A coaxial unmanned helicopter main transmission structure

A technology of unmanned helicopter and main transmission, which is applied in the field of aircraft, can solve the problems of long main transmission chain, large volume and mass, unstable transmission, etc., and achieve the effect of short transmission chain, small size and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

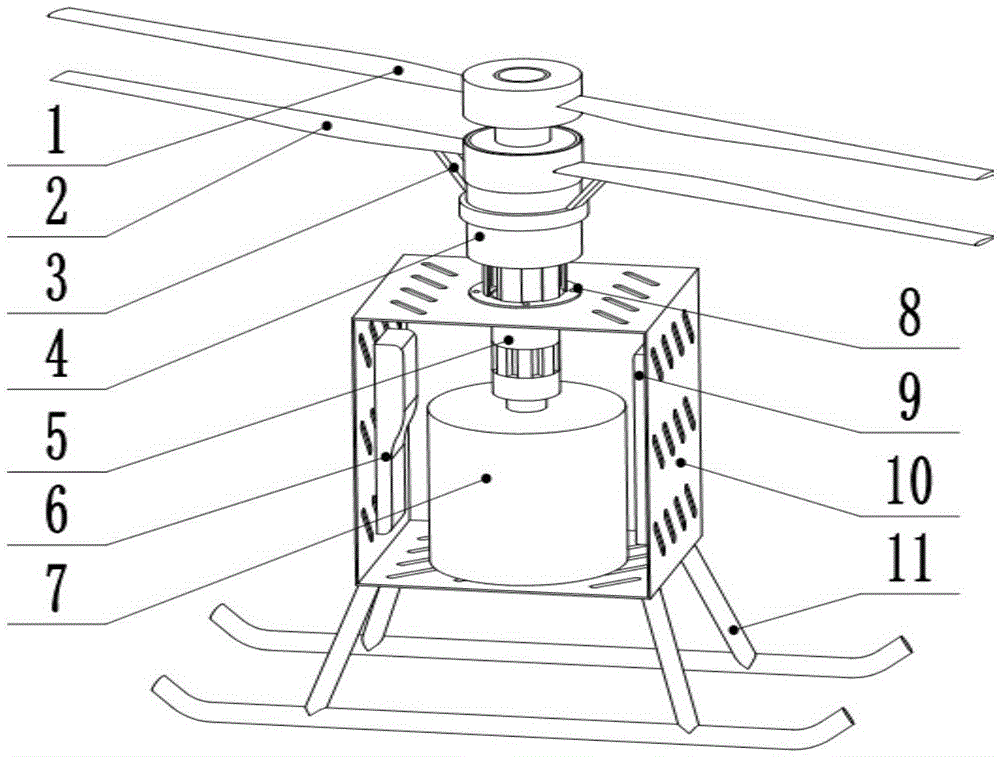

[0040] See attached figure 1 And attached figure 2 , a coaxial unmanned helicopter main transmission structure of the present invention includes an upper rotor mechanism 1, a lower rotor mechanism 2, a variable distance control mechanism 3, a same-speed reversing mechanism 4, a plum-shaped coupling 5, a brushless ESC 6. Brushless motor 7, battery 9, main support frame 10 and landing gear 11;

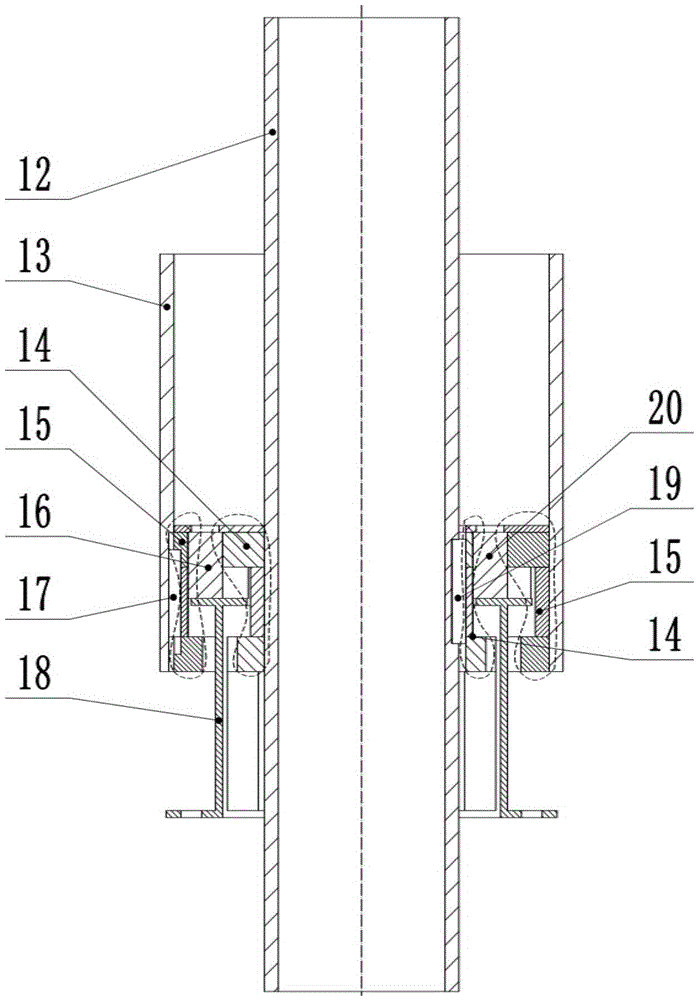

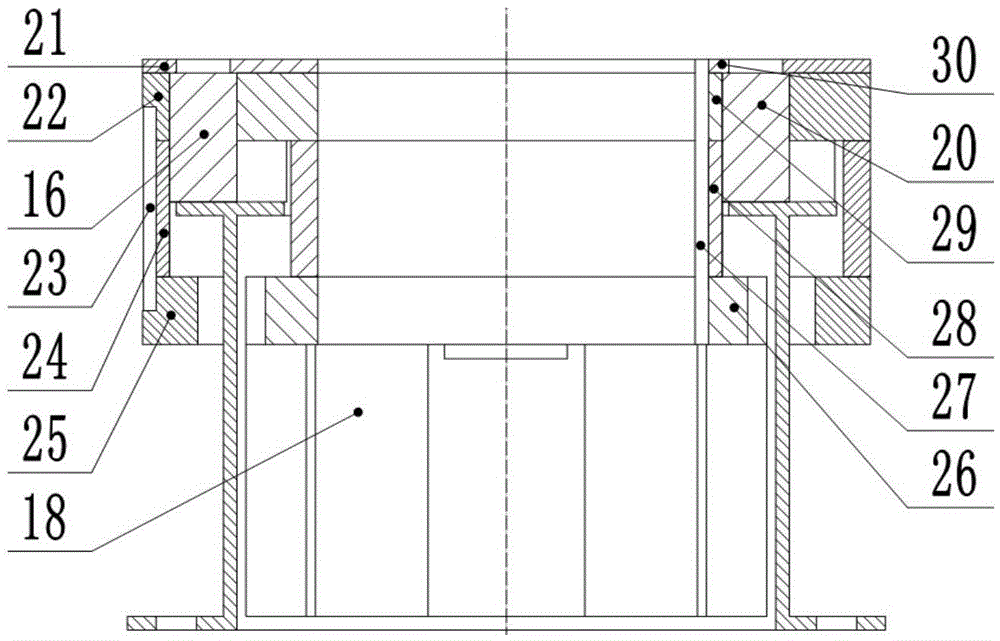

[0041] The same-speed reversing mechanism 4 includes an inner shaft 12, an outer shaft 13, an inner sleeve assembly 14, an outer sleeve assembly 15, and a transmission bracket 18; The outer sleeve assembly 15 is fixedly connected to the outer shaft 13, the inner sleeve assembly 14 is fixedly connected to the inner shaft 12, and a transmission bracket 10 is positioned between the inner sleeve assembly 14 and the outer sleeve assembly 15. Rollers, the inner sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com