Simplified tube-shell type fluid mixer

A fluid mixing, shell-and-tube technology, applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of large pressure loss, unfavorable engine fuel economy, etc., to reduce pressure loss and improve processing convenience performance, high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

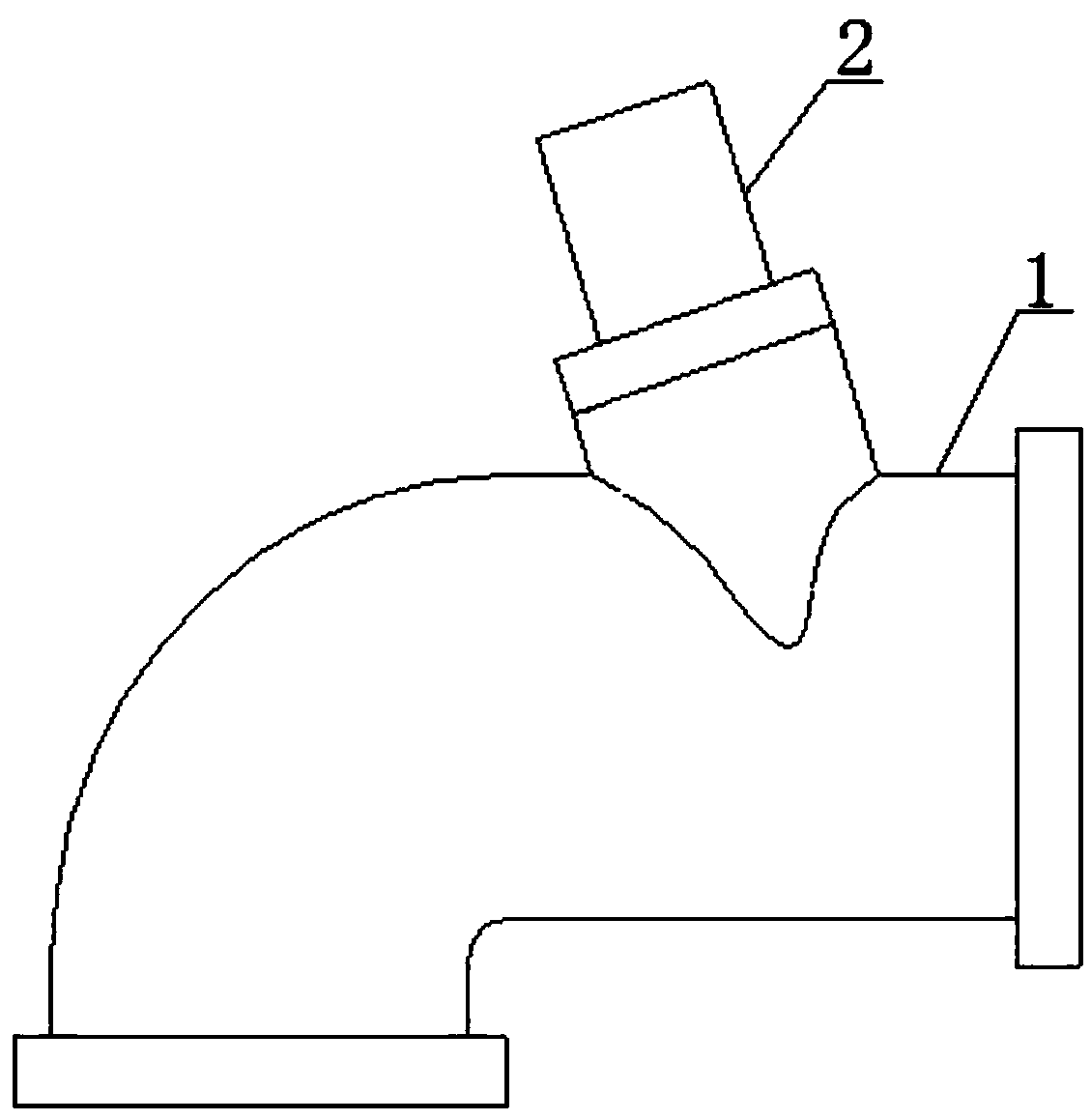

[0021] see Figure 1 to Figure 2 , a simplified shell-and-tube fluid mixer, which is suitable for mixing gas, EGR and other gases or other fluids, including a main flow pipe 1 and an EGR pipe 2 . The EGR pipe outlet end 6 of the EGR pipe 2 extends into the inner chamber of the main flow pipe 1 from the side wall of the main flow pipe 1, and the EGR pipe outlet end 6 faces away from the main flow pipe 1 airflow direction, that is, the EGR pipe outlet end 6 faces away from the inlet 3 of the main flow pipe.

[0022] see Figure 1 to Figure 2 , the EGR pipe outlet end 6 is a chamfered plane, and the chamfered plane is perpendicular to the plane formed by the axis of the main flow pipe 1 and the axis of the EGR pipe 2 . Moreover, the height of the chamfered surface at the outlet end 6 of the EGR pipe is greater than 0.5 times the diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com