Ratchet wrench and its ratchet wrench head

A wrench head and ratchet technology, applied in the field of ratchet wrench heads, can solve the problems of reducing the service life of the ratchet wrench, slipping and falling off of the ratchet wrench, and protecting the knob and tooth block, so as to improve the processing convenience and avoid slippage or falling off. , The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

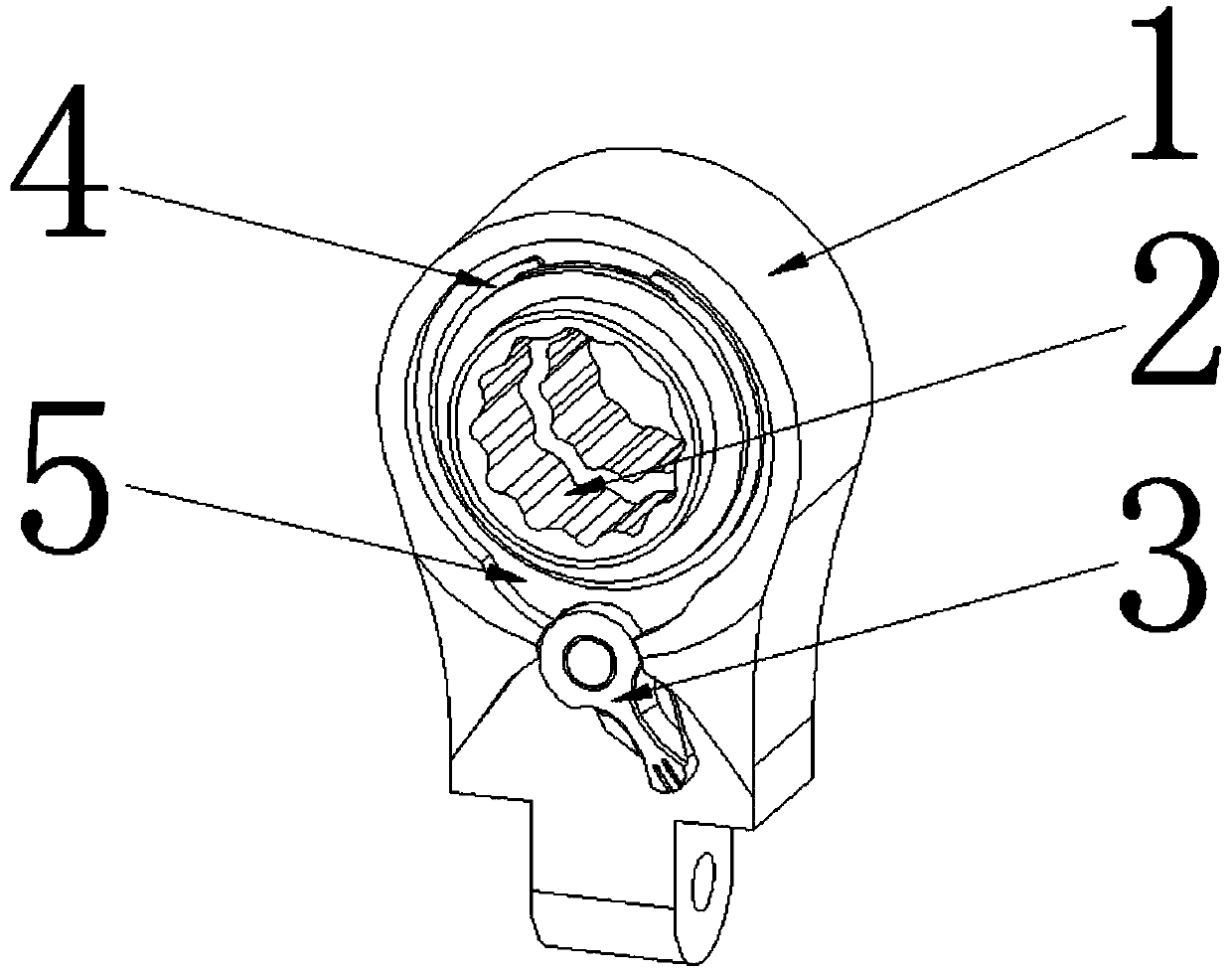

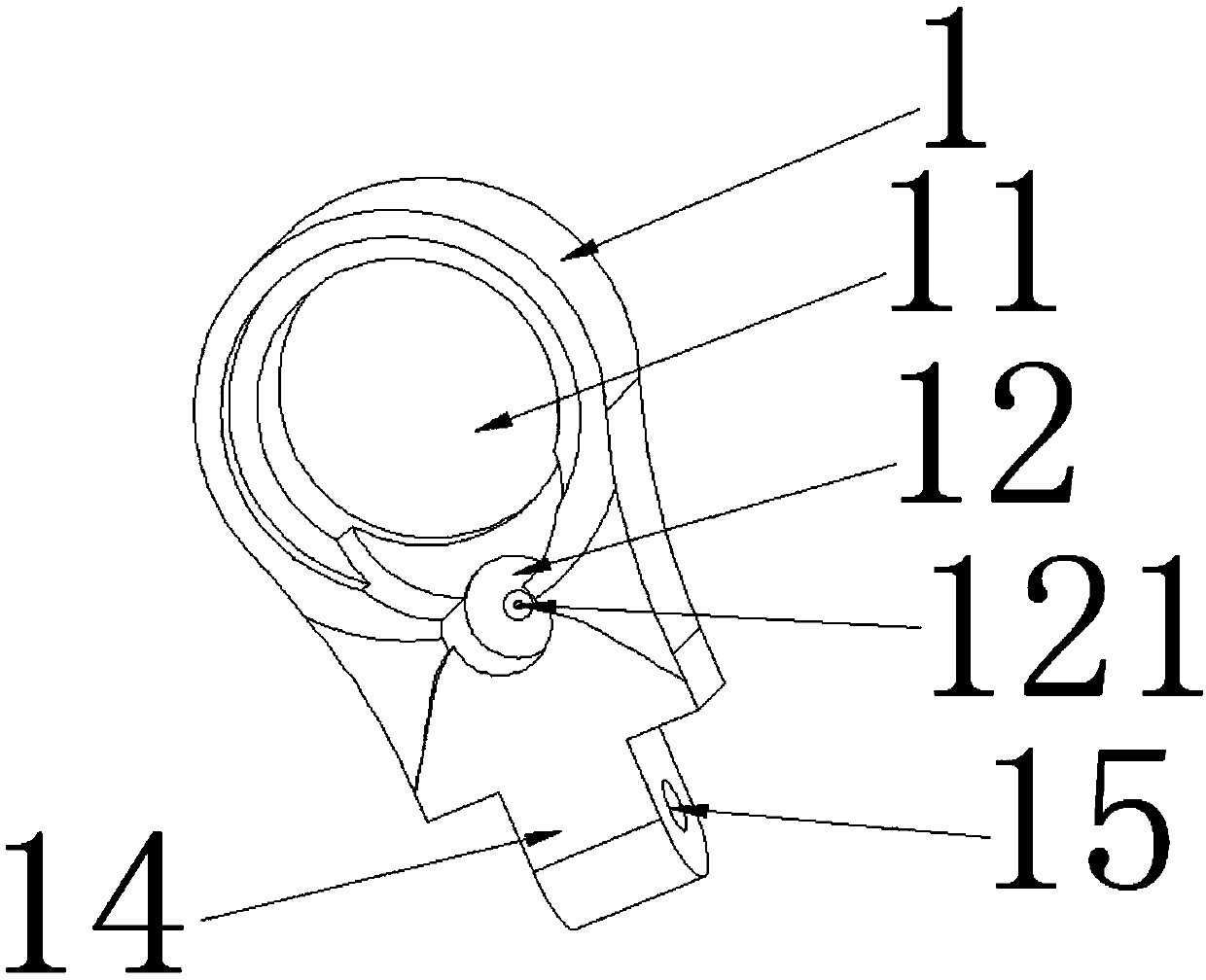

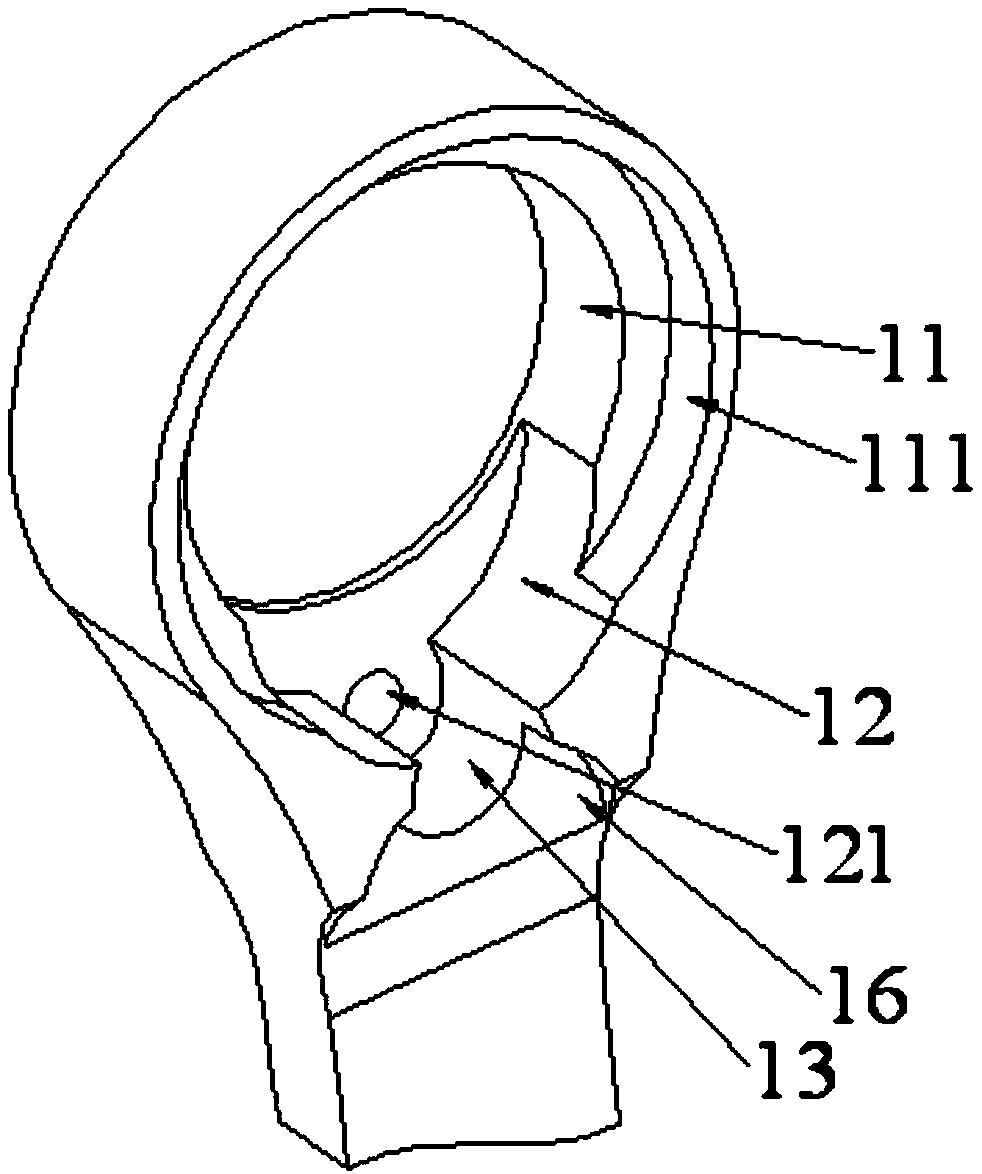

[0037] ratchet wrench head, such as Figure 1-13 As shown, it includes a ratchet seat 1 and a ratchet wheel 2. The middle part of the ratchet seat 1 is provided with a through hole 11 for installing the ratchet wheel 2. The front and rear annular concave shoulders 111 and rear annular concave shoulders 112 are respectively provided at the front and rear ends of the through hole 11 wall. The depth of the front annular concave shoulder 111 is greater than the depth of the rear annular concave shoulder 112, the bottom surfaces of the front annular concave shoulder 111 and the rear annular concave shoulder 112 respectively form the front side stepped surface 131 and the rear side stepped surface 132, and the outer surface of the ratchet 2 is provided with Two snap ring grooves 22, the snap ring grooves 22 are provided with a snap ring 4 for restricting the axial movement of the ratchet 2, and the two snap rings 4 are respectively located in the front annular concave shoulder 111 an...

Embodiment 2

[0046] ratchet wrench, such as Figure 14 As shown, the wrench body 10 is included, and the ratchet wrench head in the first embodiment is connected to the wrench body 10 through the connecting hole 15 provided on the joint 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com