Multi-point plasma spraying coating machine

A technology of plasma and coating machine, applied in spraying device, glass production and other directions, can solve the problem of uneven thickness of glass panels, and achieve the effect of improving material thickness unevenness, spraying stability, and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

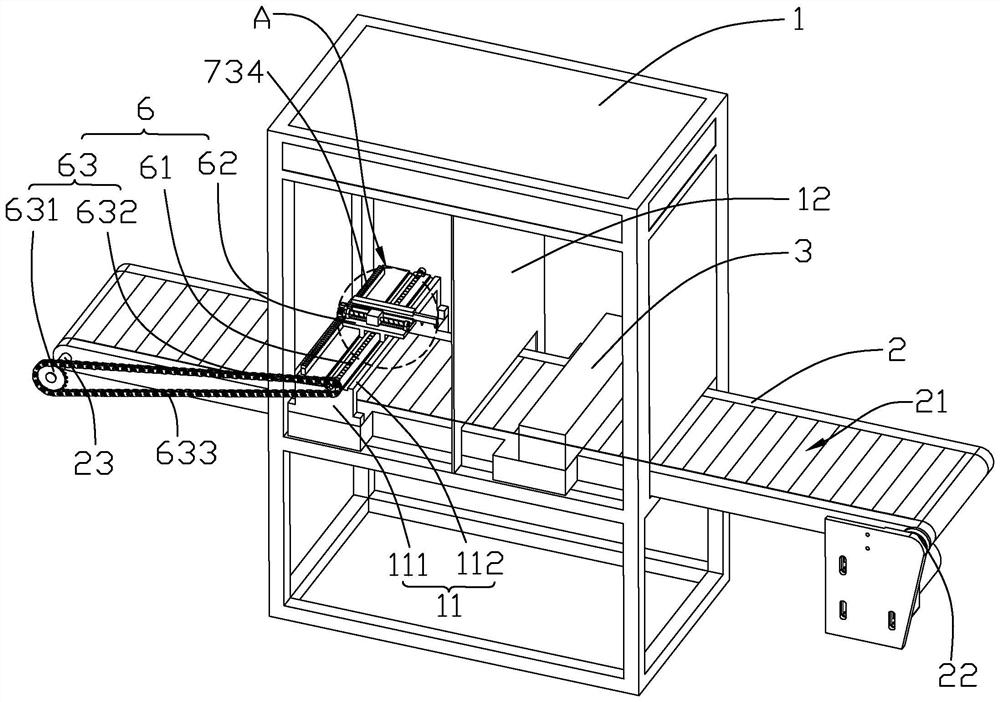

[0035] The embodiment of the present application discloses a multi-point plasma spray coating machine. refer to figure 1 and figure 2 , the coating machine includes a casing 1, a conveyor belt 2, a cleaning mechanism 3, a first spray gun 4 and a second spray gun 5; the casing 1 is set on the ground, the conveyor belt 2 is inserted in the casing 1, and both ends of the conveyor belt 2 extend Outside the casing 1, the length direction of the conveyor belt 2 is the same as the length direction of the casing 1. The conveyor belt 2 has a driving roller 22, a driven roller 23 and a motor. The motor and the driving roller 22 are located at the same end of the conveyor belt 2, and the driven roller 23 is located at the At the other end of the conveyor belt 2, the motor drives the driving roller 22 to rotate, and the driving roller 22 and the driven roller 23 cooperate with each other to drive the conveyor belt 2 to move.

[0036] refer to figure 1 and figure 2 , a separator 12 i...

Embodiment 2

[0043] The embodiment of the present application discloses a multi-point plasma spray coating machine. Different from Example 1, refer to image 3 , the drive source 63 is a servo motor, the servo motor is installed on the top surface of the top plate 112, the servo motor is located at one end of the top plate 112, and one end of the first reciprocating screw is coaxially and fixedly connected to the output shaft of the private server motor.

[0044] The implementation principle of a multi-point plasma spray coating machine in the embodiment of the present application is as follows: the first reciprocating screw is directly driven to rotate by the servo motor, and the sliding speed of the sliding seat 62 can be directly adjusted according to the speed of the conveyor belt 2 to ensure the first spray gun. 4 and the second spray gun 5 finish spraying the corresponding spraying area 21, the conveyor belt 2 advances one spraying area 21, and then the carriage 62 can return to the ...

Embodiment 3

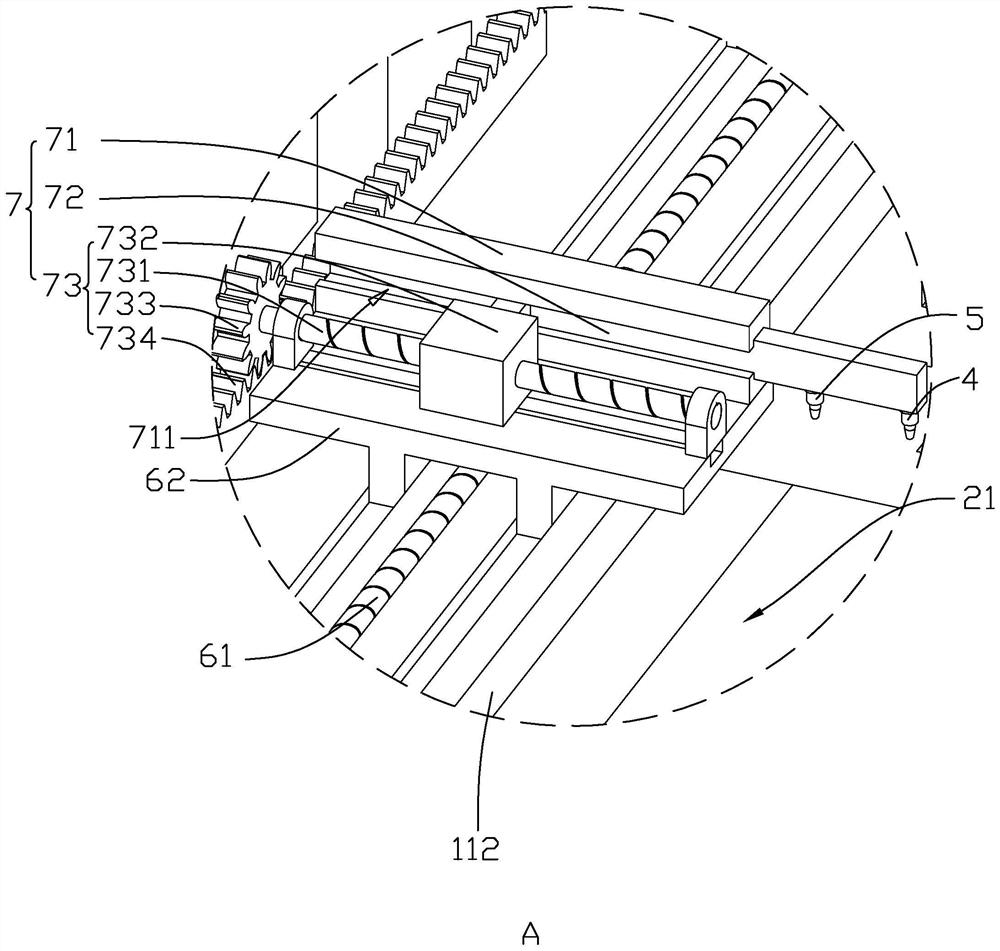

[0046] The embodiment of the present application discloses a multi-point plasma spray coating machine. Unlike Example 2, refer to Figure 4 and Figure 5 , the drive assembly 73 includes a second reciprocating screw 735, a sliding block 732 and a driving motor 736, the sliding block 732 is slidably connected to the top surface of the sliding seat 62, the sliding block 732 moves in the same direction as the conveyor belt 2, and the second reciprocating screw 735 The length direction of the second reciprocating screw 735 is the same as the moving direction of the sliding block 732. The two ends of the second reciprocating screw 735 are rotatably connected to the top surface of the sliding seat 62. 735 is used to drive the sliding block 732 to slide, the driving motor 736 is installed on the top surface of the sliding seat 62, the driving motor 736 is located on the side of the sliding block 732 away from the partition 12, and the second reciprocating screw 735 is coaxially and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com