Printing method and printing device

A printing method and printing device technology, applied to printing devices, printing, printing machines, etc., can solve problems such as poor mold release, and achieve the effect of improving transferability and preventing ink from piling up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

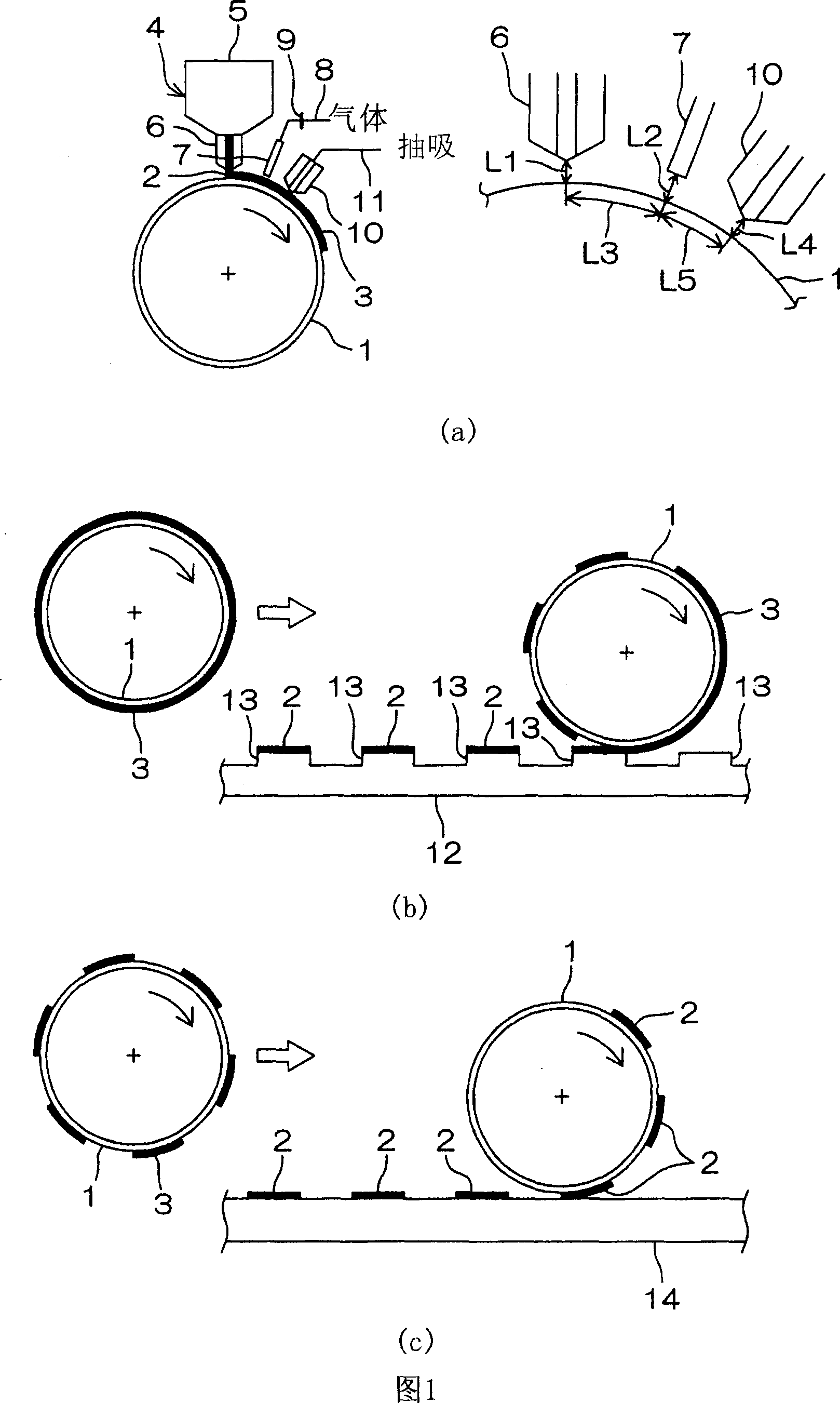

Embodiment 1

[0097] [Silicone blanket]

[0098] Prepare a support film layer containing polyethylene terephthalate with a thickness of 350 μm and a silicone rubber (manufactured by Sumitomo Rubber Co., Ltd., room temperature curing type silicone rubber, JIS-A40) with a thickness of 600 μm. A silicone blanket (10-point average surface roughness: 0.1 μm) of a silicone rubber layer on the surface was wound on a metal cylinder. The outer diameter of the silicone blanket is 500 mm, and the length in the axial direction is 1000 mm.

[0099] [Bump version]

[0100] A concavo-convex plate in which protrusions are formed of metal formed in a stripe pattern with a line width of 100 μm, a pitch of 300 μm, and a depth of 20 μm was prepared. The surface of this concave-convex plate was subjected to scratch-resistant processing by hard chrome treatment (thickness: 10 μm), and further, mirror-finished by polishing treatment.

[0101] [Preparation of ink]

Embodiment 2

[0115] The method was the same as in Example 1, except that nitrogen gas was continuously blown from the gas nozzle to the ink-coated surface before the solvent in the ink was sucked by the suction nozzle after the ink was applied to the surface of the silicone blanket. method, ink was printed on a glass substrate.

[0116] More specifically, the gas nozzle opens in a long and thin rectangular shape along the axis of the silicone blanket. The width of the horizontal opening is set to be the same as the full width of the silicone blanket, and the width of the vertical opening is set to 100 μm. . In addition, the distance between the surface of the silicone blanket and the gas nozzle along the radial direction of the silicone blanket was set to 100 μm. In addition, within 3 seconds after the ink was applied to the surface of the silicone blanket with a slit die coater, ink previously filtered through a 0.3 μm membrane filter was blown from a gas nozzle at 10 m / s. Nitrogen at 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com