Bearing ring forge piece production device and process

A technology for bearing rings and production equipment, which is applied in the direction of forging/pressing/hammer devices, hammer driving devices, manufacturing tools, etc., which can solve the problems of inconvenient application of processing bearing rings, and improve processing convenience and processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

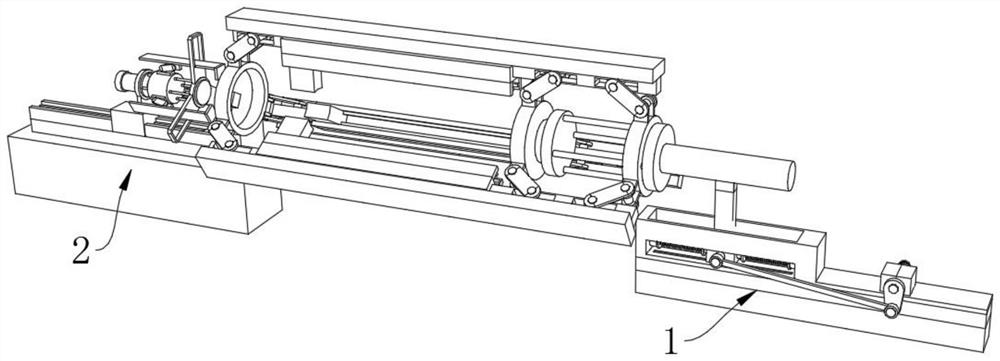

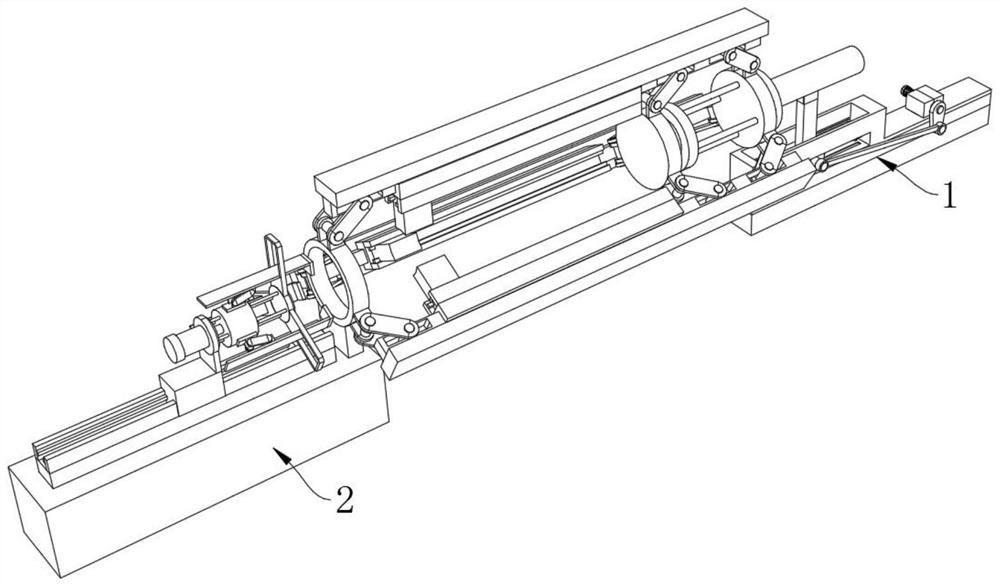

[0031] see Figure 1-7 :

[0032] A bearing ring forging production device, including an adaptive forging processing structure 1 and a three-way automatic processing and positioning structure 2, one end of the three-way automatic processing and positioning structure 2 is provided with an adaptive forging processing structure 1, and a three-way automatic processing and positioning structure 2 It is used to complete the automatic adaptive clamping of the processing shafts with different diameters used to carry the bearing ring forgings. The adaptive forging processing structure 1 is used to complete the positioning of the three-way automatic processing positioning structure 2. The bearing ring forgings on the outside of the processing shaft Perform reciprocating hammer forging.

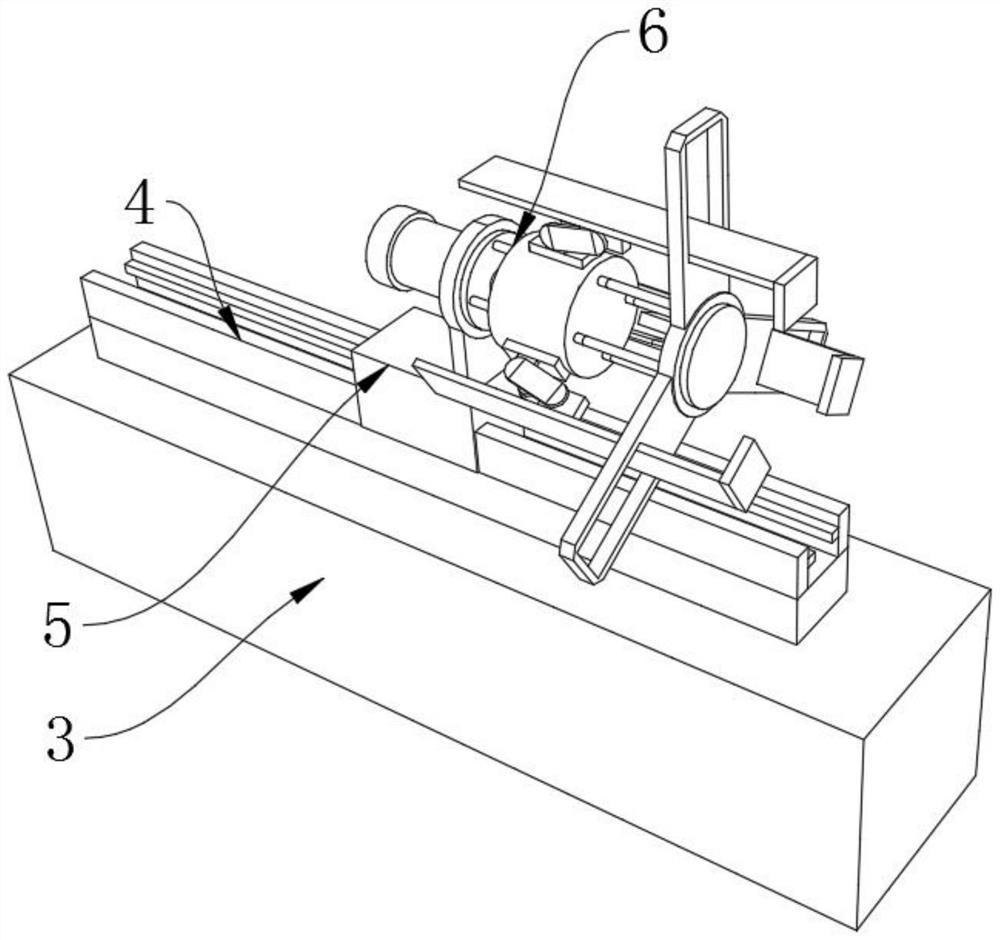

[0033] The three-way automatic processing and positioning structure 2 includes a mounting base 3, a first trackless cylinder 4, a first matching slider 5 and a moving clamp module 6. The top of the mou...

Embodiment 2

[0043] A process for producing bearing ring forgings, which is used in the production device for bearing ring forgings in the above embodiment, at least includes the following steps:

[0044] Step 1: Select the corresponding processing shaft according to the size of the bearing ring forging to be processed, and socket the bearing ring forging on the outside of the processing shaft;

[0045] The second step: utilize the movable clamp module 6 to carry the machining axis;

[0046] Step 3: Deduce the first moving slider 5 by controlling the first trackless cylinder 4, so that the processing shaft passes through the inner side of the processing and positioning hoop 45 under the driving and derivation of the movable clamp module 6;

[0047] Step 4: Control the second trackless cylinder 40 to drive the second moving slider 41 to a suitable processing position, start the adaptive forging processing structure 1 to complete the continuous forging processing and production of the bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com