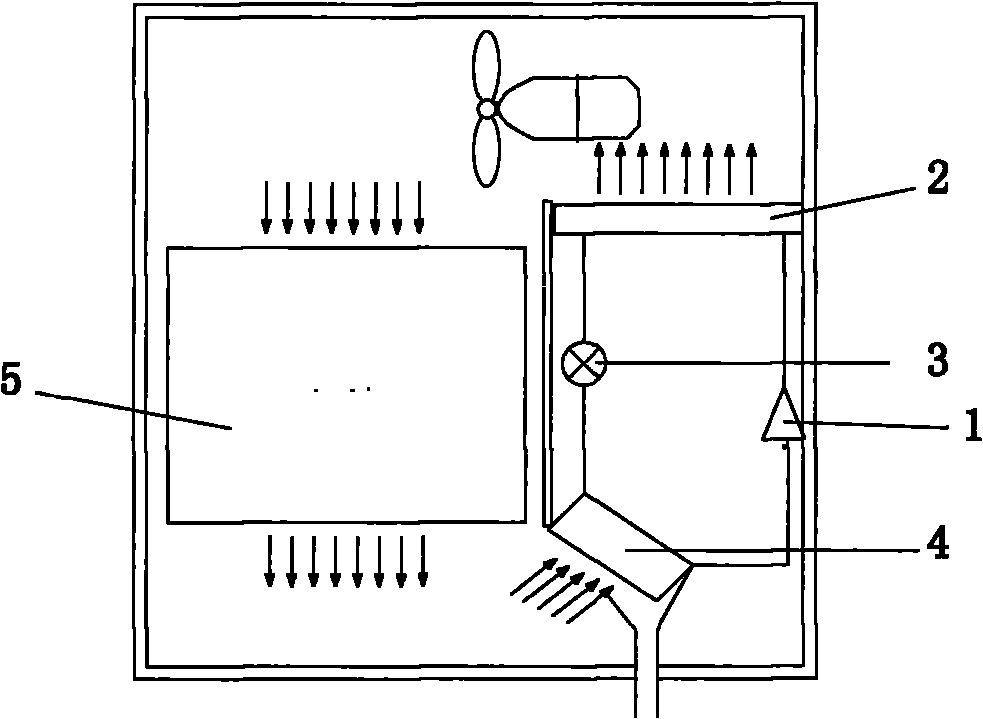

Sludge dewatering method and special oven thereof

A sludge dewatering and sludge technology, which is applied in the fields of dewatering/drying/concentrating sludge treatment, energy and wastewater treatment, solar thermal power generation, etc. Stable quality, low energy consumption and good drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The equipment design of present embodiment is dried 15 tons by every day

[0060] High temperature heat pump sludge dryer technical requirements:

[0061] 1) Processing capacity: 15t / d

[0062] 2) Moisture content of feed material ≤70%

[0063] 3) The moisture content of the discharge material is 30% (adjustable)

[0064] 4) Heating equipment: solar energy, high voltage electric field, high temperature air source heat pump.

[0065] The equipment is designed to dry 15 tons per day and work 20 hours a day, so the drying capacity per hour can be calculated as: 0.75 tons.

[0066] The heat consumed by drying mainly meets four parts:

[0067] A. The heat Q of bathing by heating 750kg of sludge to 60-65 degrees 1

[0068] B. The heat Q consumed by the evaporation of sludge water 2

[0069] C. The heat Q taken away during the dehumidification process 3

[0070] D. The heat Q absorbed by the equipment 4 (Conveyor belt, iron frame, etc.; this part has less heat and c...

Embodiment 2

[0073] The equipment design of present embodiment is dried 100 tons by every day.

[0074] High temperature heat pump sludge dryer technical requirements:

[0075] 1) Processing capacity: 100t / d sludge with a moisture content of 85%.

[0076] 2) Moisture content of feed material ≤70%

[0077] 3) The moisture content of the discharge material is 30% (adjustable)

[0078] 4) Heating equipment: high temperature air source heat pump and heat pump dehumidification unit

[0079] The equipment is designed to dry 100 tons per day and work 20 hours a day, so the drying capacity per hour can be calculated as: 5 tons. The selected units are 18 15-horsepower units.

Embodiment 3

[0081] The equipment design of present embodiment is by drying 120 tons every day

[0082] High temperature heat pump sludge dryer technical requirements:

[0083] 1) Processing capacity: 120t / d

[0084] 2) Moisture content of feed material ≤70%

[0085] 3) The moisture content of the discharge material is 30% (adjustable)

[0086] 4) Heating equipment: solar energy, high voltage electric field, high temperature air source heat pump.

[0087] The equipment is designed to dry 120 tons per day and work 20 hours a day, so the drying capacity per hour can be calculated as: 6 tons. The selected units are 22 15-hp units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com