Deep building pit trussed-beam inner support integral application pre-stress method

A truss-type, prestressed technology, applied in the engineering field, can solve the problems of small influence range (generally about 5-6m, poor integrity of prestressing, inability to apply prestressing, etc.), and achieves wide application range, long installation time, The effect of large compression deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

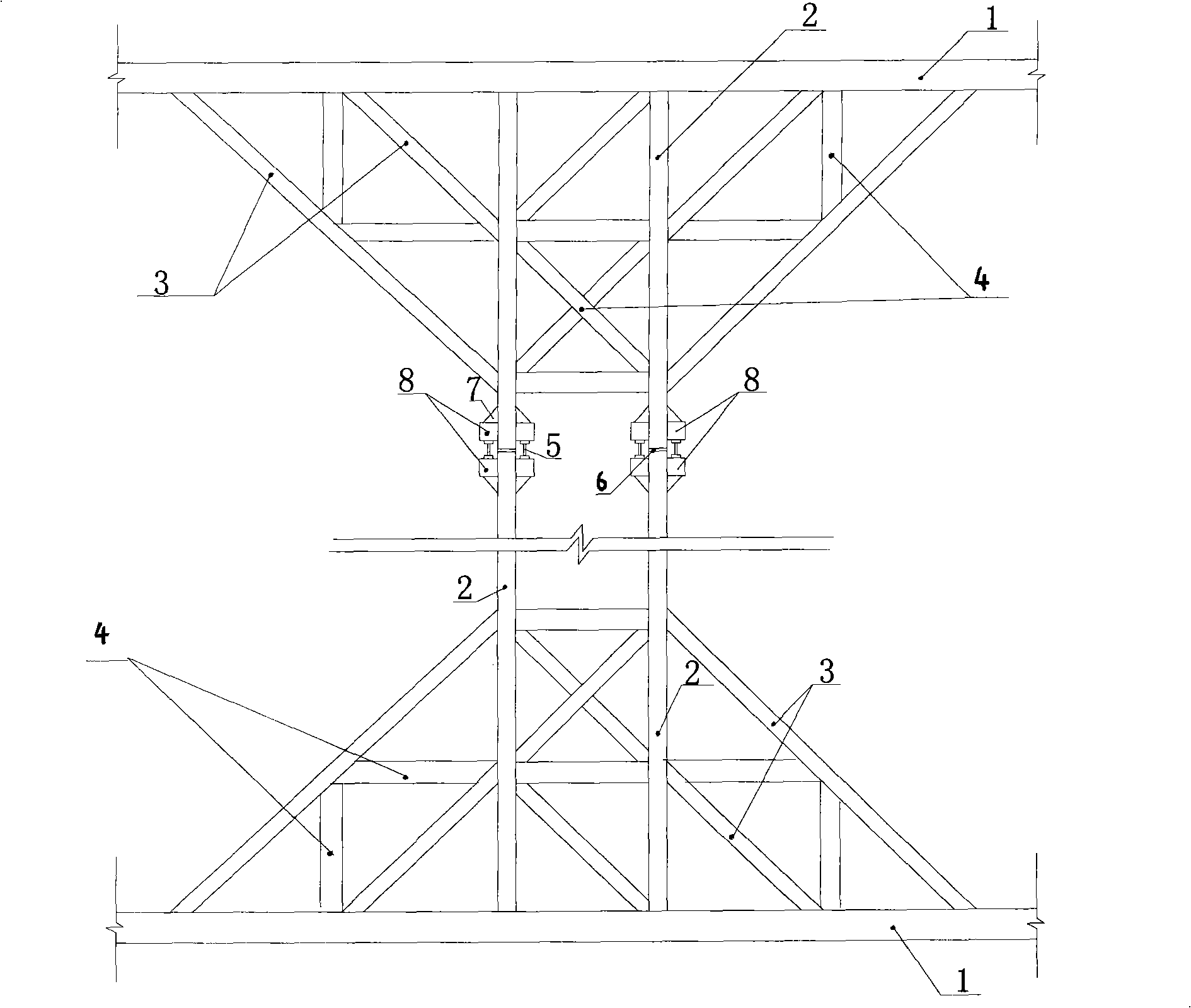

[0032] Embodiment 1: see figure 1 . This embodiment includes the following steps: (1) install the crown beam or waist beam 1 in the deep foundation pit, install the main top strut 2, the diagonal bar 3 and the web bar 4 to form a truss-type internal support, and install the above-mentioned truss-type internal support Installed between two opposite pit walls in the deep foundation pit; (2) On each main top strut 2, a prestressed force transmission seat is installed along the axial direction of the main top strut 2, and the prestressed force transmission seat It is composed of corbels 8 and stiffeners 7 welded on both sides of the main top strut 2; (3) a jack 5 or Jack group, and apply a certain prestress first or not apply prestress first, apply a certain prestress first to avoid the phenomenon of sudden increase in deformation after cutting off the main top strut; (4) Cut off each main top strut The main top strut 2 between the corbels 8 on both sides is prestressed with the...

Embodiment 2

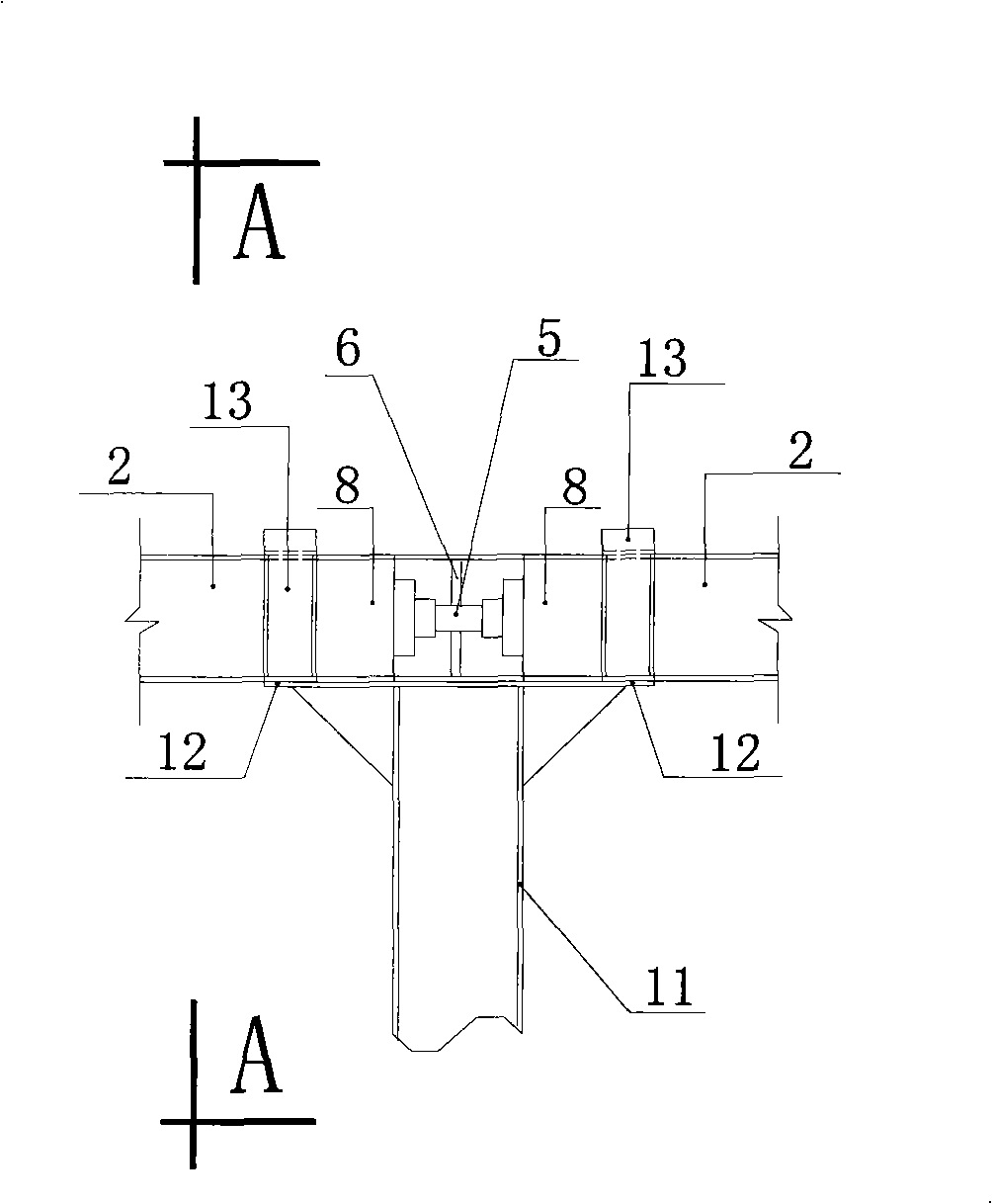

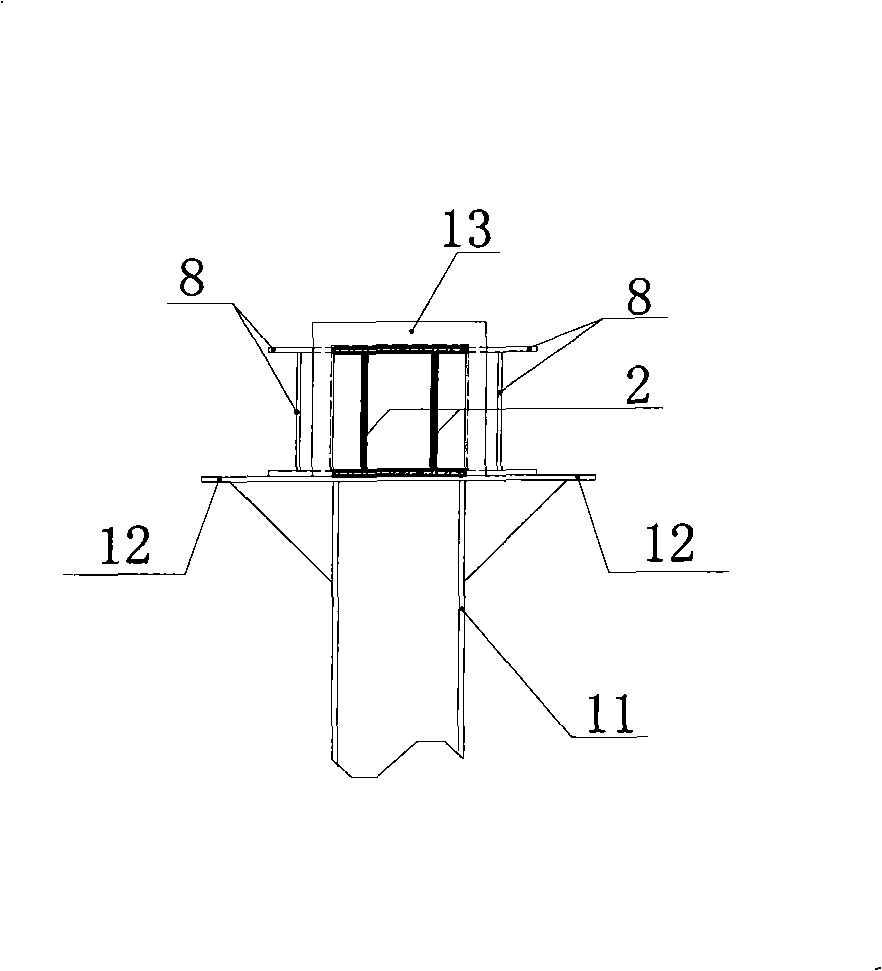

[0033] Example 2: see figure 1 , figure 2 and image 3. The steps of this embodiment are basically the same as those of Embodiment 1, the difference being that for a foundation pit with a large span, it is necessary to install the truss-type internal support described in step (1) of Embodiment 1 before connecting with each main support. Set the column 11 fixed in the column pile below the bottom surface of the deep foundation pit at the corresponding place where the jack is installed on the pole 2, set the tray 12 on the upper end of the column 11, the tray 12 and the column 11 are welded firmly, and set the fixture 13 at each column tray Before the overall prestressing of the truss-type inner support in Embodiment 1, the main top struts 2 at both ends of the jack 5 are respectively fixed on the pallet 12 with the fixture 13, so as to prevent the truss-type inner support from bulging upwards.

Embodiment 3

[0034] Embodiment 3: see figure 1 and Figure 4 , this embodiment is realized on the basis of embodiment 1 or embodiment 2, and its steps are basically the same as embodiment 1 or embodiment 2, the difference is that two or more roots in the above two embodiments Corbels 9 are arranged at the connection between the main top brace 2 and the crown beam or waist beam 1, and the corbel 9 is welded to the crown beam or waist beam 1 or the vertical structure 14 of the foundation pit. Two or more main top braces 2 The ends are respectively placed on the corbels 9, and a gap 10 of about 1 cm is maintained with the crown beam or the waist beam 1. The purpose is to ensure that the two or four oblique rods 3 are stressed first and gradually increased when the prestress is applied. , and then according to the size of the force monitoring results at these two or four inclined bars 3 places, determine the timing of closing the gap between two or more main top struts 2 and the crown beam or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com