Processing method for main pipe of stainless steel water collecting and distributing device with plane lug boss

A water collector and processing method technology, which is applied in the processing field of the main pipe of the stainless steel water collector with a flat boss, can solve the problems of unsightly appearance and weak threaded opening at the installation place of the valve, and achieve beautiful appearance and smooth inner wall. Smooth, secure installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

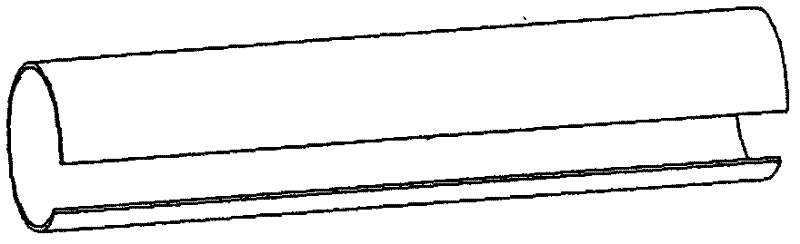

[0019] Embodiment: There are many models of the main pipe of a water collecting and distributing device with flat bosses, which are usually numbered by the number of branches. This embodiment is a water collecting and distributing device with three planar bosses. The processing process of the supervisor must go through the processes of material preparation, pipe coiling, welding, shaping, boss forming, punching, inner turning, shrinking, outer turning, turning, and grinding and polishing.

[0020] In the material preparation process: take a stainless steel plate with a thickness of 1.5 ~ 3.0mm, and cut it into a rectangle according to the diameter and length of the product. The short side of the rectangle is the perimeter of the center line of the wall thickness of the main pipe of the water collector, and the long side is The length of the main pipe and the thickness of the plate depend on the number of branches, that is, the length of the pipe. The longer the pipe, the thicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com