Support tool structure for painting inner wall of gyration shell

A supporting structure and the technology of the inner wall of the shell, which is applied in the field of supporting tooling structure painted on the inner wall of the rotary shell, can solve the problems of uneven paint film thickness, radome falling, and serious occupancy of personnel, so as to improve the uneven thickness and lighten the Labor intensity, the effect of avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

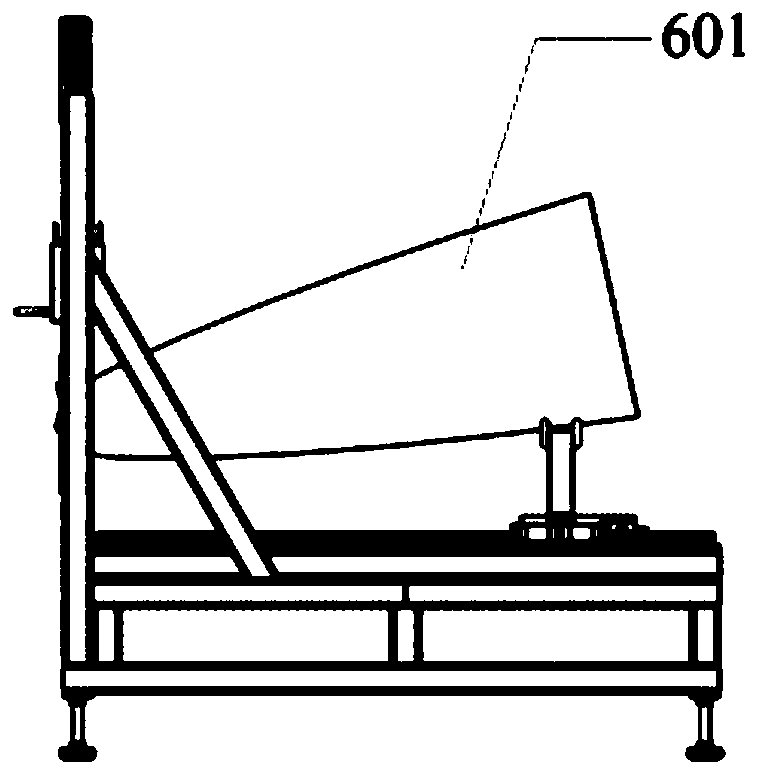

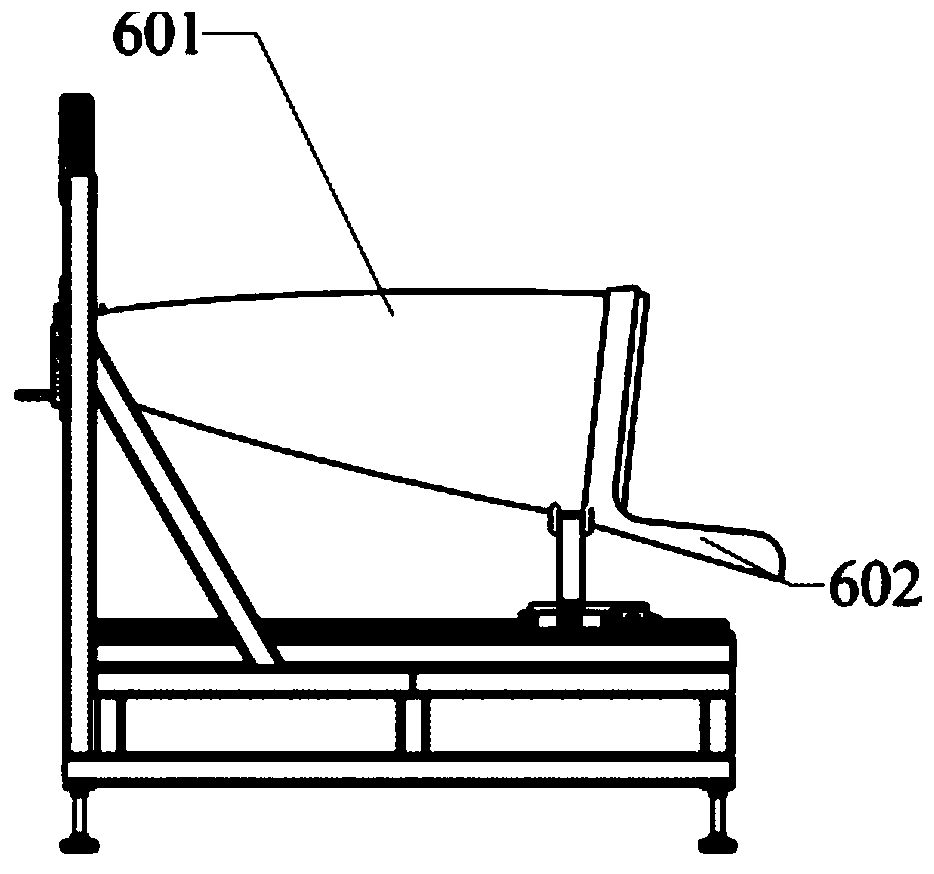

[0031] Such as figure 1 In the shown embodiment of the supporting tooling structure for painting the inner wall of the rotary housing, the supporting tooling structure includes a supporting frame 1, a horizontal guiding supporting structure 2, a vertical guiding supporting structure 3, and a lifting assembly 4 And protective net 5.

[0032] The support frame 1 includes a base and a mullion welded by a rectangular tube 101, the mullion is located at one end of the base, and the overall shape is "L" shaped, and height-adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com