Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

161results about How to "Improve transfer effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing metallic high temperature transfer base paper

ActiveCN101255662AImprove high temperature resistanceHigh strengthNatural cellulose pulp/paperWax additionFiberExtremely good

The invention discloses the production method of a metal high temperature transfer printing base paper, including to use 50-70% blanching needle wood-pulp and 30-50% blanching broad-leaf wood-pulp to be the raw material, which is pulped by a pulper, then is added by beating with chemical auxiliary materials: 1-4% a wet strength agent, 1-3% a high temperature resistance agent, 1- 4% starch, 2-4% aluminum sulfate, 1.0-2.5% a rosin milk, 0.1-1.5% a remover, and 0.03 -0.1% a retention agent to make into a slurry; after making, the slurry is rewound to be the base paper when passing through a rewinder. The transfer printing base paper produced by the method has the advantages of extremely good high temperature resistance, being able to satisfy the request of the metal high temperature transfer printing, fine superficial smoothness, and full patterns, bright color and good transfer printing effect after printed. The intensity of the paper is very high, which can satisfy the need of the transfer printing, and the paper is crispness, is not coking and has good stripping paper effect after transfer printed on metal; the waste paper can be recycled to be used as secondary fiber, which saves resources and protects environment.

Owner:HUANGSHAN XINLONG SPECIALITY PAPER

Azo dye, heat-sensitive transfer recording ink sheet, heat-sensitive transfer recording method, color toner, inkjet ink and color filter

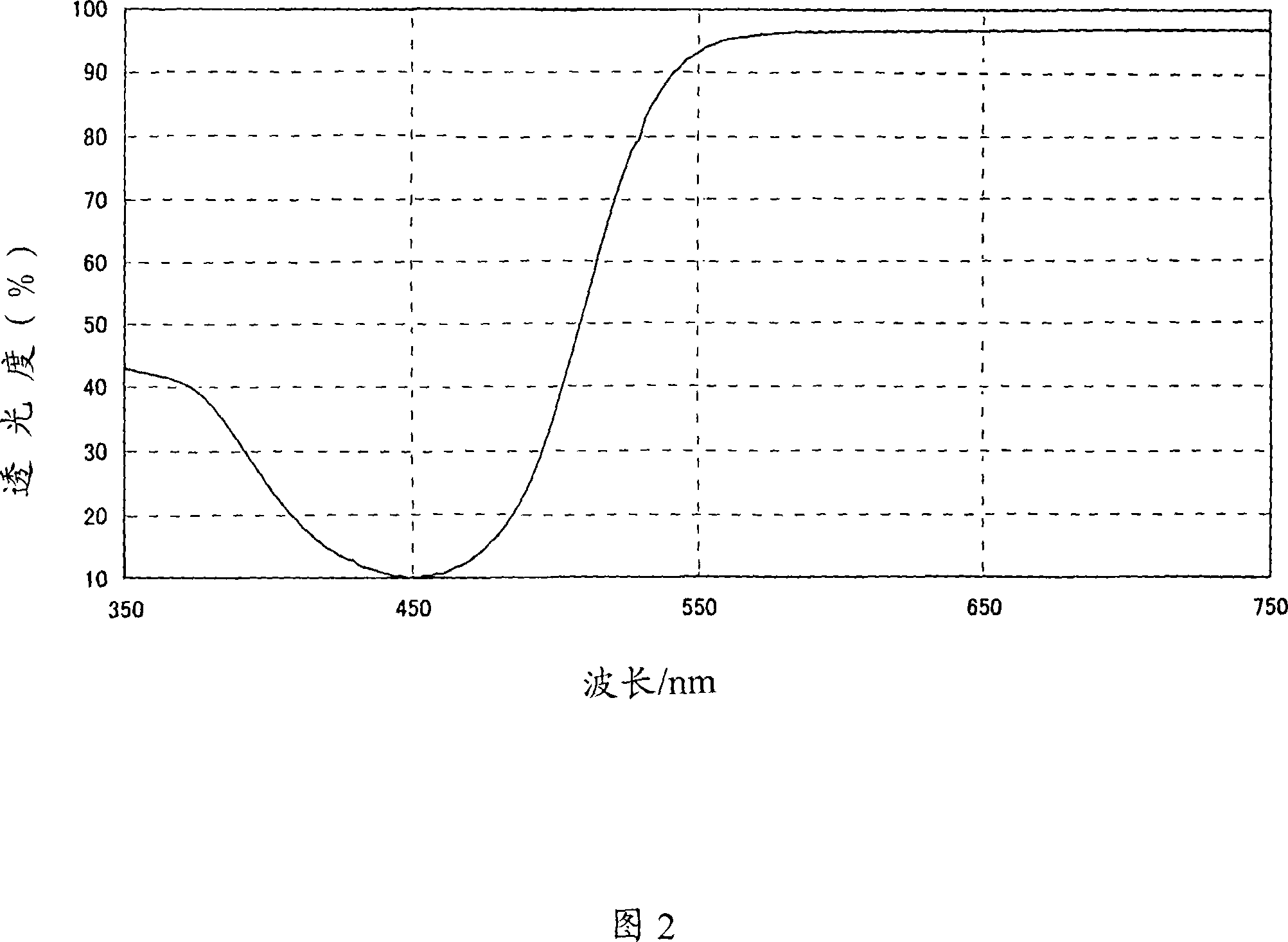

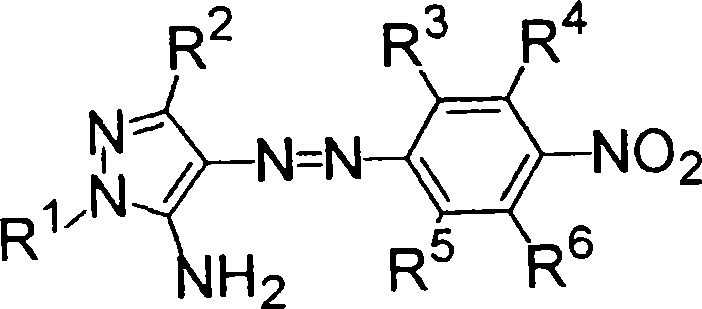

InactiveCN101096455AImprove solubilityHigh fastnessMonoazo dyesOrganic chemistryHydrogen atomColor gel

Owner:FUJIFILM CORP

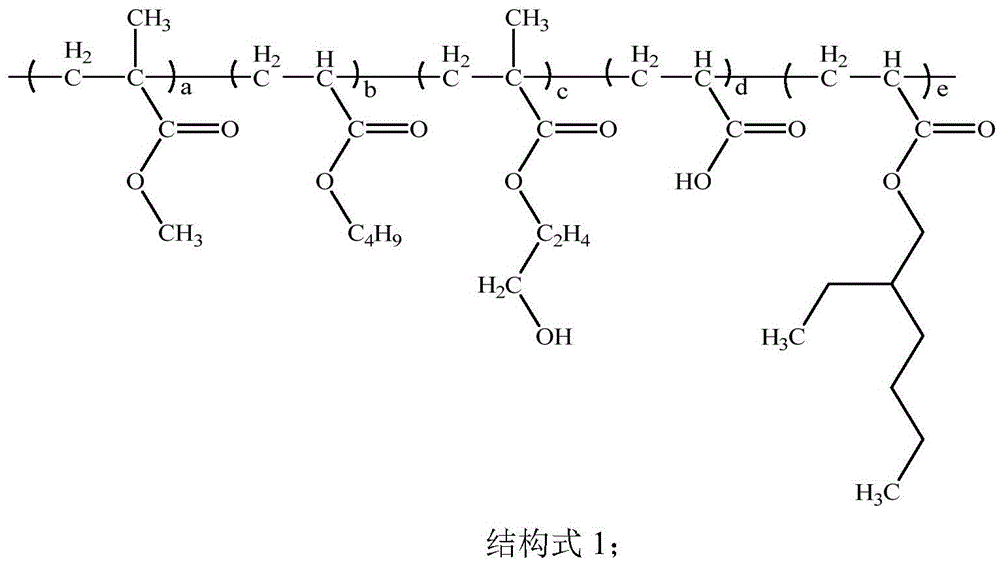

Ultraviolet light curing transfer printing glue and preparation method and application thereof

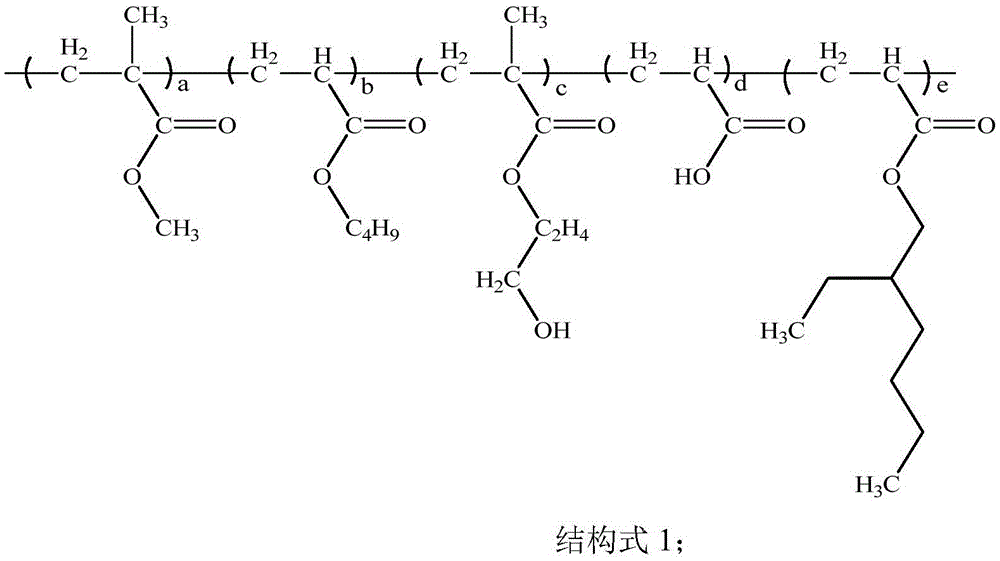

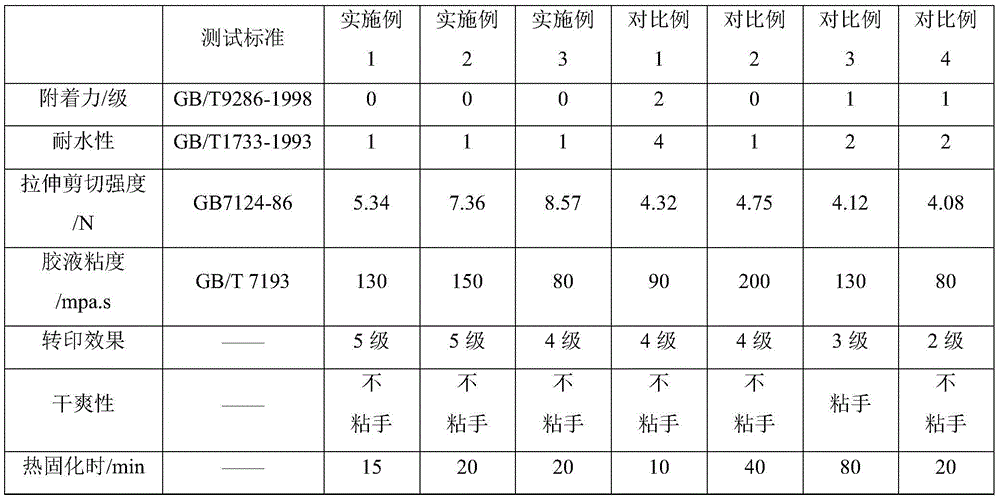

ActiveCN105602515AHigh glass transition temperatureHigh tensile shear strengthDuplicating/marking methodsPolyureas/polyurethane adhesivesIsooctyl acrylateUltraviolet lights

The invention discloses an ultraviolet light curing transfer printing glue composition for a transfer printing film. The ultraviolet light curing transfer printing glue composition comprises the following components in parts by weight: 20-40 parts of modified acrylate, 20-40 parts of epoxy resin, 10-30 parts of reactive diluent, 3-8 parts of photoinitiator, 5-15 parts of adhesion promoter, 2-5 parts of silane coupling agent and 0-1 part of auxiliary, and the modified acrylate is prepared by modifying pentapolymer prepared from methyl methacrylate (MMA), n-butyl acrylate ((i)n( / i)-BA), hydroxypropyl methacrylate (HMPA), acrylic acid (AA) and 2-ethylhexyl acrylate (EHA) through free radical copolymerization by using polyurethane containing isocyanato. The prepared ultraviolet light curing transfer printing glue has good adhesion to a glass base material, and is good in water resistance, high in tensile strength and excellent in transfer printing effect.

Owner:GUANGDONG UNIV OF TECH

Manufacturing method for polyacrylic acid (salt) -based water-absorbent resin powder

Owner:NIPPON SHOKUBAI CO LTD

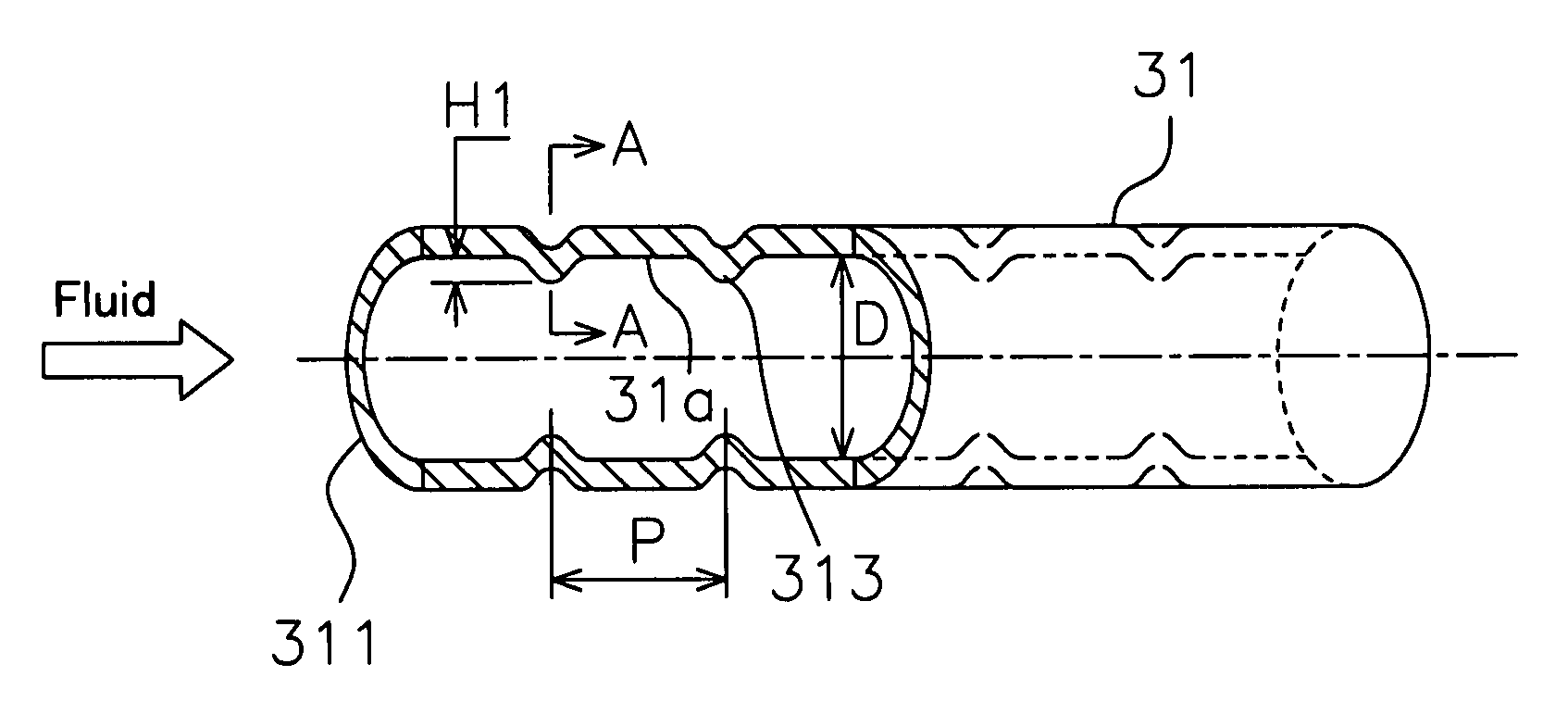

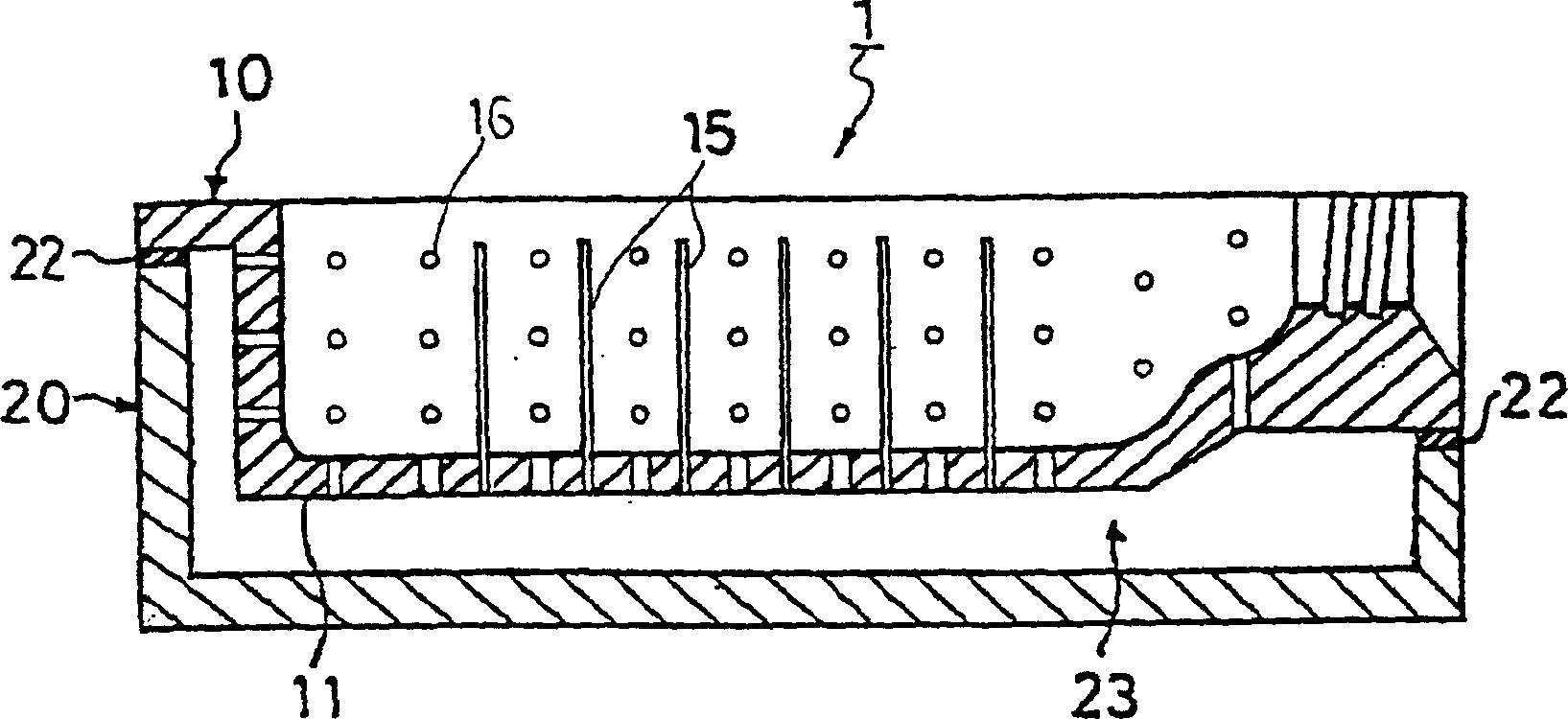

Hot Water Heat Transfer Pipe

ActiveUS20080149309A1Reduce heat transferImprove transfer effectStationary tubular conduit assembliesRigid pipesEngineeringThermal water

The present invention relates to a hot water heat transfer pipe that exchanges heat between its interior and exterior. A plurality of projections, each having a height in the range of 0.8-2.0 mm or 0.1-0.25 times the inner diameter, is provided in at least one part of an inner surface of a portion of the heat transfer pipe positioned in a section where the Reynolds number of the fluid flowing in the interior is less than 7,000 to improve the heat transfer performance in the low Reynolds number zone, and minimize pressure loss inside the pipe.

Owner:TSINGHUA UNIV +1

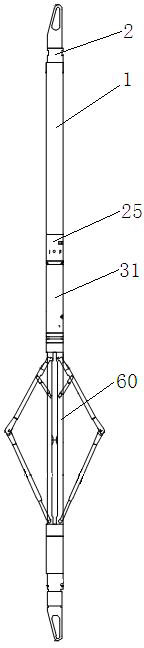

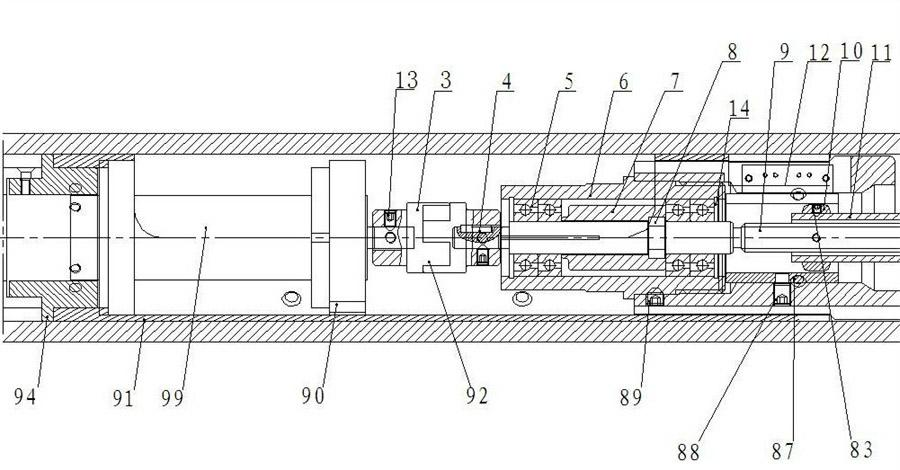

Horizontal well dual caliper

The invention provides a horizontal well dual caliper which is used for fundamentally solving the problem that the existing logging instrument can not move up and down for repeated measurement due to structural limit during the operating process. The horizontal well dual caliper comprises a cylindrical matrix as well as an upper joint and a lower joint, and the horizontal well dual caliper further comprises a drive motor, a drive assembly, a hydraulic balance assembly, a sensor assembly, a measurement assembly and a vacuum damping assembly which are sequentially assembled in the cylindrical base. In the invention, after the horizontal well dual caliper is lowered into a well, a sidewall contact device pushes away measuring arms of the caliper, then four measuring arms of the caliper are freely shrunk and expand with change of borehole diameter, and four logging support arms independently drive a potentiometer to move, thus achieving good transfer effect and accurately reflecting change of well wall diameter; and the caliper can be lowered to measure dual-borehole diameter and average borehole diameter, can be singly used and can be also connected with other instruments in series. The horizontal well dual caliper can operate steadily so as to ensure measurement stability and reliability.

Owner:沈阳新锦精密仪器仪表研究所

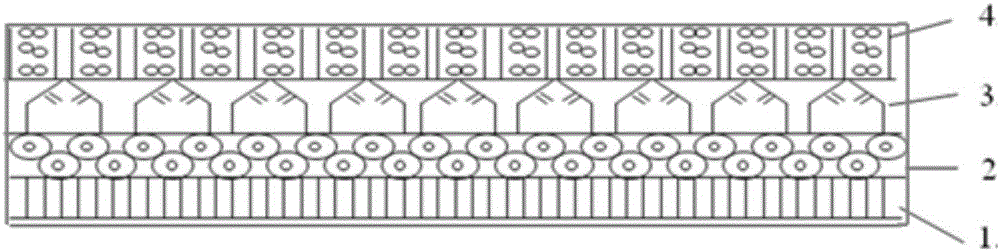

Composite membrane quick-drying type dye-sublimation transfer printing digital paper

ActiveCN103381721AGood transfer effectStrong water permeabilitySynthetic resin layered productsCellulosic plastic layered productsIonInterpenetrating polymer network

The invention belongs to the field of transfer printed paper and particularly relates to composite membrane quick-drying type dye-sublimation transfer printing digital paper which comprises base material paper, a hydrophobic layer coated on the surface of the base material paper and an ink absorption layer coated on the surface of the hydrophobic layer, wherein a surface layer is coated on the upper surface of the ink absorption layer. The ink absorption layer is made of positive ion polyacrylamide cellulose interpenetrating polymer network resin. The surface layer is one or a combination of two of polyvinyl alcohol-vinyl acetate copolymer or polyvinyl butyral or polyvinyl alcohol. The hydrophobic layer is made of organosilicone modified acrylic resin. The composite membrane quick-drying type dye-sublimation transfer printing digital paper is provided with the surface layer which is one or a combination of two of polyvinyl alcohol-vinyl acetate copolymer or polyvinyl butyral or polyvinyl alcohol and can transfer a strong water permeation capability to the ink absorption layer on the condition of normal temperature. The number of intermolecular hydrogen bonds is reduced on the condition of high temperature, the surface layer can provide a large gap, dye molecules quickly and sufficiently sublimate in transfer printing digital paper coating materials, the transfer printing effect is ideal, and the composite membrane quick-drying dye-sublimation transfer printing digital paper has a wide application prospect.

Owner:杭州华大海天科技股份有限公司

Water-based environment-friendly flat pressing resin-based carbon belt and preparing method thereof

The invention belongs to the technical field of hot stamping materials and particularly discloses a water-based environment-friendly flat pressing resin-based carbon belt which is composed of a base film, a back coating and a heat transfer printing layer. The back coating and the heat transfer printing layer are arranged on the two sides of the base film in a coating manner. The back coating comprises water-based acrylic resin. The heat transfer printing layer is divided into two parts. A release layer and an ink layer are sequentially arranged on the surface of one side of the base film from inside to outside. The main raw materials in the ink layer include, by weight percent, 8%-20% of water-based polyolefin, 2%-5% of hydroxyethyl cellulose, 10%-18% of water-soluble carbon black, and 60%-75% of deionized water. The water-based resin-based carbon belt cannot generate toxic and harmful substances in the production and use processes, environment friendliness is achieved, the production cost is low, the use effect is good, and the wide application prospect is achieved.

Owner:ZHUOLI IMAGING TECH

Method for making surface pattern by employing water transfer printing

InactiveCN101181853AUniform thicknessEasy to manufactureDecorative surface effectsPainting preservationSurface patternBiochemical engineering

The invention provides a surface pattern preparation method by adopting water-transferring printing, comprising the steps of step 1: providing the water-transferring printing paper which consists of release paper, hydrosolvent membrane arranged on the release paper and a pattern layer arranged on the hydrosolvent membrane; step 2: PP water is sprayed on the pattern layer to form a PP layer; step 3: goffered glue is glued on the circumferential edges of the PP layer; step 4: the hydrosolvent membrane is separated from the release paper and the hydrosolvent is arranged in the water trough; step 5: activator is added in the water tank and the hydrosolvent is dissolved and the pattern layer is floating in the water; step 6: an article is positioned and contacted with the pattern layer and the pattern is transferred and printed on the surface of the article. The patterns of the water-transferring printing paper made by the invention are clear and smooth and not easy to be diffused in water; furthermore, the patterns has better transfer-printing effect; the patterns on the surface of the article after the transfer-printing is clear and stable, and can fully meet the application requirement of people.

Owner:林其武

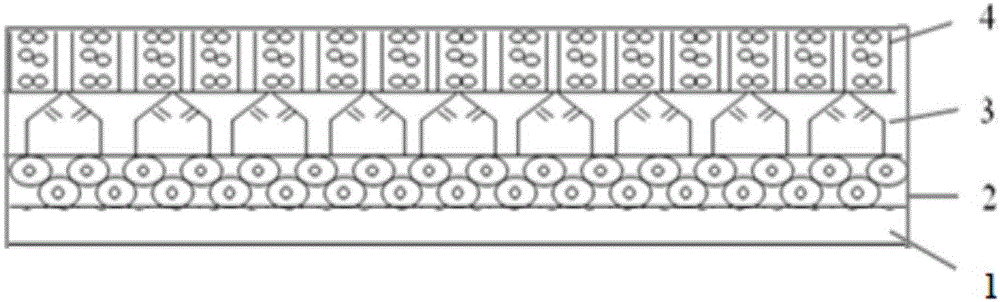

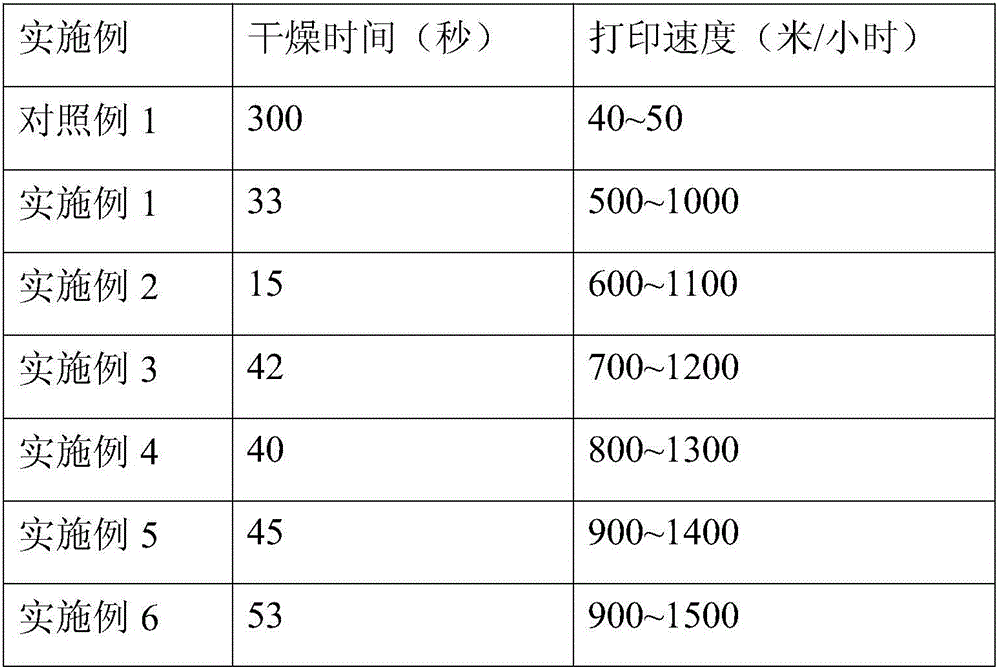

Instant-drying type high-ink-absorption heat sublimation transfer printing digital paper

ActiveCN106245461AIncrease drying speedShorten drying timeSurface covering paperPaper coatingCross-linkCellulose

The present invention relates to the technical field of heat sublimation transfer printing, and discloses instant-drying type high-ink-absorption heat sublimation transfer printing digital paper, which sequentially comprises base paper, a water absorption and water permeation layer, a porous mesh bag layer and a surface channel layer from bottom to top, wherein the porous mesh bag layer is a three-dimensional mesh-bag-like interpenetrating network resin formed by cross-linking cellulose or carboxymethyl cellulose sodium or starch and cation modified polyacrylamide, or a three-dimensional mesh-bag-like interpenetrating network resin formed by cross-linking polyacrylamide or cellulose or carboxymethyl cellulose sodium and cation modified starch so as to significantly increase the ink absorption. According to the present invention, the water permeability is increased by regulating the composition of the resin and controlling the network density, such that the water molecules rapidly enter the water absorption and water permeation layer; and the instant-drying type high-ink-absorption heat sublimation transfer printing digital paper has characteristics of high ink absorption capacity, rapid ink absorption, instant drying after printing, good transfer printing effect and the like, and meets the fast printing and efficient production requirements of various dark fabrics.

Owner:杭州华大海天科技股份有限公司

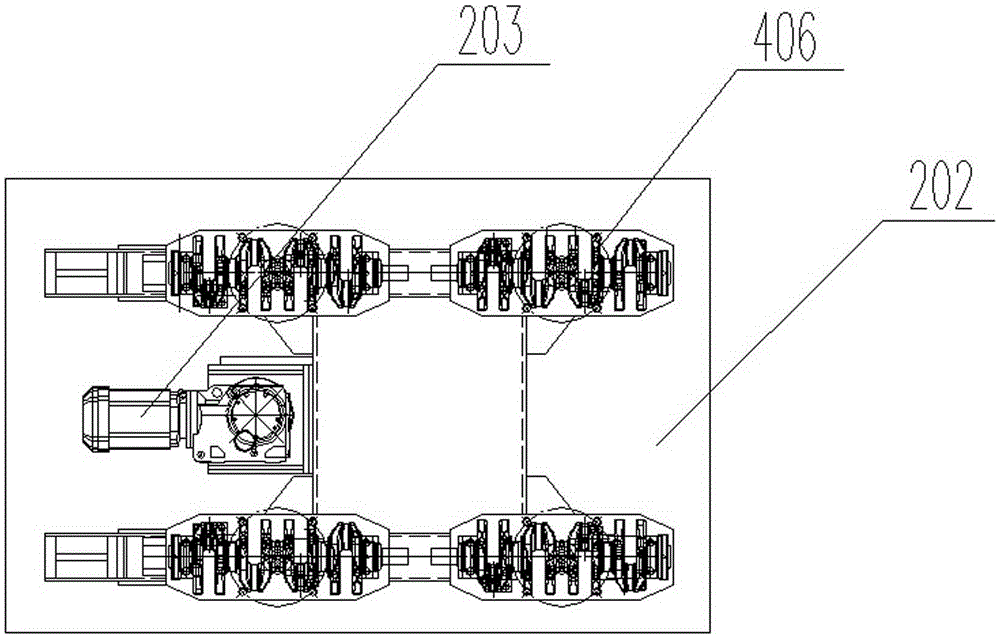

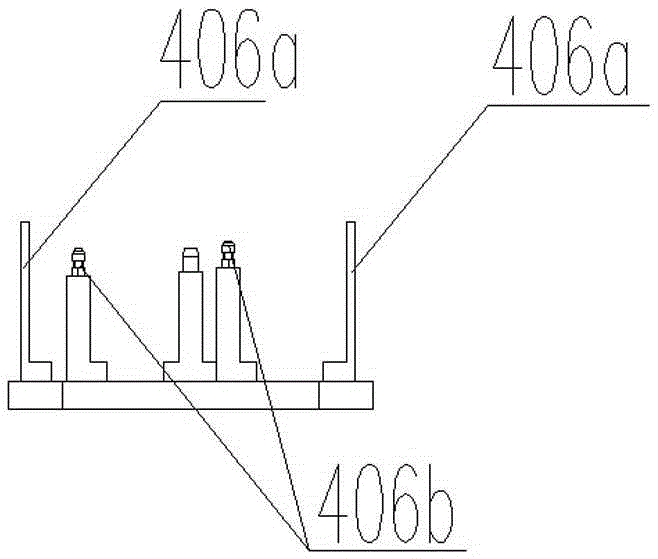

Automatic crank shaft grinding and cleaning machine

ActiveCN105364650ARealize automatic grinding and cleaningReduce labor intensityGrinding carriagesRevolution surface grinding machinesEngineeringUltimate tensile strength

An automatic crank shaft grinding and cleaning machine comprises a rack, a feeding device, a workpiece transfer device, a grinding mechanism and a discharging device, wherein the feeding device, the workpiece transfer device, the grinding mechanism and the discharging device are arranged on the rack; and the workpiece transfer device is erected above the rack through a supporting upright column, and is used for conveying to-be-ground crank shafts conveyed by the feeding device into the grinding mechanism to be ground, and conveying the crank shafts to the discharging device so as to discharge the crank shafts after the crank shafts are ground. According to the automatic crank shaft grinding and cleaning machine, workpieces are fed and discharged by a robot, four crank shaft workpieces can be simultaneously machined at a time, and through a plurality of device components which are matched with one another, the crank shaft workpieces can be ground and cleaned fully automatically, production efficiency is improved, human resources are saved, and labor intensity of operators is also reduced. By the grinding mechanism, linkage of grinding wheels in the X, Y and Z directions can be realized, the crank shaft workpieces move on a main X axis along with the stroke of a sliding table, and through four-axis linkage, the workpieces with different sizes can be ground at various angles along curves of parting faces of the crank shafts.

Owner:AUTOMOTIVE ENG CORP +1

Water-based ink thermal transfer ribbon and preparation method thereof

InactiveCN106085019ASmall finenessImprove transfer effectFireproof paintsInk ribbonsWater basedEpoxy

The invention discloses a water-based ink thermal transfer ribbon which comprises a base, a release layer, an ink layer and a heat resistant coating, wherein one side of the base is coated with the release layer, the outer side of the release layer is coated with the ink layer, and the other side of the base is coated with the heat resistant coating; the ink layer is prepared from the following raw materials in parts by weight: 14-17 parts of waterborne polyurethane resin, 10-15 parts of epoxy resin, 18-23 parts of acrylic resin, 15-20 parts of carbon black, 8-12 parts of copper chromite black, 22-26 parts of kaolin, 9-13 parts of quartz powder, 2-5 parts of diatomite, 5-8 parts of polyethylene wax, 0.7-1.5 parts of polysiloxane defoaming agents and 0.5-1.0 part of chitosan. The invention further discloses a preparation method of the water-based ink thermal transfer ribbon. The prepared thermal transfer ribbon is free from toxic solvents such as methylbenzene and butanone, operating environments can be favorably improved, health of workers is ensured, and environmental protection requirements are met.

Owner:POMA IND SHANGHAI

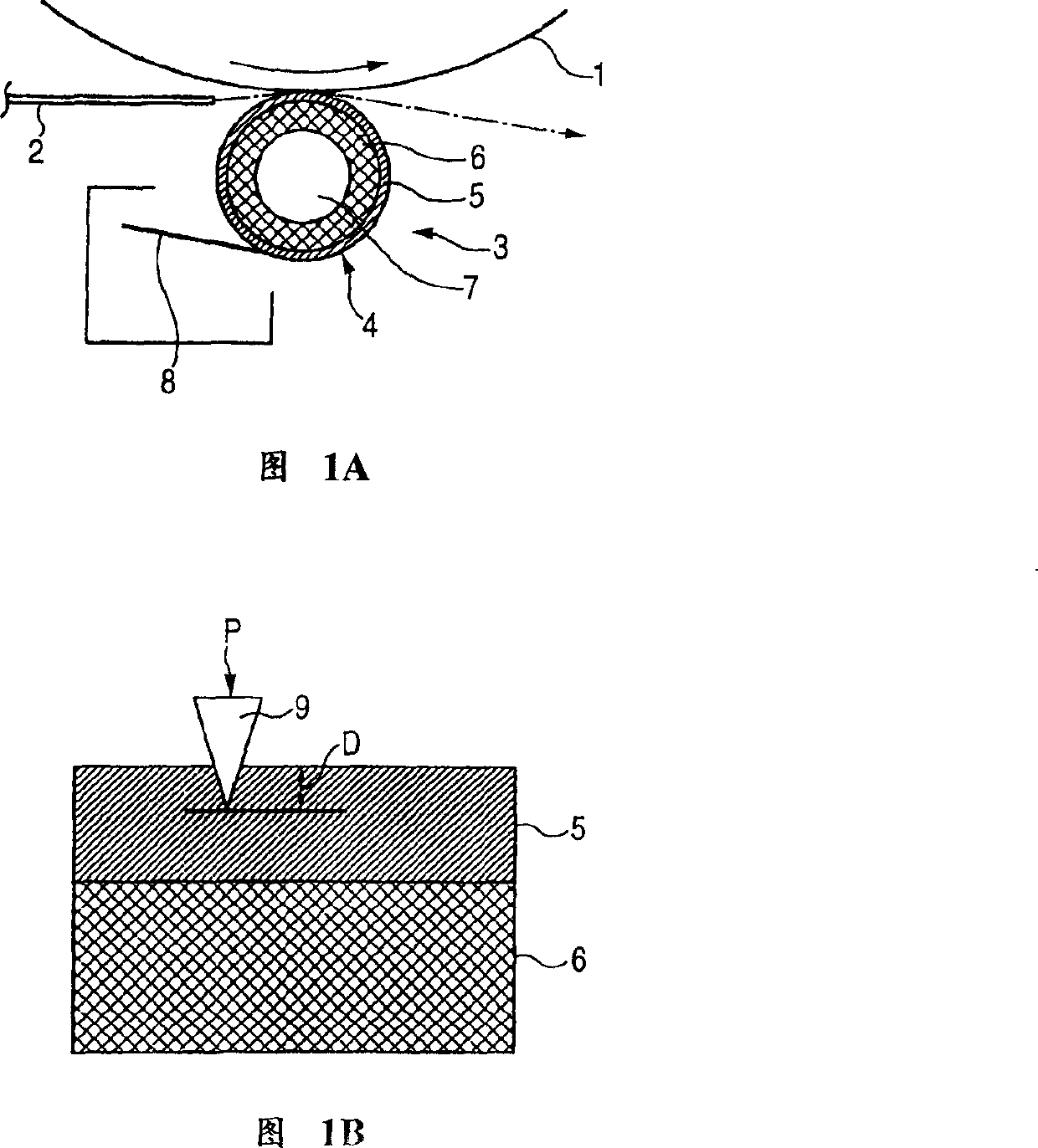

Transfer mechanism, image-forming device using same and method for mfg. transfer device

InactiveCN1360230AImprove transfer effectElectrographic process apparatusElectrical resistance and conductanceEpoxy

A transfer device for transferring an image on an image carrier 1 to a recording material 2, the transfer device comprises a transferring member 4 adapted to nip and convey the recording material 2 between the transferring member 4 and the image carrier 1, a guard resin layer 5 having a surface microhardness not smaller than surface microhardness corresponding to polyimide, the guard resin layer 5 provided on a surface of the transferring member 4, and an adjustment resistance layer 6 provided as a ground layer of the guard resin layer 5, the adjustment resistance layer 6 adapted to inhibit an accumulation of charge in the guard resin layer 5. Or, the guard resin layer 5 made of an epoxy resin is provided on the surface of the transferring member 4, the adjustment resistance layer 6 having a smooth interface with the guard resin layer 5, the adjustment resistance layer 6 adapted to inhibit accumulation of charge in the guard resin layer. Furthermore, a scraper 8 for cleaning is provided on the surface of the transferring member 4 so as to contact with the surface of the transferring member. An image-forming apparatus is constructed by using the transferring device.

Owner:FUJIFILM BUSINESS INNOVATION CORP

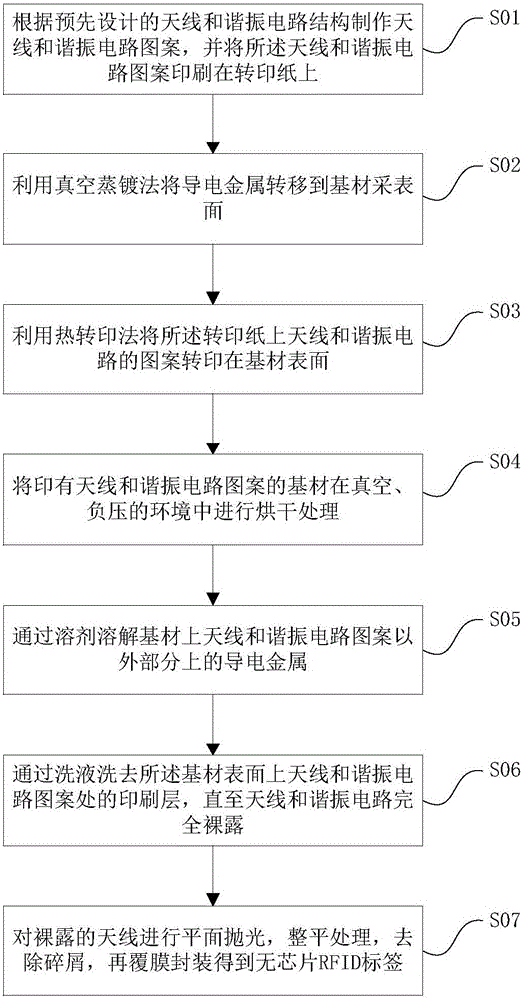

Manufacturing technology of chip-free RFID label

ActiveCN105160381ALow costImprove folding resistanceAntenna supports/mountingsRadiating elements structural formsChipless RFIDManufacturing technology

The invention relates to a manufacturing technology of a chip-free RFID label, which comprises the steps of printing an antenna and a resonance circuit pattern on a piece of transfer paper; transferring a conductive metal onto a base material surface through vacuum vaporization method; transferring the printing of the antenna and the resonance circuit pattern on the transfer paper onto the base material surface; drying the base material with the antenna and the resonance circuit pattern; washing the conductive metal on the base material apart from the antenna and the resonance circuit pattern through a solvent; washing a printing layer on the base material surface apart from the antenna and the resonance circuit pattern through a washing lotion until the antenna and the resonance circuit are fully exposed; and plane polishing and levelling the exposed antenna, removing chips and overlaying film for packaging to obtain a chip-free RFID label. According to the manufacturing technology of the chip-free RFID label, the RFID label cost is greatly reduced; a chip-free RFID label can be obtained; advantages like excellent flexibility resistance and good toughness, low manufacturing cost and simple and good operation technology are provided; and wide application prospect is provided.

Owner:WUHAN WEDO INFORMATION & TECH

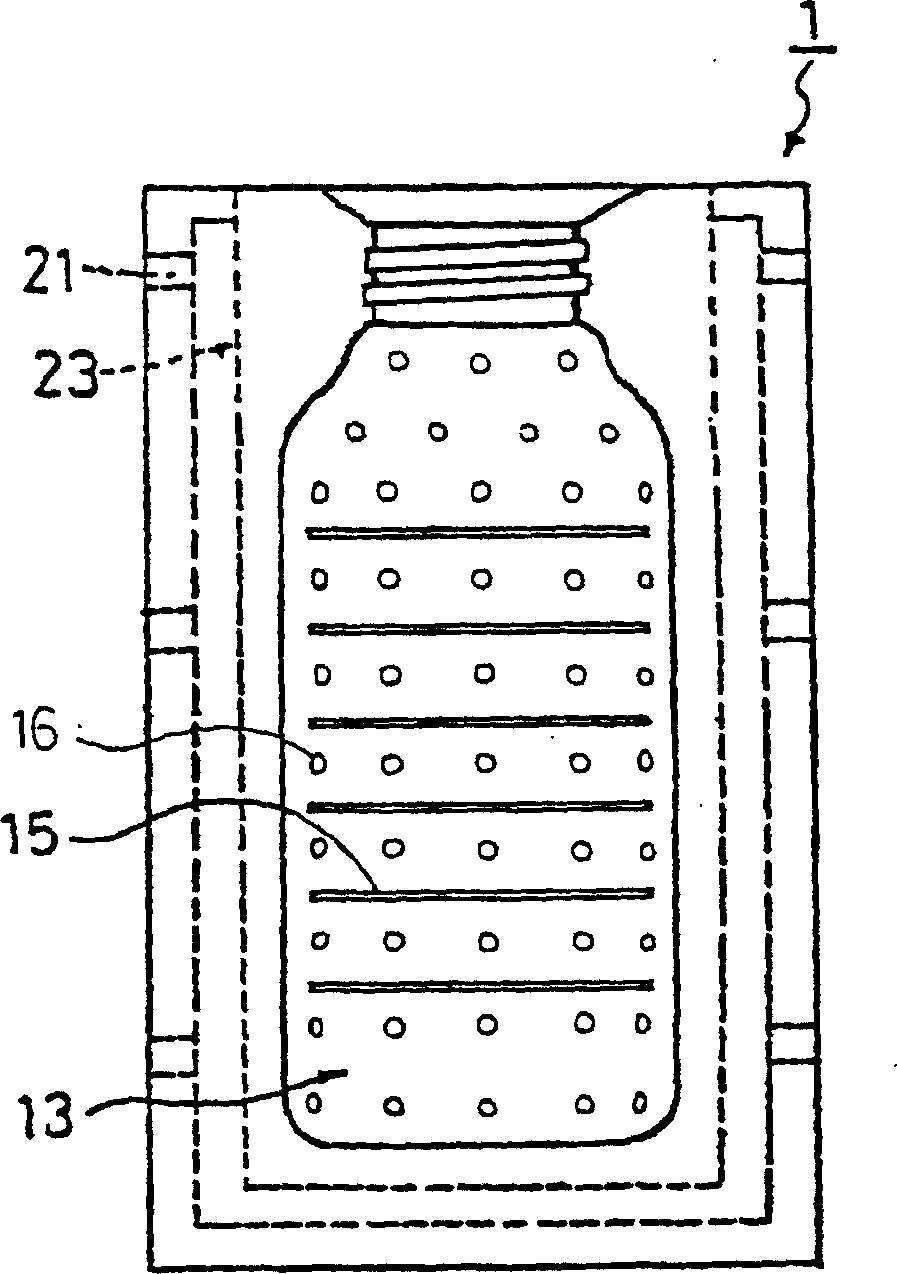

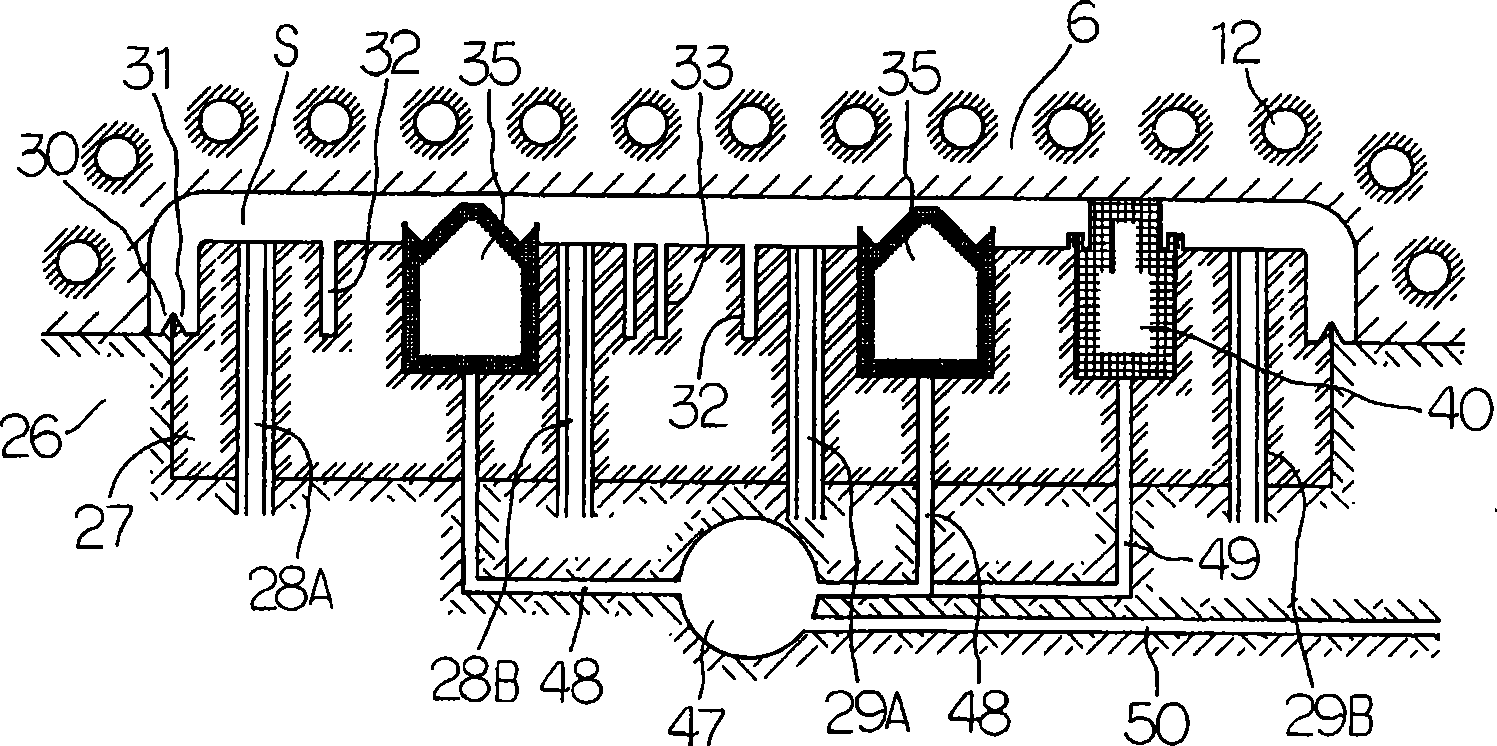

Device for manufacturing molded body

A molded body formed with pulp mold having projected lines corresponding to a slit-shaped vent passage part, capable of being provided by paper-making / dewatering, using a paper making mold, a slurry having fibers dispersed in a liquid so as to obtain a three-dimensional fiber wetted laminated body, moving the laminated body to a dry mold having an inner surface with slit-shaped vent passage, and pressing and drying that laminated body.

Owner:KAO CORP

Cleaning sheet, conveyance member with cleaning function, cleaning method of substrate processing apparatus, and substrate processing apparatus

ActiveCN102413951AGood removal effectImprove transfer effectFilm/foil adhesivesSemiconductor/solid-state device manufacturingForeign matterSurface roughness

Owner:NITTO DENKO CORP

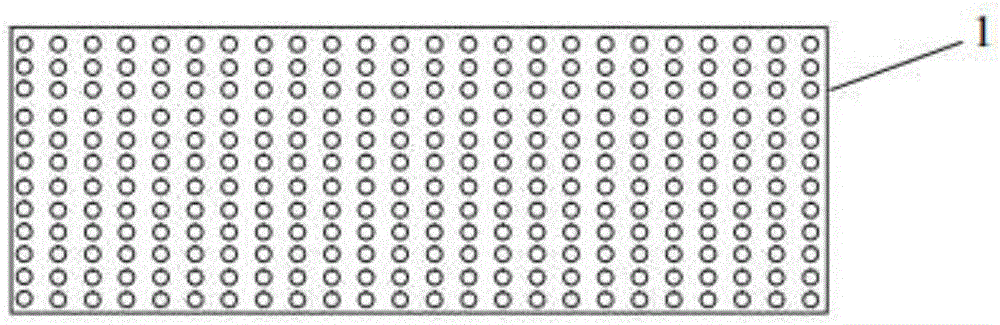

Instant dry type sublimation transfer digital PP paper

ActiveCN106379068AImprove toughnessDoes not affect strengthDuplicating/marking methodsCoatingsCelluloseDigital paper

The invention relates to the technical field of sublimation transfer printing and discloses instant dry type sublimation transfer digital paper. The instant dry type sublimation transfer digital paper comprises perforated PP paper, a water absorbing and permeable layer, a porous layer and a surface channel layer which are sequentially arranged from bottom to top; the porous layer is made of interpenetrating network resin formed by crosslinking of cellulose or sodium carboxymethylcellulose or starch and modified cationic polyacrylamide, or formed by crosslinking of polyacrylamide or cellulose or sodium carboxymethylcellulose and modified cationic starch; on one hand, the interpenetrating network resin can swell to 'catch' a dye for quick ink absorption, and on the other hand, components of the resin are adjusted and the network density is controlled to improve the water permeability, so that water molecules can quickly enter the water absorbing and permeable layer; and the perforated PP paper has excellent flexibility and mechanical strength and is stable in size in the printing process, so that the problem of shrinkage, caused by weather, of the conventional paper base material is solved. The instant dry type sublimation transfer digital PP paper has the characteristics of being instant in drying, quick in ink absorption, good in size stability and low in cost, and can meet the requirements for quick printing and efficient manufacturing at present.

Owner:杭州华大海天科技股份有限公司

Plate surface pattern manufacturing technology and manufactured plate and furniture

InactiveCN104691203AFirmly attachedNo color differenceNon-macromolecular adhesive additivesDecorative surface effectsSurface patternCooking & baking

The invention discloses a plate surface pattern manufacturing technology. The plate surface pattern manufacturing technology comprises the following steps: (1) carrying out primary treatment on the surface of a plate blank; (2) charging powder on the surface of the plate so as to form a paint layer; (3) carrying out surface treatment on the paint layer; (4) pasting transfer paper on the surface of the paint layer of the plate, baking at 160-180 DEG C for 40-50 minutes, then stripping the transfer paper so as to obtain the plate. By adopting the technology, the high-quality plate product is obtained by the working procedures of primary treatment of the blank surface, oil charge on the blank surface, paint surface treatment and transfer, especially the working procedure of controlling the baking temperature and time in transfer, so that the surface pattern of the plate is firm in attachment, has no color difference, and is difficult to discolor; patterns of the surfaces of plates of various furniture can be manufactured by the technology; especially the surface transfer wood grain patterns of steel plates have high-quality and emulational wood effect, the steel plates are relatively environmentally friendly and durable compared with the traditional wood plate, and the manufactured furniture also inherits the corresponding effect.

Owner:SUZHOU METAL PROD

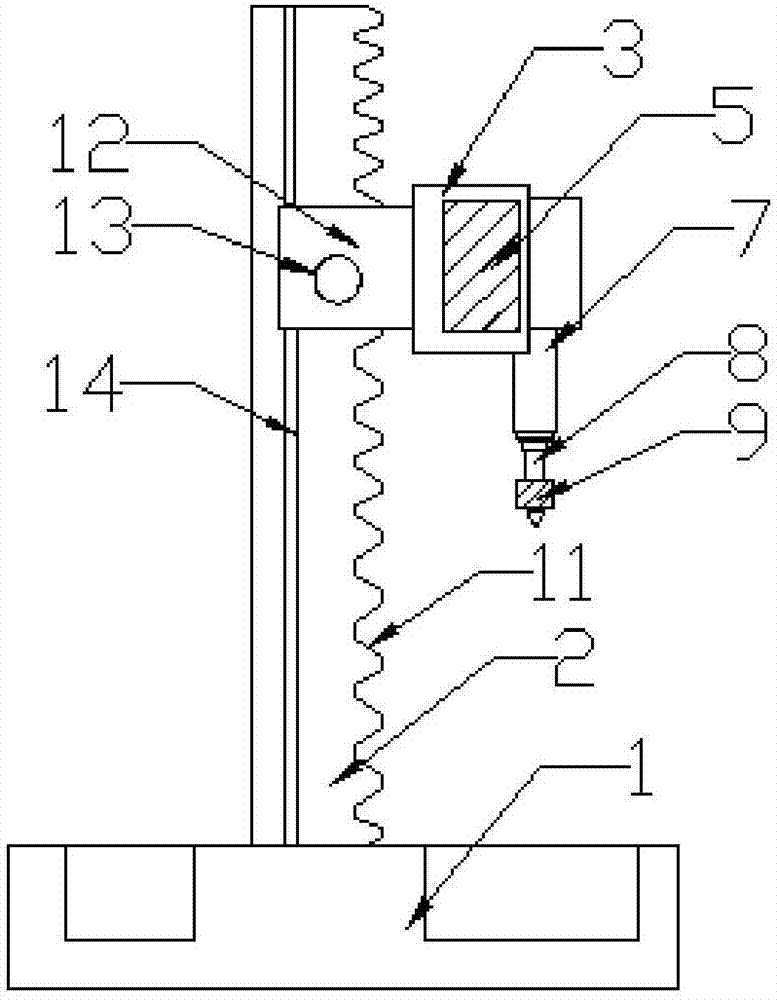

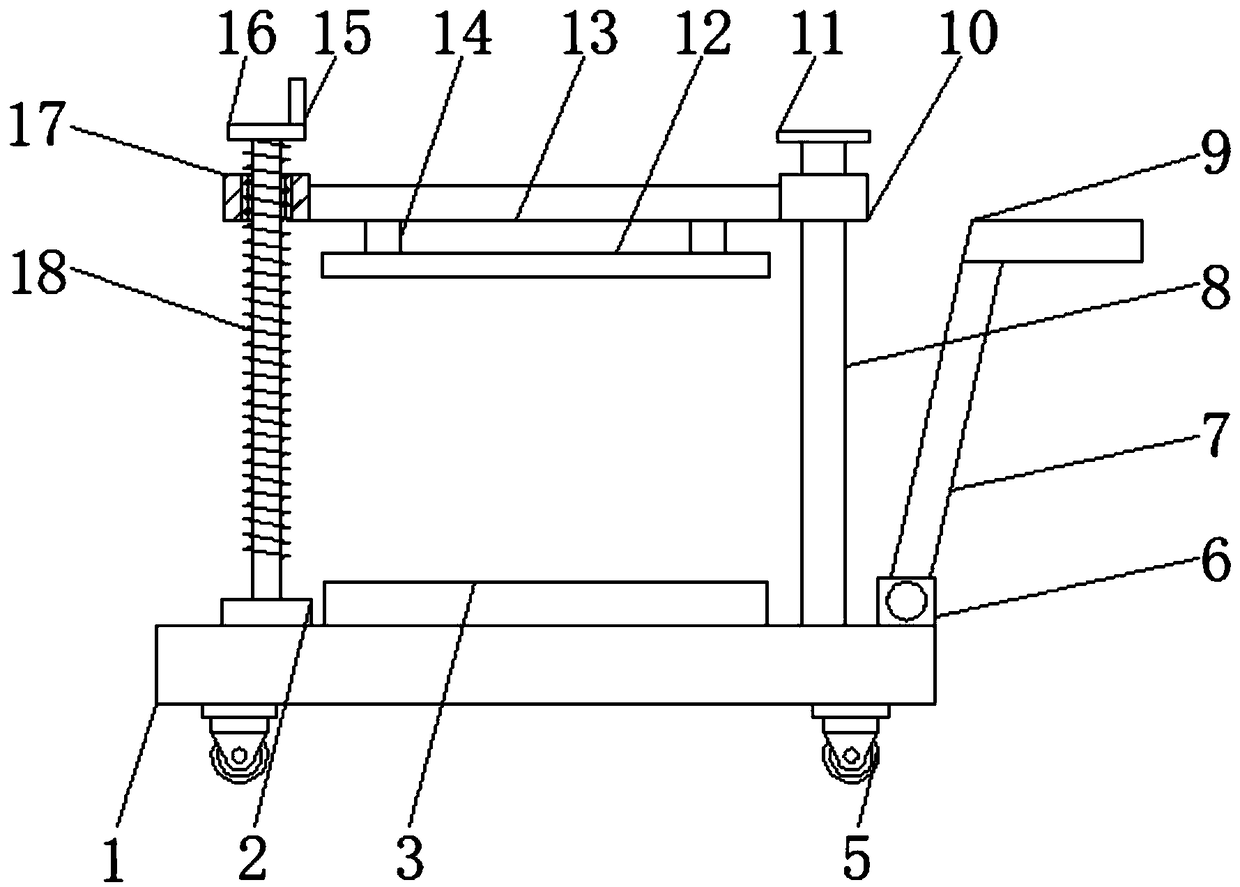

Lithium battery clamping and transferring device on production line

PendingCN107298302AImprove clamping efficiencyImprove transfer effectConveyor partsProduction lineEngineering

The invention discloses a lithium battery clamping and transferring device on a production line. The lithium battery clamping and transferring device comprises a base, a stand column and clamp air cylinders, the stand column is welded to the base, the stand column is fixed with a transverse plate through a movable plate, and a sliding plate is clamped in a sliding rail of the transverse plate; one end of the transverse plate is connected with the sliding plate through a telescopic air cylinder fixed by a bolt, and a lifting air cylinder is fixed to the sliding plate through a bolt; the piston end of the lifting air cylinder is fixedly provided with a fixing plate through a bolt, and the clamp air cylinders are installed at the bottom of the fixing plate through bolts. According to the clamping and transferring device, by means of the lifting air cylinder and the telescopic air cylinder, lithium batteries can be transferred on conveying devices at different heights; the lithium batteries can be clamped at a time through the clamp air cylinders for transferring, the clamping efficiency is high, and the transferring effect is good; the heights of the clamp air cylinders can be adjusted through the movable plate and the stand column with sawteeth, so that the application range of the clamping and transferring device is widened, and the using effect of the clamping and transferring device is further improved.

Owner:ZHEJIANG GODSEND POWER TECH

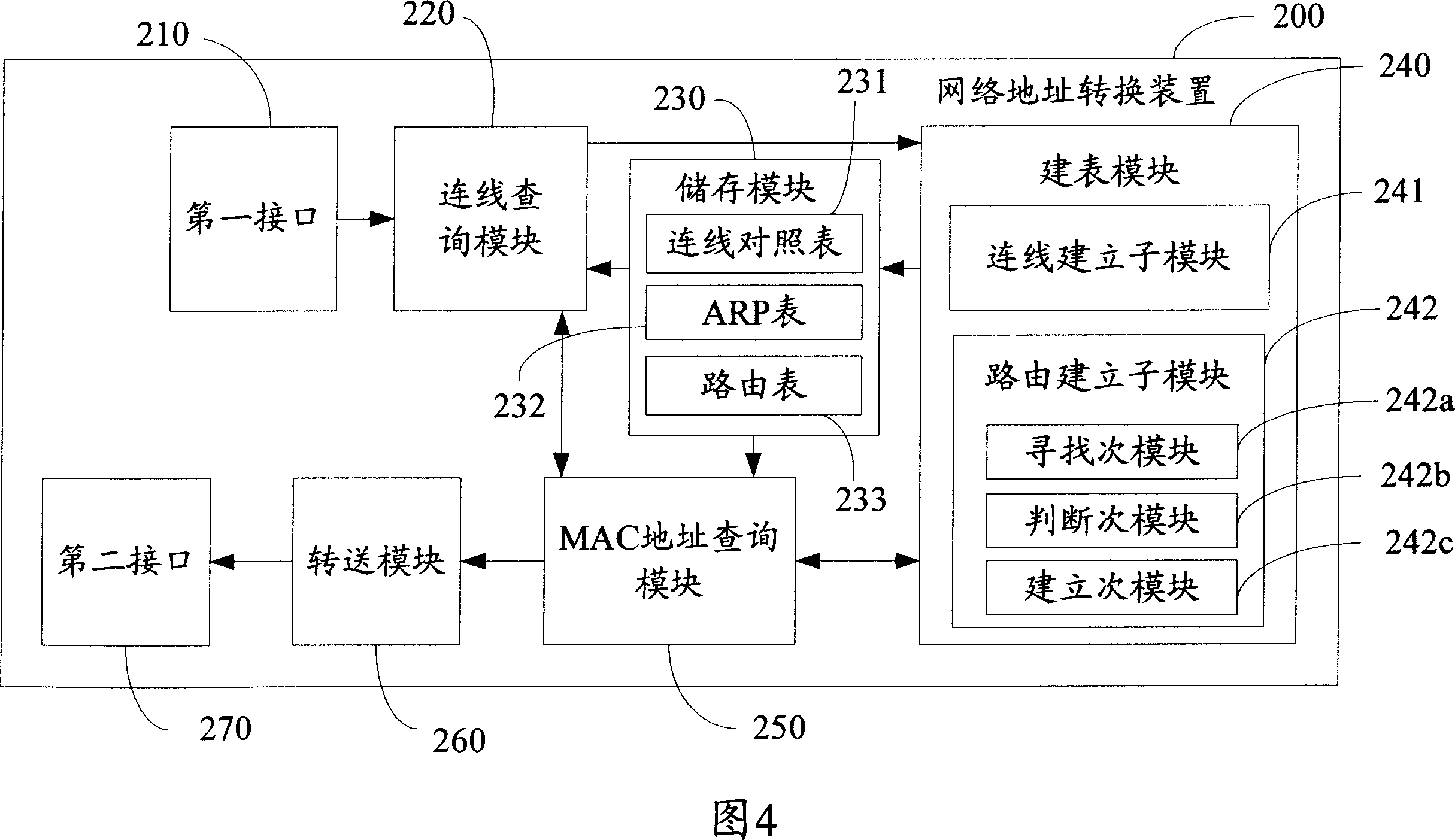

Network address switching device and its transfer sealed packet method

InactiveCN1988495AImprove transfer effectAvoid the burdenData switching networksNetwork addressingNetwork address translation

The invention relates to a network address transition device for transmitting packets, which includes a connecting query module, a tabulation module, a media access control (MAC) address query module and a transference module. The connecting query module for receiving a packet inquires a connecting reference table including a number of connecting entries, in which each entry includes a routing entry, and judge whether the connecting entry with the same packet connectivity in the connecting reference table. Tabulation id used for establishing a connecting entry of the packet and a routing entry. MAC address query module is used for getting a purpose of the MAC address based on routing entries. Transference module is for attaching the purpose of the MAC address on the packets, and transmitting the packets. The devices can avoid the processing packet burden of Internet protocol (IP) layer, thereby, improves the effectiveness of packet transference.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Instant dry type heat sublimation transfer digital paper

The invention relates to the technical field of heat sublimation transfer, and discloses instant dry type heat sublimation transfer digital paper. The instant dry type heat sublimation transfer digital paper sequentially comprises base material paper, a water absorbing and permeating layer, a porous layer and a surface channel layer from bottom to top. The porous layer is interpenetrating polymer network resin formed by cross linking of cellulose or sodium carboxymethylcellulose or starch and cation modified polyacrylamide or formed through cross linking of polyacrylamide or cellulose or sodium carboxymethylcellulose and cation modified starch. On one hand, the interpenetrating polymer network resin can expand to pocket dyestuff, and rapid ink sucking is conducted; and on the other hand, resin components are adjusted, the network density is controlled, so that the water permeability is improved, and water molecules rapidly enter the water absorbing and permeating layer. Holes are formed in the hydrophilia end of the water absorbing and permeating layer, and water in ink is adsorbed into the holes and rapidly transmitted to the cellulose paper base material. The instant dry type heat sublimation transfer digital paper has the beneficial effects that dryness can be achieved immediately during printing, ink absorbing is rapid, and the transfer effect is good; and requirements of existing rapid printing and efficient manufacturing are met.

Owner:杭州华大海天科技股份有限公司

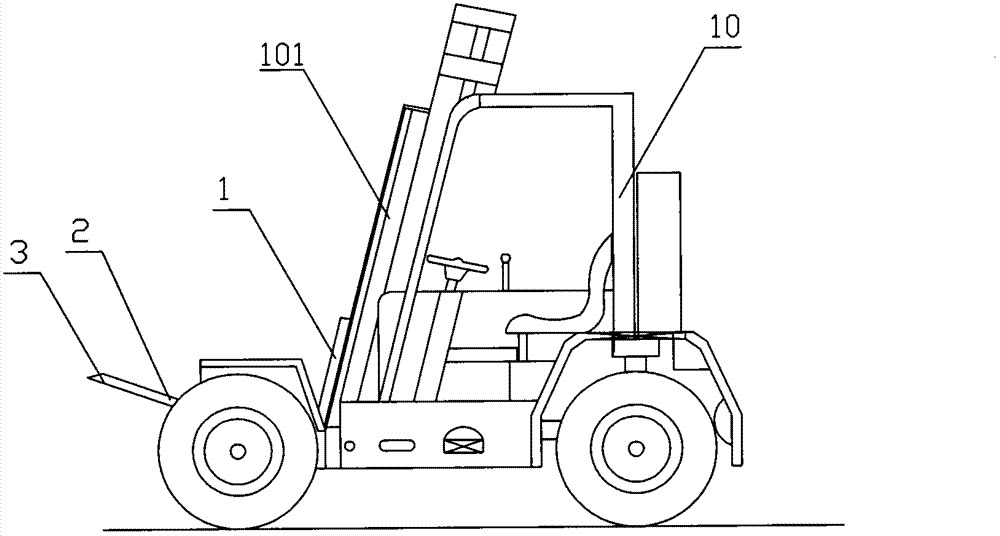

Fork and forklift comprising fork

The invention belongs to the technical field of a forklift, in particular to a fork and a forklift comprising the fork. The fork comprises a fork back, a fork arm connected to the fork back and a scraper knife arranged at the front end of the fork arm. The fork back is provided with an upper hook and a lower hook connected with a portal of the forklift. The fork is characterized in that the fork arm is further provided with a transfer mechanism for transferring a load on the fork arm. The transfer mechanism comprises a strip-like groove arranged in the length direction of the fork arm, and a transfer belt which is arranged in the groove and can rotate positively and negatively. The transfer belt prior to the fork arm is first contacted with the lower surface of the load. The fork provided by the invention solves the problem of current forklift which loads and unloads cargos, and can be directly inserted on the lower surface of the cargo to support the cargo, so that the transfer efficiency of cargo is improved. The fork is strong in adaptability and suitable for loads in any shapes, and is simple in structure, good in transfer effect, replaceable, and long in service life.

Owner:FUJIAN ZHENBAO MACHINERY

Novel polyolefin resin composition and molded resin obtained therefrom

A polyolefin resin composition which comprises: 100 parts by weight of a polyolefin resin; 0.01-1 part by weight of (A) a specific amide compound; and 0.005-1 part by weight of (B) at least one inorganic compound selected from the group consisting of hydrotalcites, burned hydrotalcites, talc, alkali aluminum composite hydroxides, magnesium hydroxide, magnesium oxide, calcium carbonate, and calcium oxide. Also provided is a polyolefin resin molding excellent in crystallinity, rigidity, and transparency.

Owner:NEW JAPAN CHEM CO

Transfer device with clamping function for construction

InactiveCN108791440AWith clamping functionImprove transfer effectSupporting partsHand carts with multiple axesEngineering

The invention discloses a transfer device with a clamping function for construction. The transfer device comprises a bottom plate, a placemat plate is fixedly connected to the center of the surface ofthe top of the bottom plate, locating blocks are fixedly connected to the front side and the rear side of the right side of the surface of the top of the bottom plate, a rotating shaft is arranged onthe corresponding ends of the two locating blocks in a penetrating mode, a moving rod is arranged at the center of the surface of the rotating shaft in a sleeving mode, and a handle is fixedly connected to the top of the moving rod. The transfer device has a clamping function through the matching use of a moving sleeve, a sliding rod, a sliding sleeve, a locating plate, a pressing plate, a locating rod, a rocker, a rotary table, a thread sleeve and a screw, the transferring effect of the transfer device is better, the problem that objects are prone to falling from the transfer device due to the lack of positioning on the transfer device due to the lack of clamping function when the transfer device is in use, the practicability of the transfer device is greatly improved, and popularizationis facilitated.

Owner:成都智宸科技有限公司

Method of producing photopolymerizable lithographic plate

InactiveCN1695959AReduce adhesionExcellent peelabilityPhotomechanical coating apparatusPlate printingCrystallinityPlanographic printing

At an overcoat layer applying / drying section (24), an overcoat layer is coated on the photosensitive layer by a coater and at the same time, the crystallization degree of the overcoat layer is controlled from 0.2 to 0.5. <IMAGE>

Owner:FUJIFILM CORP

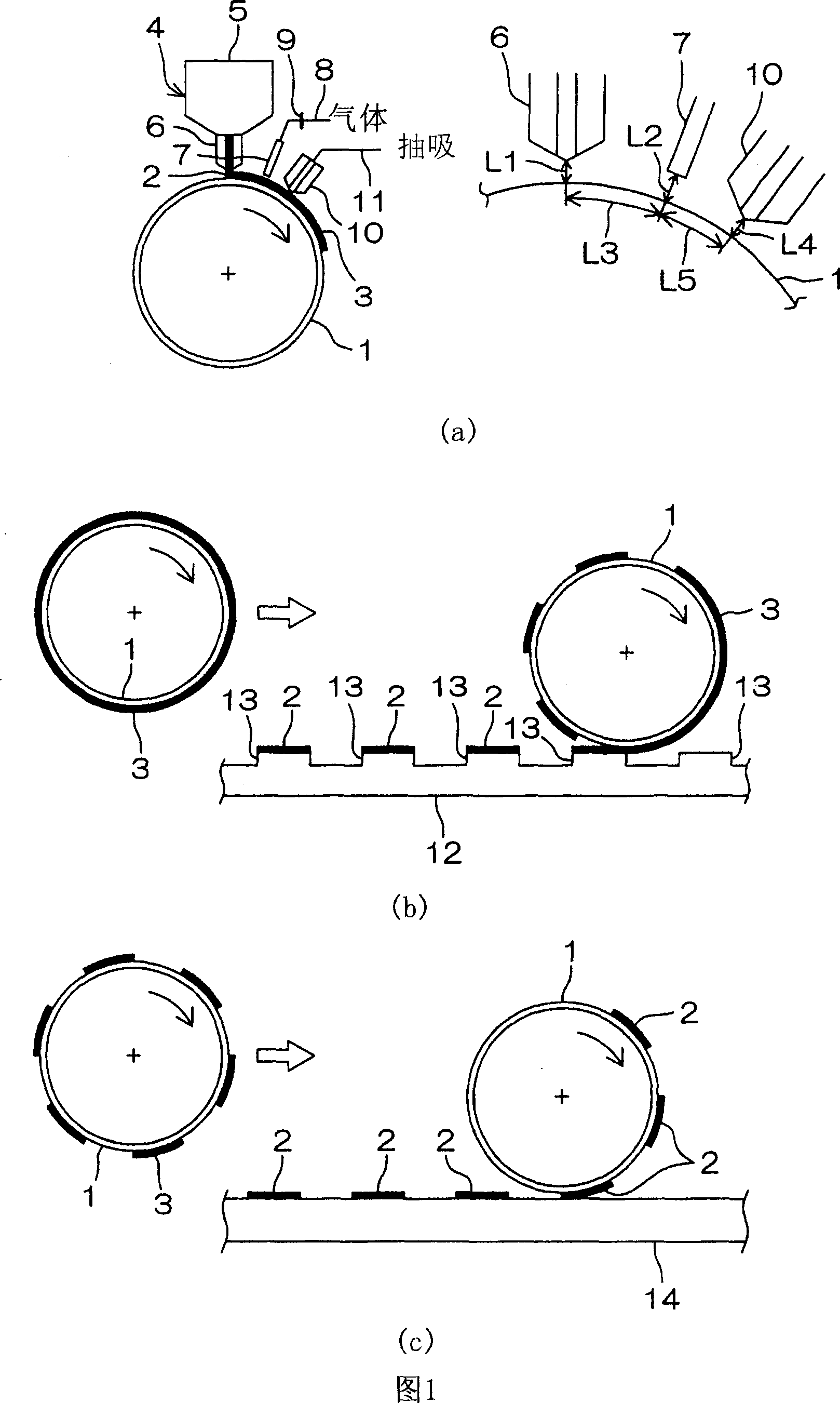

Printing method and printing device

Provided is a printing method which can form a uniform ink coating surface with stable coating properties, on the surface of a silicone blanket, prevent an ink from piling by improving transferability, and further, meet the requirements of an oversized printable object, and a printing device to be used for this printing method. In this printing method, the ink is applied by a slit die coater so as to allow forming of a coating surface of the ink on the surface of a silicone blanket, then a drying gas is blown to the coating surface of the ink from a gas nozzle and a solvent contained in the ink is sucked by a suction nozzle. After that, the coating surface of the ink is removed partially by rolling the silicone blanket over an indented plate, and the coating surface of the residual ink is transferred to the surface of a substrate.

Owner:SUMITOMO RUBBER IND LTD +1

Mixed polyester resin for indoor thermal transfer printing matt powder coating and preparation method of mixed polyester resin

ActiveCN107936236ASuitable glass transition temperatureAppropriate viscosityPowdery paintsPolyester coatingsGlass transitionFatty acid

The invention discloses mixed polyester resin for an indoor thermal transfer printing matt powder coating. The resin is carboxyl-terminated saturated polyester resin, and has an acid value of 45-75 mgKOH / g, a glass transition temperature of 55-60 DEG C, a softening point of 93-103 DEG C, a melt viscosity of 3000-4500 mPa*s at 200 DEG C and reactivity of 150-250 s at 180 DEG C, and the resin is mainly prepared by performing a melt polycondensation reaction on the following monomer components in percent by mass: 30-37% of a diol, 0-3% of a trihydric alcohol, 55-62% of an aromatic dibasic acid,0-5% of a fatty acid, 5-10% of an acidolysis agent, 0.01-0.15% of an esterifying catalyst and 0.01-0.8% of a thermal transfer printing assistant. The polyester resin has a high glass transition temperature, good storage stability, and a good appearance levelling property. The invention also discloses a preparation method of the mixed polyester resin for the indoor thermal transfer printing matt powder coating.

Owner:GUANGZHOU KINTE IND

Injection molding method and device

InactiveCN101422956AEliminate deformationShorten molding timeInjection molding machineInjection moulding

In an injection moulding method, vapor is supplied in a thermal medium channel of master mould. The mould is closed after heating a mould cavity forming side of master mould part for raising the temperature of mould cavity forming side. The temperature raising is stopped after the mould cavity forming side obtains a preset temperature, and melted synthetic resin J with a preset amount is injected into the mould cavity S. Afterwards, pressurized gas is injected between the back surface of synthetic resin J and the cavity forming surface of male mould part. The surface of synthetic resin J is pressed to the mould cavity forming surface for maintaining pressure. The pressure is maintained while cooling water is started to feed into the heat medium channel for hardening the synthetic resin on the surface of master mold. When the synthetic resin is hardened to a certain degree, the injection of pressurized gas is stopped, and furthermore the pressurized gas is discharged out of the device. Cold gas is injected between the back surface of synthetic resin and the mould cavity forming surface of male mould part when the discharging of pressurized gas to the outside is finished. Lastly the mould is opened when the synthetic resin is hardened to a degree that the synthetic resin can be taken out.

Owner:FUJISEIKO

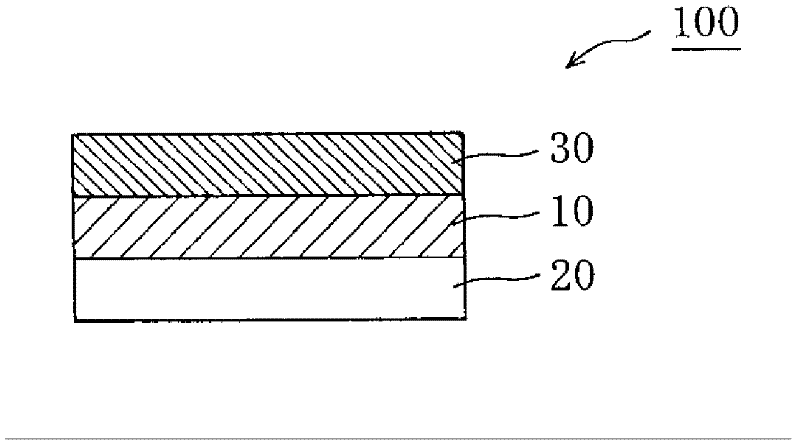

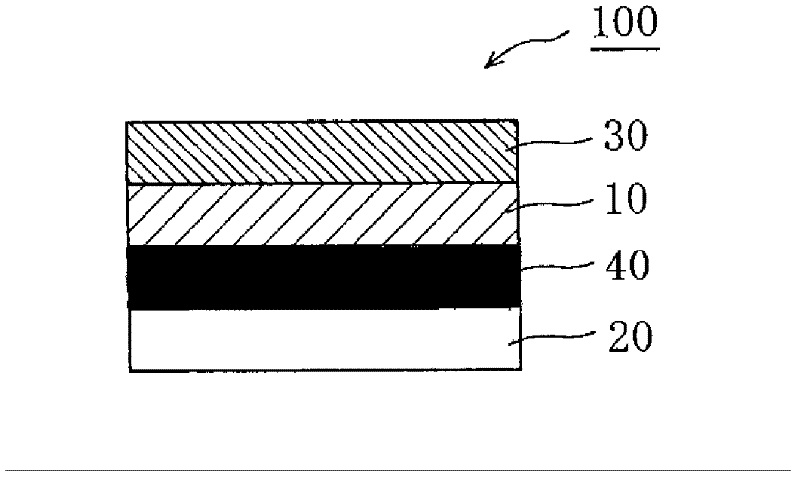

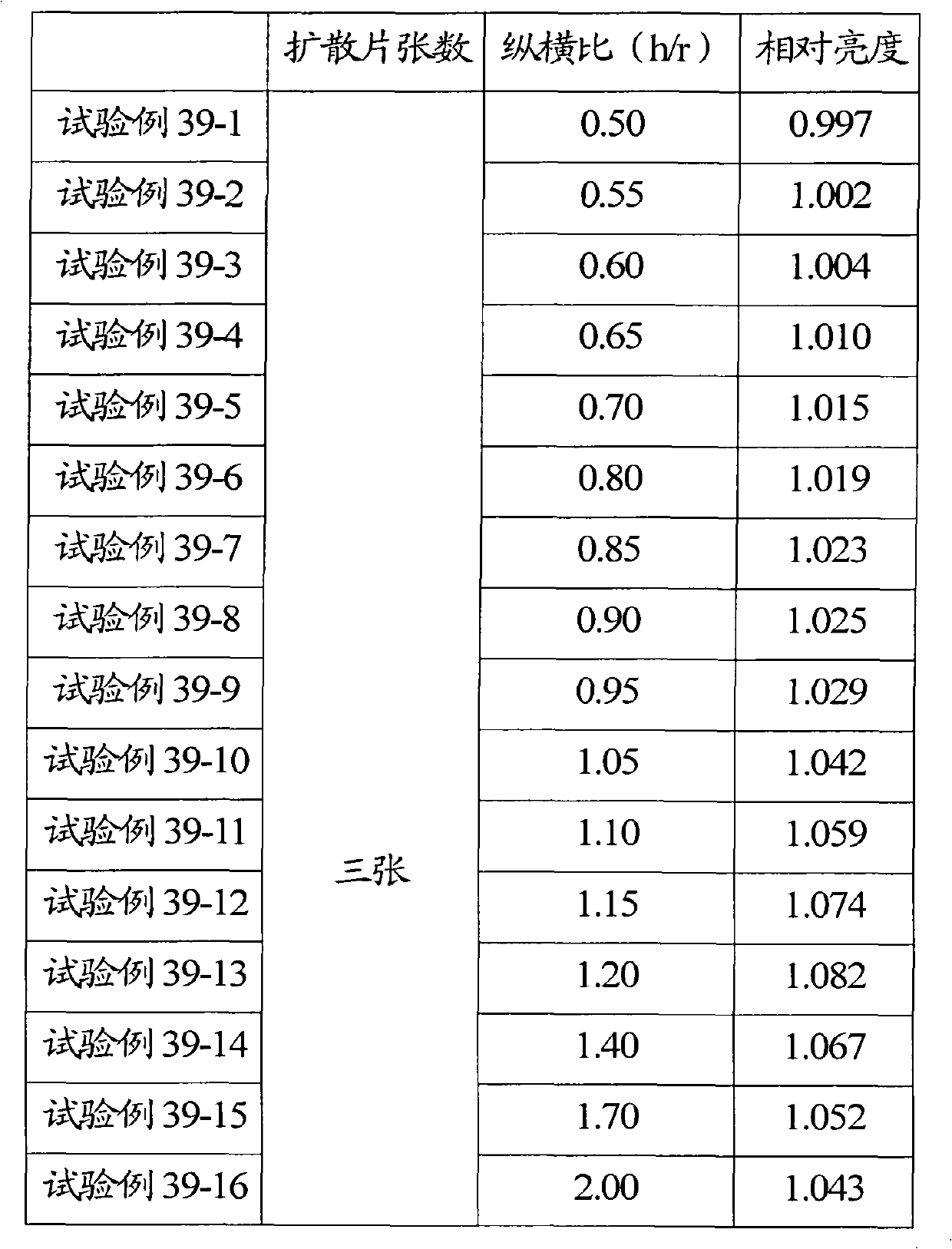

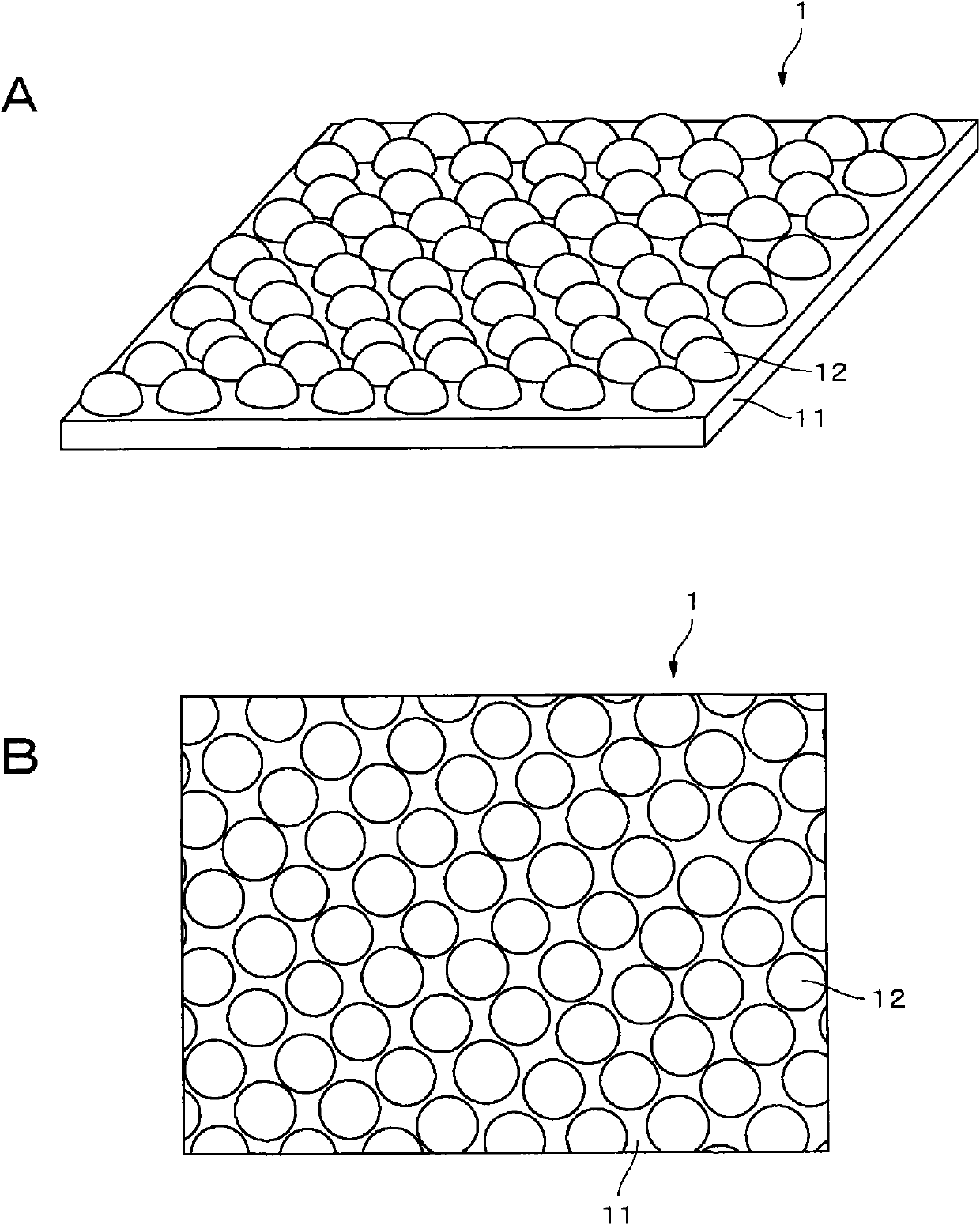

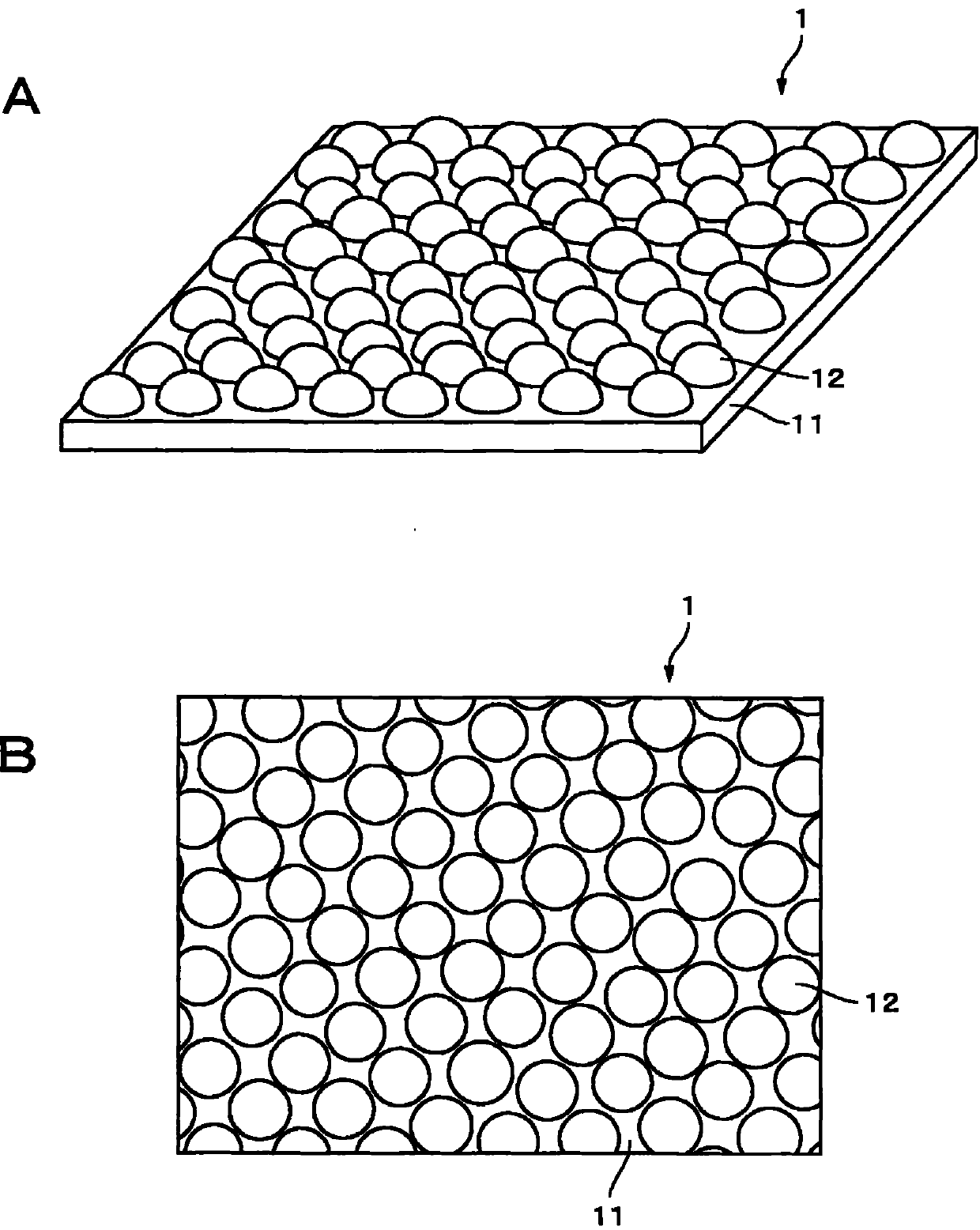

Diffusion sheet and method of manufacturing the same, backlight, and liquid crystal display device

ActiveCN101907734AImprove transfer effectInhibitionDiffusing elementsOptical articlesDiffusionLiquid-crystal display

The invention provides a diffusion sheet and a method of manufacturing the same, a backlight, and a liquid crystal display device. The diffusion sheet includes: a substrate having a first principal surface and a second principal surface; and structures each in a convex shape formed randomly on the first principal surface or the second principal surface of the substrate. The structures have an identical or almost identical height. The structures have an aspect ratio h / r, where r denotes an average radius of the structures and h denotes an average height of the structures, of more than 0.85 and not more than 1.50. The structures have a filling factor of not less than 60% and not more than 80%.

Owner:SONY CORP

Multicolor and multi-pattern printing process for fabric products

The invention relates to a method for printing pattern on fiber product, which comprises: slicing the fiber cloth to final product or half-finished product that needed printing; selecting at least two transfer paper with different patterns; slicing the transfer paper to assemble them on white paper to form seamless color assembled paper; closing the transfer surface of assembled paper and said final or half-finished product to be heated and pressurized, to transfer the pattern on the product; separating the assembled paper from said final or semi-finished product, releasing pressure and cooling; attaining needed multi-patter seamless print, to meet the demand of consumer.

Owner:张勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com