Method for preparing HA-containing biological composite film layer through ultrasonic-assisted titanium alloy micro-arc oxidation hydro-thermal treatment

A bio-composite membrane, micro-arc oxidation technology, applied in coatings, surface reaction electrolytic coatings, electrolytic coatings, etc., to achieve the effect of improving corrosion resistance and wear resistance, improving corrosion resistance, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

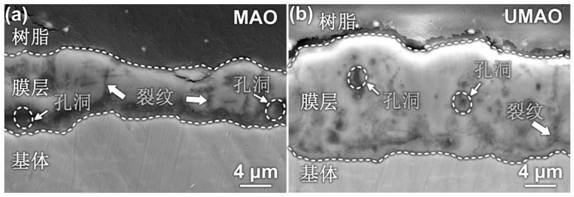

Image

Examples

Embodiment approach 1

[0027] First, the preparation of the electrolyte: 6g / L sodium silicate, 1 g / L of calcium acetate, 0.8 g / l sodium sodium hydrogen sodium, 0.55 g / L sodium hydrogen phosphate, 3 ml / L propanol and 5 ml / L lactate, sodium In turn, poured into the deionized water to obtain an electrolytic solution.

[0028] Second, the preparation of the hydrothermal solution: 0.839 g / l NaOH was limited to dissolve in deionized water, the pH is 9, and then ultrasonic treatment for 30 min, resulting in a hydrothermal solution.

[0029]Third, the preparation of the micro-arc oxide film layer of ultrasound synergies: pretreatment (400 #, 800 #, 1000 # and 1500 # sandpaper water rubbing, using a titanium alloy material, then use acetone, alcohol and deionized water The titanium alloy of the sample was easily cleaned by the sample, and then the preparation) was placed in the electrolyte as an anode, the stainless steel plate was used as the cathode, and the micro-arc oxidation treatment was 15 m...

Embodiment approach 2

[0043] The present embodiment differs from the first embodiment that the electrolyte in the step one is from the concentration of 8 g / L sodium silicate, 2 g / L acetate, 1.5 g / L hexaposphatsolate solution, 1 g / L sodium dihydrogen phosphate Solution, 3 g / L sodium hydroxide, 3 ml / L propanol and 8 ml / L sodium lactate. Other parameters are identical to the implementation.

Embodiment approach 3

[0045] The present embodiment differs from the first embodiment to the electrolyte in the steps from the concentration of 10 g / L sodium silicate, 5 g / L acetate, 2 g / l hexagonophosphate solution, 4g / L phosphate dihydrogen sodium hydrogen sodium hydrogen sodium hydrogen phosphate solution, 5g / L sodium hydroxide, 2 ml / L propanol and 4.5 ml / L sodium lactate. Other parameters are identical to the implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com