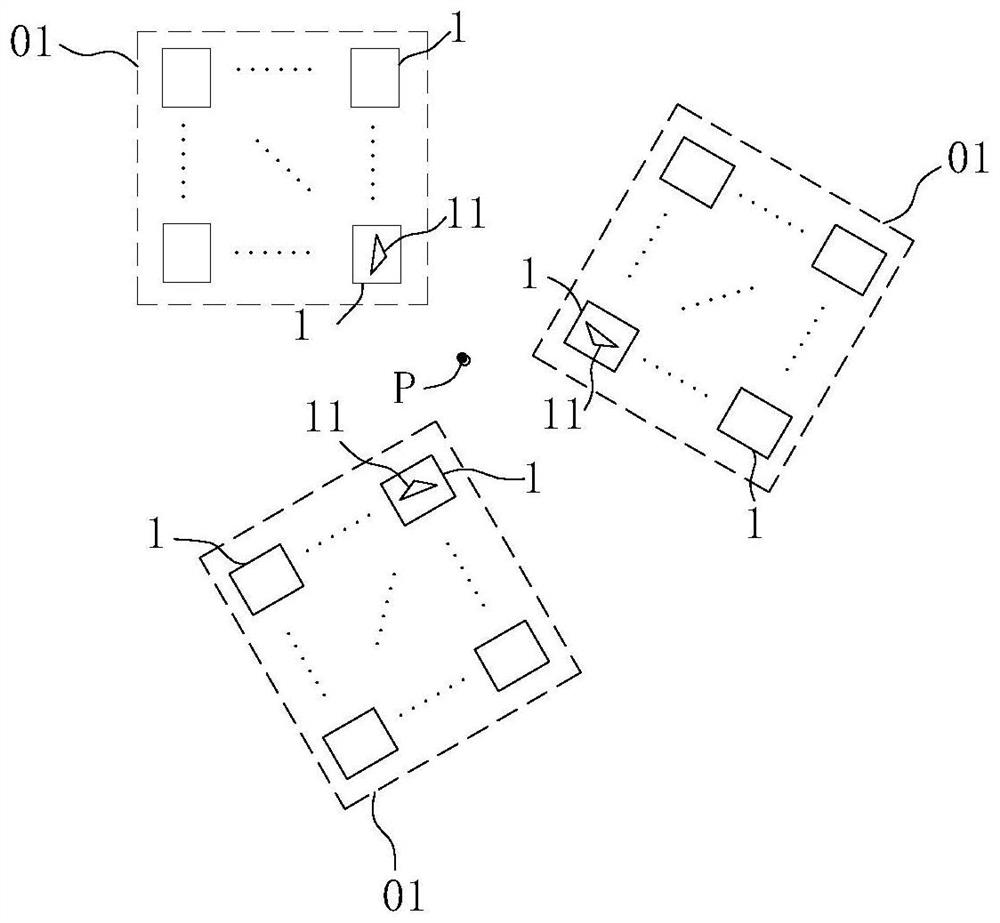

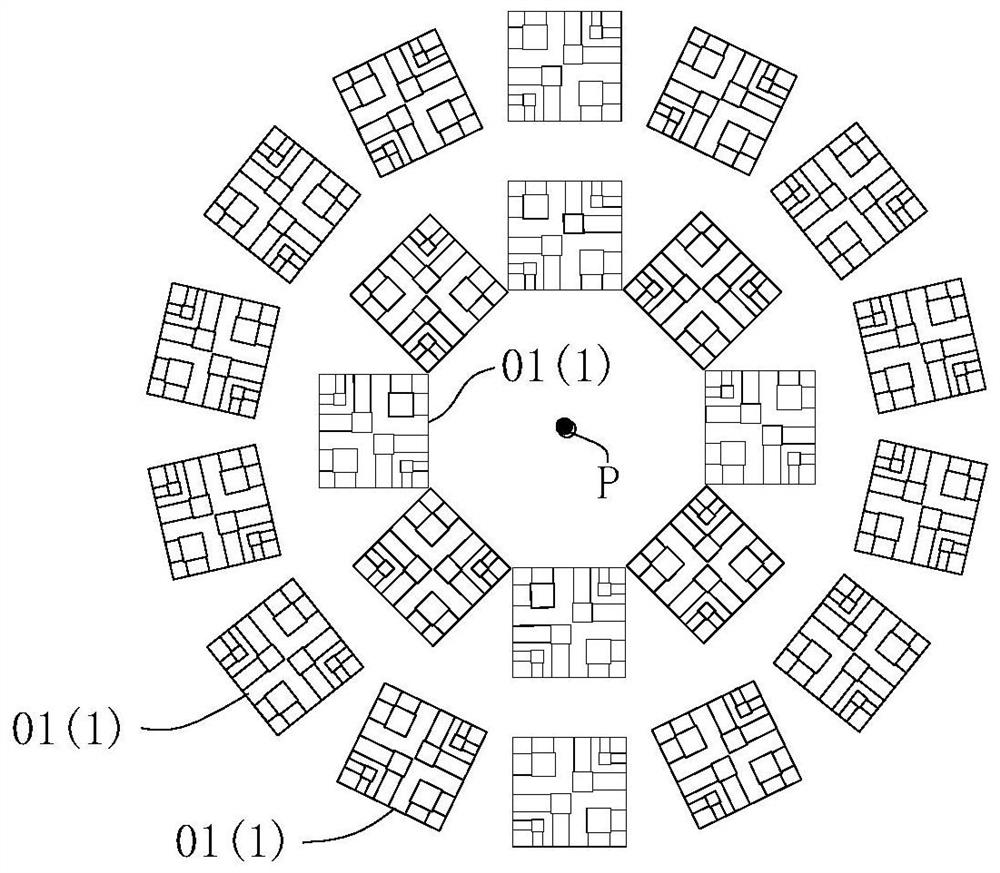

Test piece arrangement structure and test substrate

PendingCN114823407AConsistent thicknessImprove uneven thicknessSemiconductor/solid-state device testing/measurementSolid-state devicesStructural engineeringMechanical engineering

The invention discloses a test piece arrangement structure and a test substrate. The test piece arrangement structure comprises a plurality of test groups, each test group comprises at least one test piece, the number of the test pieces in each test group is the same, the plurality of test groups are arranged around a virtual mark point, the test pieces are provided with patterned structures, and the patterned structures are arranged around the virtual mark point. Each test group is provided with at least one test piece with the same patterned structure, and the distances from the same patterned structures in the test groups to the virtual mark points are the same. The thickness of the film layer of each patterned structure obtained by performing evaporation by utilizing the evaporation equipment is relatively consistent, so that the thickness uniformity of the evaporation film layer of the same patterned structure of each test group is improved, and the phenomenon that the thickness of the evaporation film layer of the test piece in each test group is not uniform is improved to a certain extent. The test piece has enough film layer precision, so that a more accurate test result can be obtained when the test piece is used for testing.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

A movable supporting component, a mammary gland machine, and a mammary gland machine compression method

ActiveCN106963404BImprove uneven thicknessImprove stressPatient positioning for diagnosticsMammographyImaging qualityEngineering

The embodiment of the invention provides a movable support assembly, a mammary radiography machine and a mammary radiography machine pressing method. The movable support assembly comprises a movable support plate and a support rail, wherein a revolving shaft is arranged on the support rail, the movable support plate is movably connected to the support rail through the revolving shaft, and the movable support plate can move up and down through the revolving shaft; the back end of the support rail is connected to a fixed portion, the fixed portion comprises a force application part, and the force application part is used for applying downward force to the movable support plate so that the movable support plate can be upwarped relative to the horizontal direction in the initial state. According to the embodiment of the invention, the oppressing and releasing effect can be effectively improved, the comfort of patients is improved, the phenomenon that the examined body is extruded in oppressing is effectively improved, and the quality of imaging is improved.

Owner:NEUSOFT MEDICAL SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com