Multicolor and multi-pattern printing process for fabric products

A printing process and sewing product technology, applied in the field of multi-pattern printing process, can solve the problems of destroying the overall composition effect, difficult to ensure the sewing quality, etc., and achieve the effect of meeting individual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

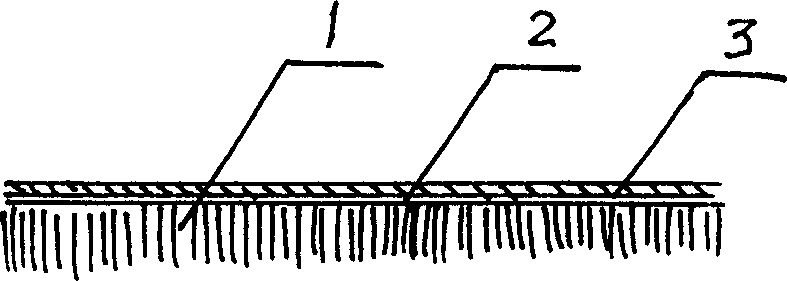

[0019] The main raw material used in this embodiment is polyester fiber cloth called suede. In order to avoid excessive shrinkage of the finished product due to heating and pressure in the subsequent process steps, and to improve the mating contact between the integrated paper and the fiber sewn product or semi-finished product during transfer printing, the polyester fiber cloth 3 and the chemical fiber plush 1 are firstly combined before sewing. Sponge 2 of 0.5 mm (0.2-0.8 mm range all can) is sandwiched between, heat and pressurize, make sponge melt, polyester fiber cloth and chemical fiber plush are bonded into composite fiber material to be printed (see figure 2 ). According to the characteristics of the selected sponge, it is advisable to control the heating temperature at 130°C-150°C, the pressure at 0.4Mpa-0.5Mpa, and the time at 15 seconds-30 seconds. Then follow these steps:

[0020] 1. After cutting and compounding the fiber material to be printed, the fiber garme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com