Super-small resonant cavity

A resonant cavity and ultra-small technology, applied in the field of resonant cavity, can solve the problem of resonant cavity miniaturization and resonant cavity cannot be processed and manufactured, and achieve the effect of easy manufacture and wide application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

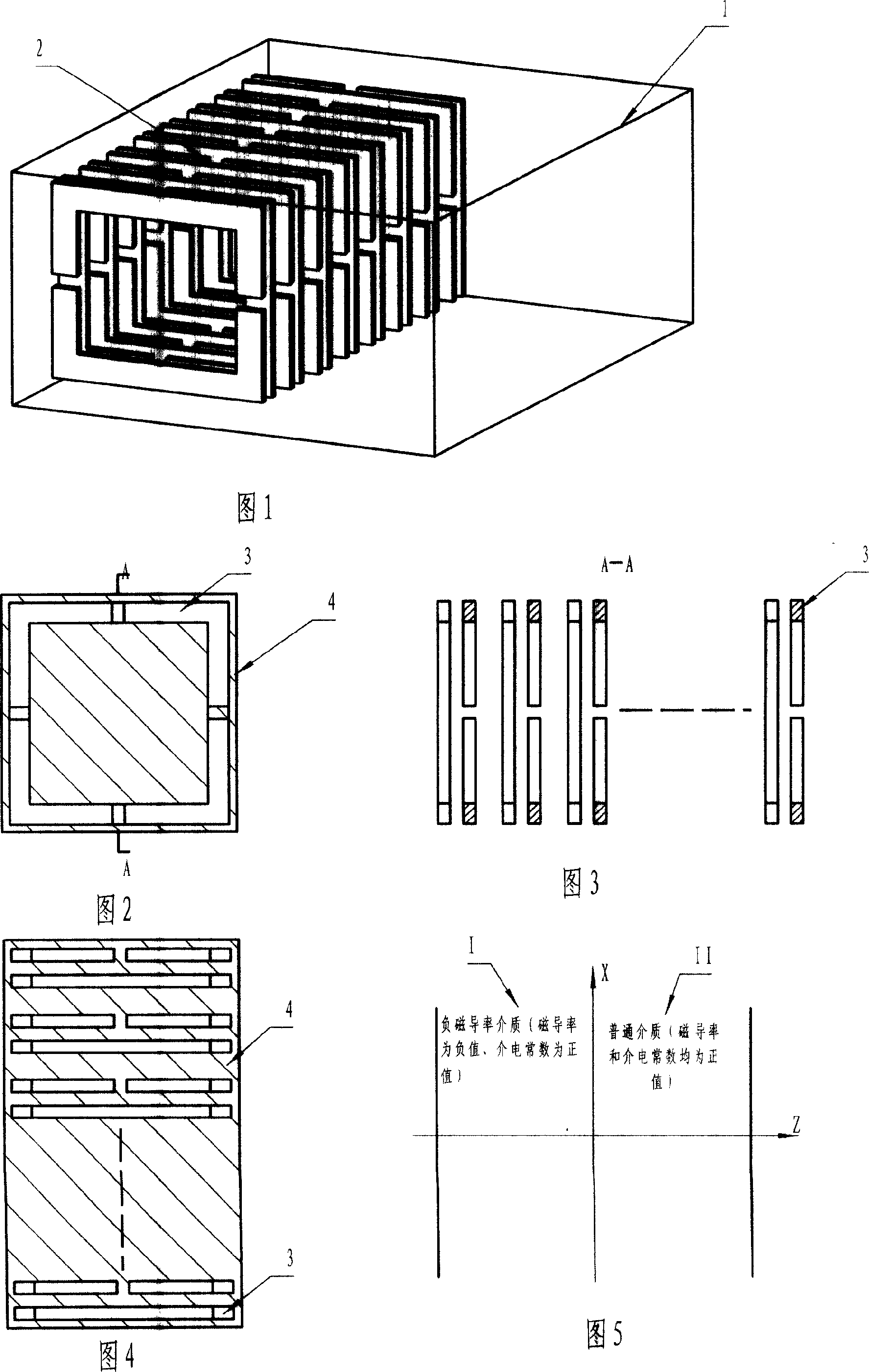

[0009] Specific Embodiment 1: Referring to FIG. 1 , in this embodiment, there is a negative magnetic permeability medium 2 occupying the space on the left side in the cavity of the micron-wave or millimeter-wave resonant cavity 1 .

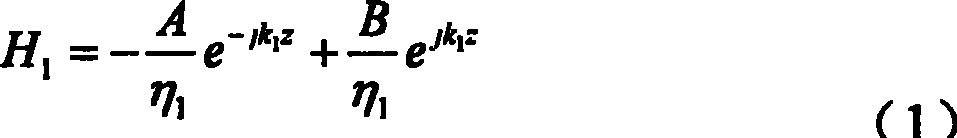

[0010] The theoretical derivation used to determine the above design is as follows:

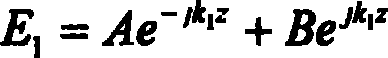

[0011] According to the electromagnetic field theory, the ultra-small resonant cavity will have the same resonance characteristics as the electromagnetic equivalent diagram shown in Figure 5

[0012] Region II in Fig. 5 describes the resonant cavity filled with common medium, and region I describes the resonant cavity filled with negative permeability medium, and the total thickness of the two regions is much smaller than half the working wavelength. Suppose there is a current source in X direction between I and II (Z=0), and its surface current density is J s (x, y, z) = I 0 δ(z), then the electromagnetic fields generated by the current source in region I and ...

specific Embodiment approach 2

[0026] Specific embodiment 2: With reference to Fig. 2, Fig. 3 and Fig. 4, the difference between this embodiment and specific embodiment 1 is that the negative magnetic permeability medium 2 is embedded between the non-magnetic fillers 4 by multi-layer alternate grids 3 The grid 3 is a sheet-shaped frame made of conductive material with at least two fractures, the fractures of each grid 3 and the fractures of the adjacent grid 3 are arranged in a staggered manner, and the other composition and connection relationship are the same as the specific embodiment One is the same. According to tests, this structure can produce one-dimensional negative magnetic permeability in the front and rear directions, and has a simple structure and is easy to manufacture.

specific Embodiment approach 3

[0027] Specific embodiment three: with reference to Fig. 2 and Fig. 4, the difference between this embodiment and specific embodiment one and two is that the non-magnetic filler 4 is a Teflon material, and other composition and connection relations are the same as those of specific embodiment one and two same. Teflon material has excellent anti-aging properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com