Quick detachable plate locking mechanism

A locking mechanism and plate technology, applied in the direction of thin plate connection, connecting components, mechanical equipment, etc., can solve problems such as inconvenient loading and unloading, and achieve the effects of saving time, improving competitiveness, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

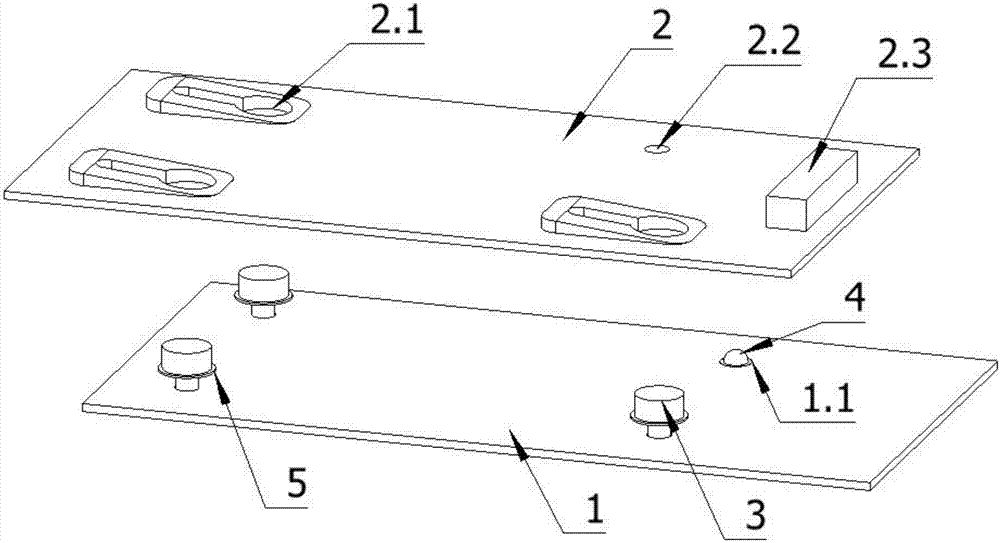

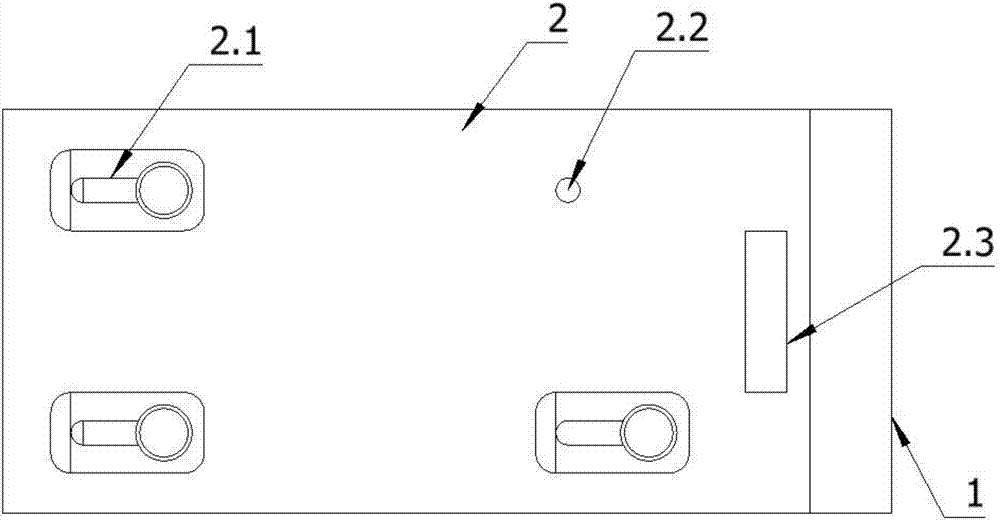

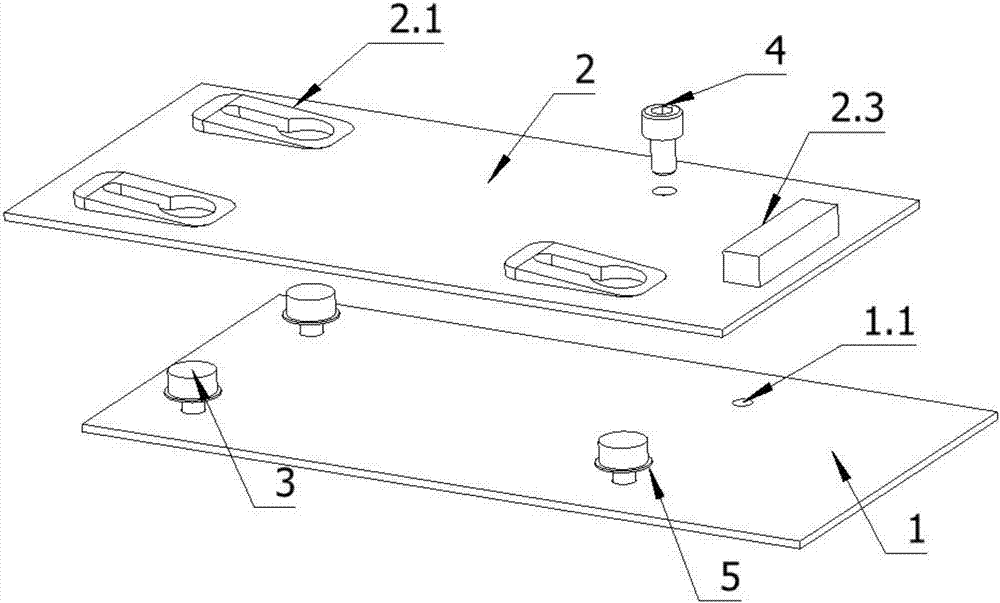

[0026] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0027] figure 1 , figure 2 It is an embodiment of the present invention. As shown in the figure, a quick-detachable plate locking mechanism includes a base plate 1 and a mounting plate 2. The base plate 1 is equipped with a plurality of gourd nails 3, and the mounting plate 2 is provided with a The gourd nail 3 corresponds to the gourd hole 2.1, the base plate 1 is also provided with a limit hole a1.1, and the mounting plate 2 is provided with a limit hole b2.2 corresponding to the limit hole a1.1; the gourd nail 3 is snapped into the gourd hole After the narrow end of 2.1, the limit hole a1.1 is aligned with the limit hole b2.2, and the limit nail 4 is installed in the limit hole a1.1 and the limit hole b2.2; the gourd nail 3 from the gourd hole 2.1 When the wide end moves to the na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com