Lamp

一种灯具、灯罩的技术,应用在具有散热功能的灯具领域,能够解决除尘便利性不佳、制造不便等问题,达到增加组装便利性、提升使用寿命、提升散热效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

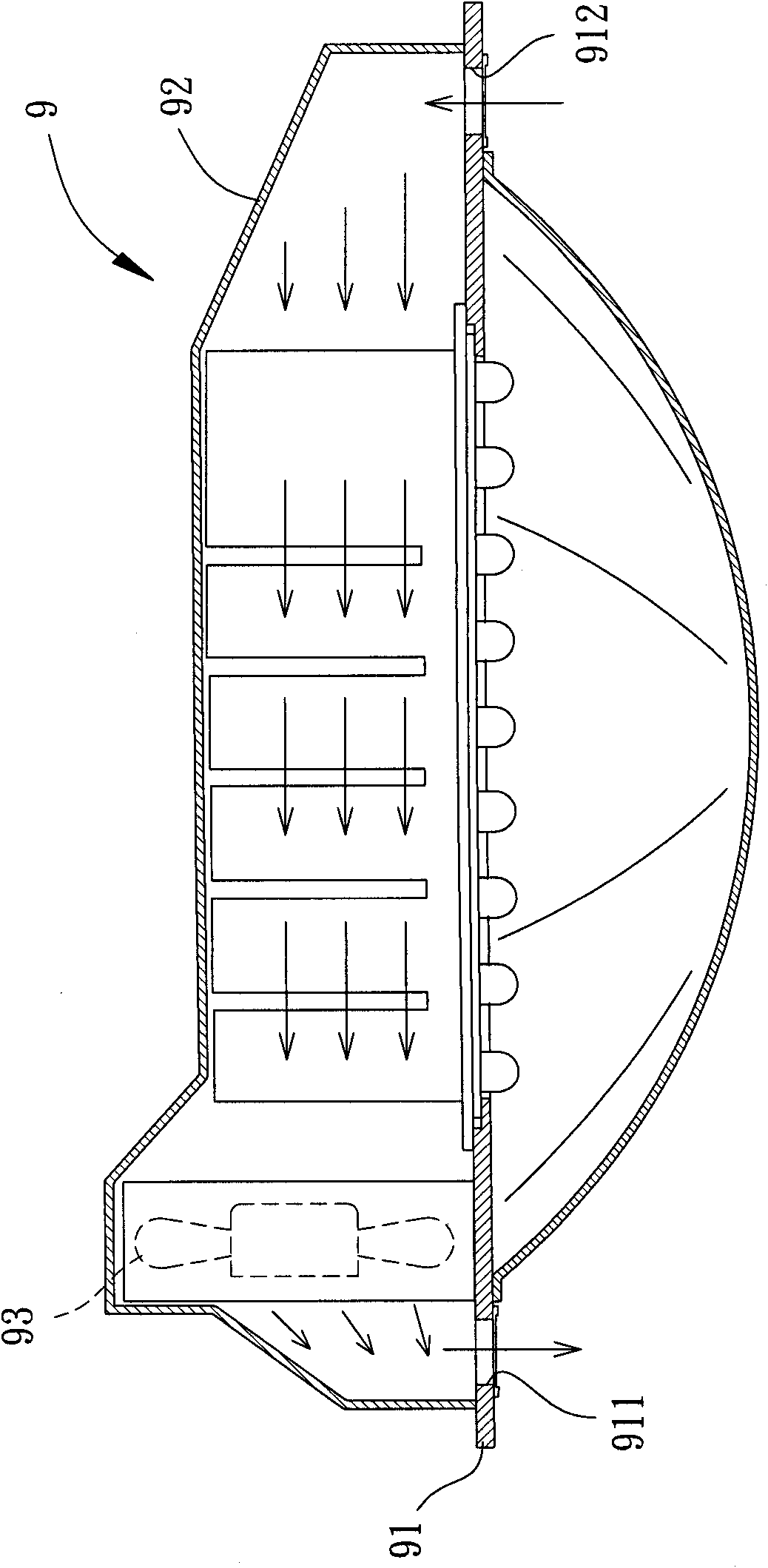

[0103] Please refer to Figure 4 , 5 As shown in and 6 , the lamp 1 of the first embodiment of the present invention at least includes a heat spreading element 11 , a light emitting module 12 , a housing 13 and a cooling fan 14 . Wherein the light-emitting module 12 is combined with the heat spreader 11; the housing 13 is also combined with the heat spreader 11 to cooperate with the heat spreader 11 to form a structural design for air flow; the cooling fan 14 is combined with the inside of the shell 13 , to provide a predetermined conduction heat dissipation function.

[0104] The heat spreader 11 is a component made of heat-conducting material, and the heat spreader 11 can be designed in various geometric shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com