Conductive adhesive film

A technology of conductive film and conductive adhesive layer, which is used in conductive adhesives, adhesives, epoxy resin adhesives, etc. and other problems to achieve the effect of improving the convenience of processing, prolonging the validity period of the product, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

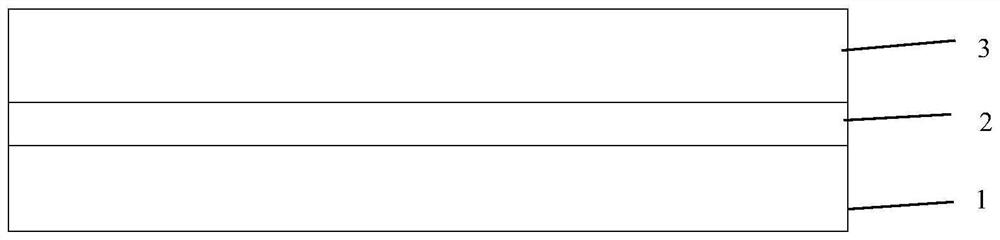

Image

Examples

Embodiment 1

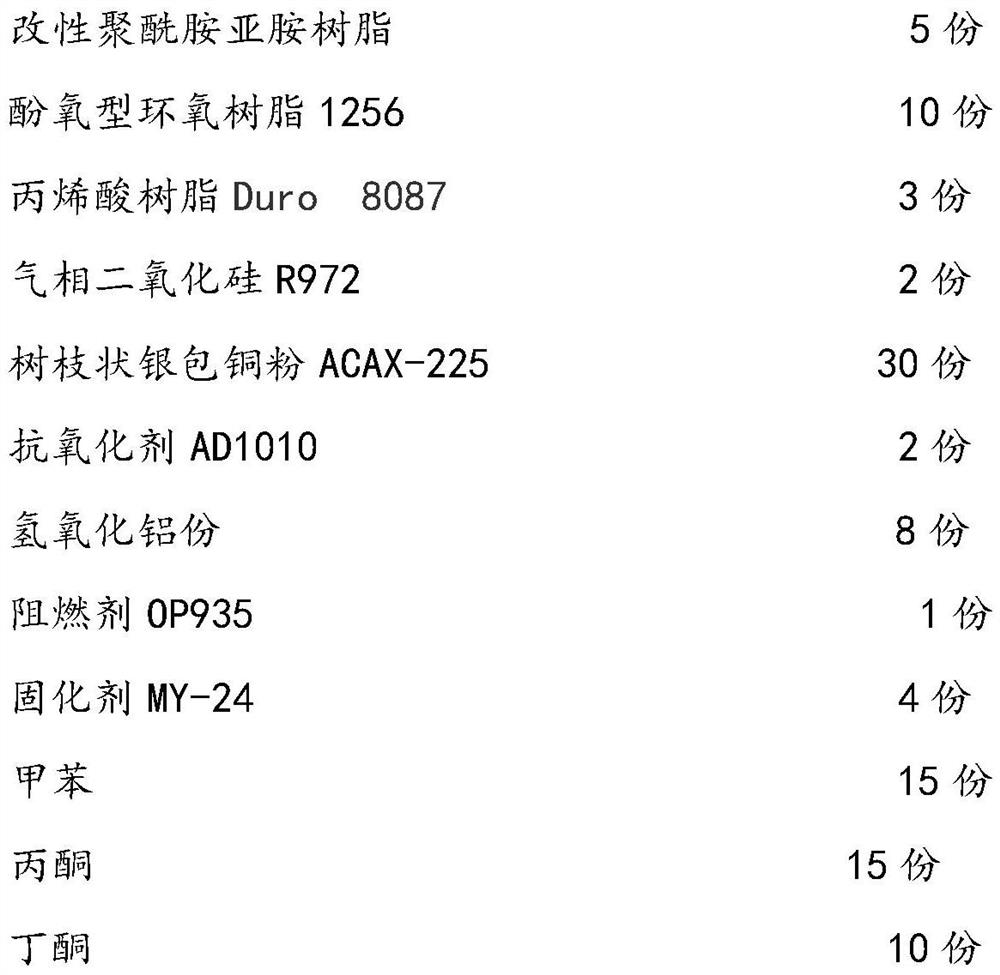

[0043] After preparing the coated release film, prepare the conductive adhesive coating solution, the proportion is as follows:

[0044]

[0045]Dissolve the mixed solvent, polyamideimide resin, acrylic resin and phenolic epoxy resin in the dissolution tank and mix them evenly, then put them into the dispersion tank, add fumed silica and alumina powder, and disperse at high speed for 30 minutes. After sanding 3 times with a sand mill, add the material to the planetary mixer, add dendritic metal powder, vacuumize and stir for 60 minutes, add antioxidants, flame retardants and curing agents, and stir for another 30 minutes, and the conductive adhesive After filtering, apply a layer of conductive adhesive, and dry at a temperature of 90-110°C.

[0046] After the conductive film is aged at high temperature and high humidity (85°C, 85%RH) for 100 hours, it is flatly attached to a PI film or a reinforcing board, and laminated to a flexible circuit board at 180°C for performance t...

Embodiment 2

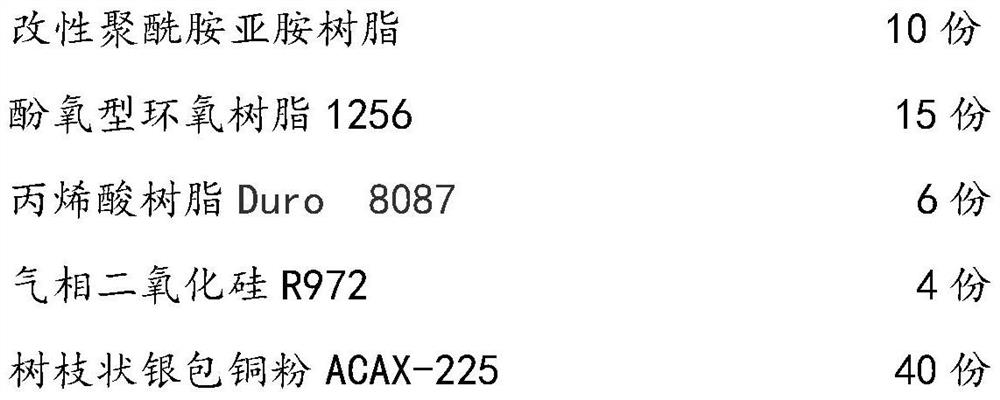

[0048] After preparing the coated release film, prepare the conductive adhesive coating solution, the proportion is as follows:

[0049]

[0050]

[0051] Dissolve the mixed solvent, polyamideimide resin, acrylic resin and phenolic epoxy resin in the dissolution tank and mix them evenly, then put them into the dispersion tank, add fumed silica and alumina powder, and disperse at high speed for 30 minutes. After sanding 3 times with a sand mill, add the material to the planetary mixer, add dendritic metal powder, vacuumize and stir for 60 minutes, add antioxidants, flame retardants and curing agents, and stir for another 30 minutes, and the conductive adhesive After filtering, apply a layer of conductive adhesive, and dry at a temperature of 90-110°C. .

[0052] After the conductive film is aged at high temperature and high humidity (85°C, 85%RH) for 100 hours, it is flatly attached to a PI film or a reinforcing board, and laminated to a flexible circuit board at 180°C f...

Embodiment 3

[0054] After preparing the coated release film, prepare the conductive adhesive coating solution, the proportion is as follows:

[0055]

[0056] Dissolve the mixed solvent, polyamideimide resin, acrylic resin and phenolic epoxy resin in the dissolution tank and mix them evenly, then put them into the dispersion tank, add fumed silica and alumina powder, and disperse at high speed for 30 minutes. After sanding 3 times with a sand mill, add the material to the planetary mixer, add dendritic metal powder, vacuumize and stir for 60 minutes, add antioxidants, flame retardants and curing agents, and stir for another 30 minutes, and the conductive adhesive After filtering, apply a layer of conductive adhesive, and dry at a temperature of 90-110°C. .

[0057] After the conductive film is aged at high temperature and high humidity (85°C, 85%RH) for 100 hours, it is flatly attached to a PI film or a reinforcing board, and laminated to a flexible circuit board at 180°C for performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com