Drilling method on sheet metal

A metal sheet, a technology to be drilled, applied in the field of metal processing, to achieve the effect of smoothing the inner wall of the hole and improving the quality of the hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

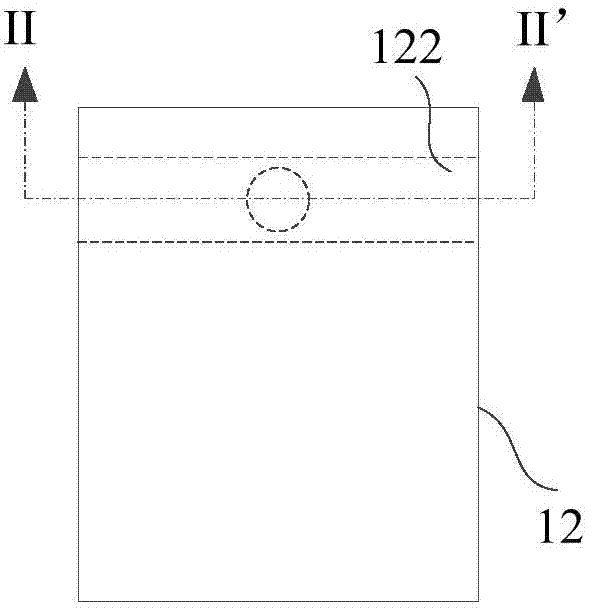

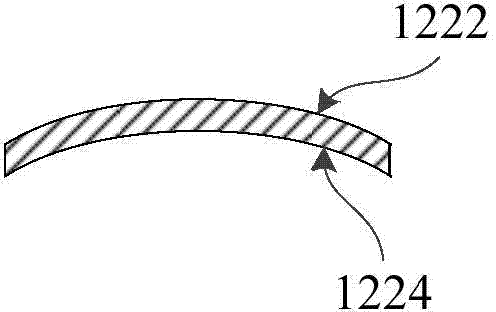

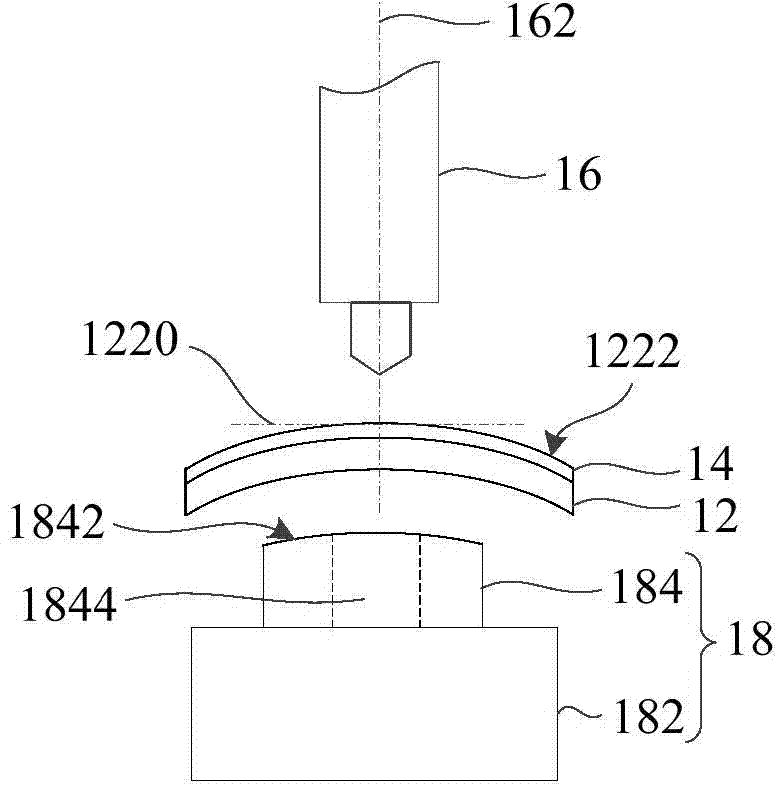

[0022] The method for forming a hole on the metal plate of the embodiment of the present invention is used for specific experiments, wherein the material of the metal plate is aluminum alloy, the material of the auxiliary processing sheet is plastic, the area to be drilled is curved, and the first surface of the area to be drilled is curved. Attaching the auxiliary processing sheet, some experimental data are shown in the table below:

[0023]

[0024] As can be seen from the table, when the hardness value of the auxiliary processing sheet is greater than 0.7 times of the hardness value of the metal plate, and the rotating speed of the drill bit is greater than 8000 rpm, the first surface of the metal plate is almost free of burrs and has a high quality. Especially when the hardness value of the auxiliary processing sheet is 0.8 to 1.2 times that of the metal plate, the first surface of the metal plate is almost free of burrs and has a uniform appearance and higher quality. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com