Wall climbing robot with V-shaped permanent magnet chain sheets buffered by elastic steel sheets

An elastic steel sheet and robot technology, which is applied in the field of climbing arm robots, can solve the problems of inflexible robot movement and climbing, and achieve the effects of increasing the scope of application, being convenient and quick to use, and ensuring comprehensiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

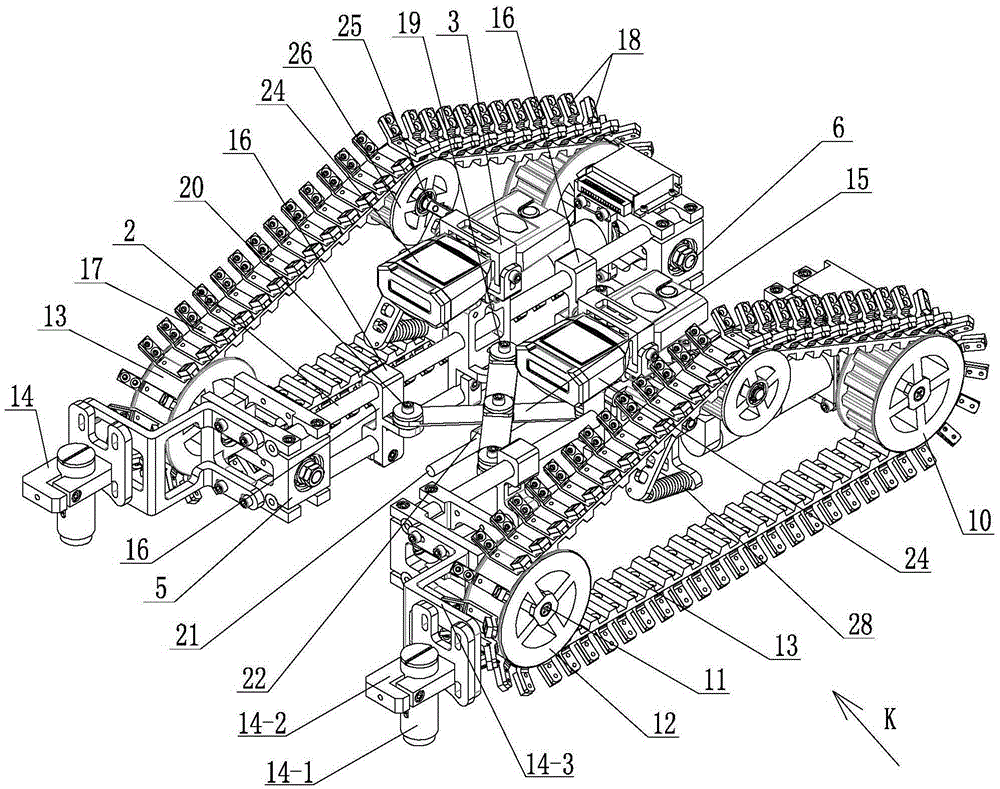

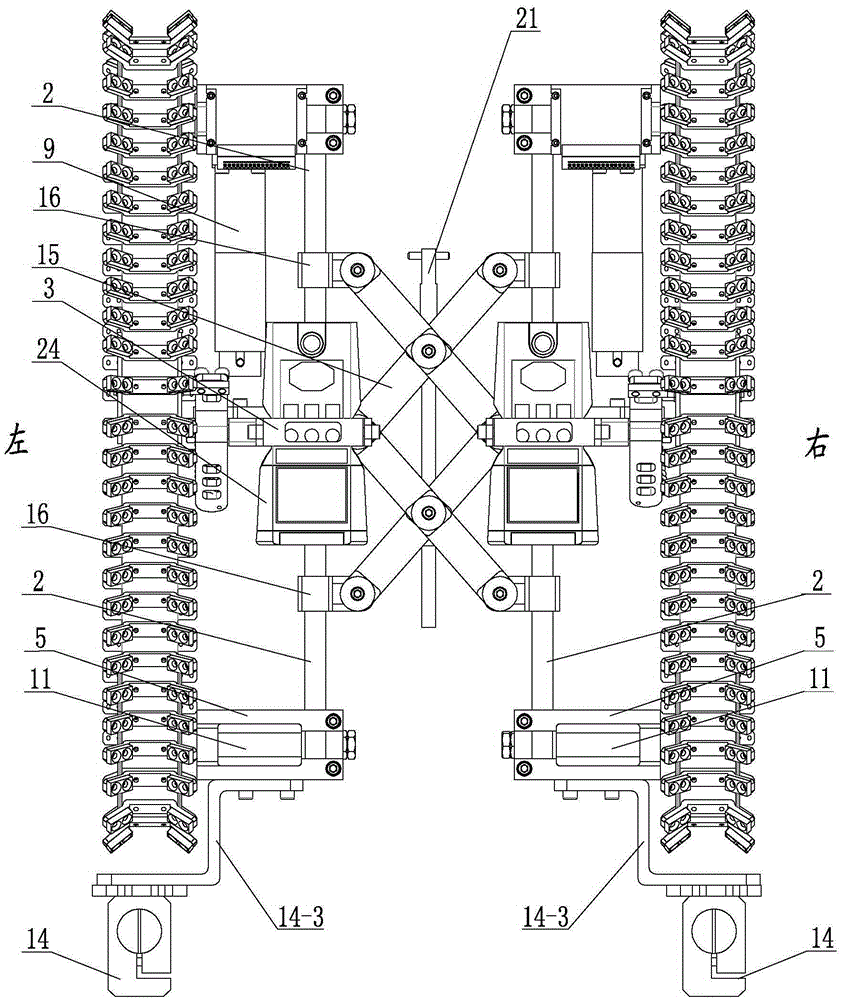

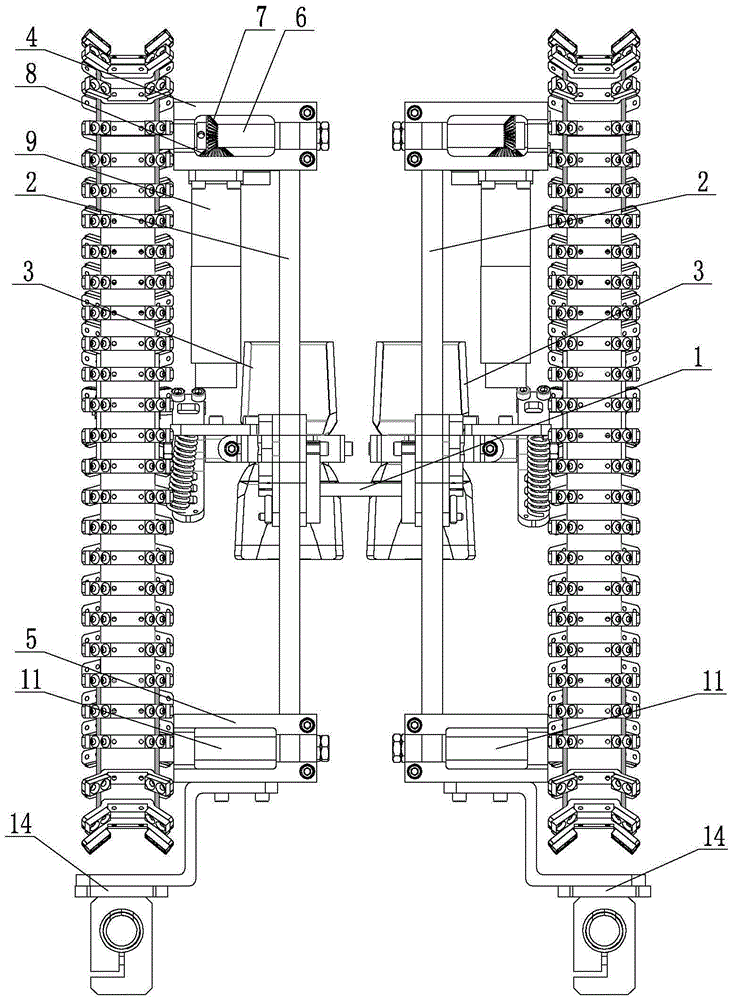

[0019] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, this embodiment includes connector 1, elastic steel sheet buffer connection mechanism 15, two connecting rods 2, two main frame bodies 3, two driving wheel fixing frames 4, two driven wheel fixing frames 5, Two driving shafts 6, two driven bevel gears 7, two driving bevel gears 8, two driving motors 9, two driving trapezoidal pulleys 10, two driven shafts 11, two driven trapezoidal pulleys 12, Two trapezoidal synchronous belts 13, two probe support mechanisms 14, two first pins 19, four fixing parts 16, four second pins 20, several V-shaped brackets 17 and several magnetic blocks 18, two connected The rods 2 are arranged in parallel, and each connecting rod 2 is installed on its corresponding main frame body 3, and the two main frame bodies 3 are connected by a connecting piece 1, and one end of each connecting rod 2 is fixedly equipped with a driving wheel fixing frame 4, The oth...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 2 The present embodiment will be described. The drive motor 9 of the present embodiment is a DC servo motor. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination Image 6 Describe this embodiment, the V-shaped bracket 17 of this embodiment includes a bottom plate 17-1 and two side plates 17-2, and the two side plates 17-2 are V-shaped and arranged at both ends of the bottom plate 17-1, and the bottom plate 17-1 1 and two side panels 17-2 are made into one. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com