Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Improve processing convenience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

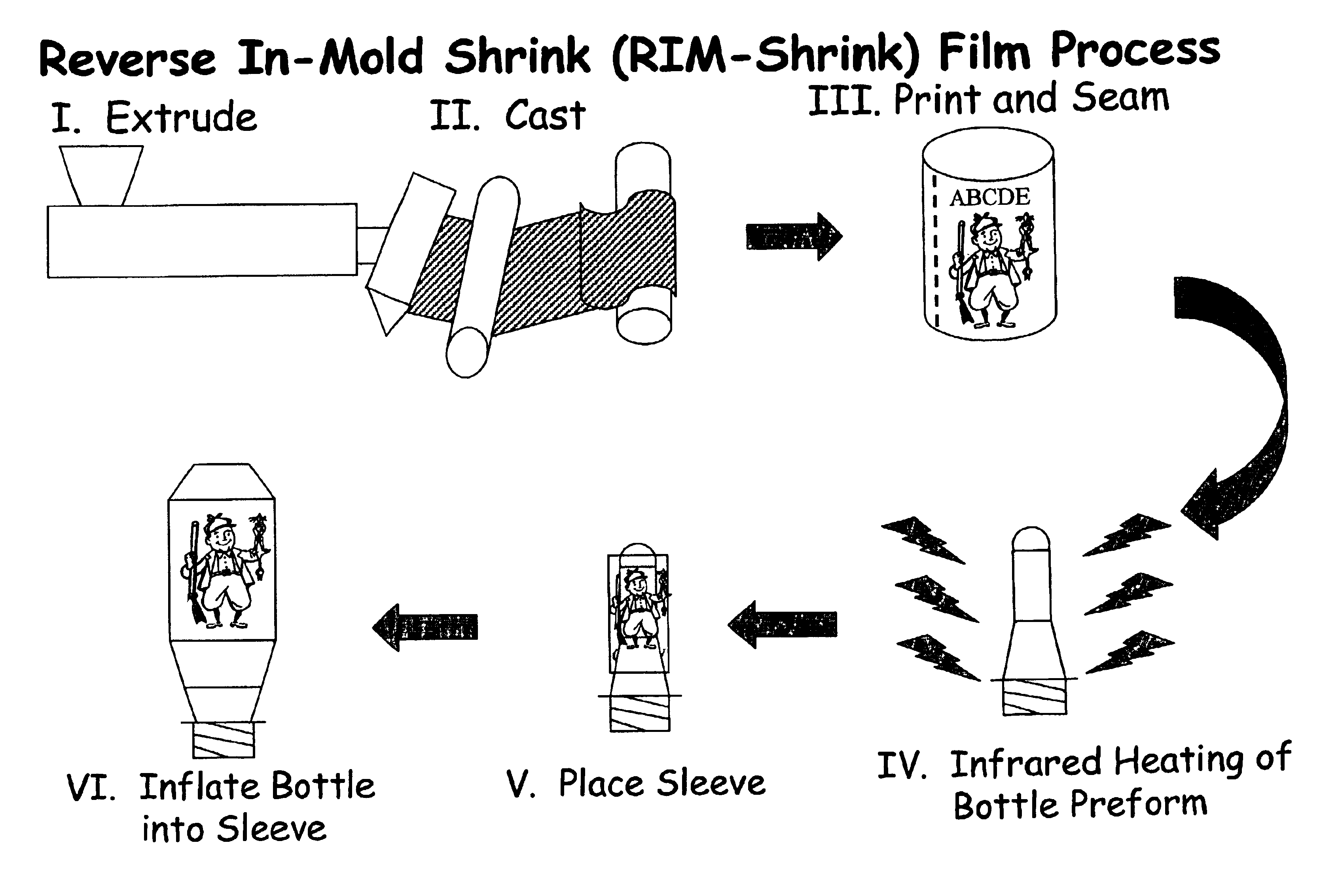

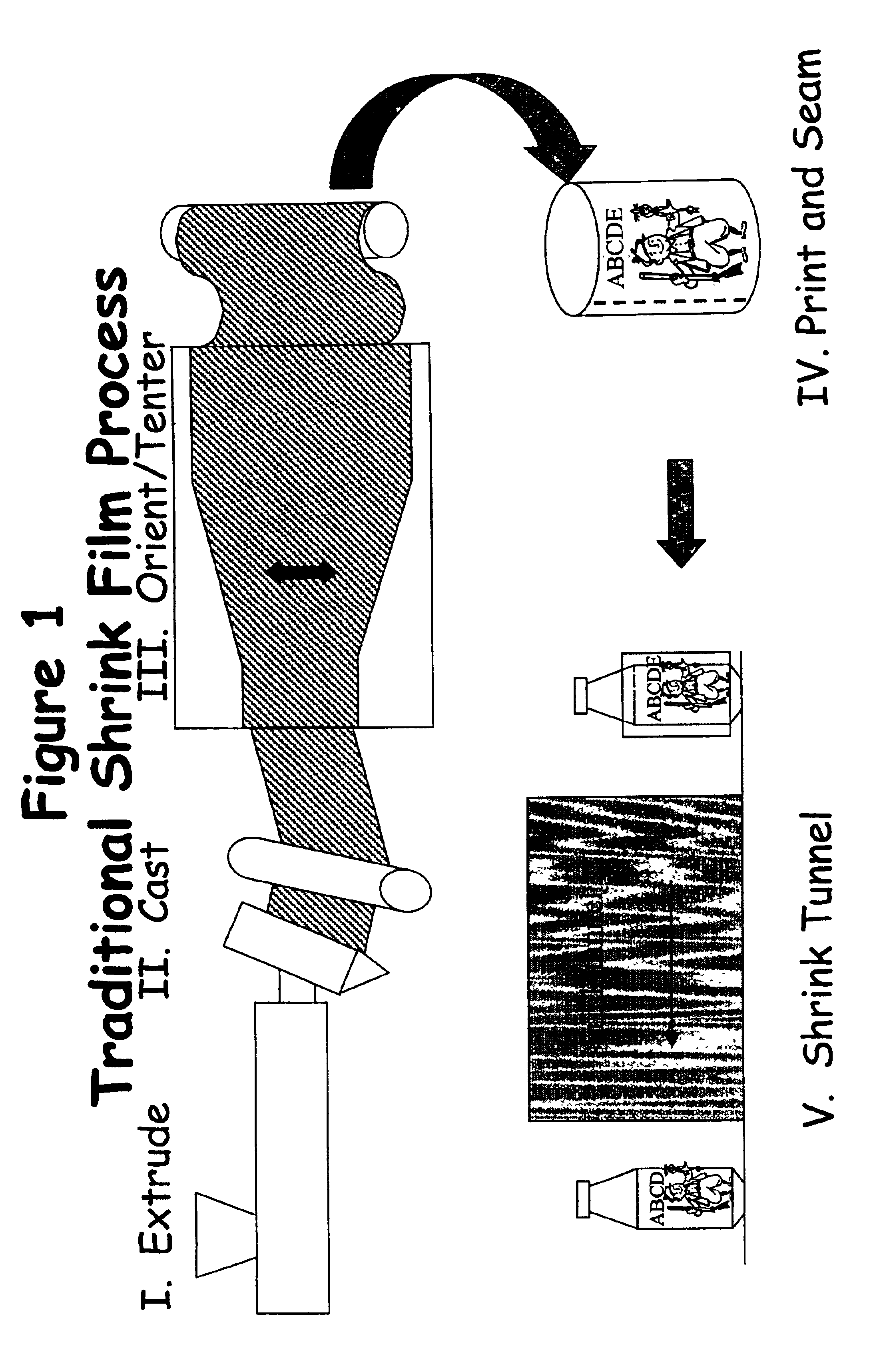

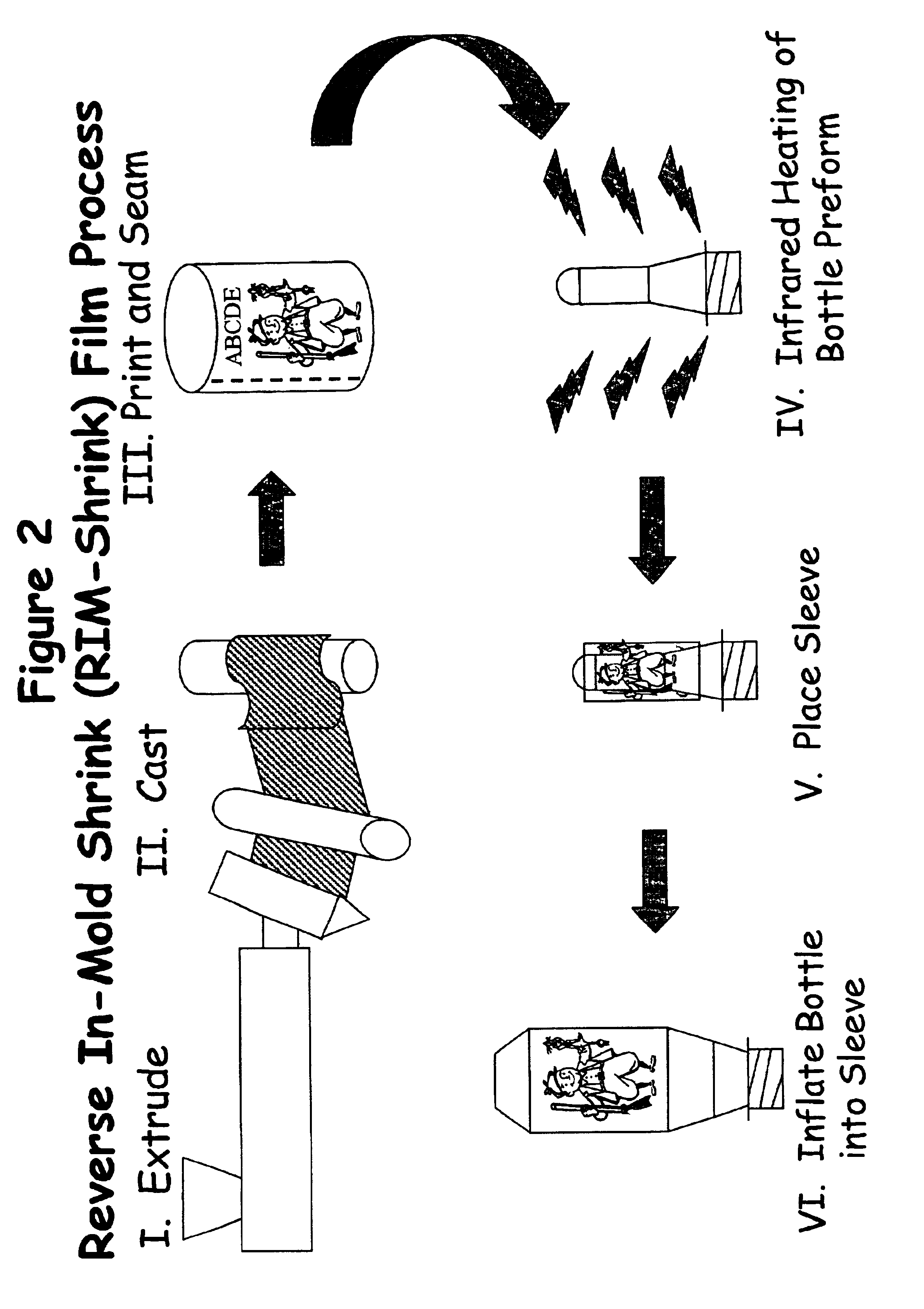

Process for making labeled containers using a stretch blow molding process

InactiveUS6984354B2Low costImprove processing convenienceBottlesNon-pressured vesselsBlow moldingMechanical engineering

A new process for making a labeled container using a stretch blow molding process wherein a label sleeve is positioned over at least a portion of the exterior surface of a preform to produce a sleeved preform and the sleeved preform is stretch blow molded to produce a labeled container having a snug-fit label.

Owner:EASTMAN CHEM CO

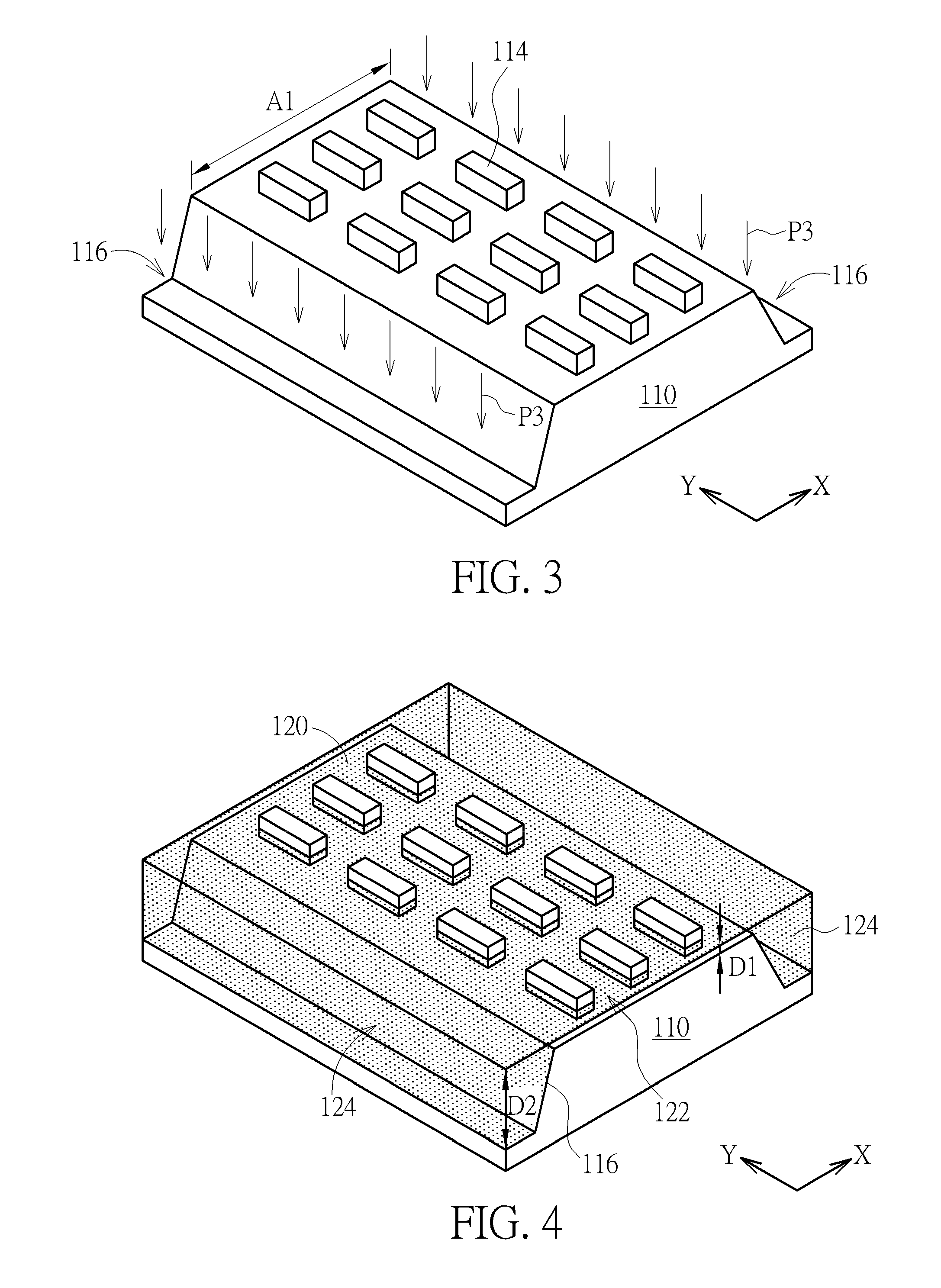

Semiconductor structure and manufacturing method thereof

ActiveUS9502410B1Improve semiconductor device performanceImprove processing convenienceTransistorSolid-state devicesSemiconductor structureEngineering

The present invention provides a semiconductor structure, including a substrate having a first fin structure and a second fin structure disposed thereon, a first isolation region located between the first fin structure and the second fin structure, a second isolation region located opposite the first fin structure from the first isolation region, and at least an epitaxial layer disposed on the side of the first fin structure and the second fin structure. The epitaxial layer has a bottom surface, the bottom surface extending from the first fin structure to the second fin structure, and the bottom surface is lower than a bottom surface of the first isolation region and a top surface of the second isolation region.

Owner:MARLIN SEMICON LTD

Drilling method on sheet metal

The present invention provides a drilling method on a sheet metal. The drilling method comprises the following steps that: the sheet metal and an auxiliary processing piece are provided, the sheet metal includes an area to be drilled, the area to be drilled include a first surface and a second surface relative to the first surface, and the hardness number of the auxiliary processing piece is 0.7 times larger than that of the sheet metal. The auxiliary processing piece fit on the first surface of the area to be drilled. Holes are drilled between the auxiliary processing piece and auxiliary processing piece through a drill head, and the rotate speed of the drill head is larger than 8000 r / min during the drilling course. The auxiliary processing piece is taken down from the area to be drilled. The drilling method on the sheet metal has the advantage that qualities of the holes are improved.

Owner:文霞

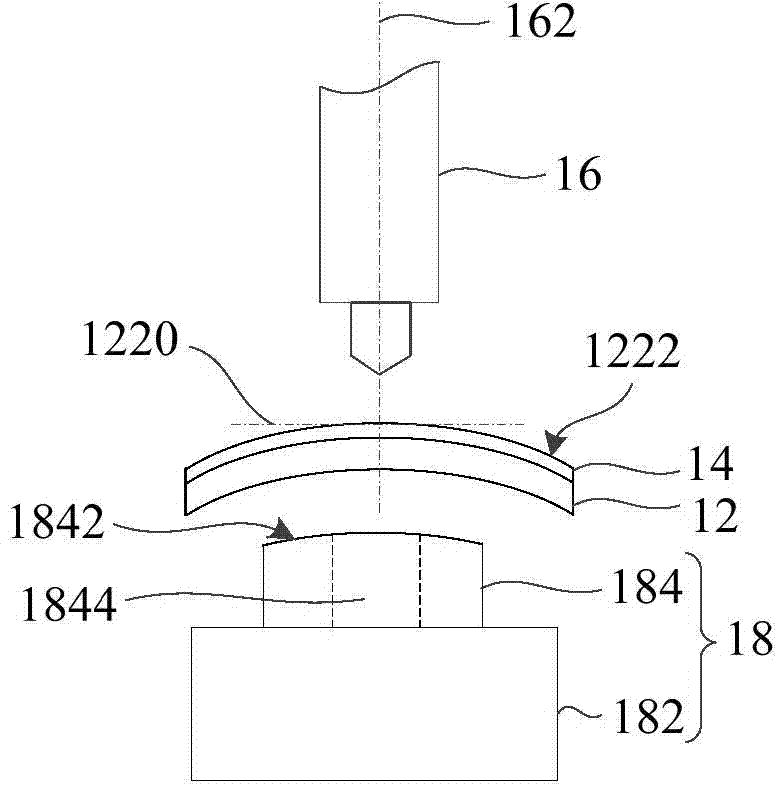

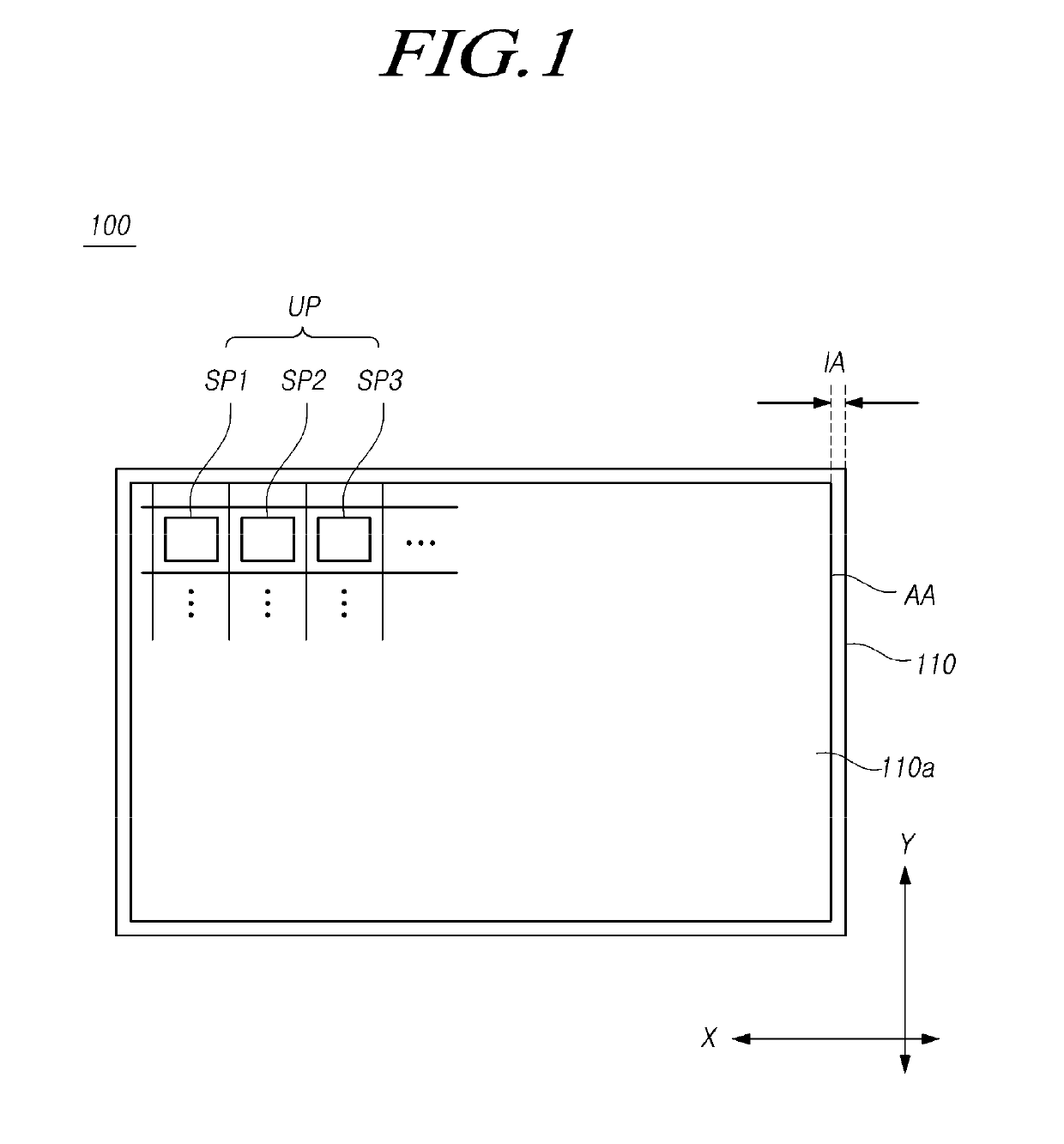

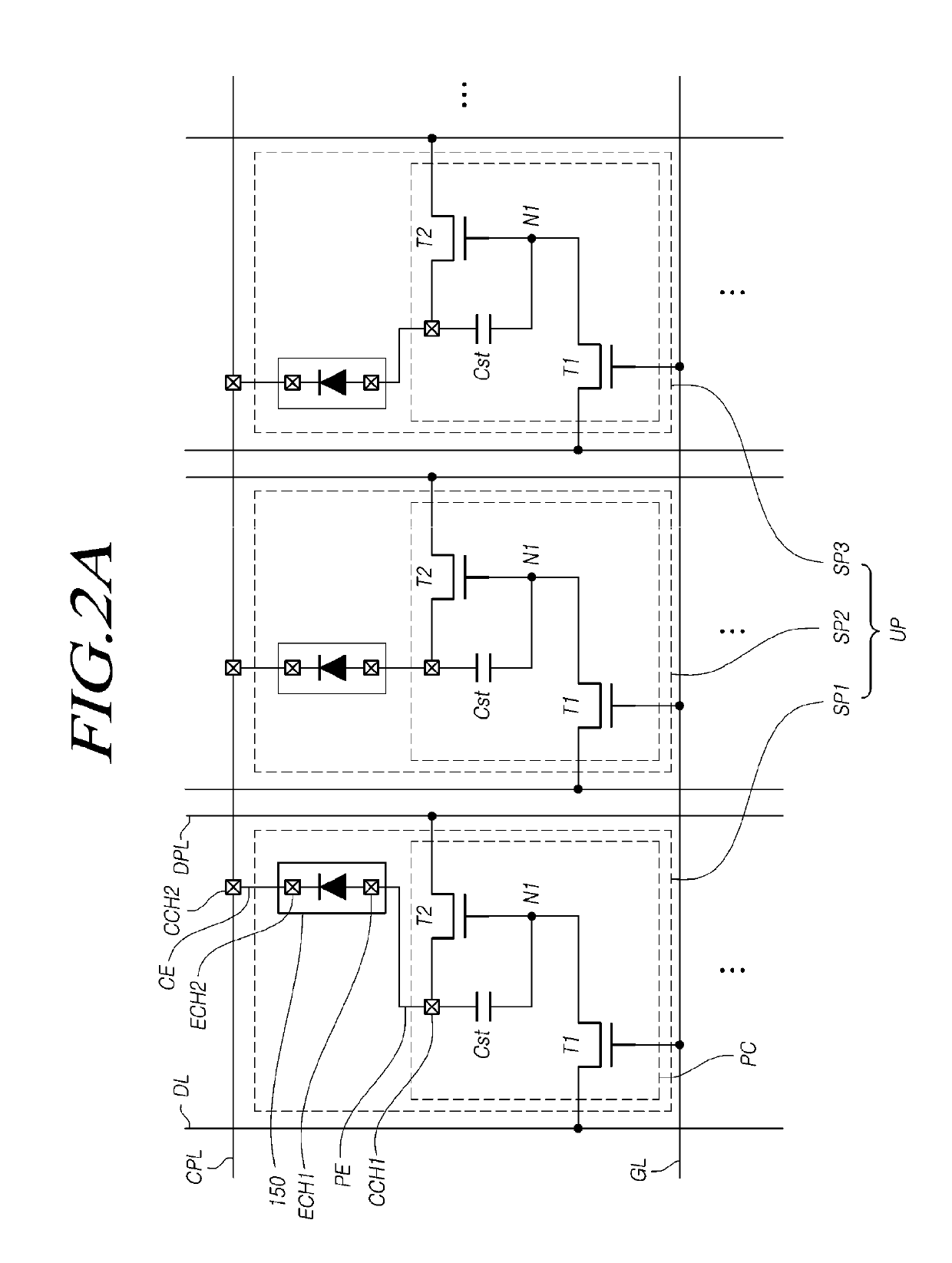

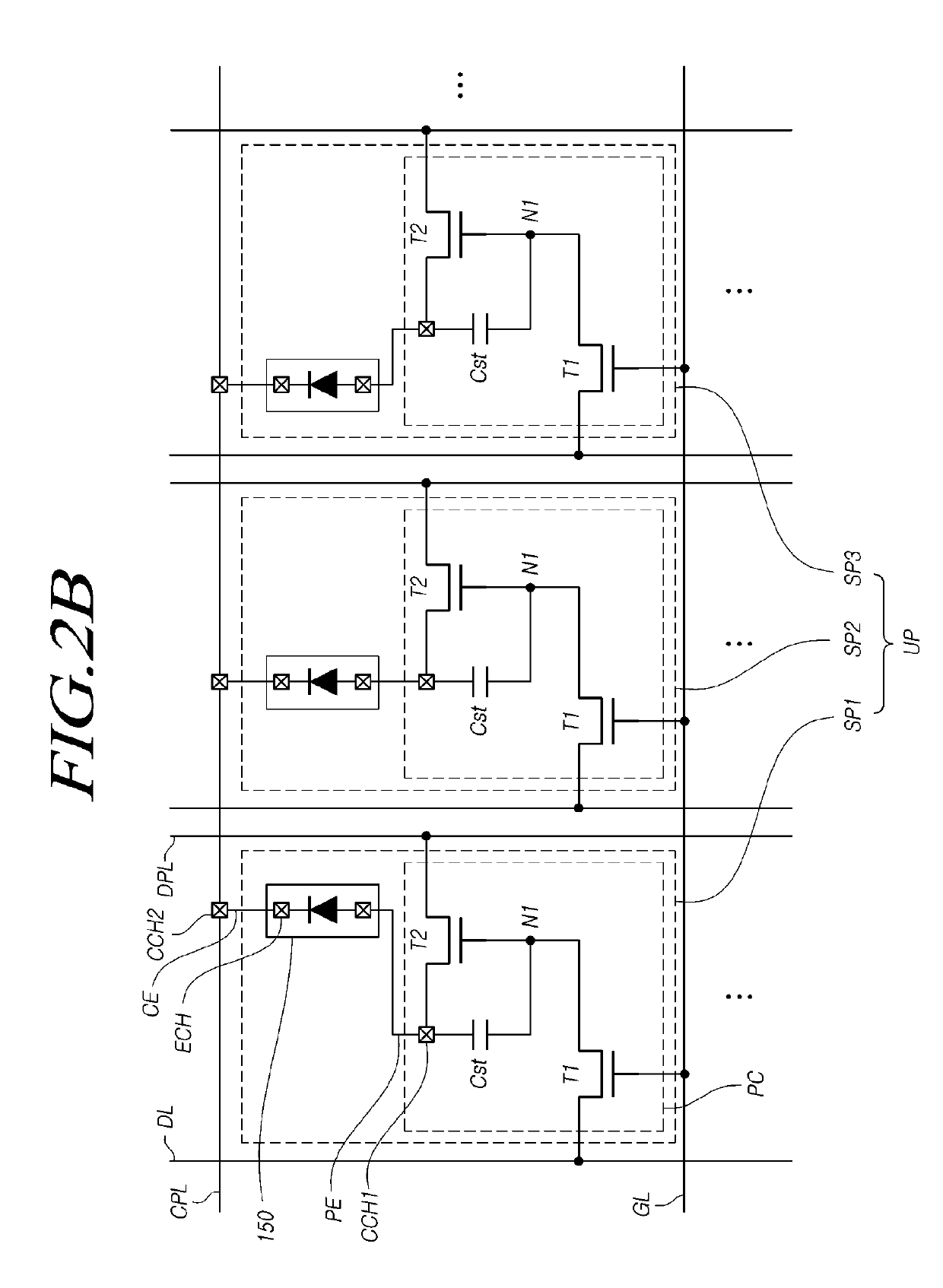

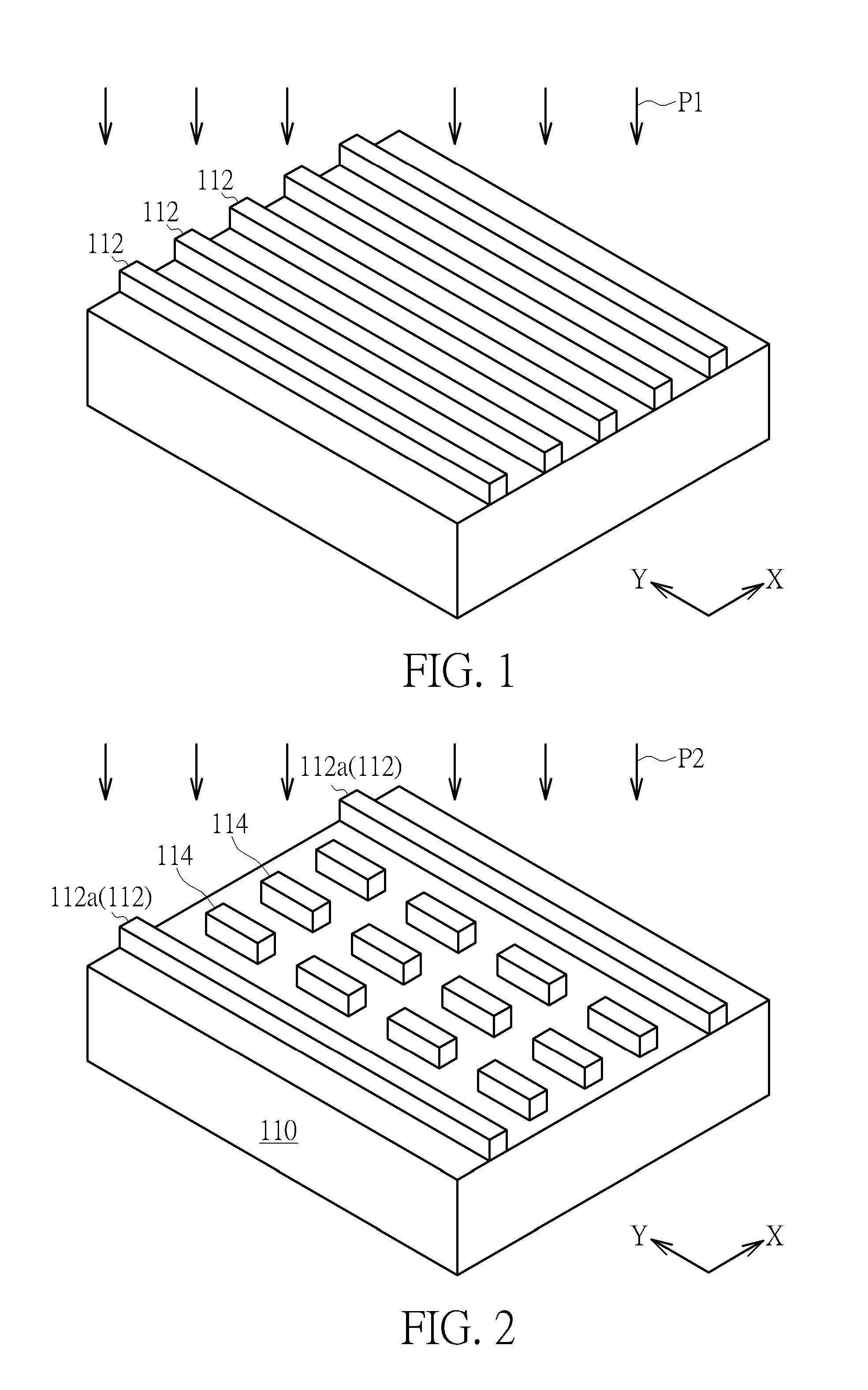

Light-emitting device and display device using the same

ActiveUS20190157512A1Provide reliablyReduce defective rateSolid-state devicesSemiconductor devicesDisplay deviceElectrical connection

A light-emitting device and a display device using the same. The light-emitting device improves the reliability of a process of disposing light-emitting devices. The light-emitting device is configured to ensure electrical connections even if the light-emitting device is inverted while being disposed on a substrate. The light-emitting device includes an n-type semiconductor layer and a p-type semiconductor layer. N-type electrodes and p-type electrodes are disposed on both sides of top and bottom surfaces of the light-emitting device. Contact holes are provided to electrically connect one of the n-type electrodes to the n-type semiconductor layer and one of the p-type electrodes to the p-type semiconductor layer. When the light-emitting device is inverted while being disposed on a substrate, the light-emitting device operates ordinarily, thereby reducing the defect rate of a display device.

Owner:LG DISPLAY CO LTD

Preparation method of LED light source and preparation method of LED light-emitting module

ActiveCN104485327AShorten the timeImprove light distribution designPoint-like light sourceSolid-state devicesFluorescenceAdhesive

The invention discloses a preparation method of an LED light source and a preparation method of an LED light-emitting module. The preparation method of the LED light source comprises the following steps: bonding an LED chip on a PET film or a PTFE film with UV adhesive on the surface, and carrying out ultraviolet irradiation for initial curing; preparing an insulation rubber layer on the LED chip; then preparing a fluorescent colloid layer; using UV light to irradiate the PET film or the PTFE film to enable the UV adhesive on the surface to lose viscidity, and taking down the LED chip after encapsulation to obtain the LED light source. The LED light sources are arranged in a series-parallel connection mode, and are welded on a base plate, so that the LED light-emitting module is obtained. According to the preparation methods, in the aspect of material composition, supports and money are saved, the reliability is improved while the cost is reduced, the material cost can be reduced, the light-emitting angle is increased, the processing convenience is increased, and the production link is simplified. The position of fluorescent powder is far away from the chip through the insulation rubber layer, so that the thermal quenching and thermal efficiency of the fluorescent powder are reduced, and the lighting effect and long-term lumen maintenance are improved.

Owner:HANGZHOU HANGKE OPTOELECTRONICS

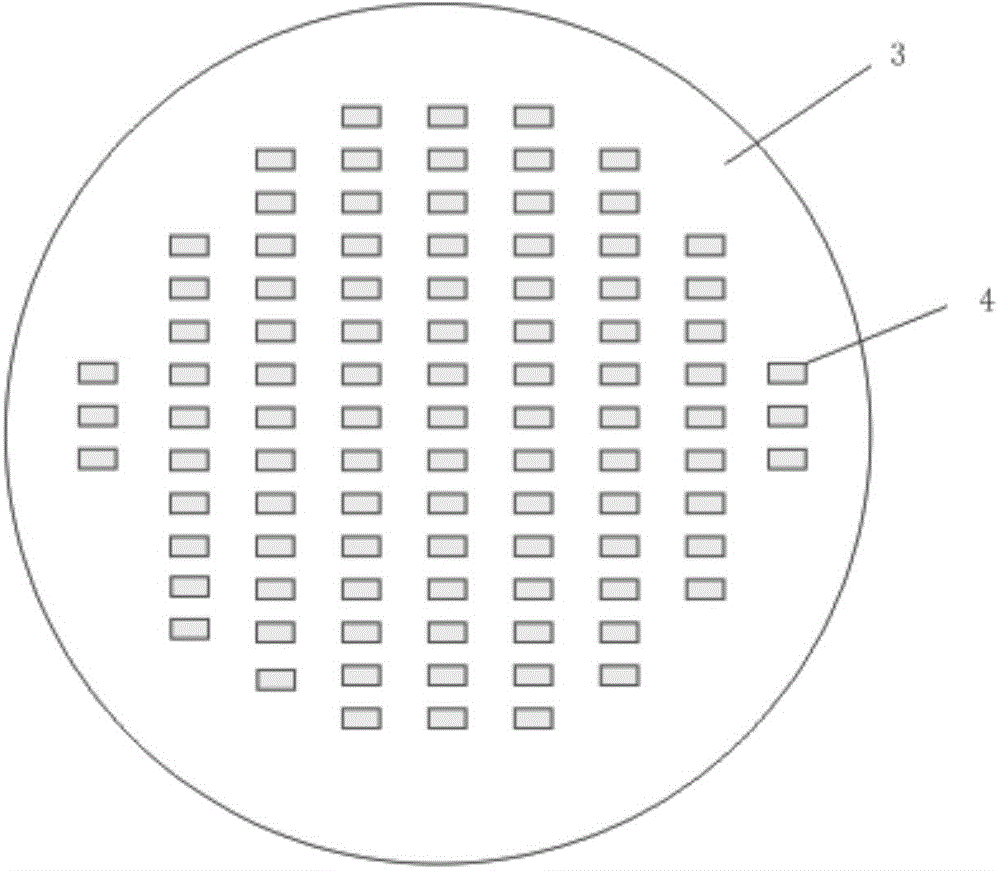

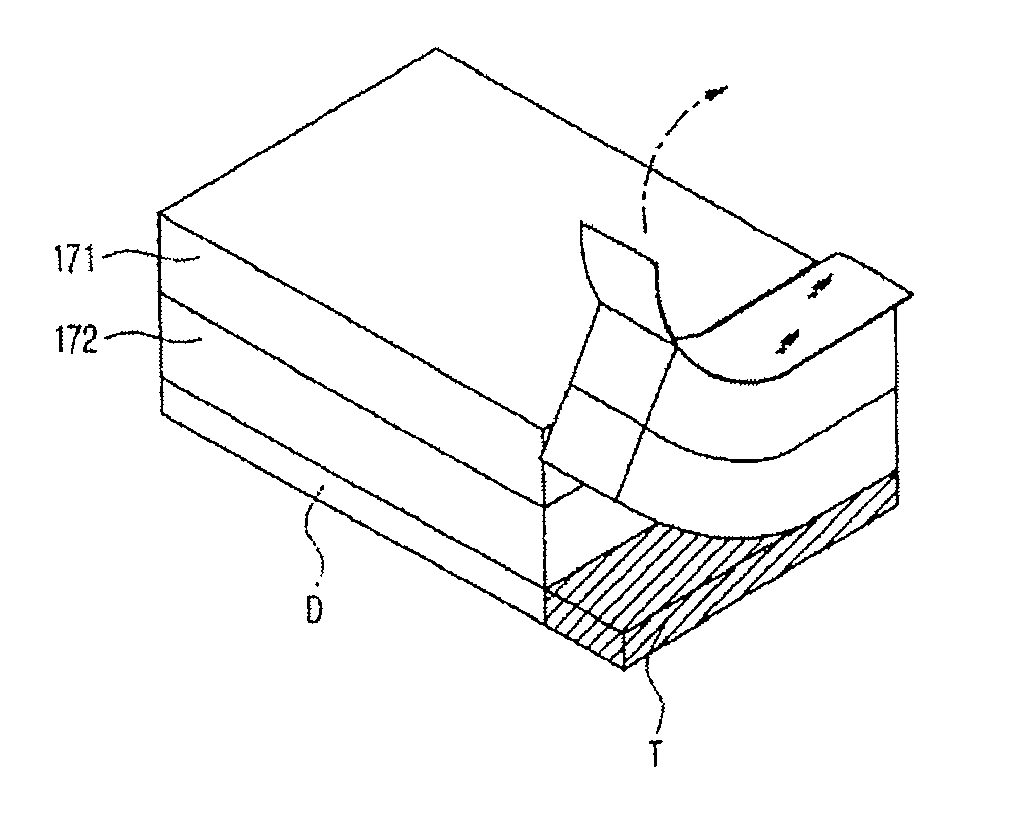

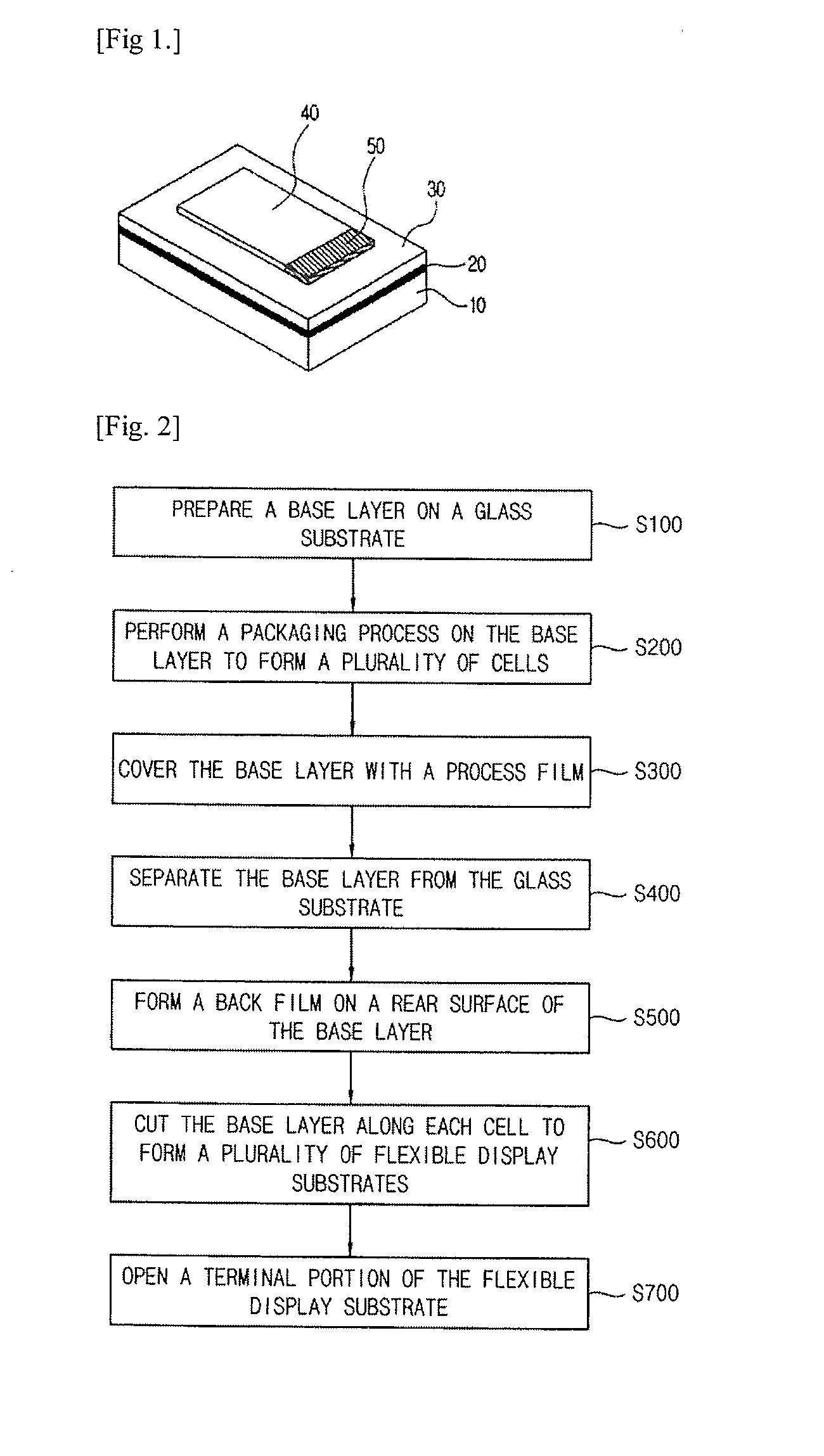

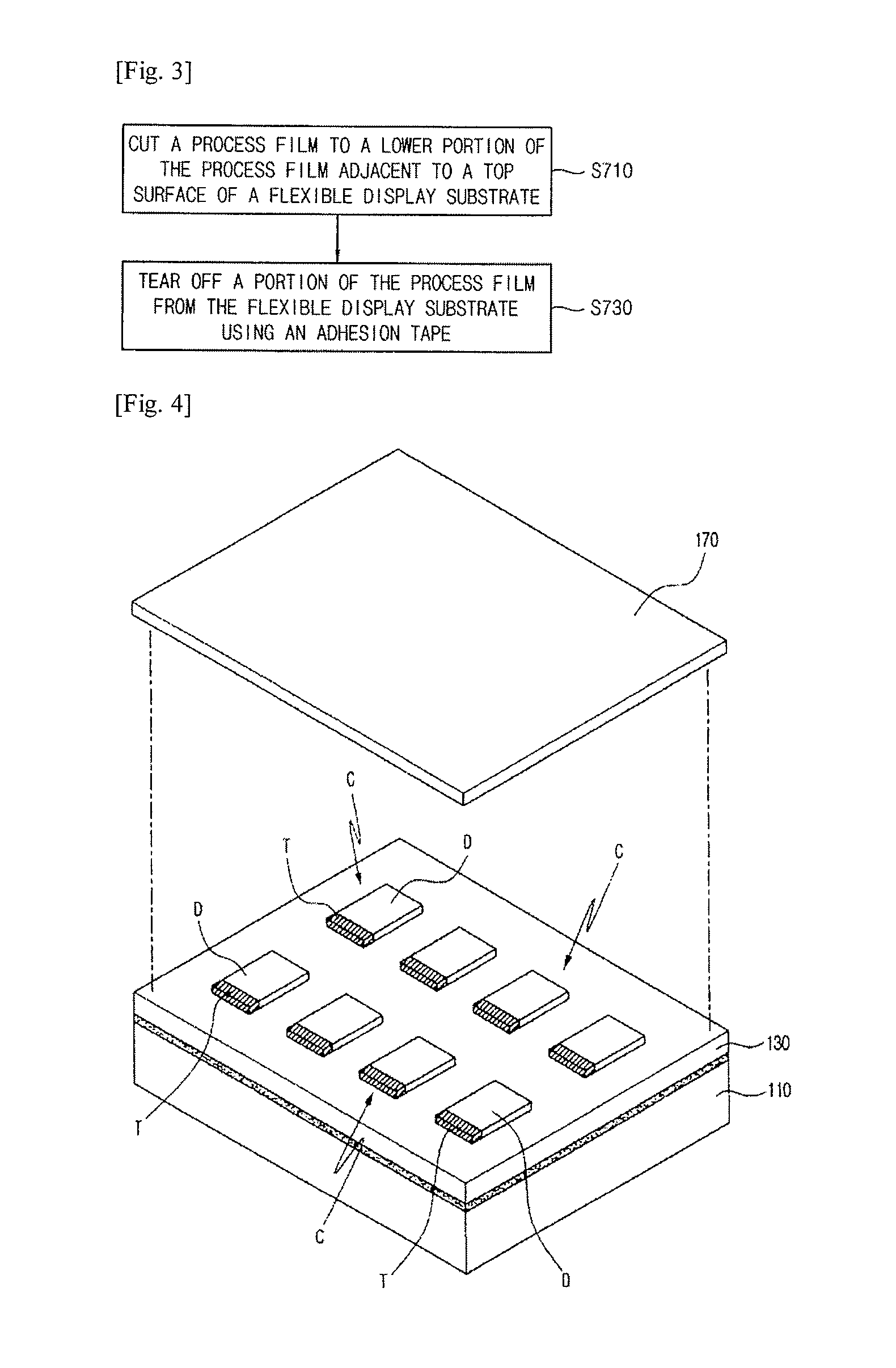

Method of manufacturing a flexible display substrate and process film for manufacturing a flexible display substrate

ActiveUS20140318690A1Improve processing convenienceImprove reliabilityLamination ancillary operationsLayered product treatmentEngineeringFlexible display

A method of manufacturing a flexible display substrate using a process film and a process film for manufacturing a flexible display substrate are provided. The method of manufacturing the flexible display substrate using the process film is as follows. A base layer for the flexible display substrate is prepared on a glass substrate. A packaging process is performed on the base layer to form a plurality of cells which are spaced apart from one another at a predetermined distance. The base layer is covered with the process film, after forming the plurality of cells. The base layer is separated from the glass substrate, while the base layer is laminated to the process film. The base layer is cut along each cell to form a plurality of flexible display substrates. Accordingly, the method of manufacturing the flexible display substrate using the process film is provided to improve the convenience of a manufacturing process and the reliability of the manufactured flexible display substrate by manufacturing the plurality of display substrates using the process film.

Owner:SAMSUNG DISPLAY CO LTD

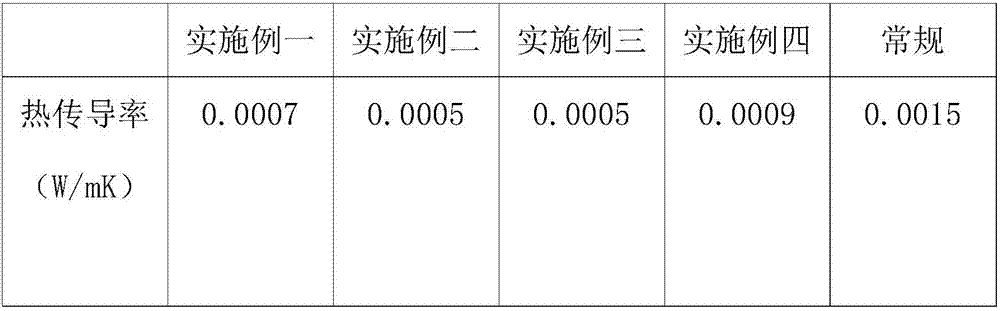

Vacuum thermal-insulation plate core material for building

InactiveCN106946535AImprove stabilityReduce manufacturing costClimate change adaptationInsulation improvementSodium BentonitePolyvinyl alcohol

The invention belongs to the field of vacuum thermal-insulation plates, and particularly relates to a vacuum thermal-insulation plate core material for building. In the prior art, the existing core material does not have excellent pressure-resistant stability and excellent thermal-insulation stability, and has disadvantages of high heat thermal conductivity, high cost and difficult processing, and the heat inertness and the thermal insulation do not meet the stringent requirements. A purpose of the present invention is to solve the problems in the prior art. The technical scheme of the present invention is that the raw materials comprise, by weight, 20-25 parts of stone wool fibers, 18-22 parts of glass fibers, 23-26 parts of mineral wool, 22-26 parts of silicon dioxide, 14-18 parts of calcium chloride hexahydrate, 8-12 parts of quicklime, 6-9 parts of acrylic acid, 7-11 parts of polyvinyl alcohol, 4-8 parts of potassium bisulfite, 13-16 parts of bentonite, 11-14 parts of quartz sand, 9-13 parts of magnesium oxide, 5-8 parts of zinc oxide, and 30-35 parts of deionized water. The preparation method comprises: S1, adding acrylic acid and deionized water to a reaction kettle. According to the present invention, the vacuum thermal-insulation plate core material has advantages of excellent pressure-resistant stability, excellent thermal-insulation stability, low thermal conductivity, high hardness, excellent heat inertness, excellent heat insulation effect, low production cost, and convenient processing.

Owner:HUANGHE S & T COLLEGE

Polycarbonate/polyethylene alloy conductive composite material and preparation method thereof

ActiveCN101870807AFill percolation value reducedImprove conductivityNon-conductive material with dispersed conductive materialProcedure AgentsAlloy

The invention discloses a polycarbonate / polyethylene alloy conductive composite material and a preparation method thereof. The polycarbonate / polyethylene alloy conductive composite material comprises the following components by weight part: 50-80 parts of polycarbonate, 10-30 parts of polyethylene resin, 6-12 parts of conductive carbon black and 2-6 part of compatibilizer. The preparation method comprises the following steps: uniformly mixing the polyethylene resin, the conductive carbon black, heat stabilizers and processing aids in a high-speed mixer, and then entering a co-rotating twin screw extruder to be melted and granulated by extrusion at a temperature of 190 DEG C and 220 DEG C; and after being uniformly mixed, the polycarbonate, the compatibilizer and the conductive polyethylene substrate are directly injected by an injection molding machine to finally obtain the product. The whole composite material of the invention has greatly reduced filling percolation value of the conductive carbon black, and has excellent overall performance. The preparation method has improved processing convenience and reduced production cost.

Owner:KINGFA SCI & TECH CO LTD +1

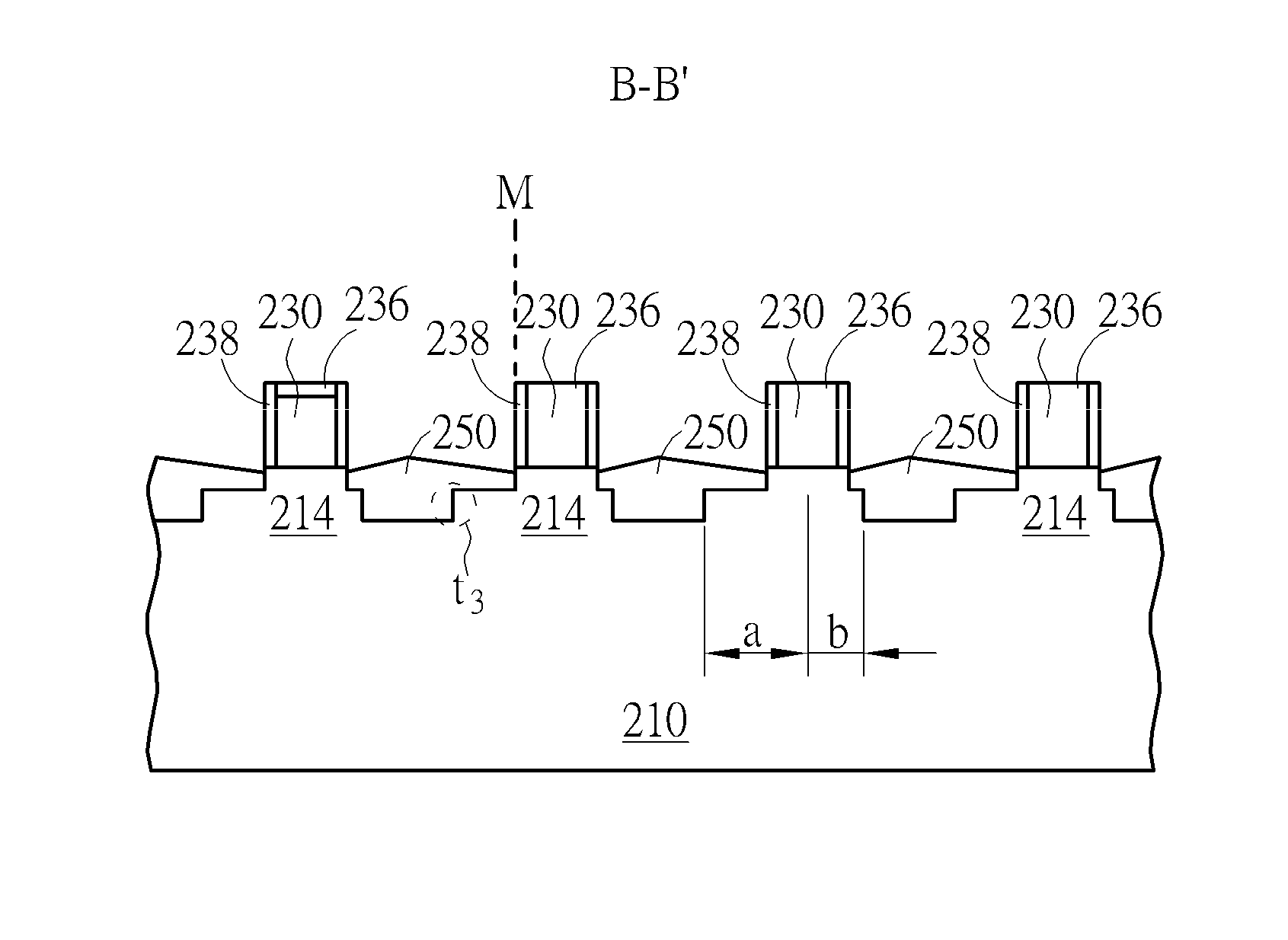

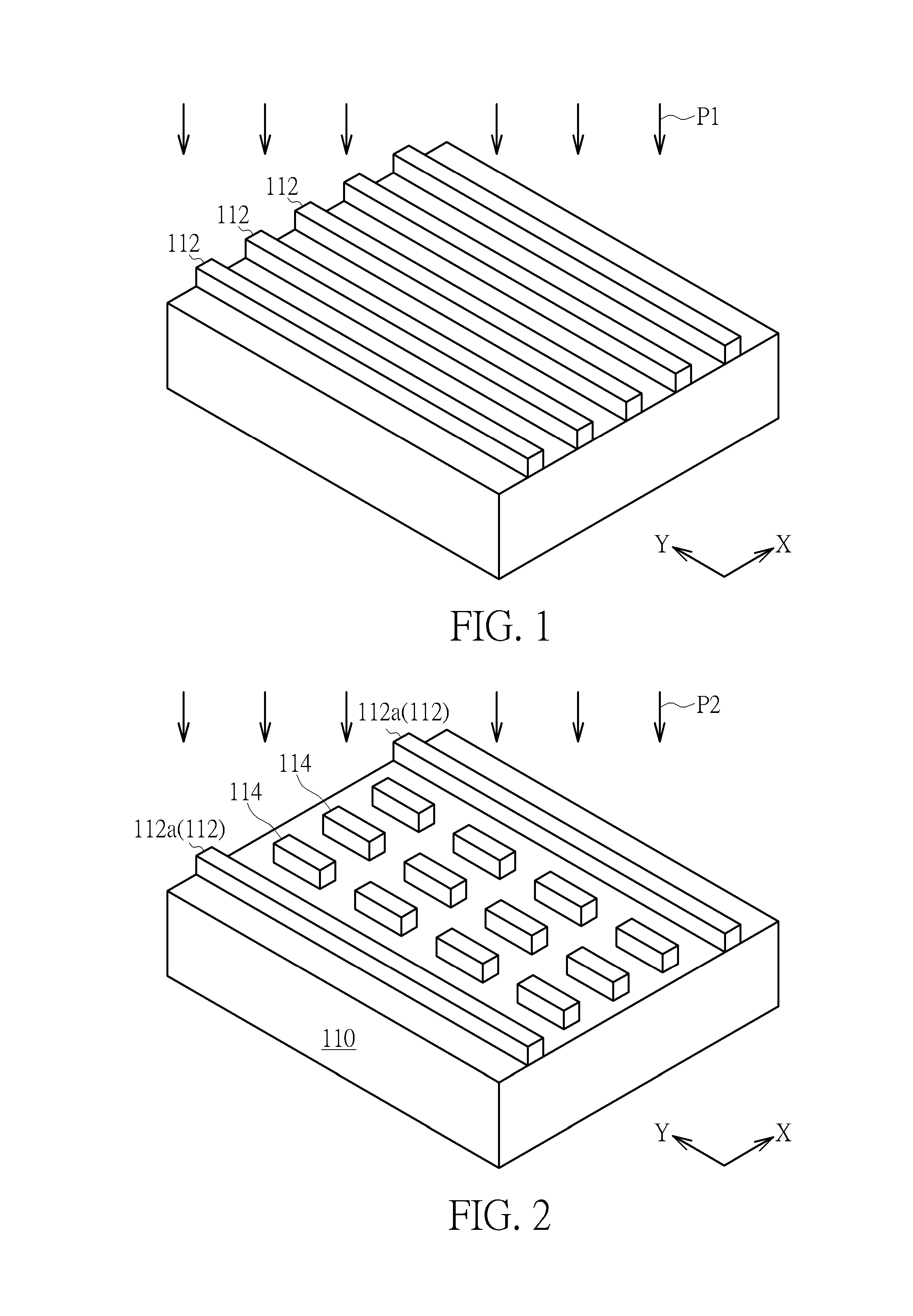

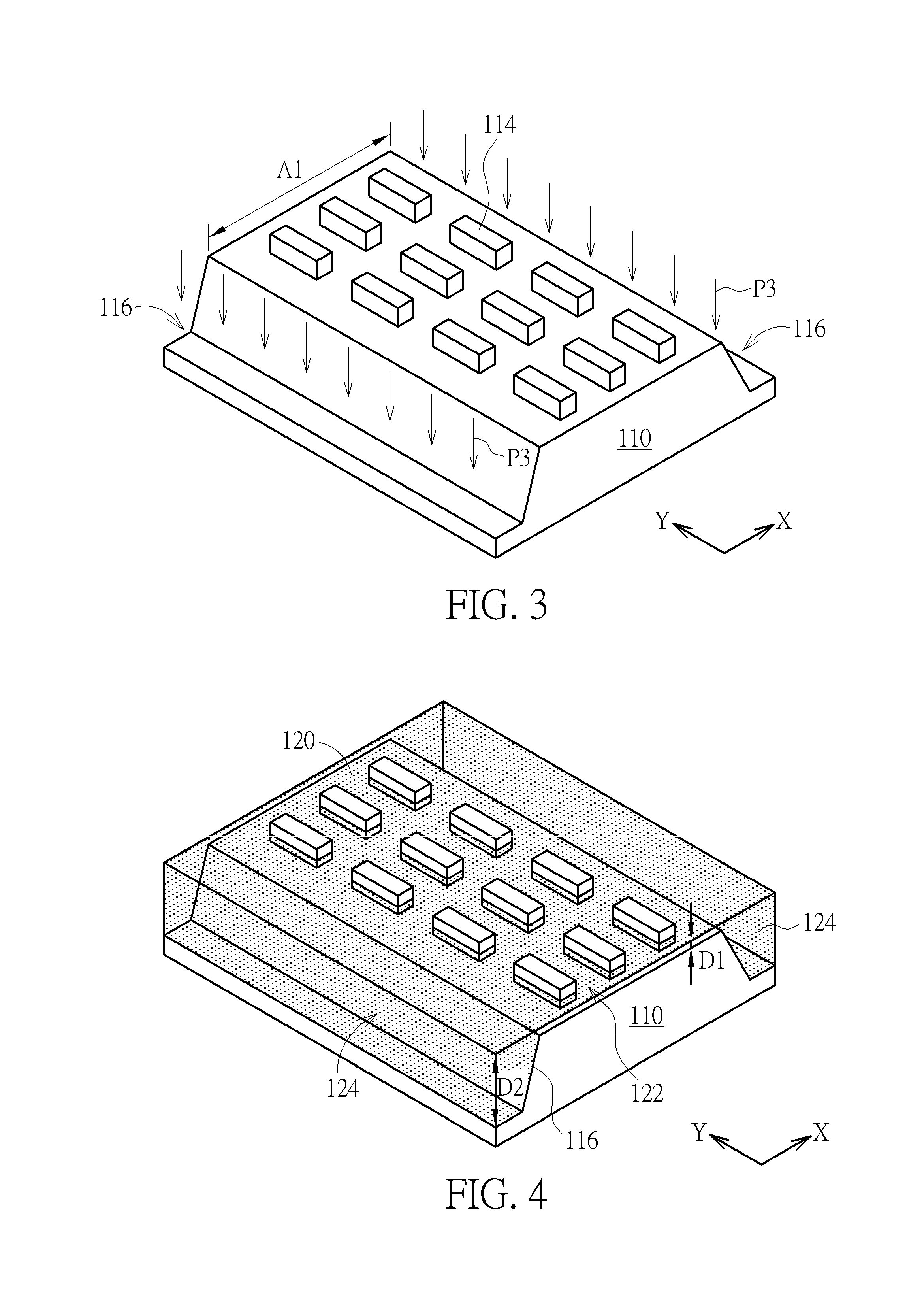

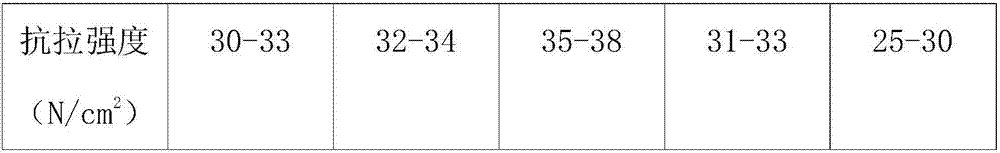

Semiconductor structure and manufacturing method thereof

ActiveUS20160365344A1Improve processing convenienceImprove epitaxial layer qualityTransistorSolid-state devicesSemiconductor structureEngineering

The present invention provides a semiconductor structure, including a substrate having a first fin structure and a second fin structure disposed thereon, a first isolation region located between the first fin structure and the second fin structure, a second isolation region located opposite the first fin structure from the first isolation region, and at least an epitaxial layer disposed on the side of the first fin structure and the second fin structure. The epitaxial layer has a bottom surface, the bottom surface extending from the first fin structure to the second fin structure, and the bottom surface is lower than a bottom surface of the first isolation region and a top surface of the second isolation region.

Owner:MARLIN SEMICON LTD

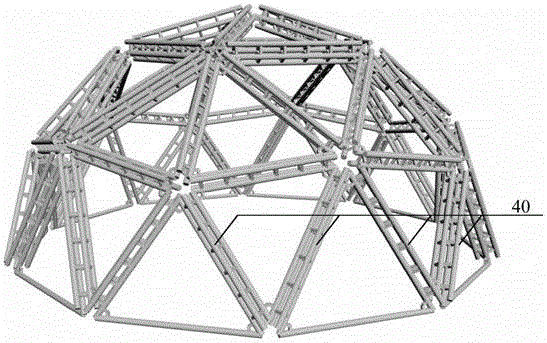

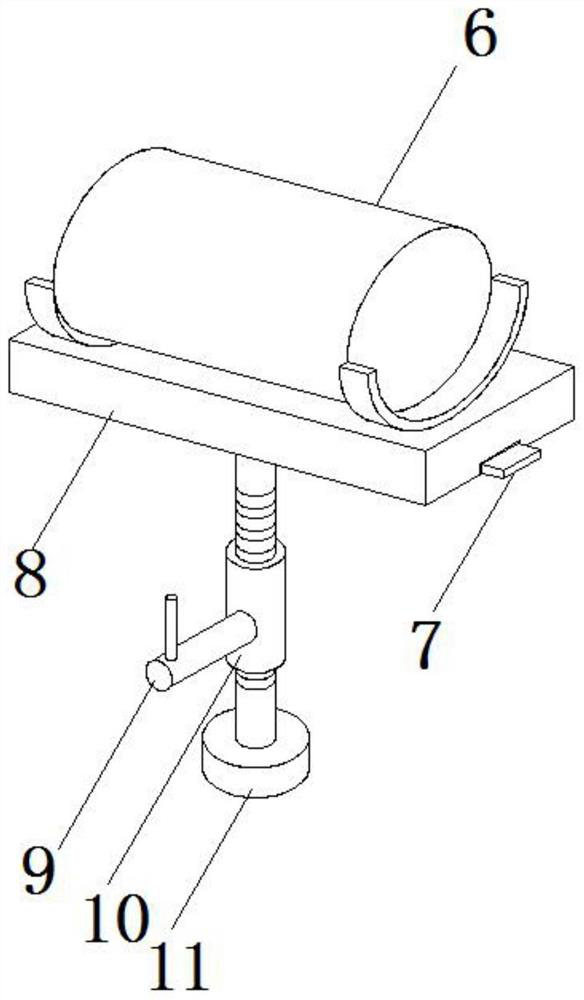

Raw bamboo multi-pipe beam space lattice structure system and double-pipe-clamp type connecting element series

The invention discloses a raw bamboo multi-pipe beam space lattice structure system and a double-pipe clamp type connecting element series. A single double-pipe clamp comprises a left circular ring, a right circular ring and screw bolts; the left and right circular rings have the same or different dimensions, are respectively hooped on the outer wall of one bamboo pipe and are tightly hooped and fixed by screw bolts arranged at the two sides; the sides between the left circular ring and the right circular ring are connected through being fastened and hooped by the same screw bolt; the single bamboo pipe triangular shape is mainly formed by connecting three bamboo pipes as rod elements by a folding type double-pipe clamp; the raw bamboo multi-pipe beam space lattice structure is mainly formed by connecting a plurality of bamboo pipe triangles as installing units by the double-pipe clamp; the bamboo pipe or the bamboo pipe triangular shape can be sequentially and singly replaced through dismounting and mounting the double-pipe clamp; the structure repair is completed. The structure of the double-pipe clamp type connecting element is simple; the universality is high; the processing convenience is good; the connection reliability of the bamboo pipe and the double-pipe clamp is high; the integral structure bearing force is great; the building use comfort is good; the structure repair is convenient; the structure durability is high.

Owner:ZHEJIANG UNIV

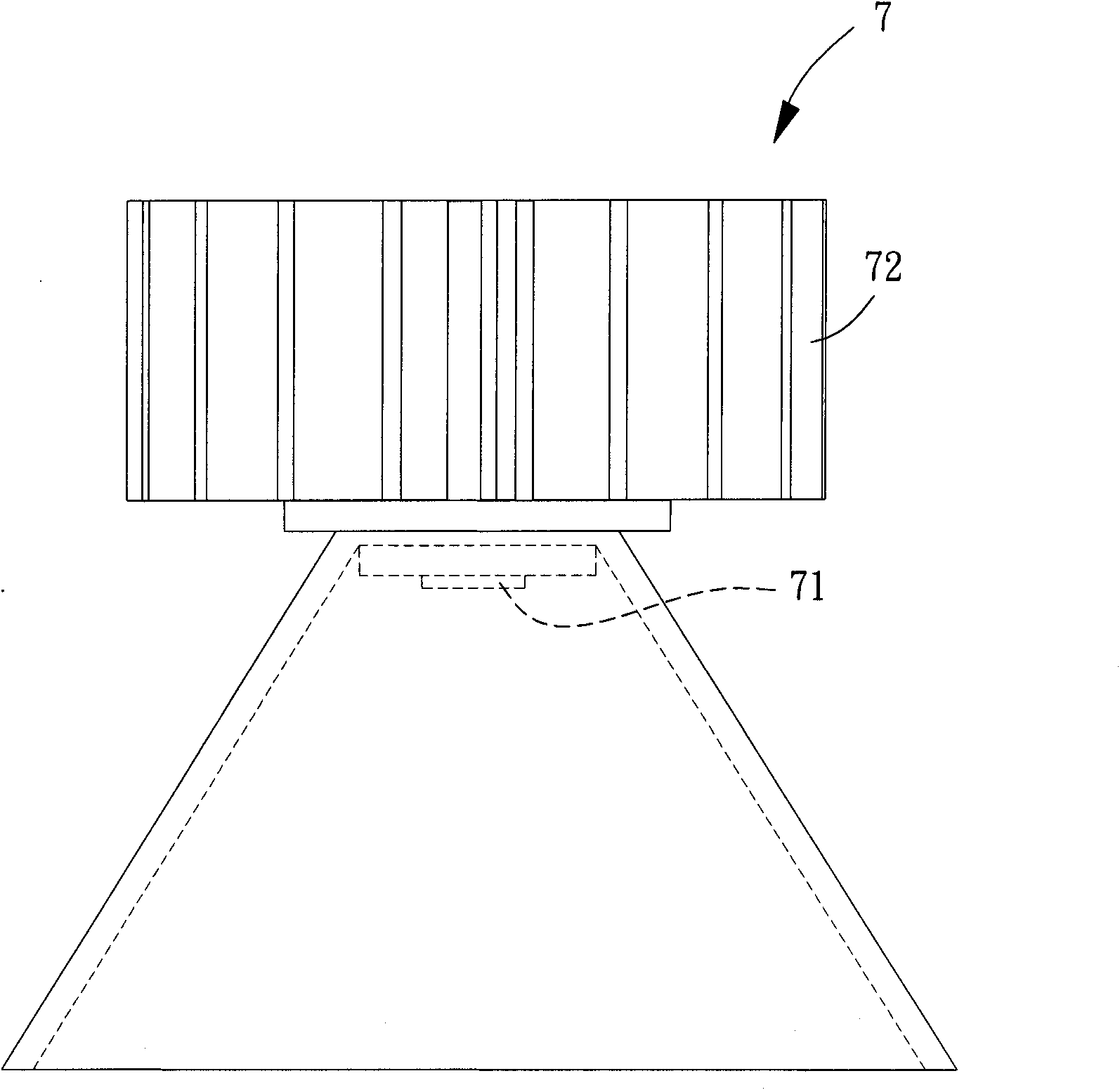

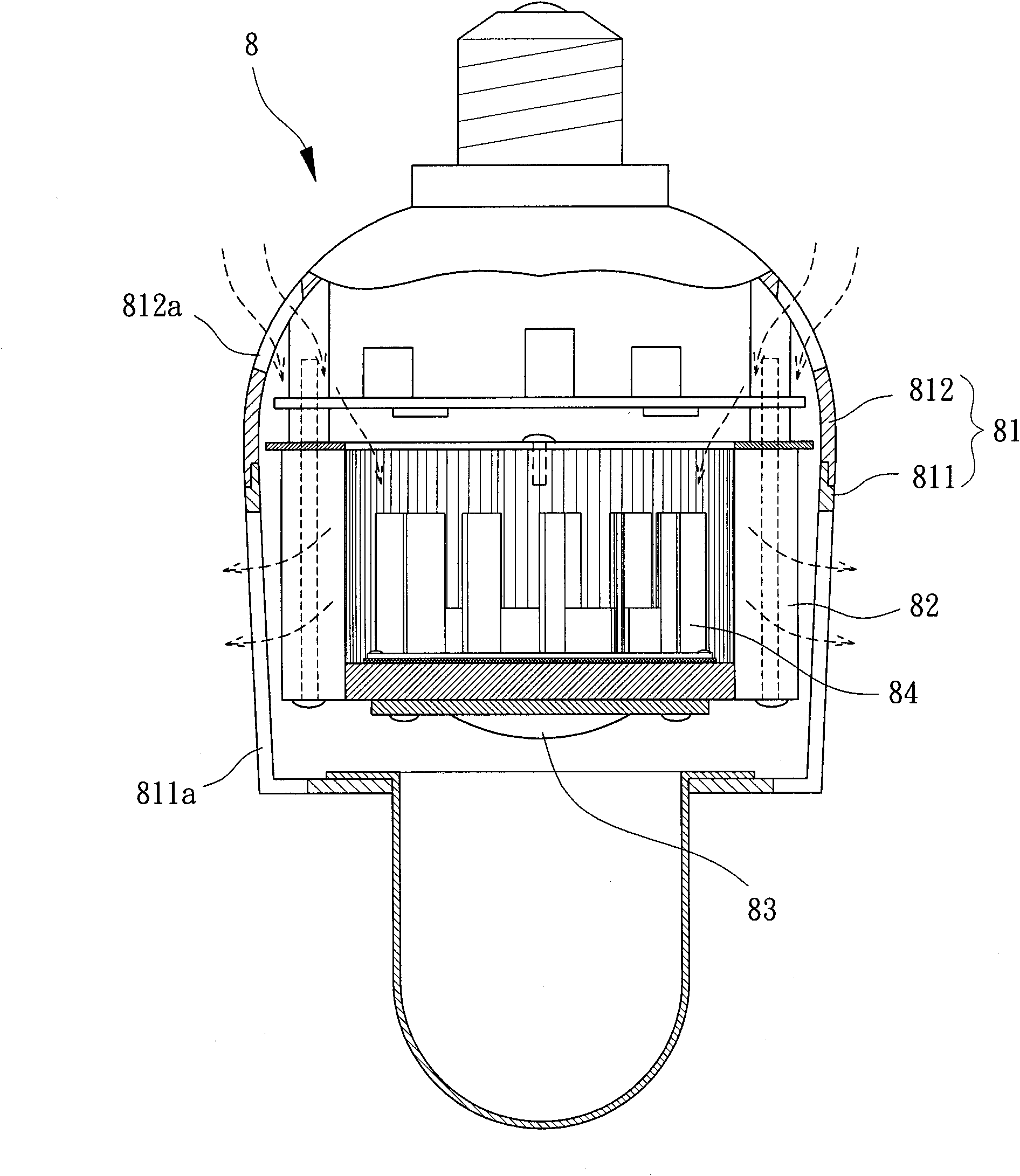

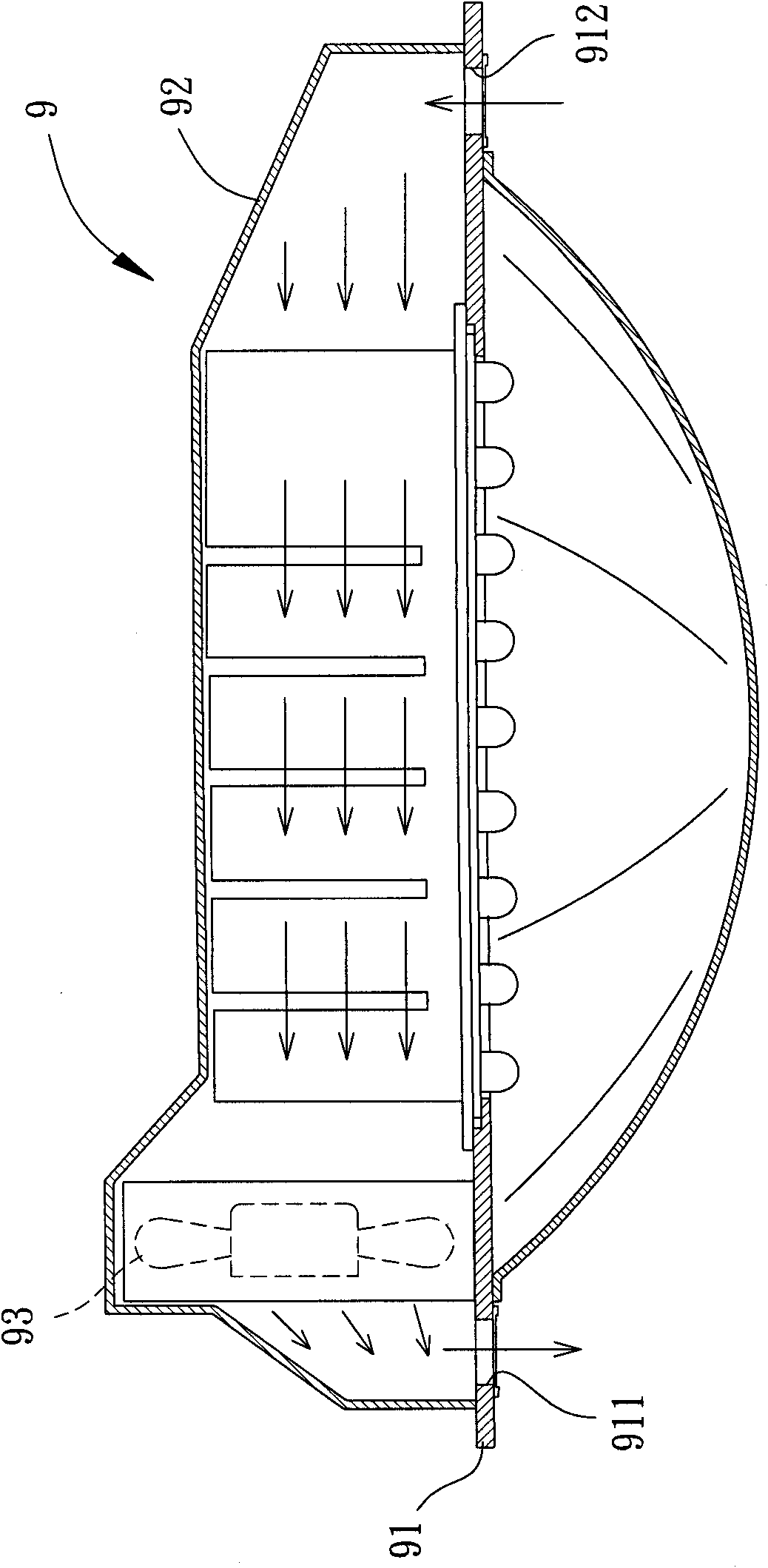

Lamp

InactiveCN102679196AImprove cooling effectReduce manufacturing costPoint-like light sourceLighting heating/cooling arrangementsManufacturing cost reductionHeat conducting

A lamp includes a heat conducting member, a light-emitting module, a housing and a cooling fan. The heat conducting member has a first face and a second face opposite to the first face. The light-emitting module is coupled with the first face. The housing is coupled with the heat conducting member and has a terminal opening, wherein first and second air-guiding openings are formed between the terminal opening and the heat conducting member. The housing has an inner circumferential wall. An air-flowing room is formed between the inner circumferential wall and the second face. The air-flowing room communicates with the first air-guiding opening and the second air-guiding opening. The cooling fan is disposed at the first or second air-guiding opening. Via the above structure, cooling effect can be improved, assembly convenience, dedusting convenience, and processing convenience are improved, manufacture cost is reduced and service lifetime of the lamp is improved.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

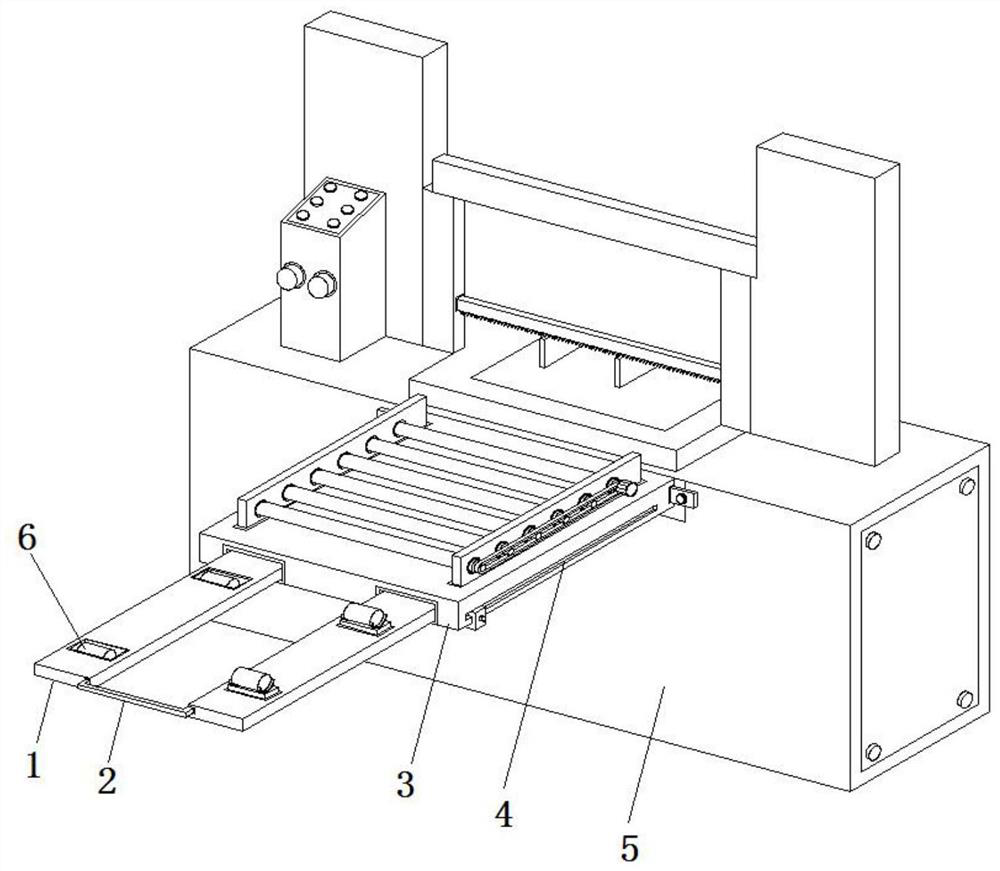

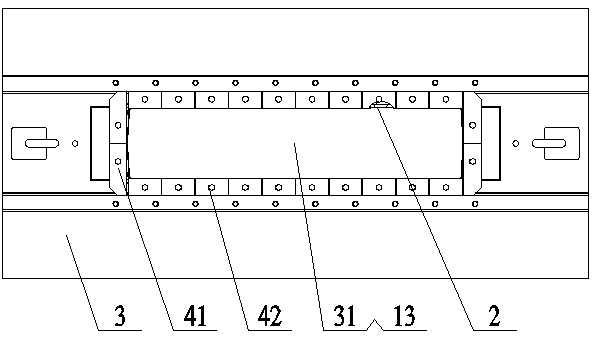

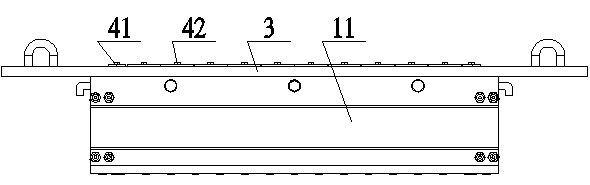

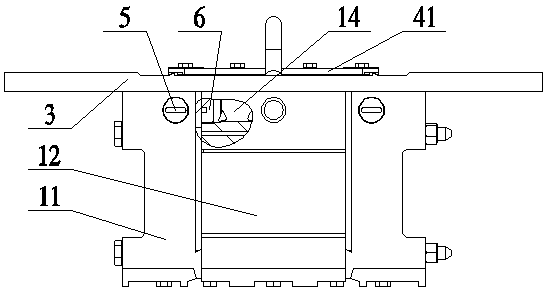

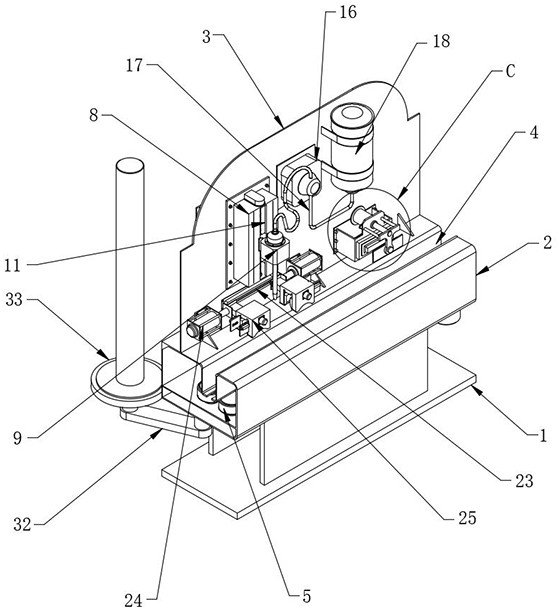

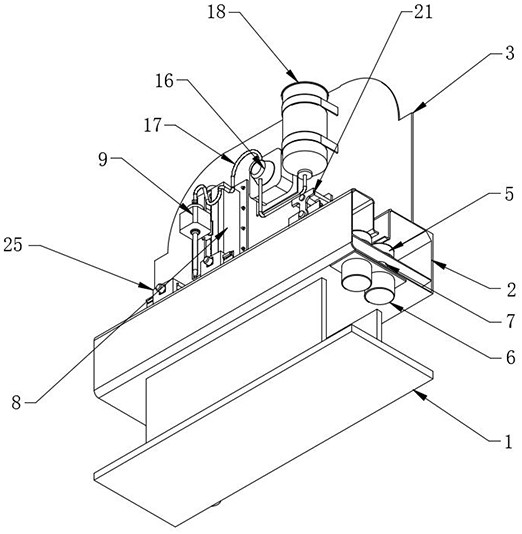

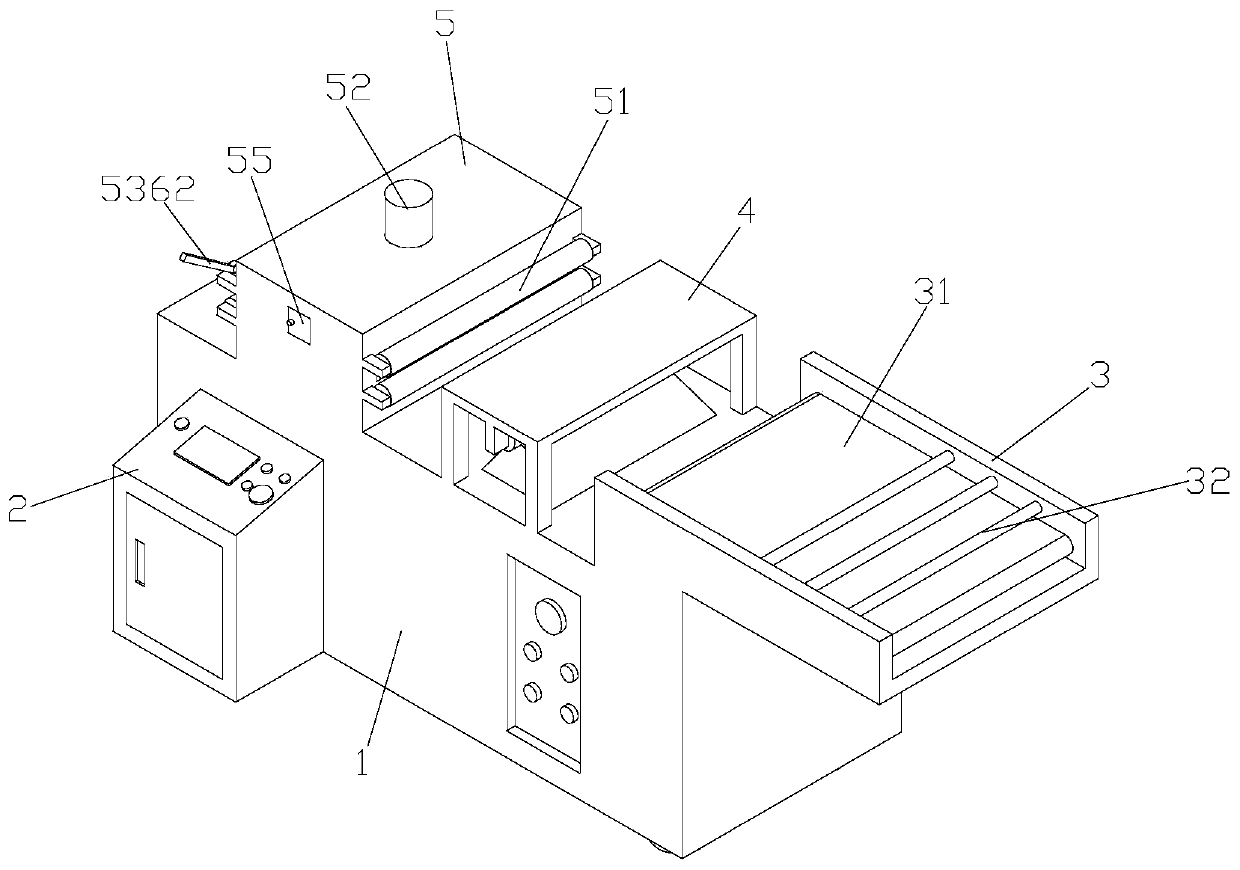

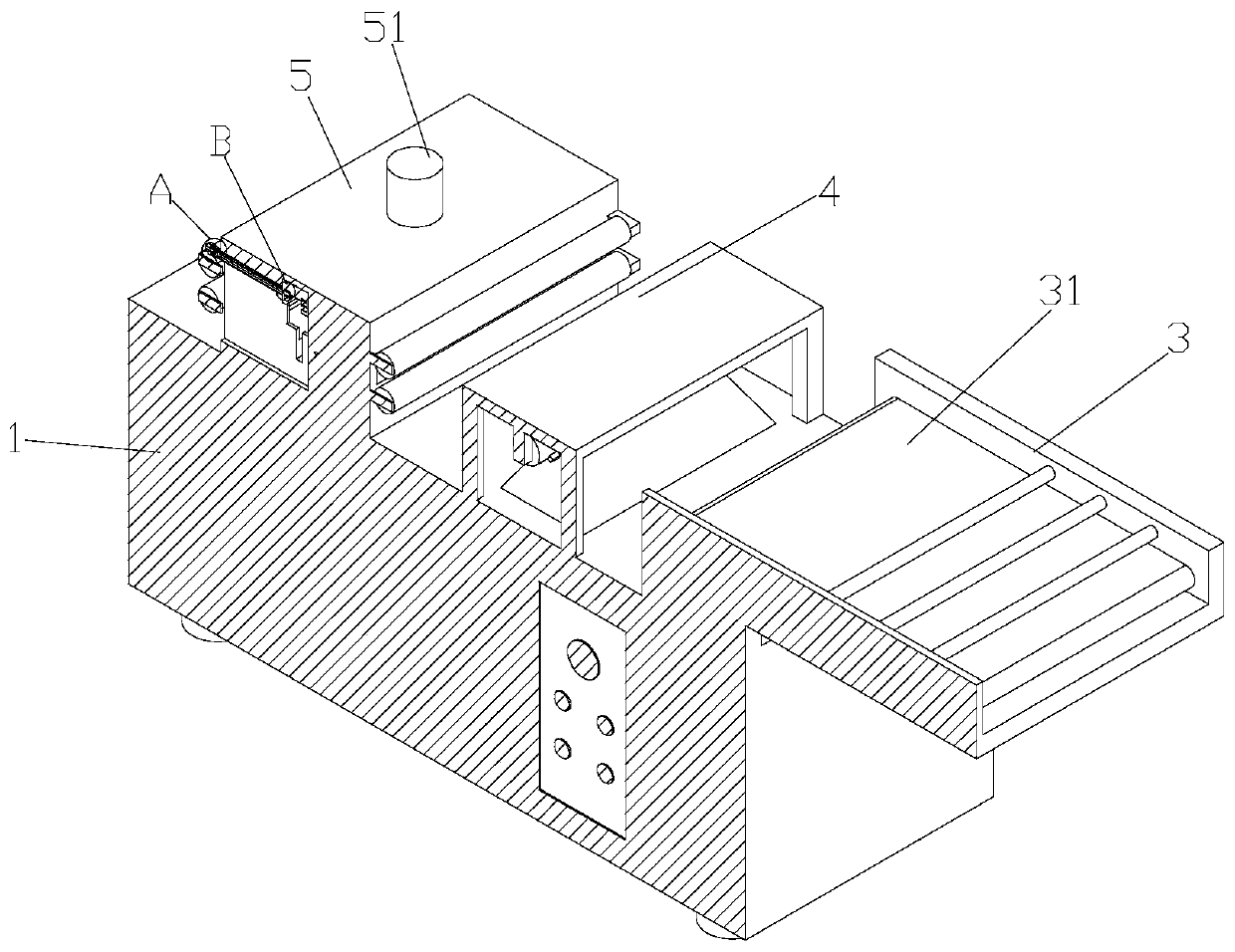

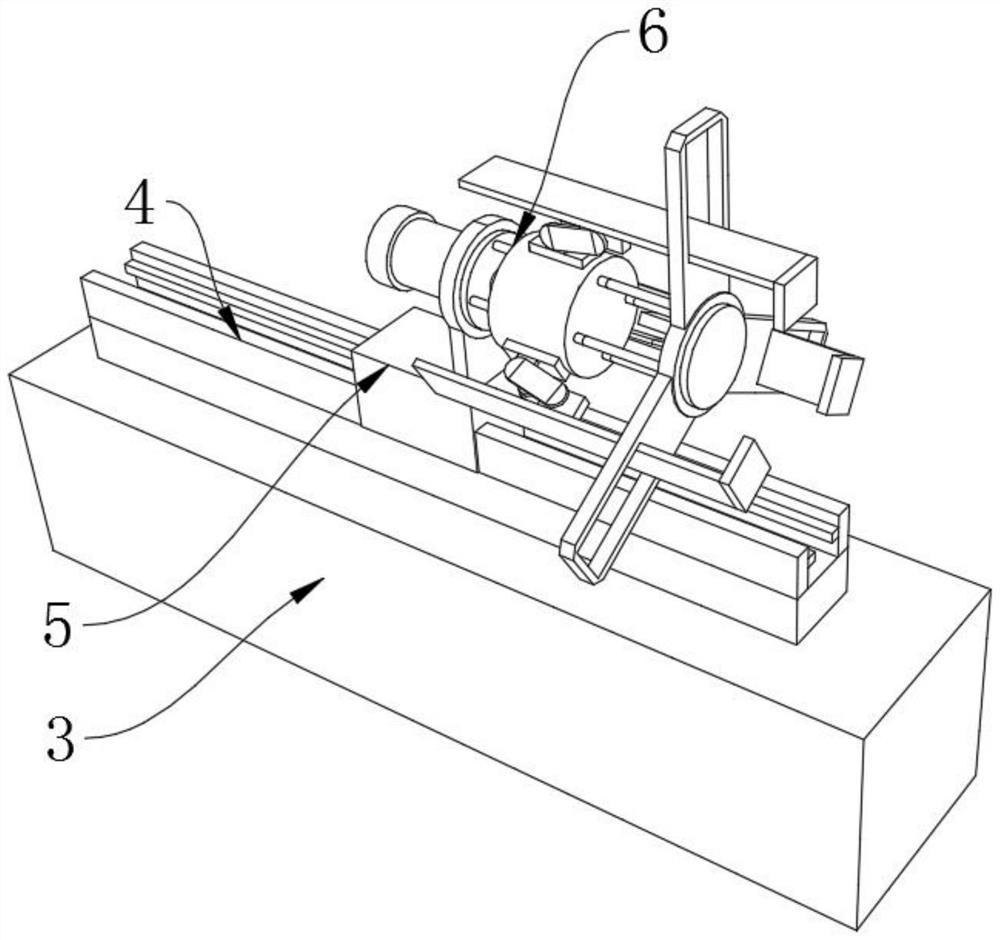

Novel sawing machine with feeding platform

PendingCN112720038AImprove processing efficiencyImprove processing convenienceMetal working apparatusElectric machineryDrive motor

The invention discloses a novel sawing machine with a feeding platform. The novel sawing machine comprises a sawing machine body, a pair of sliding plates, a fixing plate and a driving motor; the fixing plate flush with the upper surface of the sawing machine body is arranged on the back face of the sawing machine body, two moving grooves are horizontally formed in the fixing plate, and the sliding plates are installed in the moving grooves in a sliding mode; and the pair of sliding plates are arranged, a handle is arranged at the ends, away from the sawing machine body, of the pair of sliding plates in a series connection mode; and two mounting grooves are formed in each sliding plate in a penetrating mode, supporting plates are embedded into the mounting grooves in a sliding mode, limiting blocks are welded to the side walls of one sides of the supporting plates in a protruding mode, limiting grooves allowing the limiting blocks to extend into and slide are vertically formed in the inner walls of the mounting grooves, sliding wheels are rotatably mounted on the upper surfaces of the supporting plates, the bottoms are rotationally connected with one ends of threaded rods, and the threaded rods are vertically arranged. The novel sawing machine with the feeding platform is reasonable in structure, the machining convenience of the sawing machine is improved, and the sawing machine can be widely popularized.

Owner:无锡卓荣精密机械有限公司

Polylactic acid film material for small packaging of traditional Chinese medicine decoction pieces and preparation method of polylactic acid film material

The invention relates to a polylactic acid film material for small packaging of traditional Chinese medicine decoction pieces and a preparation method of the polylactic acid film material. The polylactic acid film material is mainly prepared from the following raw materials in parts by weight: 80 parts of polylactic acid, 4.0-5.0 parts of poly succinic acid-butanediol ester, 10-12 parts of polycaprolactone, 4.0-5.0 parts of epoxidized soybean oil, 0.40-0.50 part of nano SiO2, 0.45-0.55 part of nano ZnO, 0.45-0.55 part of nano kaolin, 0.40-0.50 part of nano TiO2, 1.0-1.2 parts of an amino silane coupling agent, 0.30-0.40 part of stearate, and 0.40-0.45 part of an antioxidant. According to the polylactic acid film material, good mechanical strength and toughness are achieved, obstructing performance on oxygen and water vapor is achieved, an addition agent is not prone to removing and dissolving out, bag making processing is easy, the polylactic acid film material is suitable for use andpopularization in the field of the small package traditional Chinese medicine decoction pieces, rapid degradation can be achieved in the environment, and the safety and reliability are achieved.

Owner:巩义市欧洁源环保技术服务有限公司

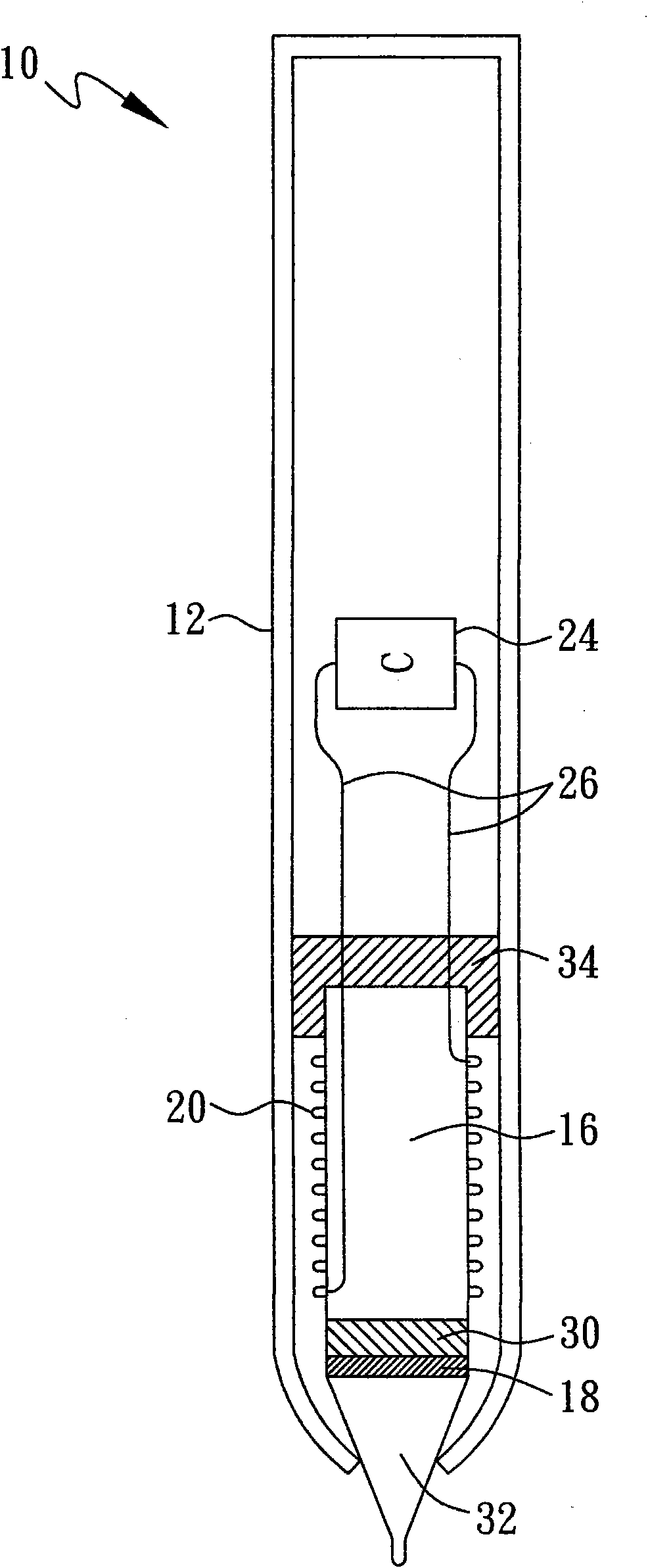

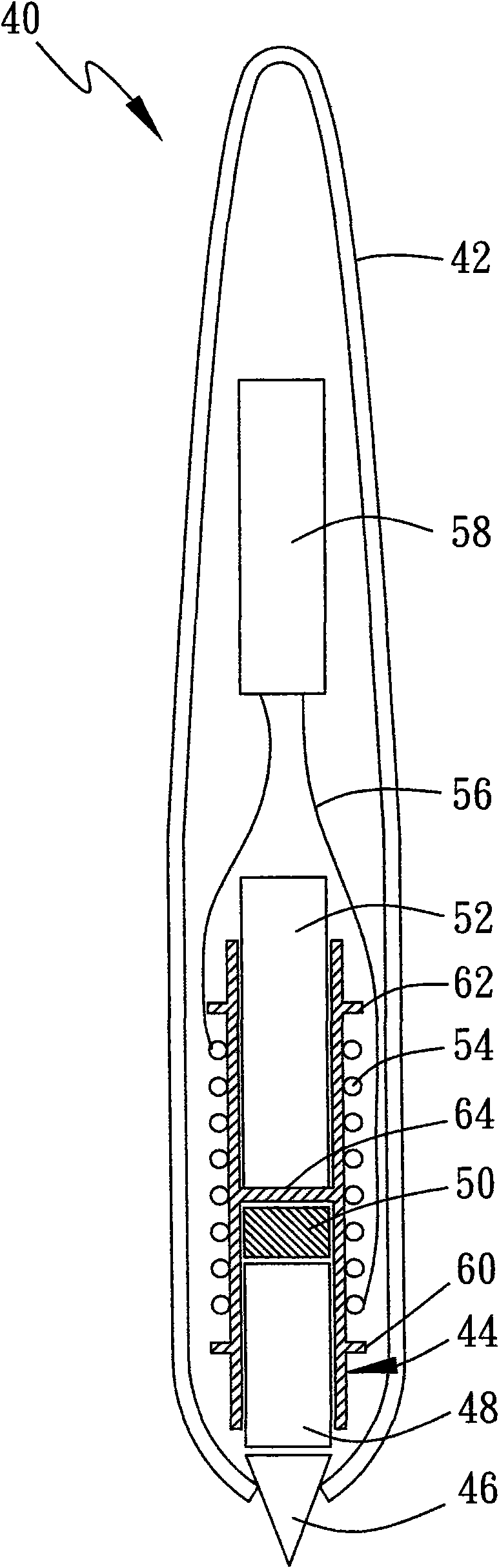

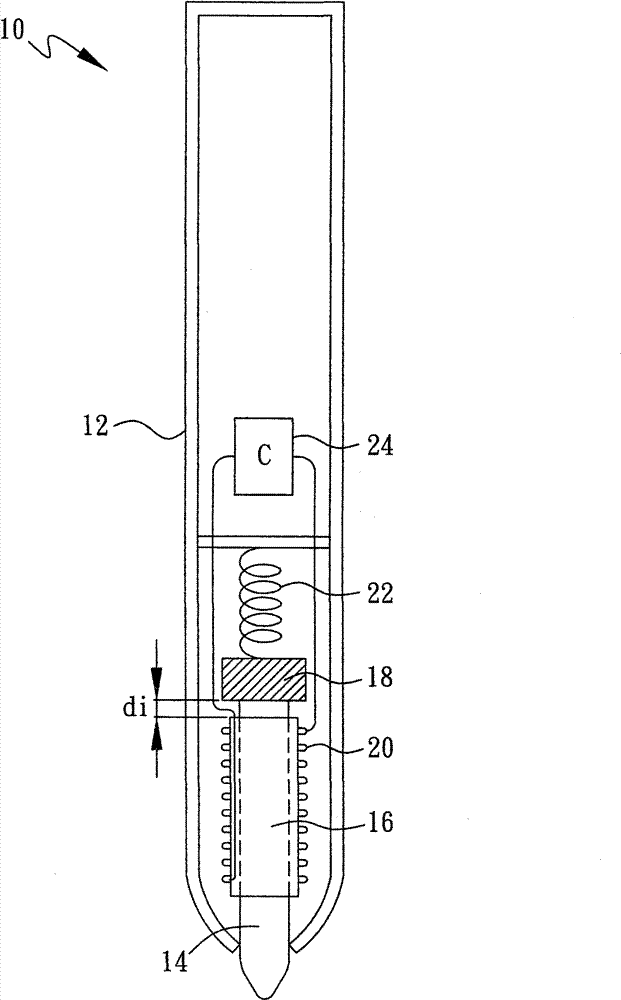

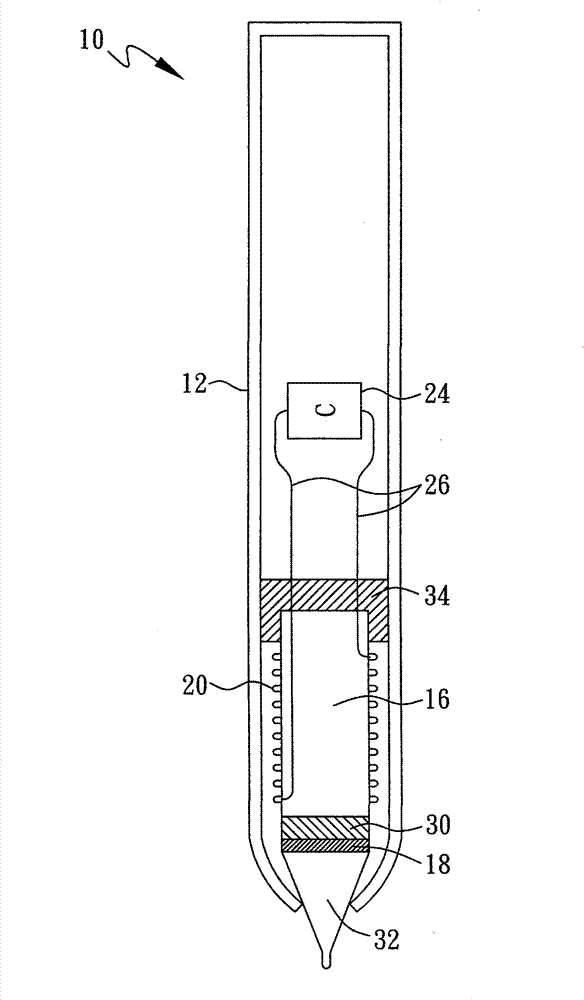

Input pen with function of electromagnetic induction

ActiveCN101995968AImprove processing convenienceImprove pressure sensing accuracyInput/output processes for data processingEngineeringElectromagnetic shielding

The invention relates to an input pen with a function of electromagnetic induction, which comprises a pen point, a movable ferromagnetic material, a fixed ferromagnetic material, an elastic material, a shell substance and a shell, wherein one end of the movable ferromagnetic material is adjacent to the pen point; the elastic material is arranged between the movable ferromagnetic material and the fixed ferromagnetic material; the shell is fixed with the lamella object; the lamella object coats the elastic material, a part of the movable ferromagnetic material and a part of the fixed ferromagnetic material; and a coil coats the lamella object and is connected with an oscillating circuit through a lead.

Owner:WACOM CO LTD

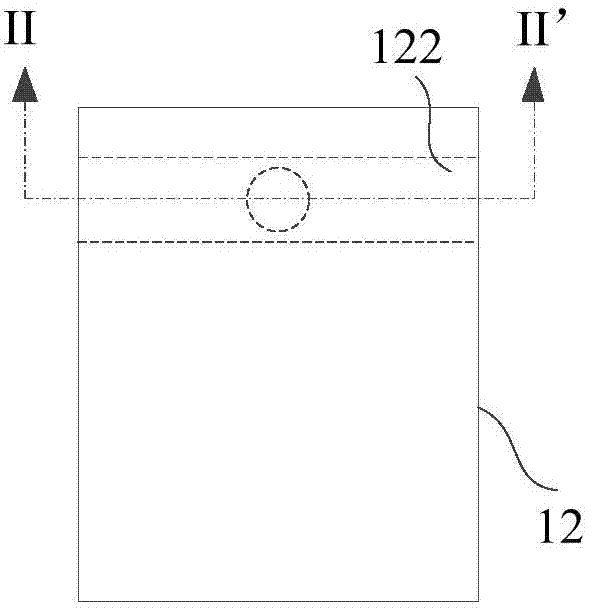

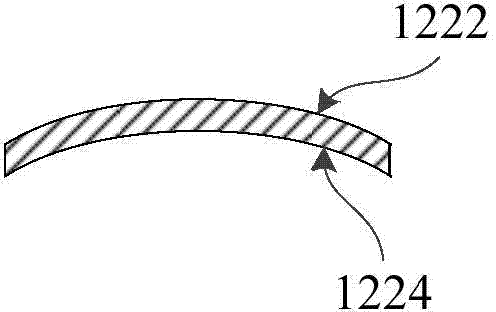

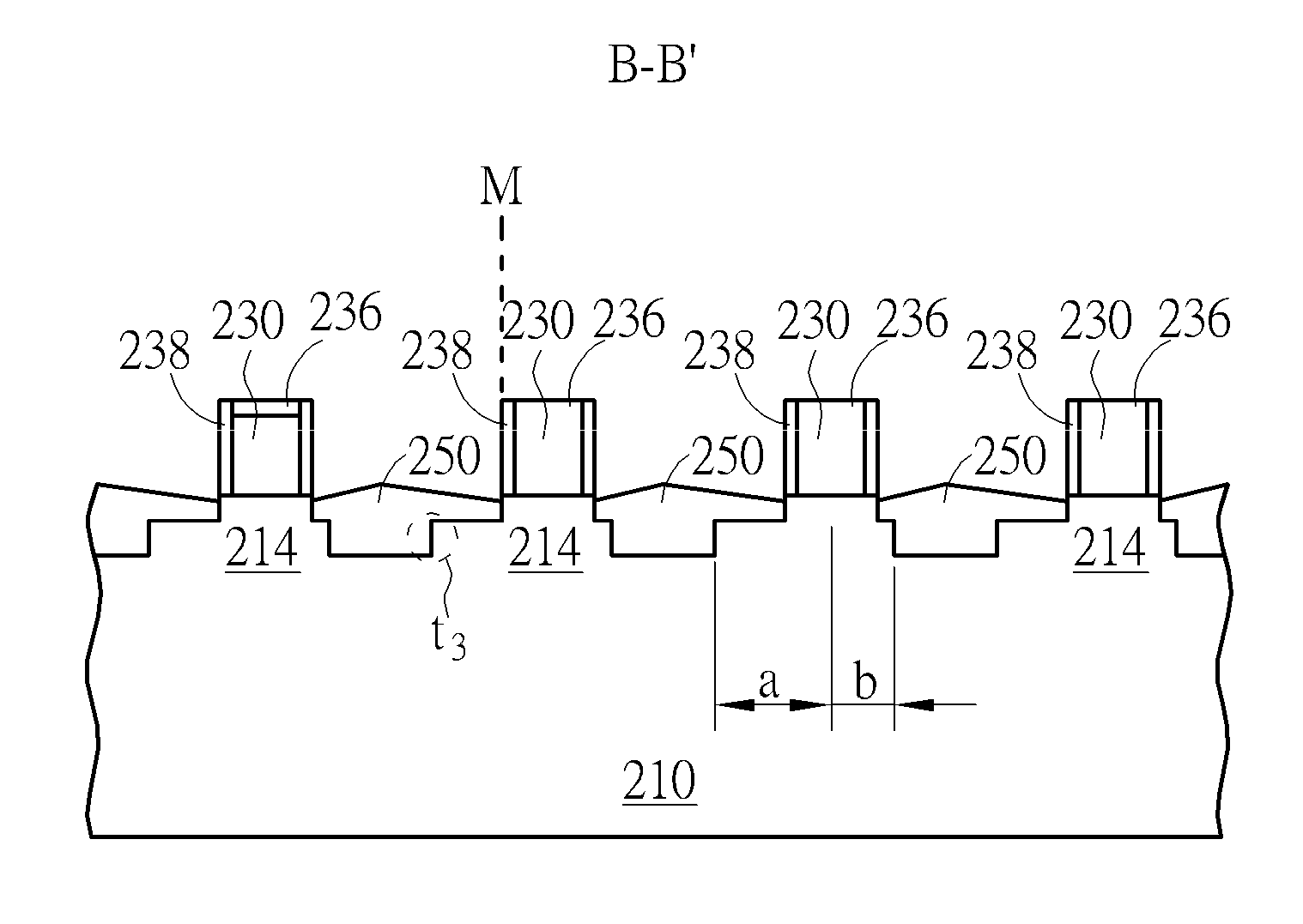

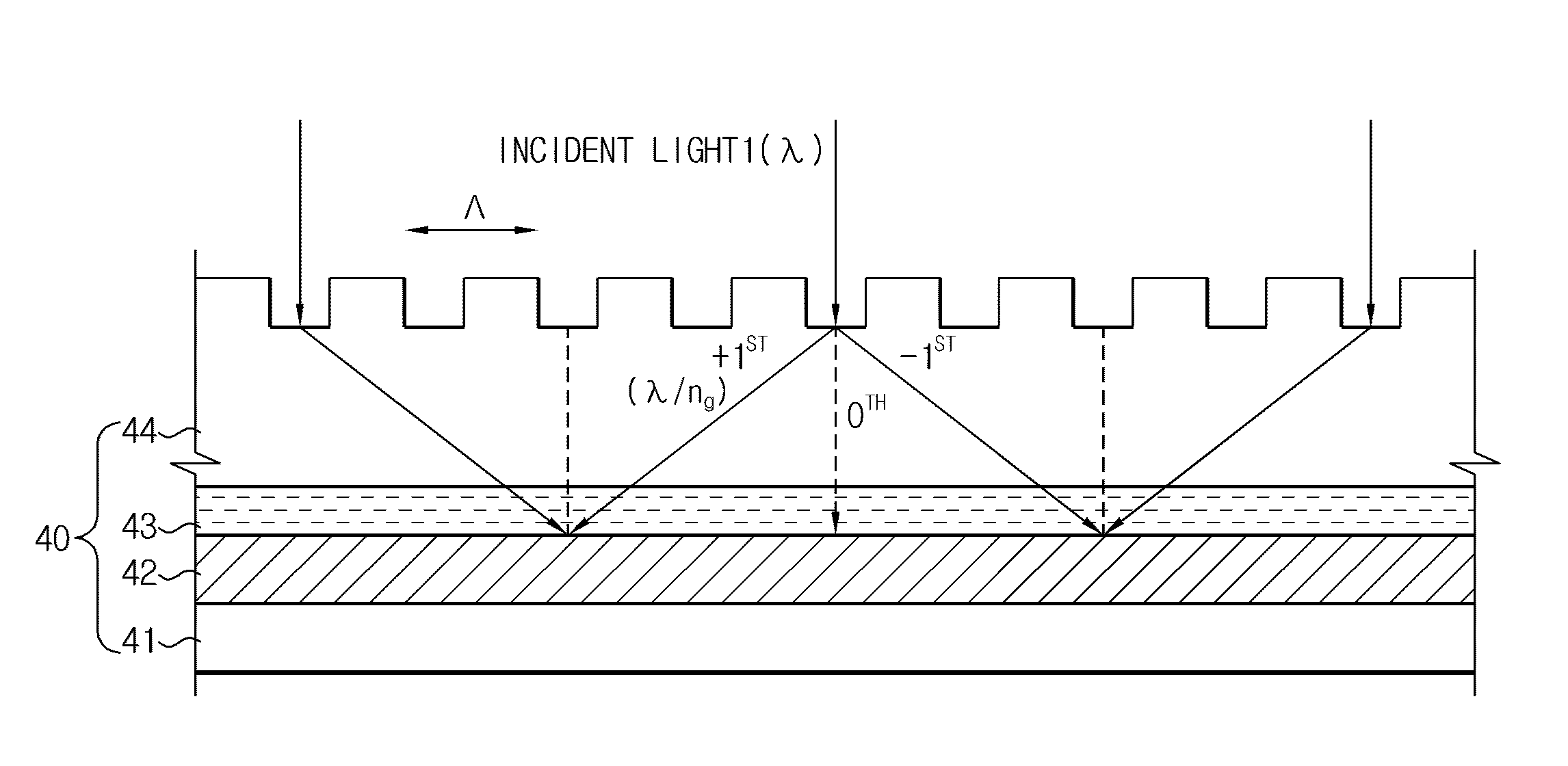

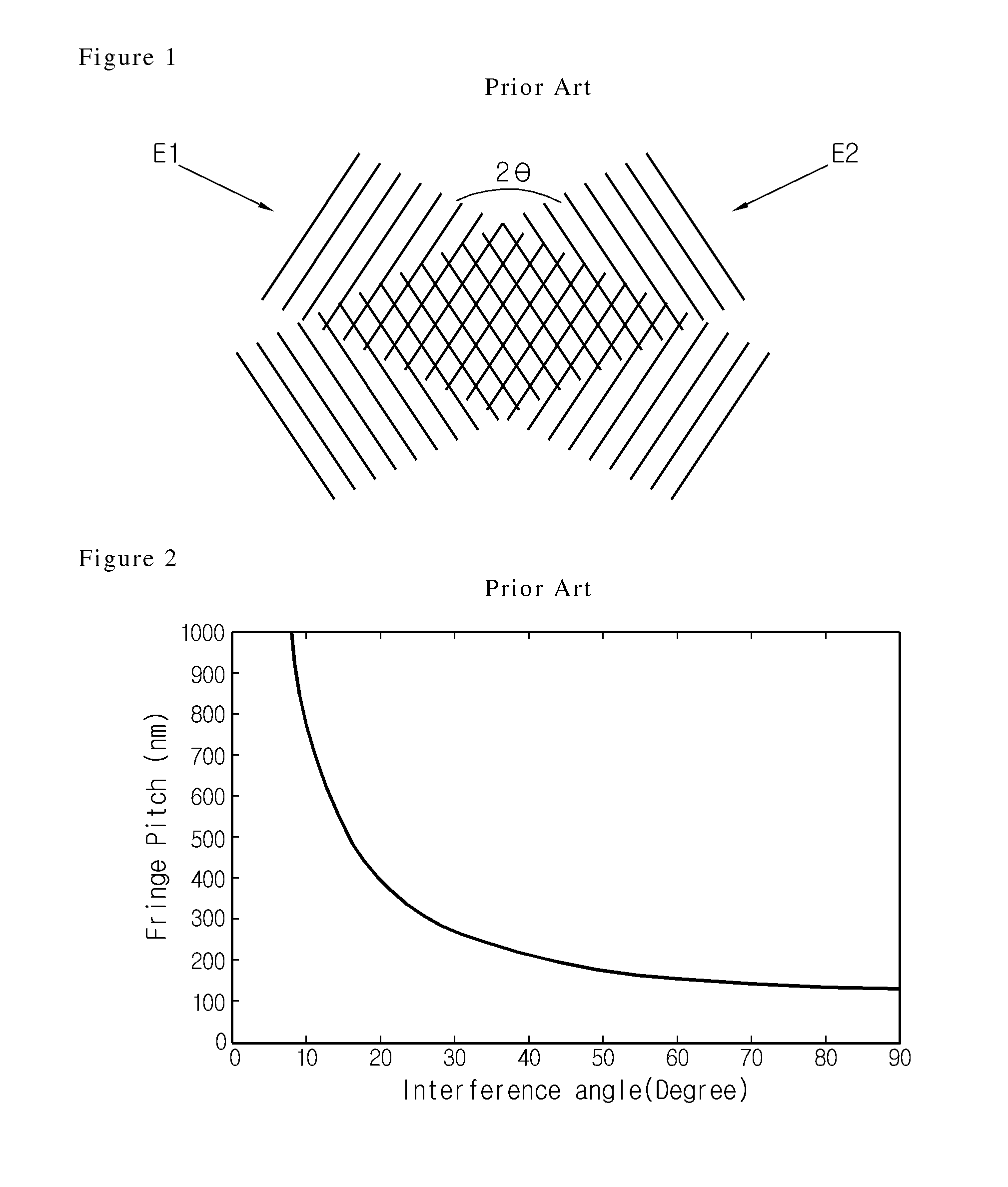

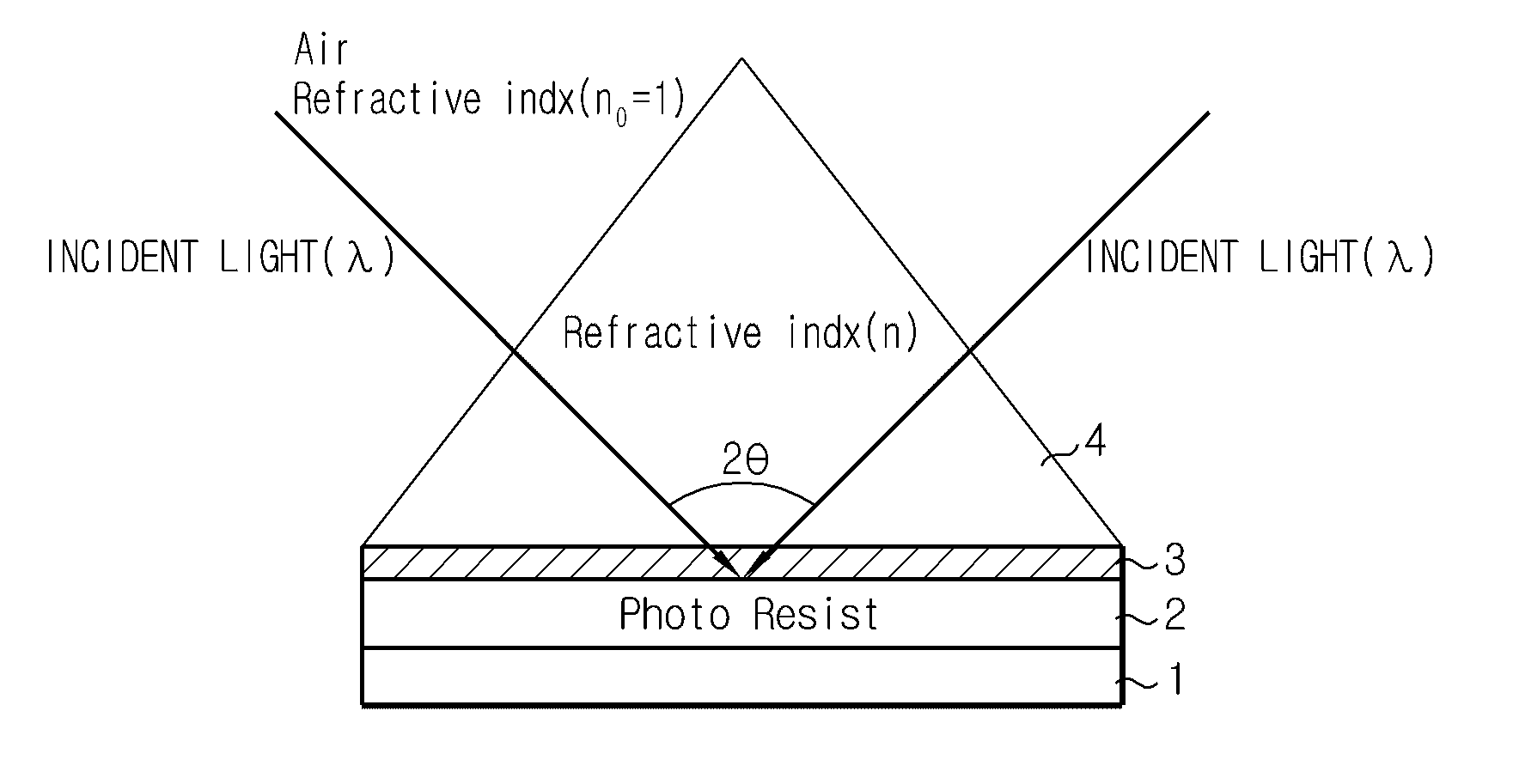

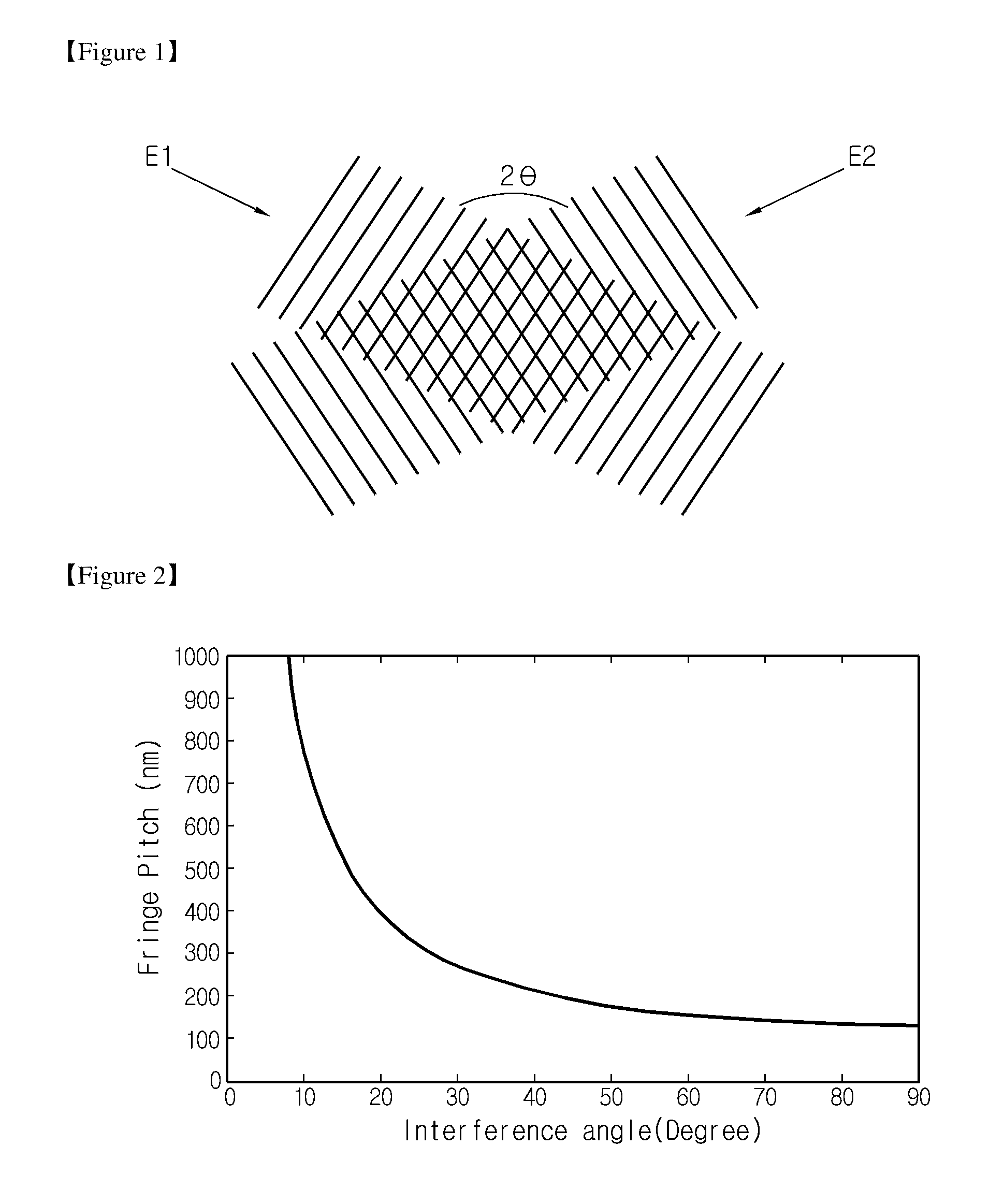

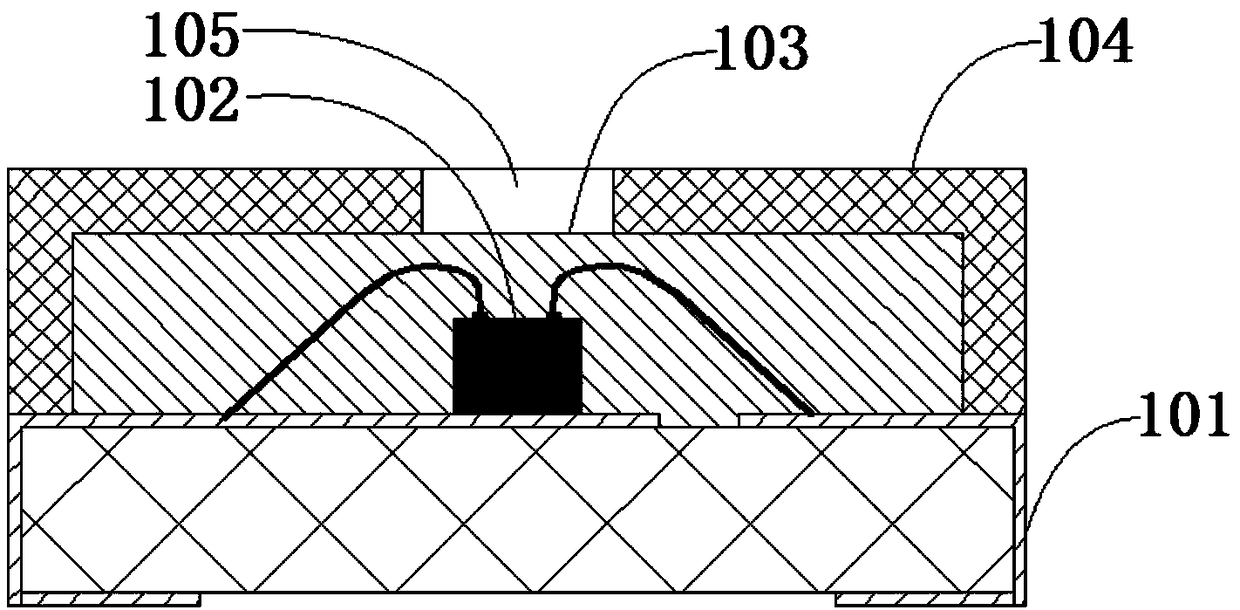

Method for laser interference lithography using diffraction grating

ActiveUS8399184B2High resolutionReduce coherencePhotomechanical exposure apparatusMicrolithography exposure apparatusResistIndex-matching material

A method for laser interference lithography using a diffraction grating includes (a) forming a photoresist layer on a work substrate to which a repeated fine pattern is to be formed; (b) forming a refractive index matching material layer on the photoresist layer; (c) forming on the refractive index matching material layer a diffraction grating layer having a period of diffraction grating within the range from λ / ng to λ / n0 (λ is a wavelength of laser beam, ng is a refractive index of the diffraction grating, and n0 is a refractive index in the air or in vacuum); and (d) exposing the photoresist layer by means of mutual interference of positive and negative diffracted lights with the same absolute value by inputting a laser beam perpendicularly to the diffraction grating layer. This method allows to realize an interference pattern with higher resolution and to use a laser source with lower coherence.

Owner:LG CHEM LTD

Method for laser interference lithography using diffraction grating

ActiveUS20100279233A1High resolutionImprove processing conveniencePhotomechanical exposure apparatusMicrolithography exposure apparatusResistIndex-matching material

A method for laser interference lithography using a diffraction grating includes (a) forming a photoresist layer on a work substrate to which a repeated fine pattern is to be formed; (b) forming a refractive index matching material layer on the photoresist layer; (c) forming on the refractive index matching material layer a diffraction grating layer having a period of diffraction grating within the range from λ / ng to λ / n0 (λ is a wavelength of laser beam, ng is a refractive index of the diffraction grating, and n0 is a refractive index in the air or in vacuum); and (d) exposing the photoresist layer by means of mutual interference of positive and negative diffracted lights with the same absolute value by inputting a laser beam perpendicularly to the diffraction grating layer. This method allows to realize an interference pattern with higher resolution and to use a laser source with lower coherence.

Owner:LG CHEM LTD

LED device and manufacturing method thereof

PendingCN109449274AEfficient cutting and separationImprove processing efficiencySemiconductor devicesRest positionEngineering

The invention provides an LED device and a manufacturing method thereof. The LED device comprises a substrate unit, a light emitting unit, a light transmitting unit and a light shielding unit; the light emitting unit is fixed on the substrate unit, and the light transmitting unit is covered on the periphery of the light emitting unit; and a light transmitting portion for allowing the light of thelight emitting unit to pass through is arranged at the outside of the surface of the light transmitting unit in advance, and the light shielding unit covers the rest positions excluding the light transmitting portion on the surface of the light transmitting unit. The light emitting direction of the LED device can be controlled as needed through a light transmitting hole on the light shielding unit, so that the practicability is good. The manufacturing method of the LED device comprises: forming the light transmitting units and the light shielding units of a plurality of LED devices in one injection molding process by using a light transmitting layer mould and a light shielding layer mould, so that the processing efficiency is higher; and by using a cutter cutting mode and by reasonably setting the cutting track, the cutting object and the cutting depth of a cutter, a light transmitting layer, a light shielding layer and a substrate can be efficiently separated.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD

Split type crystallizer

The invention discloses a split type crystallizer. The split type crystallizer comprises two large surface walls, two small surface walls and a plurality of graphite flakes, wherein the larger surface walls and the small surface walls jointly form a crystal passage in a surrounding mode, and the graphite flakes are shaped like strips and vertically arranged on the inner wall of the crystal passage. According to the split type crystallizer, the graphite flakes are arranged on the inner wall of the crystal passage, and therefore the high temperature resistance is improved compared with a crystal passage with chrome plated on the inner wall, and the service life of the split type crystallizer is prolonged. In addition, the structure spliced by the multiple strip-shaped graphite flakes is adopted, damaged graphite flakes can be replaced conveniently, and therefore the maintenance cost of the split type crystallizer is lowered, and only the partial damaged graphite flakes are replaced rather than all the graphite flakes or even the whole crystallizer.

Owner:TONGLING NONFERROUS XINGTONG ELECTROMECHANICAL MFG CO LTD

Full-automatic boar semen filling machine

ActiveCN114104360ADon't pull too muchAvoid damageWrapper twisting/gatheringLiquid materialAnimal scienceMedicine

The full-automatic boar semen filling machine comprises a base and a packaging bag, a shell is mounted at the top end of the base, a guide groove is formed in the top end of the shell, and a mounting plate is mounted on one side of the top of the shell; in the machining process, when a package penetrates through the space between the two grating assemblies, two shadow blocks at the top end of the packaging bag are scanned through the grating assemblies, and then the packaging bag is positioned; after positioning is completed, a third motor is matched with a third motor shaft to drive two clamping blocks to clamp the two ends of the packaging bag, then a second air cylinder pushes a movable sliding block to synchronously extrude the top end of the packaging bag inwards, at the moment, opening structures on the two sides of a feeding opening are matched, the feeding opening is temporarily expanded, and then a liquid injection pipe is conveniently inserted into the packaging bag; and the processing efficiency is improved.

Owner:济南约克农牧器械有限公司

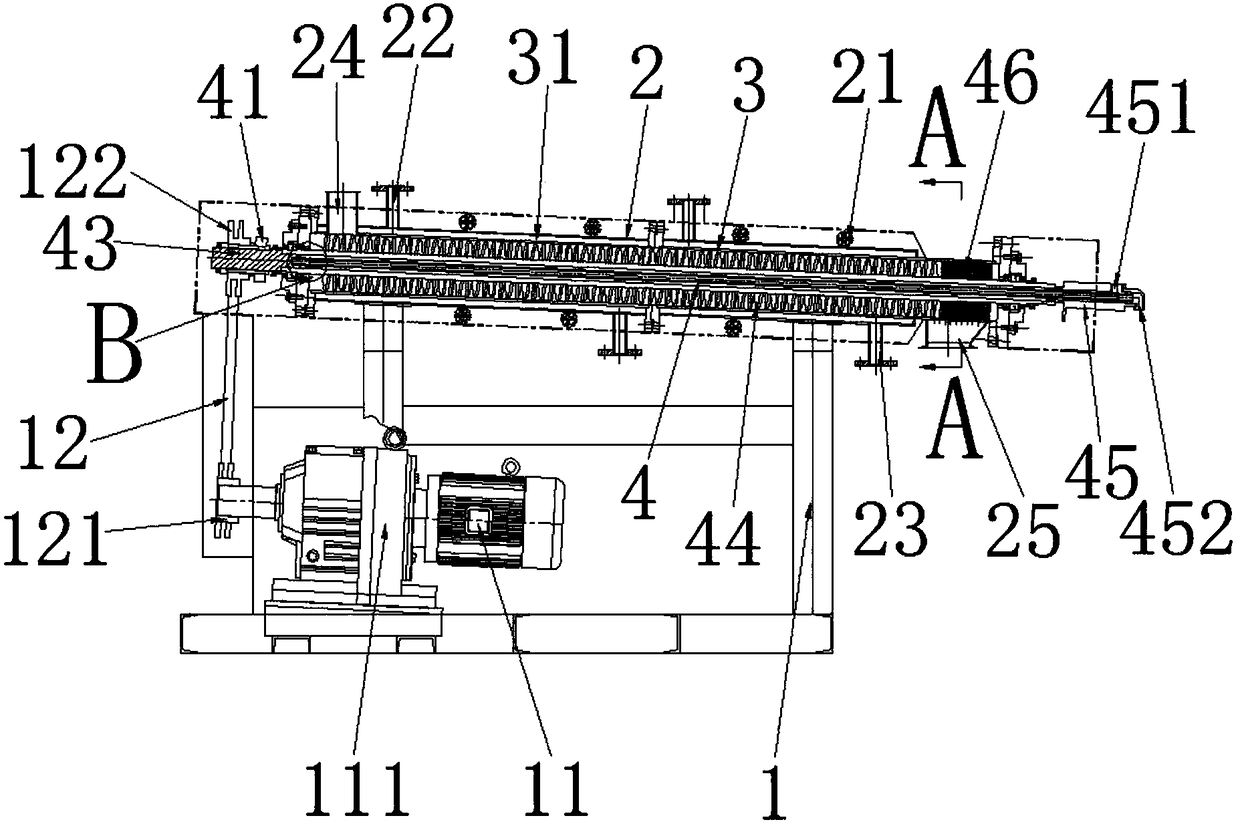

Multipurpose mixed processing all-in-one machine

PendingCN108273411AImprove processing efficiencyImprove processing qualityRotary stirring mixersTransportation and packagingMaterials processingScrew head

The invention discloses a multipurpose mixed processing all-in-one machine which comprises an outer barrel, an inner barrel arranged inside the outer barrel, and a stirring mechanism arranged inside the inner barrel, wherein a sandwich layer is arranged between the outer barrel and the inner barrel; the outer surface of the outer barrel is connected with a material inlet, a material outlet, a water inlet and a water outlet; the stirring mechanism comprises a master shaft and a slave shaft; the outer surfaces of the master shaft and the slave shaft are connected with a helical tape and a scraper blade; shaft cavities are formed inside the master shaft and a slave shaft; inner pipes are arranged inside the shaft cavities; through holes are formed in the surfaces of the inner pipes; the end parts of the master shaft and the slave shaft are both connected with screw heads; the screw heads are communicated with the inner pipes and the shaft cavities; the end part of the main shaft is connected with a power mechanism in a matching manner; the master shaft is connected with the slave shaft in a matching manner. The multipurpose mixed processing all-in-one machine can perform processing treatment such as mixing, smashing, stirring, cooling and conveying on materials, so that the cooling efficiency during material processing is improved, and the processing quality and the processing efficiency of the materials are also improved.

Owner:JINHUA JINGRUI PHARMA MACHINERY

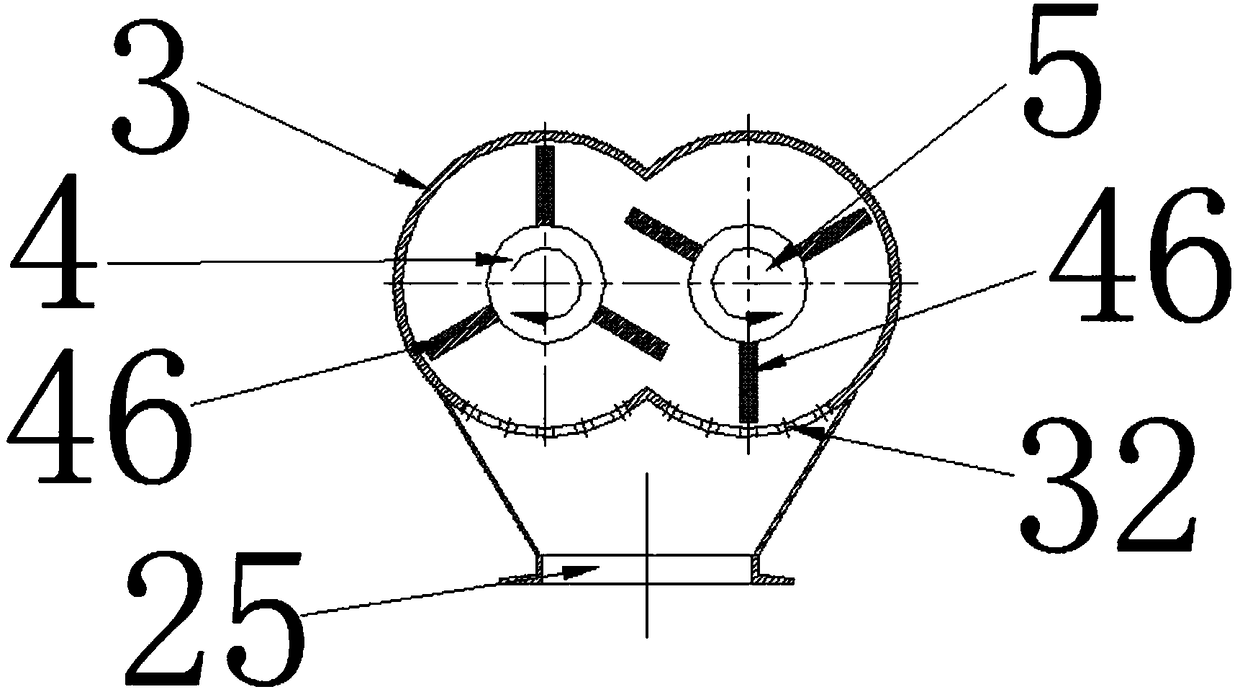

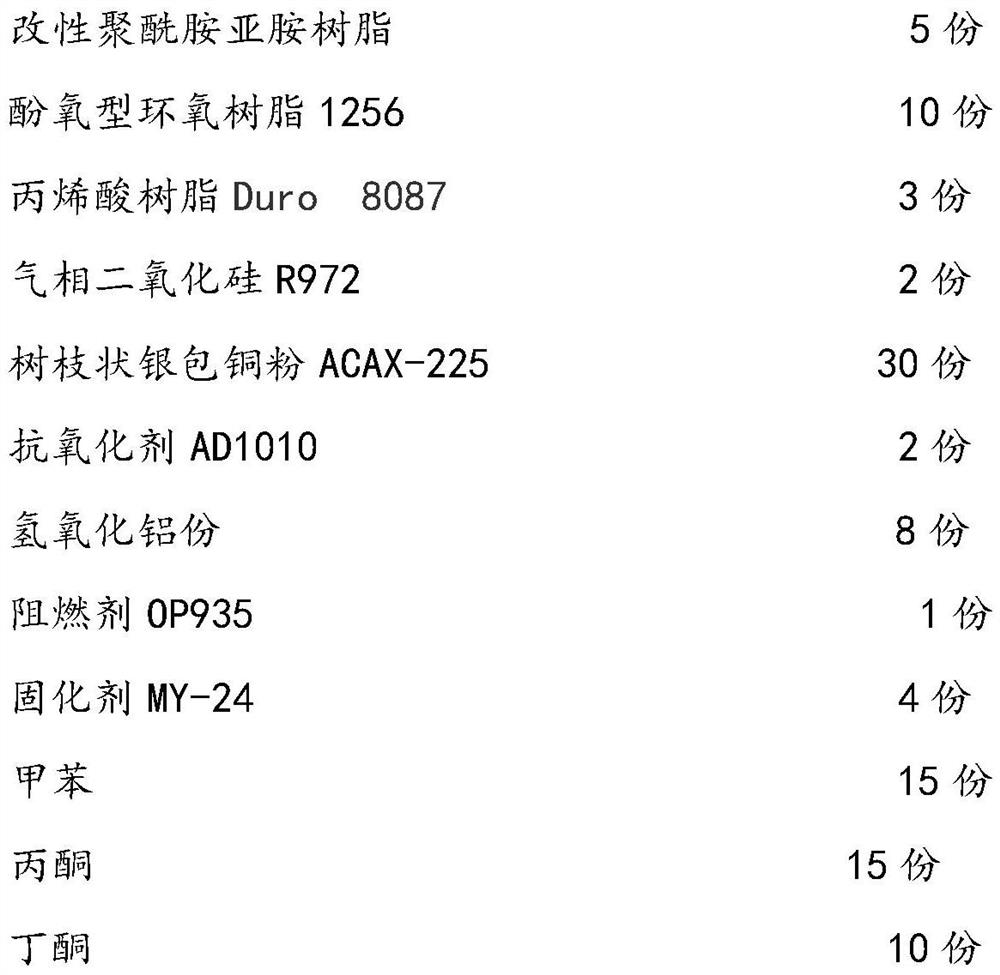

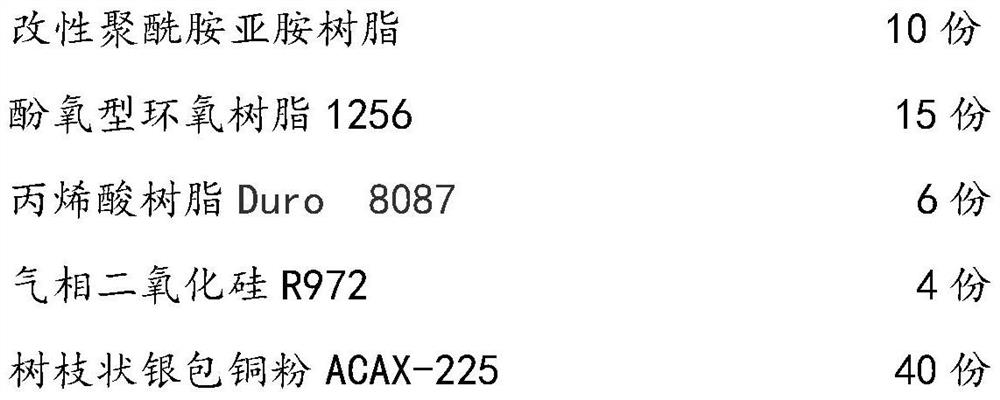

Conductive adhesive film

PendingCN112391125AEasy to operateExtended storage timeNon-macromolecular adhesive additivesEster polymer adhesivesEpoxyPolymer science

The invention discloses a pressure-sensitive conductive film with a long validity period, the conductive film comprises a base material 1, a release layer 2 and a conductive adhesive layer 3, and theconductive adhesive layer is composed of organosilicon modified thermoplastic polyamide-imide, phenoxy epoxy resin, low Tg value acrylic resin, fumed silica, conductive metal powder, an antioxidant, aflame retardant, a latent curing agent and a mixed solvent. Compared with the prior art, the pressure-sensitive conductive film has the following advantages: the conductive adhesive layer has strongviscosity, does not need refrigeration storage, can be rapidly processed to the flexible substrate plate, and has excellent adhesion fastness, filling property and storage timeliness.

Owner:铠博新材料(天津)有限公司

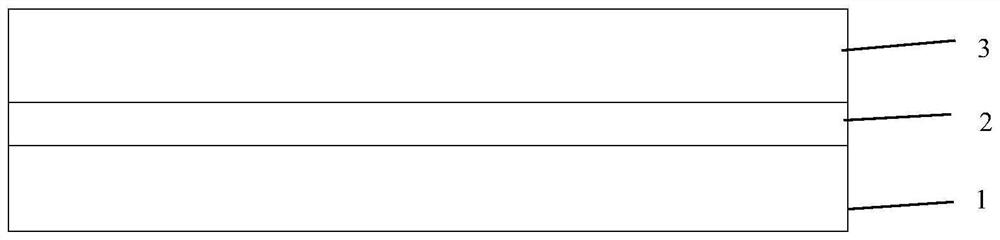

Method for ultrasonic welding of fabric

ActiveCN110696370AImprove cutting effectFlat cutSeaming textilesSevering textilesUltrasonic weldingEngineering

The invention discloses a method for ultrasonic welding of a fabric. The fabric comprises a top layer, a sandwich layer, and a bottom layer. The method comprises the following steps: a. cutting the top layer, the sandwich layer, and the bottom layer to a desired width respectively, and sheathing the cut top, sandwich and bottom layers on fixed wheels respectively; and b. pulling one ends of the top, sandwich and bottom layers out separately to enable the top, sandwich and bottom layers to be stacked together in a certain distance from top to bottom, placing the stacked fabric on an ultrasonicwelding machine, and welding the overlapped edges to form a product.

Owner:杭州眠之梦科技有限公司

Input pen with function of electromagnetic induction

ActiveCN101995968BImprove processing convenienceImprove pressure sensing accuracyInput/output processes for data processingElectromagnetic shieldingEngineering

Owner:WACOM CO LTD

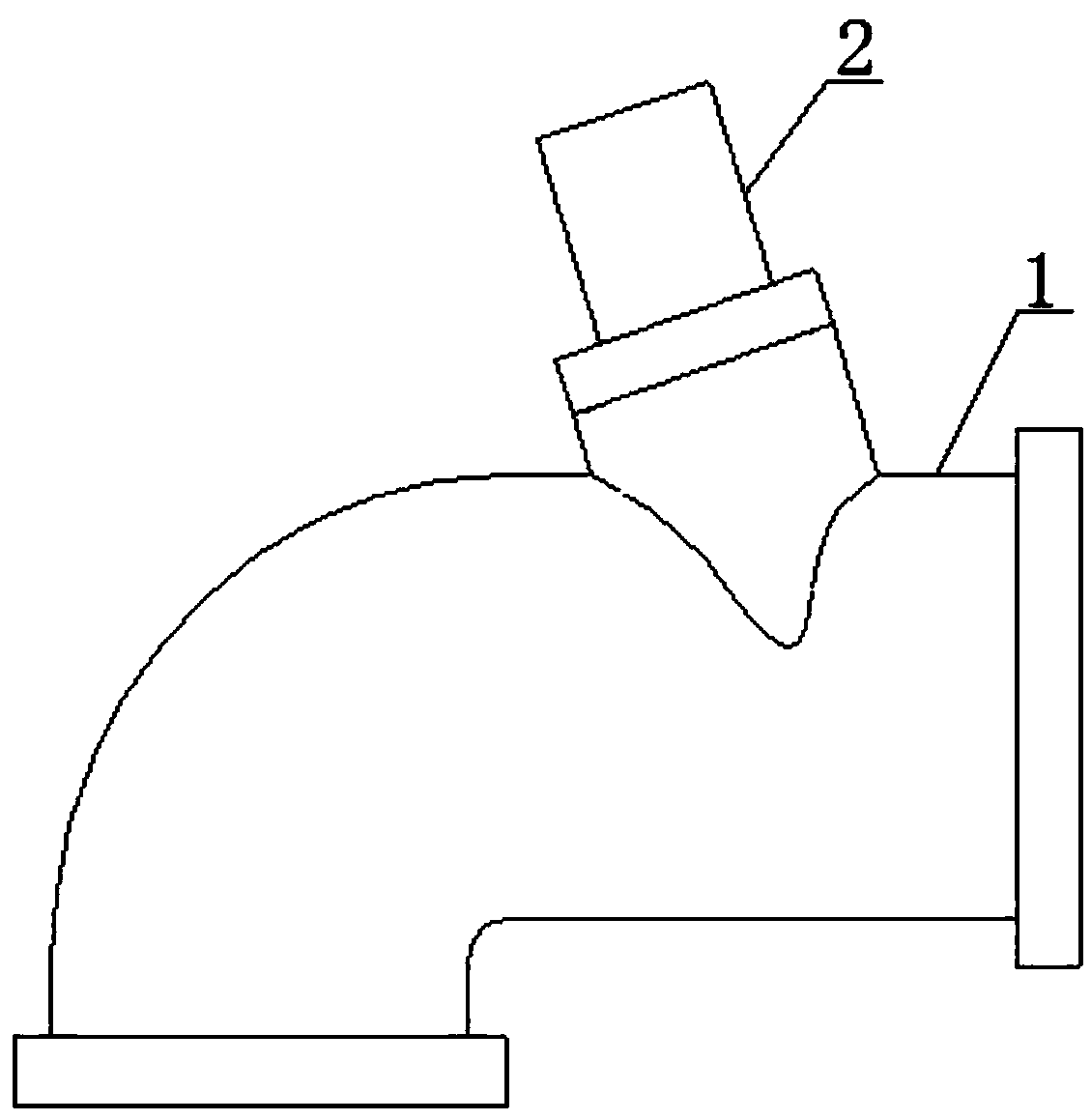

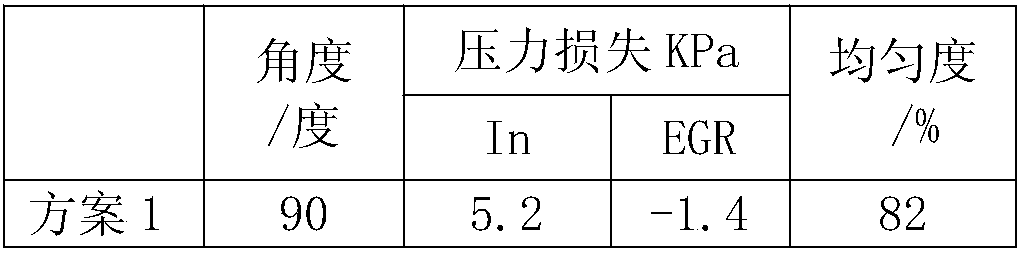

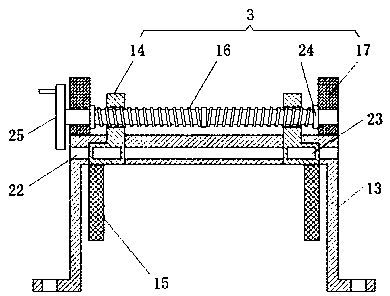

Simplified tube-shell type fluid mixer

PendingCN108686531AEasy to driveSmall pressure lossFlow mixersTransportation and packagingEngineeringExhaust gas recirculation

The invention discloses a simplified tube-shell type fluid mixer. The simplified tube-shell type fluid mixer comprises a main flow tube (1) and an EGR (Exhaust Gas Recirculation) tube (2), wherein anEGR tube outlet end (6) of the EGR tube (2) extends into an inner cavity of the main flow tube (1) from the side wall of the main flow tube (1), and is opposite to the airflow direction of the main flow tube (1). The EGR tube outlet end (6) is an inclined section which is vertical to a plane formed by the axis of the main flow tube (1) and the axis of the EGR tube (2); the height of the inclined section of the EGR tube outlet end (6) is larger than the diameter of the main flow tube (1) by more than 0.5 time. The simplified tube-shell type fluid mixer disclosed by the invention has the beneficial effects that airflow generates suctioning effect for the EGR tube outlet end (6) to form negative pressure, so that the pressure loss of the EGR side is reduced and the EGR driving force is improved.

Owner:DONGFENG COMML VEHICLE CO LTD

Width-adjustable transfer belt for bearing production

InactiveCN110577063AImprove processing convenienceReduce structural complexityConveyorsElectric machineryDrive motor

The invention discloses a width-adjustable transfer belt for bearing production. The width-adjustable transfer belt comprises a rack, a conveying device and an adjusting device; the conveying device is fixedly mounted on the surface of the rack, and the adjusting device is arranged above the conveying device; the adjusting device and the rack are fixedly connected, and the rack comprises supporting legs, a supporting cross beam and fixing oblique rods; the supporting legs are vertically fixed to the two ends of the supporting cross beam, and the junctions of the supporting legs and the supporting cross beam are provided with the fixing oblique rods; the two ends of the fixing oblique rods are connected with the supporting legs and the supporting cross beam in a welded mode correspondingly;the conveying device comprises a driving motor, a driving roller, a driven roller and a conveying belt; and a belt is arranged between the output end of the driving motor and the driving roller. By arranging the adjusting device above the conveying belt, the passing width of the surface of the conveying belt is convenient to adjust, bearings are orderly transferred along the surface of the conveying belt in a single-row mode, and the machining convenience of machining equipment is improved.

Owner:灵璧翔宇轴承有限公司

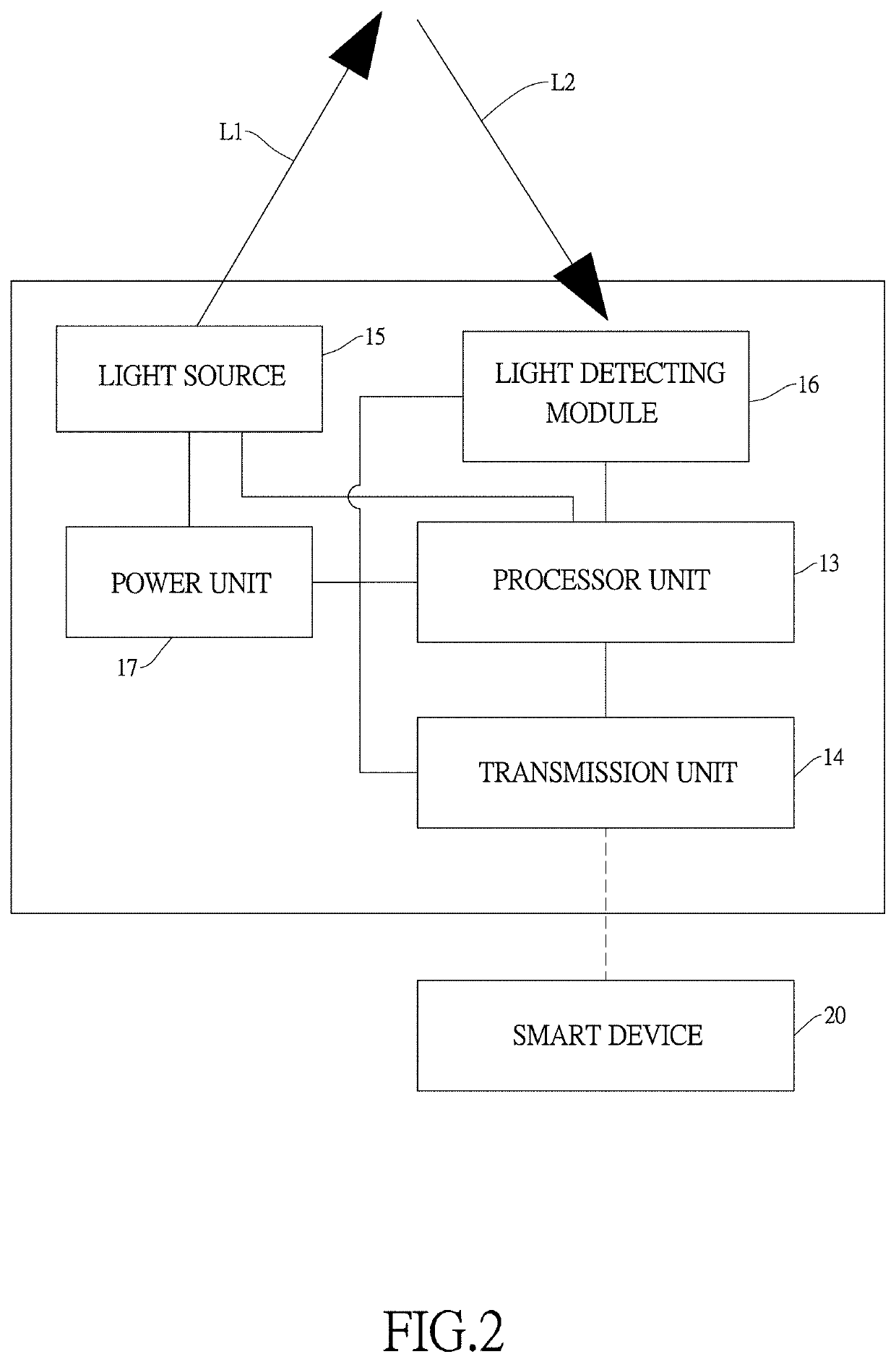

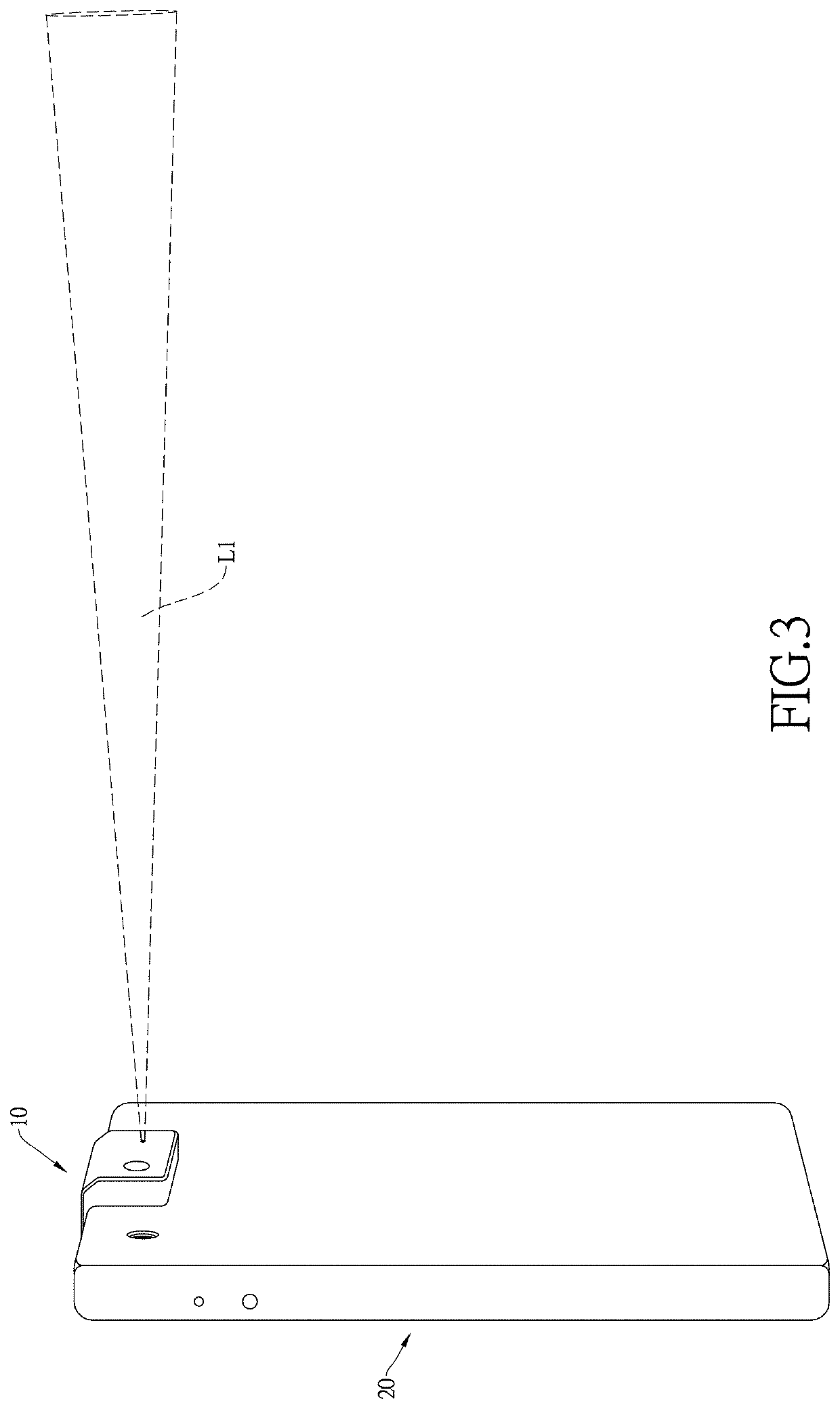

Hemoglobin detecting device

ActiveUS10883927B2Improve reliabilityImprove processing convenienceRadiation pyrometryAbsorption/flicker/reflection spectroscopyEngineeringAbsorbance spectra

A hemoglobin detecting device includes a shell component connected with a fixing part that engages with an outer side of a smart device. A processor unit, a light source, a light detection module and a transmission unit are mounted inside the shell component. The light source generates a first light beam, and the light detection module receives a second light beam that is generated when the first light beam travels through an analyte solution and is reflected. The processor unit determines whether the absorption spectrum of the analyte solution matches a target spectrum, and generates a result information according to the detection. The transmission unit transmits the result information to the smart device and displays an indication of the result. The hemoglobin detecting device provides a fast and accurate way to detect blood in a stool solution, and can be applied to and cooperate with all kinds of smart devices.

Owner:TAIWAN REDEYE BIOMEDICAL INC

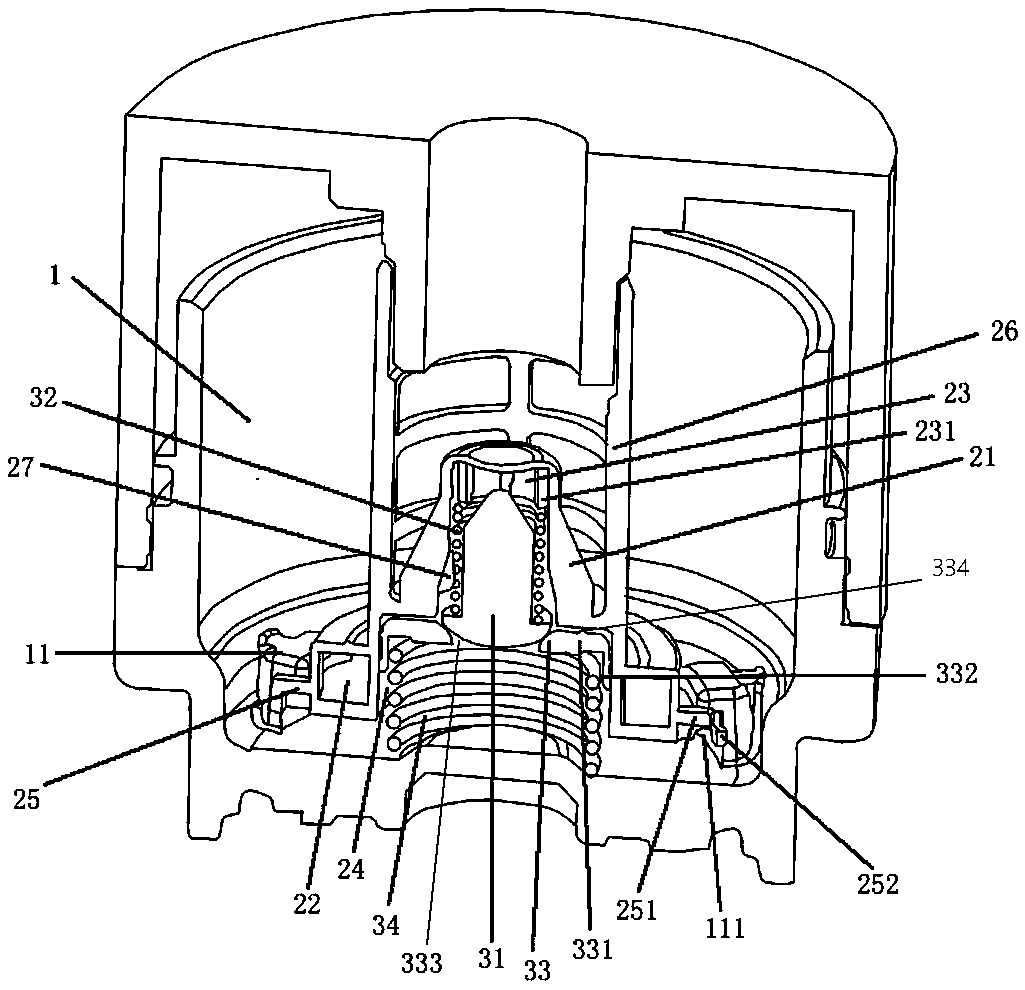

Novel oil filter by-pass valve mounting structure

PendingCN108757096AImprove sealingImprove structural integrityLubricant mounting/connectionPressure lubricationWork performanceEngineering

The invention relates to a novel oil filter by-pass valve mounting structure and relates to the field of oil filters. The novel oil filter by-pass valve mounting structure comprises an oil filter spiral cover and a by-pass valve arranged on the inner side of the spiral cover, wherein the oil filter spiral cover comprises at least two connecting parts arranged in the circumferential direction of the axis of the spiral cover; the by-pass valve comprises a shell and a by-pass assembly; the shell comprises a valve shell and a functional shell below the valve shell; the valve shell is provided witha first valve chamber, and the opening of the valve chamber is downwards; a plurality of support ridges are arranged on the wall face of the first valve chamber at intervals in the circumferential direction and in the first valve chamber; the by-pass assembly is arranged in the valve shell; the valve shell and the inner wall of the functional shell are combined to form a second valve chamber; anda mounting part corresponding to and detachably connected with a connecting part is arranged in the circumferential direction of the functional shell. The novel oil filter by-pass valve mounting structure is detachably connected onto the oil filter spiral cover, so that the mounting structure does not need to be discarded along with a filter element; in addition, the novel oil filter by-pass valve mounting structure has high processing convenience and maintaining convenience; and moreover, the novel oil filter by-pass valve mounting structure has high working performance. The novel oil filterby-pass valve mounting structure has the advantages of being high in structural integrity and processing convenience, convenient to detach, mount and maintain and high in machine oil leakproofness.

Owner:ZHEJIANG WEITAI AUTOMOBILE PARTS

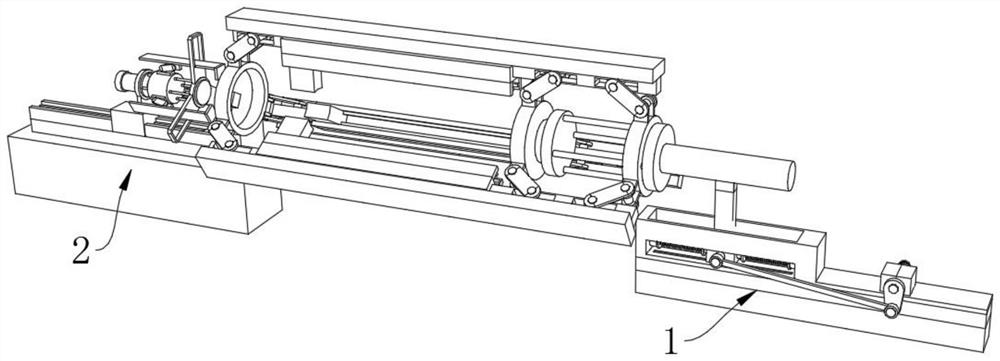

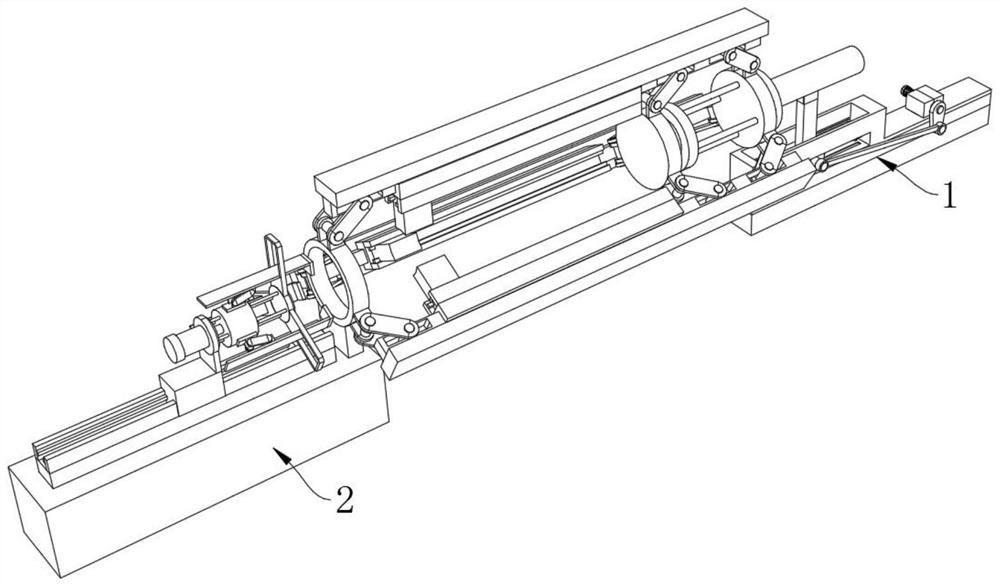

Bearing ring forge piece production device and process

PendingCN114309440AImprove processing efficiencyImprove processing conveniencePower hammersHammer drivesMachiningIndustrial engineering

The invention discloses a bearing ring forge piece production device and process, and relates to the technical field of bearing production. The device comprises an adaptive forging machining structure and a three-way automatic machining positioning structure, the adaptive forging machining structure is arranged at one end of the three-way automatic machining positioning structure, and the three-way automatic machining positioning structure is used for automatically and adaptively clamping machining shafts which are different in diameter and used for carrying bearing ring forgings. Through the design of an adaptive forging machining structure, the device can conveniently and automatically complete multi-face continuous automatic adjustable reciprocating forging and pressing treatment on a bearing ring in a reciprocating mode, the machining efficiency is greatly improved, and through the design of a three-direction automatic machining positioning structure, the machining efficiency is greatly improved. And the device can conveniently complete automatic, stable and adaptive clamping on a machining shaft carrying a plurality of bearing rings, so that the device is suitable for machining of various bearing rings with different diameters, and the machining convenience is greatly improved.

Owner:常山县鑫龙轴承有限公司

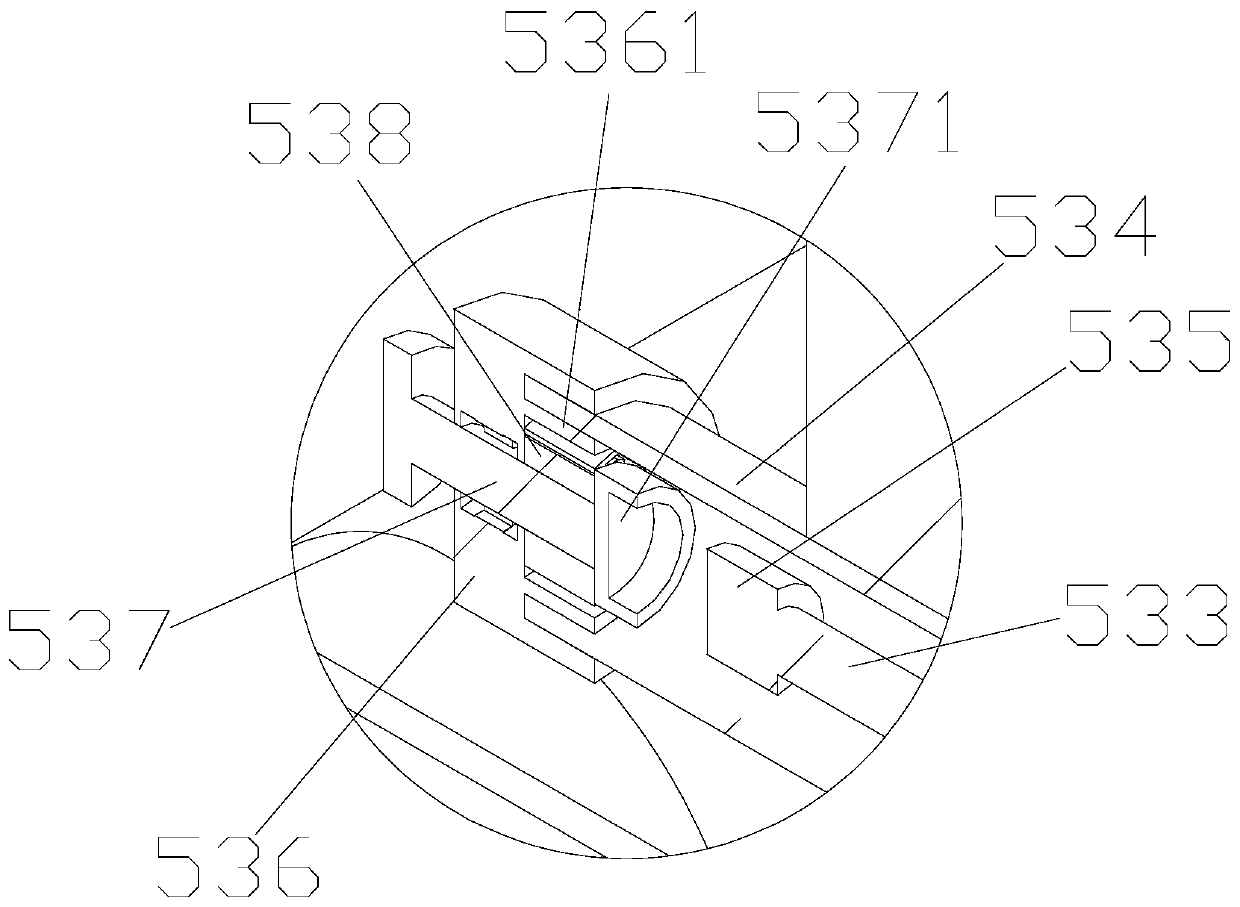

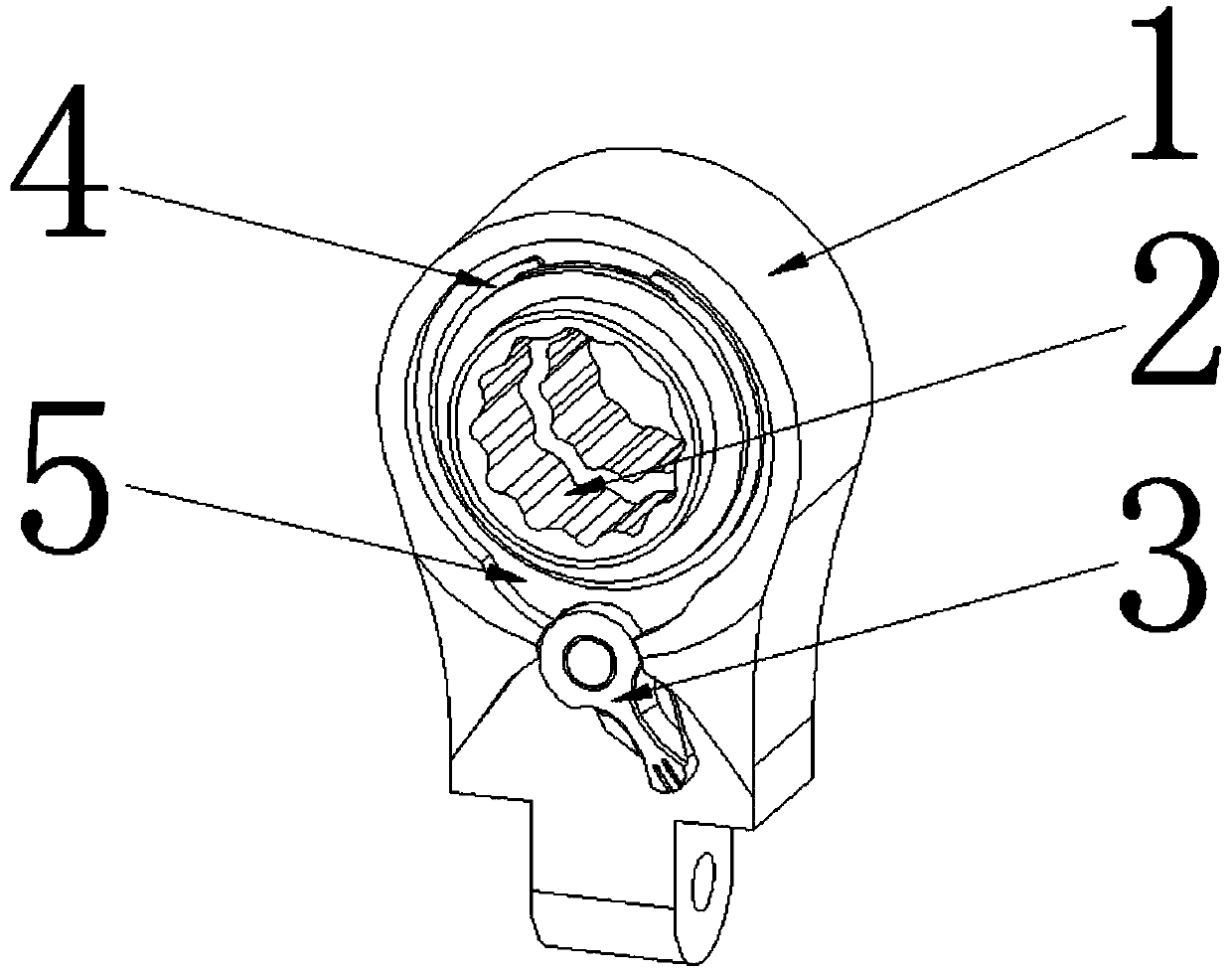

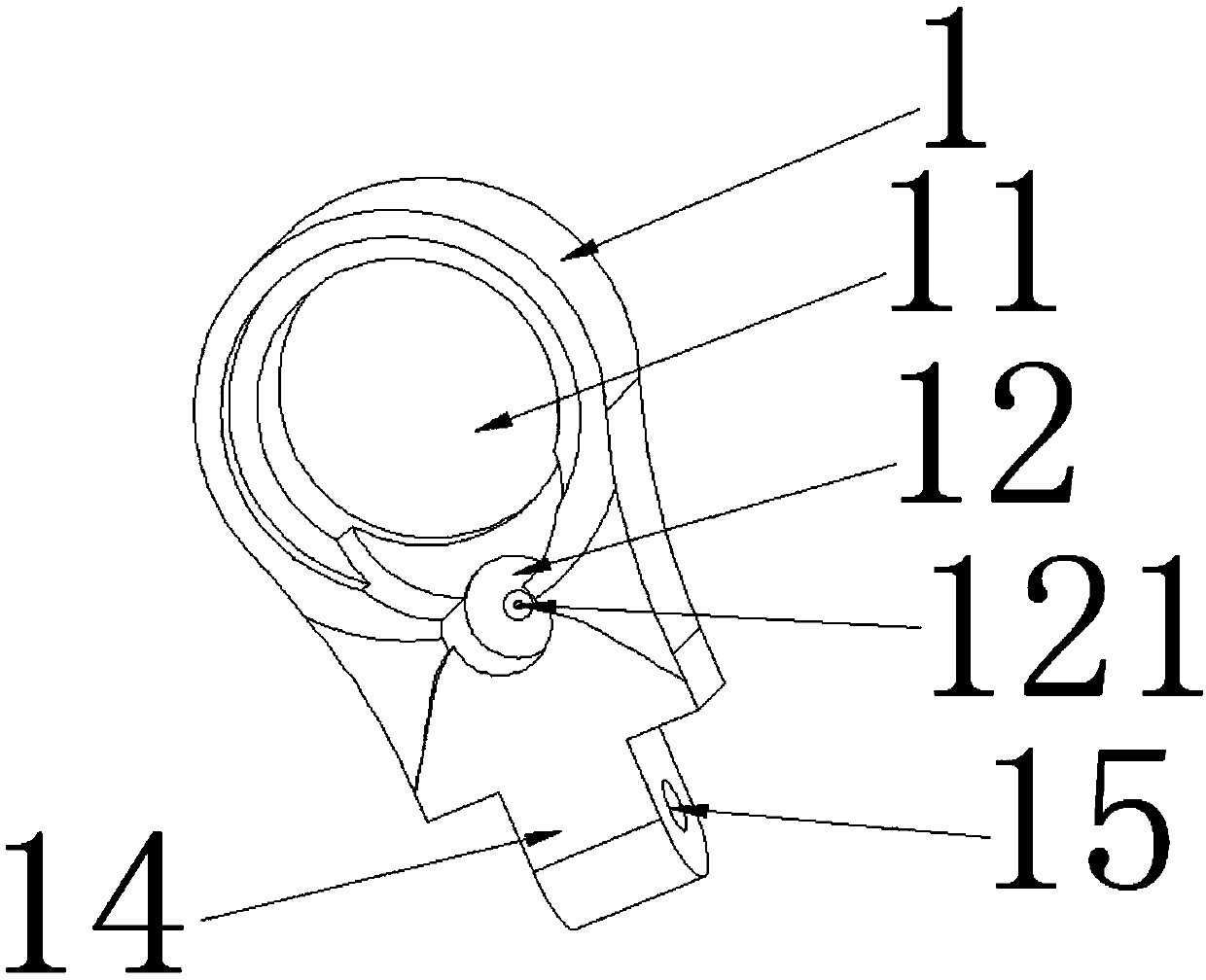

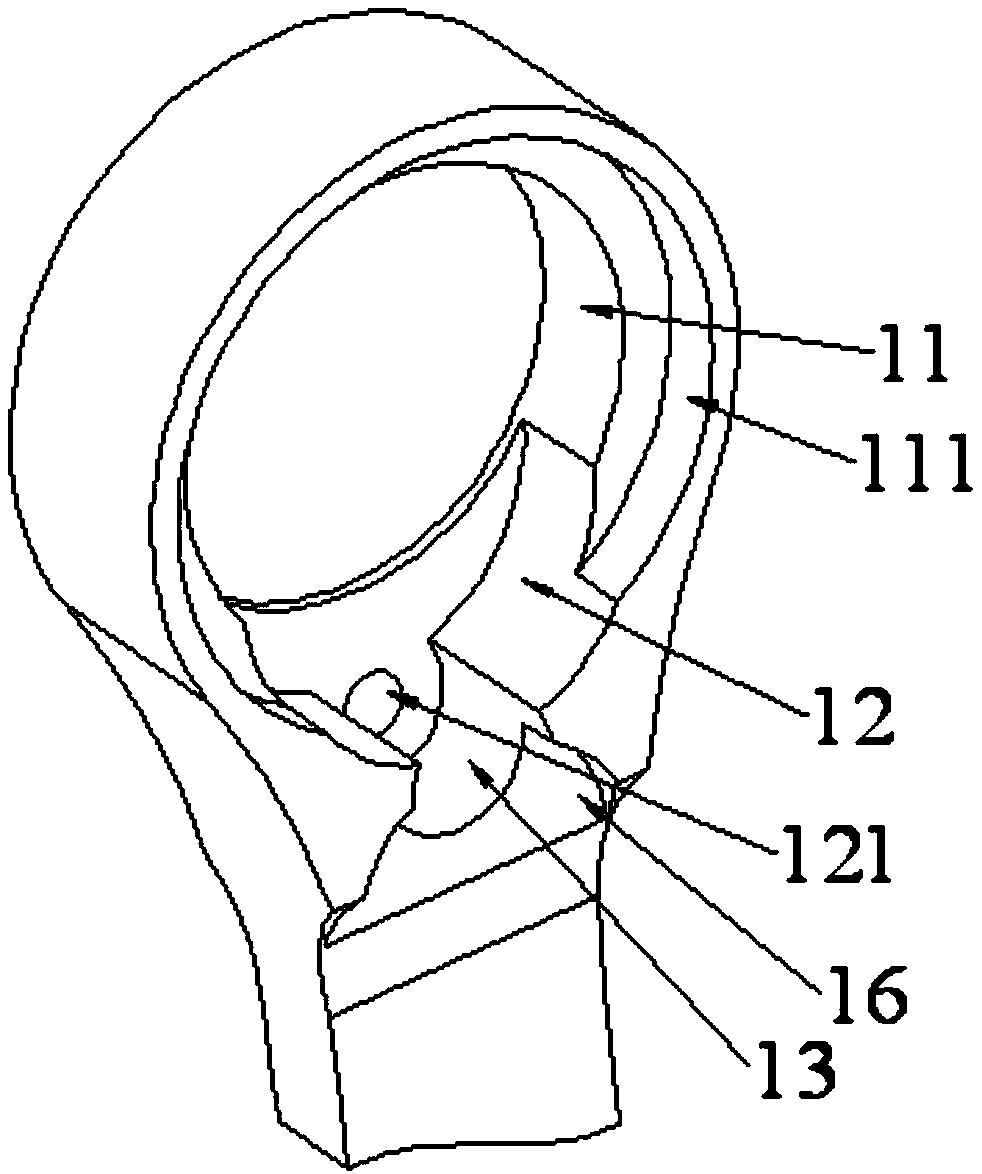

Ratchet wrench and its ratchet wrench head

The invention relates to a ratchet wrench and discloses the ratchet wrench and a ratchet wrench head. The ratchet wrench comprises a ratchet base (1) and a ratchet (2). A through hole (11) used for installing the ratchet (2) is formed in the middle of the ratchet base (1); the front end and the rear end of the wall of the through hole (11) are separately provided with a front annular concave shoulder (111) and a rear annular concave shoulder (112); the bottom faces of the front annular concave shoulder (111) and the rear annular concave shoulder (112) separately form a front stepped face (131) and a rear stepped face (132); the outer surface of the ratchet (2) is provided with two snap ring grooves (22) which are internally provided with two snap rings (4); and the two snap rings (4) are separately located in the front annular concave shoulder (111) and the rear annular concave shoulder (112). According to the ratchet wrench and the ratchet wrench head, by adopting the two snap rings (4) and the stepped faces (131) matched with the two snap rings (4), limit to the ratchet (2) can be effectively achieved, an installation person can install the ratchet wrench head conveniently, and the assembly efficiency of the installation person is improved.

Owner:ZHEJIANG YIYANG TOOL MFG

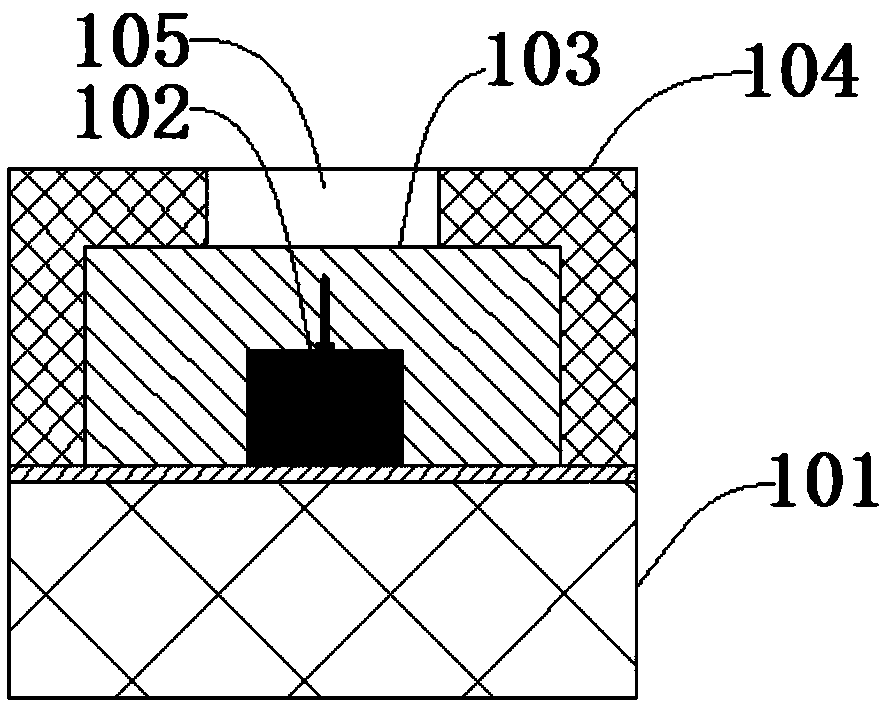

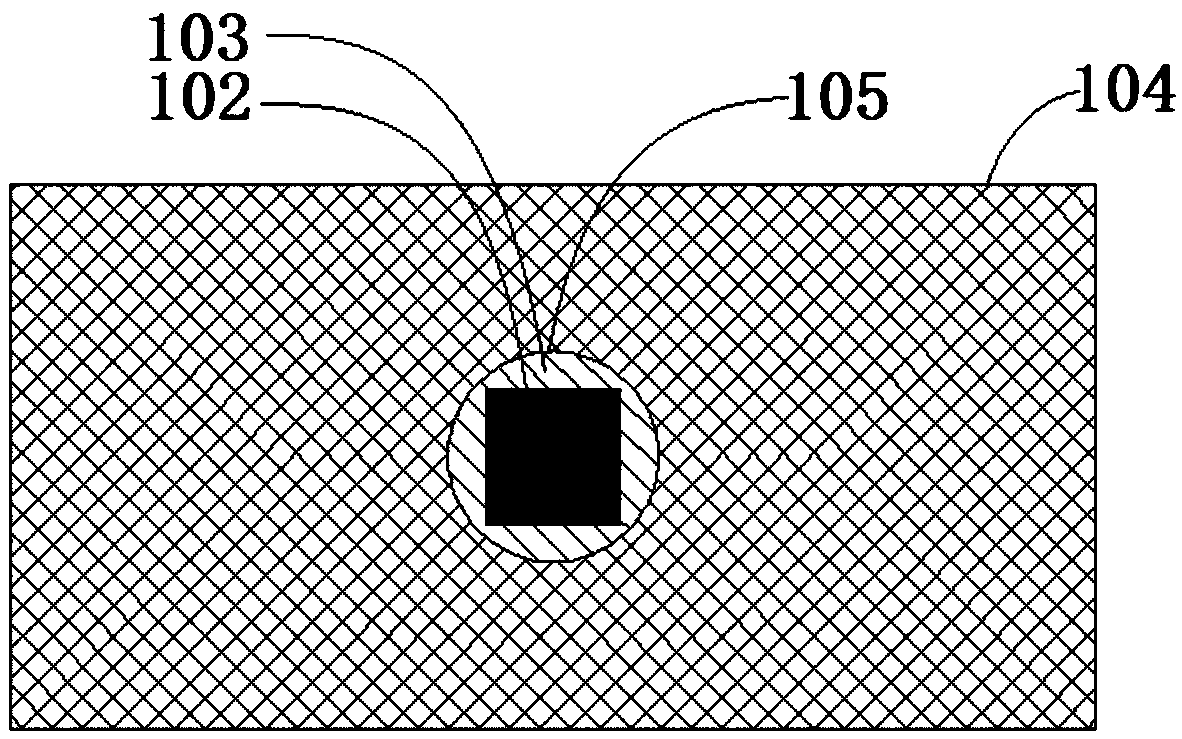

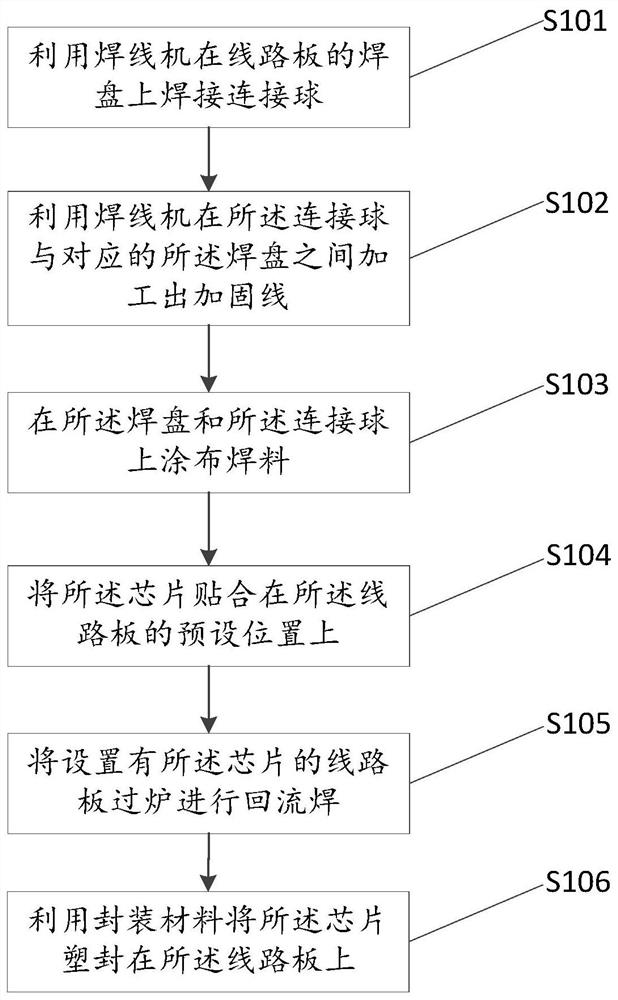

Module processing method, module and device

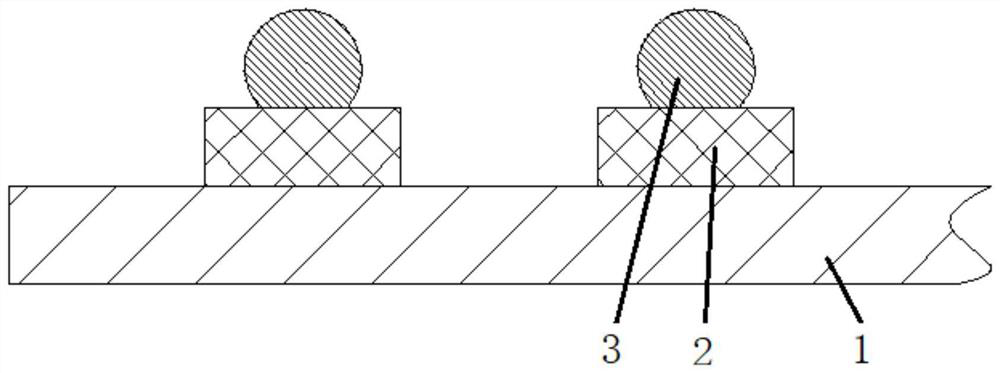

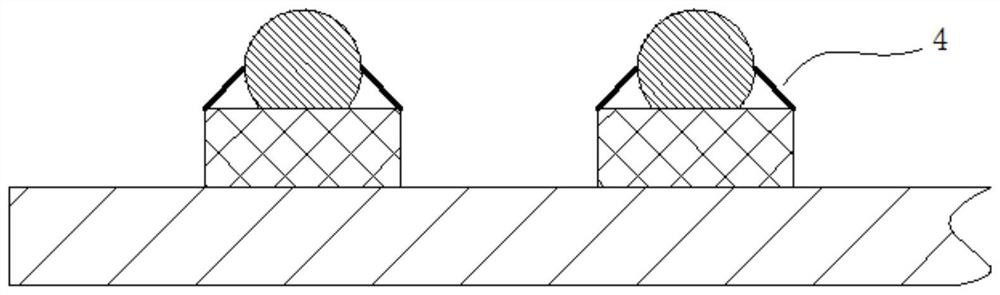

ActiveCN113395841AReduce manufacturing costReduce collapseElectrical connection printed elementsElectrical componentsMechanical engineeringWire bonding

The invention provides a module processing method, module and device. The module processing method comprises the following steps: welding a connecting ball on a bonding pad of a circuit board by using a wire bonding machine; coating the bonding pad and the connecting ball with solder; attaching a chip to a preset position of the circuit board; carrying out reflow soldering on the circuit board provided with the chip through a furnace to make the electrode of the chip, the connecting ball, the solder and the bonding pad jointed; and plastic-packaging the chip on the circuit board by using a packaging material, and enabling the packaging material, the chip and the circuit board to form the module. According to the module processing method, the chip is fixed after the connecting ball is welded on the bonding pad of the circuit board, so that the binding force between the chip and the circuit board can be effectively improved, and the use reliability of the module and the device is ensured.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com