Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Improve low temperature flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

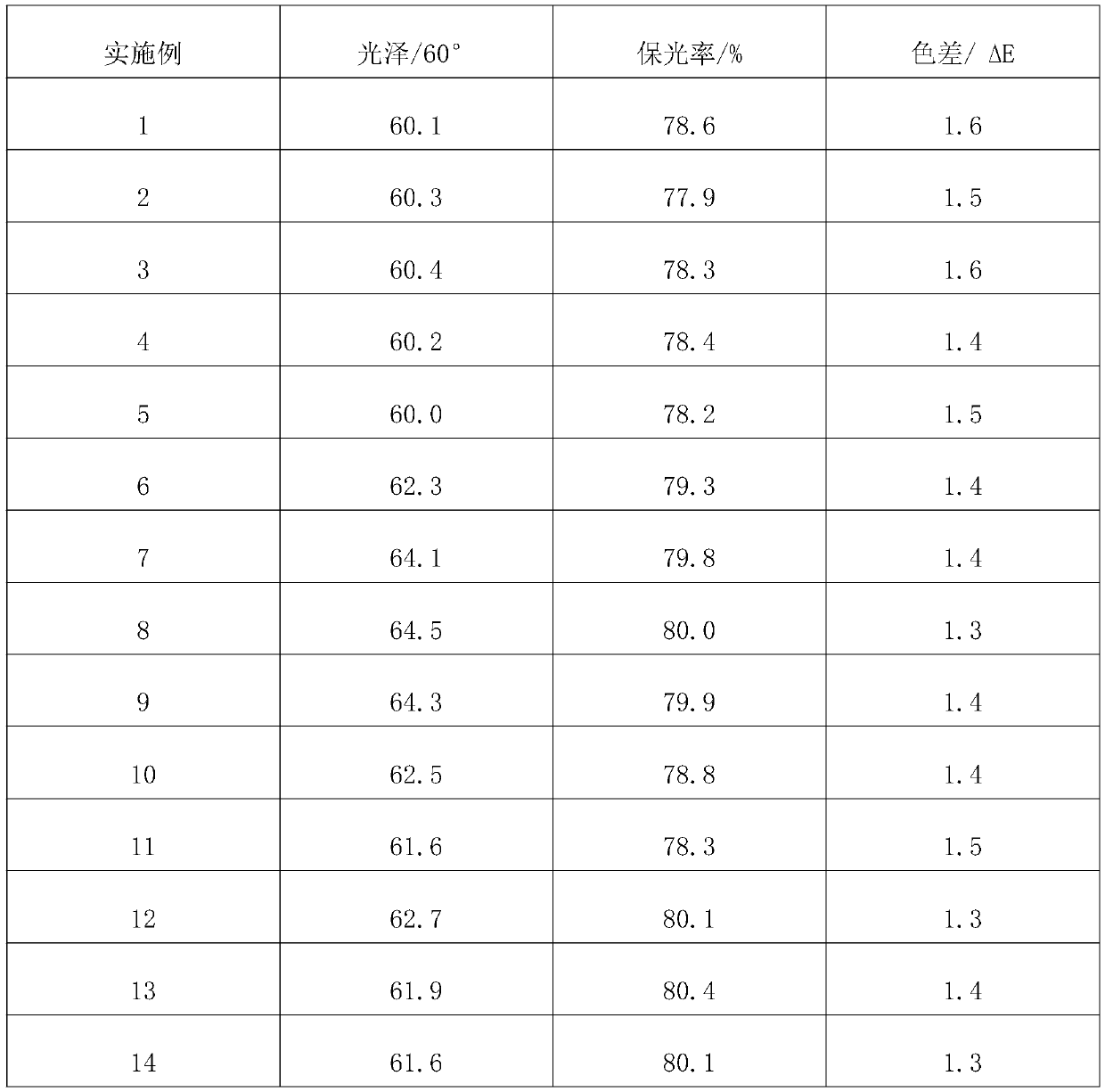

Acrylic ester elastic emulsion of room temperature self-crosslinking core-shell structure and preparing method thereof

InactiveCN102321326AImprove scratch resistanceImprove stain resistanceCoatingsCross-linkPolymer science

The invention relates to an acrylic ester elastic emulsion of a room temperature self-crosslinking core-shell structure and a preparing method thereof, and belongs to the field of macromolecular polymer. The purpose of the invention is to improve the application requirements of elastic coating, such as low-temperature elasticity and anti-contamination, tensile strength and flexibility and the like. The technical scheme adopted in the invention is as follows: using a core-shell polymerization process, introducing cross-linking monomer to shell layer, designing core layer glass state temperature (Tg) to be minus 40 to minus 15 DEG C and shell layer glass state temperature Tg to be 5 to 40 DEG C, and after polymerization of the emulsion and regulating pH to be 8 to 9, adding a certain amount of cross-linking agent, and obtaining the room temperature self-crosslinking elastic emulsion of core-shell structure. The elastic emulsion prepared by the invention can be self-crosslinked at room temperature, and has excellent low-temperature elasticity, scratch resistance, anti-contamination and surface finish, and can meet the requirements of actual application.

Owner:SKSHU PAINT

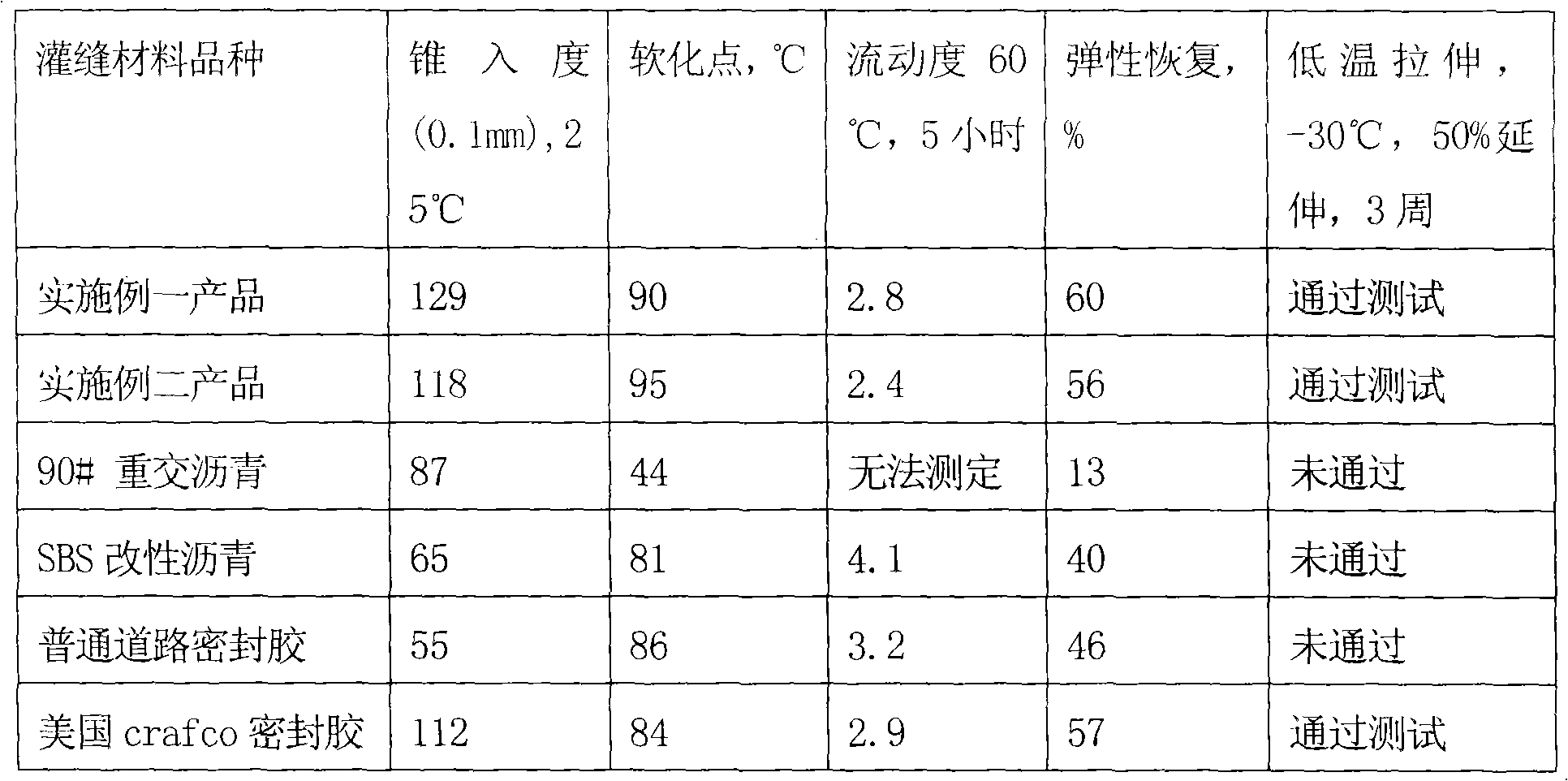

Fissure cementation glue for pavement, and preparation method for fissure cementation glue

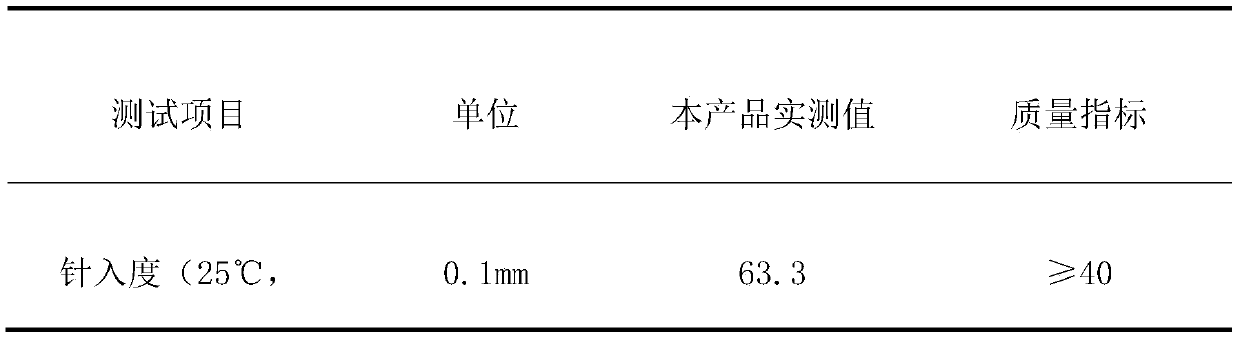

InactiveCN102433008AImprove high temperature stabilityImprove low temperature flexibilityPaving detailsBuilding insulationsRevolutions per minuteColloid mill

The invention discloses fissure cementation glue for pavement, and a preparation method for the fissure cementation glue. The fissure cementation glue consists of the following components in percentage by mass: 45 to 75 percent of petroleum asphalt, 4 to 10 percent of polymer, 0.06 to 0.2 percent of stabilizing agent, 8 to 15 percent of compatilizer, 3 to 10 percent of softener and 6 to 20 percent of waster rubber powder. The preparation method comprises the following steps of: heating 45 to 75 mass percent of petroleum asphalt to 185 to 195 DEG C, wherein the petroleum asphalt flows at the temperature of between 185 and 195 DEG C, adding 4 to 10 percent of polymer with stirring, grinding by using a colloid mill at the revolving speed of 2,000 to 4,000 revolutions per minute, adding 8 to 15 percent of compatilizer, 3 to 10 percent of softener and 6 to 20 percent of waster rubber powder sequentially, swelling with stirring for 2 to 10 hours, adding 0.06 to 0.2 percent of stabilizing agent, and reacting for 1 to 5 hours to obtain a product. The fissure cementation glue for the pavement is high in high temperature stability and low temperature flexibility and elastic recovery capacity, and is special for cementation and filling of fissures and joints on bituminous pavement or cement concrete pavement under the weather conditions of a frigid zone and a polar zone.

Owner:HEILONGJIANG CHANGHE CHEM CORP

Preparation process of bicomponent castor oil polyurethane waterproof coating

ActiveCN102417779AImprove low temperature flexibilityImprove statusCoatingsPolymer sciencePtru catalyst

A preparation process of a bicomponent castor oil polyurethane waterproof coating is characterized in that the coating is obtained by interpenetrating a component A of polyurethane prepolymer and a component B of a colorful color paste system under the action of an initiator and a catalyst; wherein the component A is obtained by allowing castor oil and 2,4-toluene diisocyanate to react in an organic solvent dissolved with an initiator; the component B is obtained by mixing a blending agent, a solid pigment and / or a solid filler with a coupling agent, milling, orderly adding a alkene monomer, a catalyst, a polymerization inhibitor, and a light stabilizer, and stirring uniformly. The coating of the invention has excellent waterproofness, a good apparent state, abundant colors, good decorative effect, adjustable curing time, adjustable film flexibility and hardness, and simple operations.

Owner:湖北蓝盾之星科技有限公司 +1

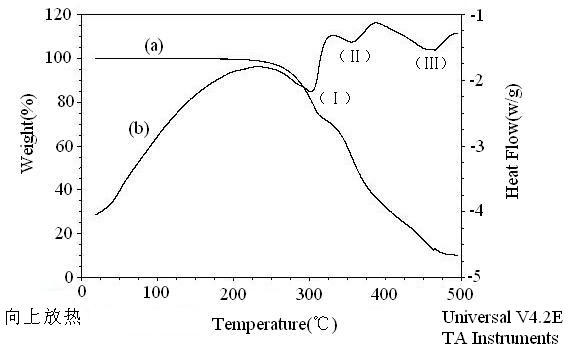

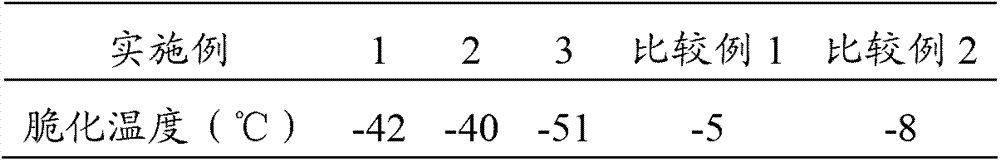

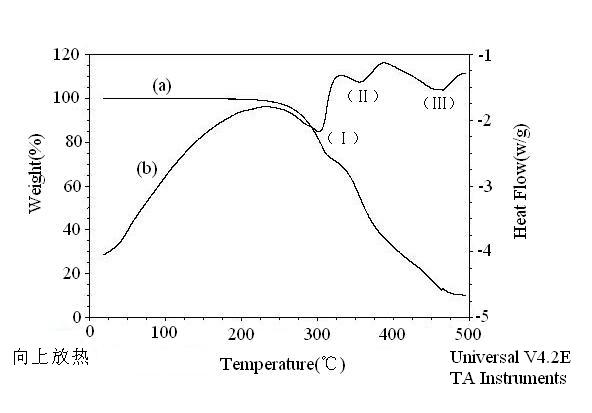

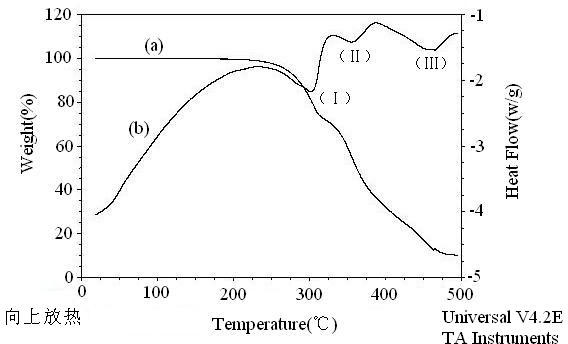

Hydroxy acrylic resin for reflective film and preparation method thereof

ActiveCN103044615AHigh strengthDoes not damage low temperature flexibilityMethacrylateOrganic solvent

The invention provides a hydroxy acrylic resin for a reflective film, which is prepared by reacting the following components in parts by weight: 35-60 parts of organic solvent, 15-25 parts of first acrylic monomer, 25-35 parts of second acrylic monomer, 5-10 parts of third acrylic monomer and 0.3-1 part of initiator, wherein the first acrylic monomer is a non-substituted acrylate compound, the second acrylic monomer is a methacrylate compound, and the third acrylic monomer is a hydroxyacrylate compound. In the invention, the hydroxy acrylic resin prepared from the first acrylic monomer and second acrylic monomer has both low glass transition temperature and favorable strength; and the third acrylic monomer provides a crosslinkable functional group for the resin, thereby enhancing the temperature resistance of the resin. The experimental result indicates that the brittle temperature of the hydroxy acrylic resin provided by the invention can be down to -51 DEG C.

Owner:JIAOZUO RUIFULAI REFLECTIVE MATERIAL

Two-component castor oil polyurethane waterproof paint

InactiveCN102417790AImprove low temperature flexibilityImprove statusPolyurea/polyurethane coatingsPrepolymerChemistry

A two-component castor oil polyurethane waterproof paint is obtained by interpenetrating a polyurethane prepolymer (component A) and a colorant (component B) under the actions of an initiator and a catalyst. The component A is obtained by reacting castor oil and 2,4-toluene diisocynate in an organic solvent with a dissolved initiator. The preparation method of the component B comprises the following steps of: mixing a blending agent and a solid pigment (or solid filler) with a coupling agent, grinding, and then adding an allyl monomer, a catalyst, a polymerization inhibitor and a light stabilizer in turn to stir evenly. The two-component castor oil polyurethane waterproof paint has excellent waterproof performance, good appearance, rich colors, good decorative effect, adjustable curing time, adjustable flexibility and hardness and convenience in operations.

Owner:湖北蓝盾之星科技有限公司 +1

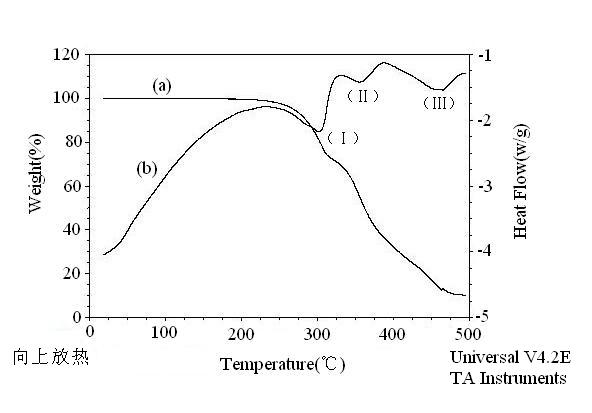

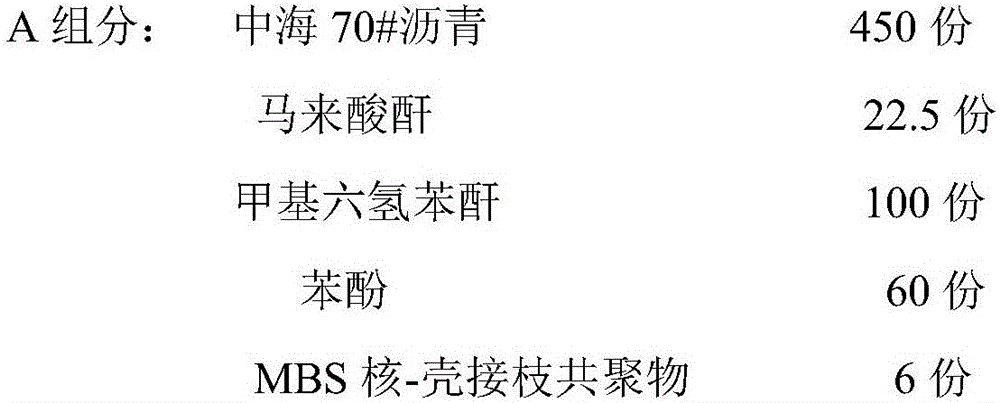

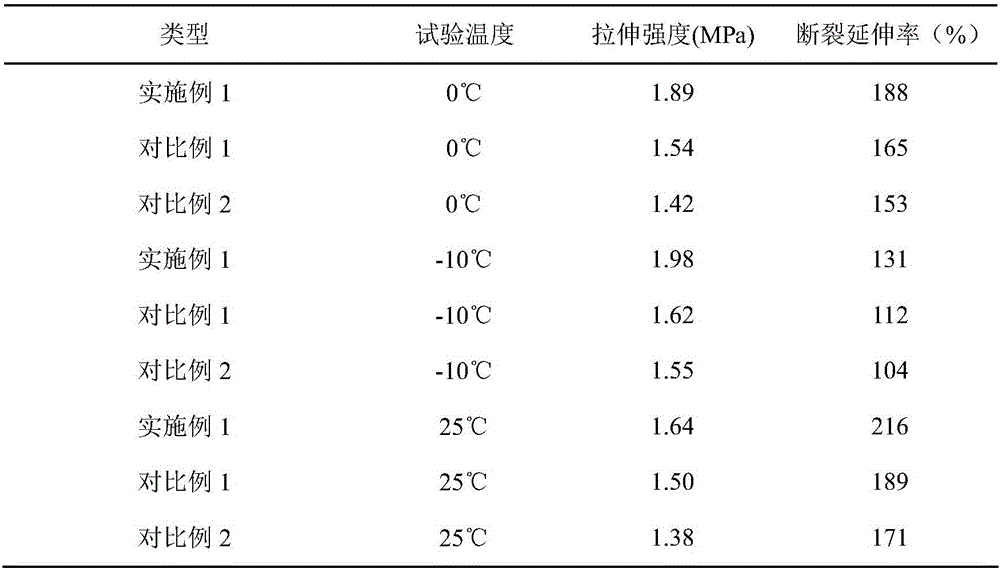

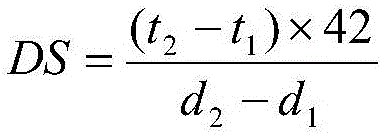

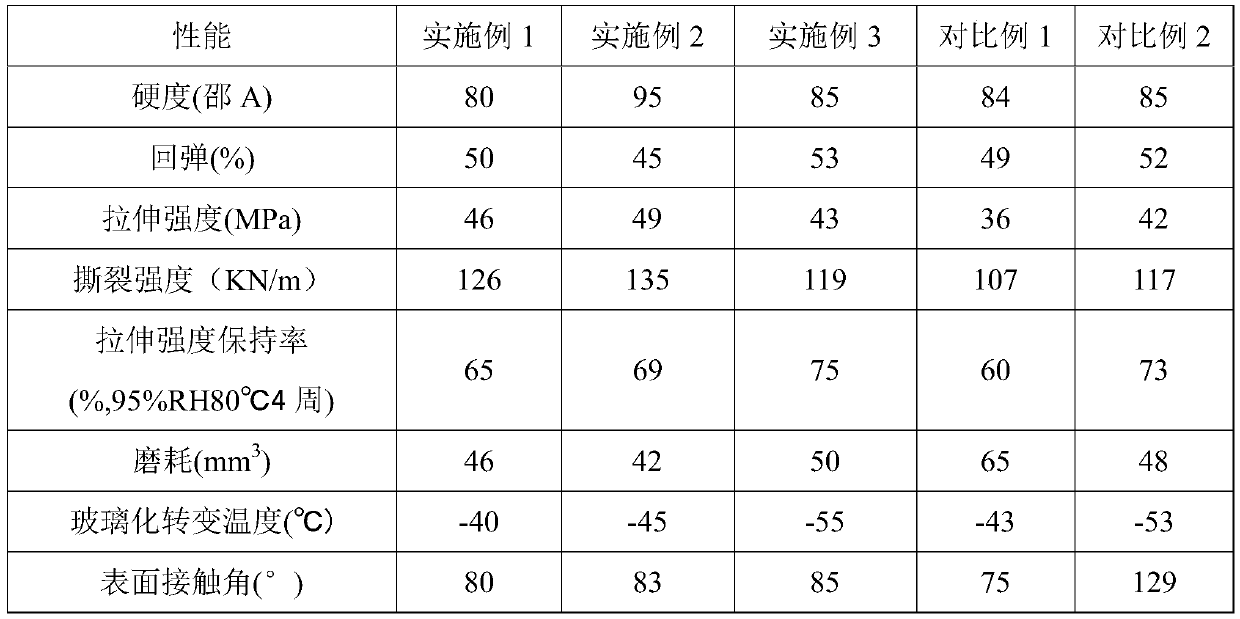

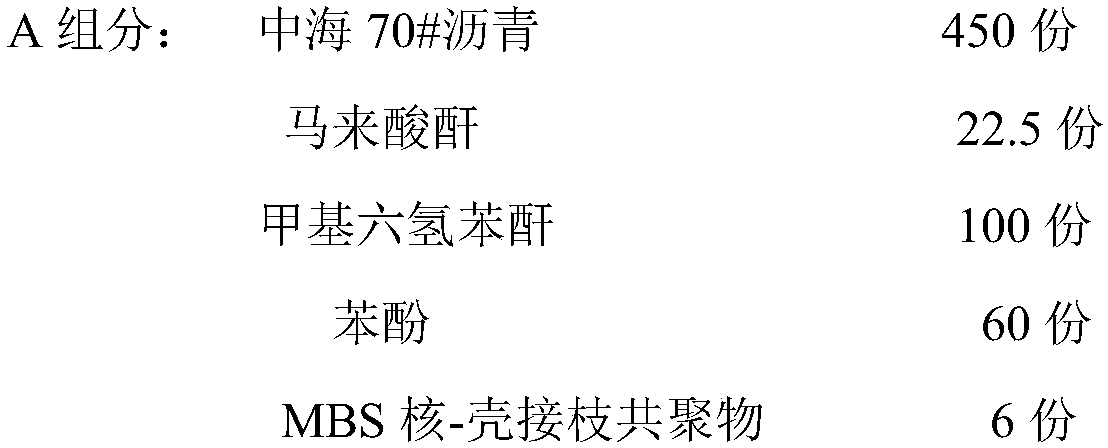

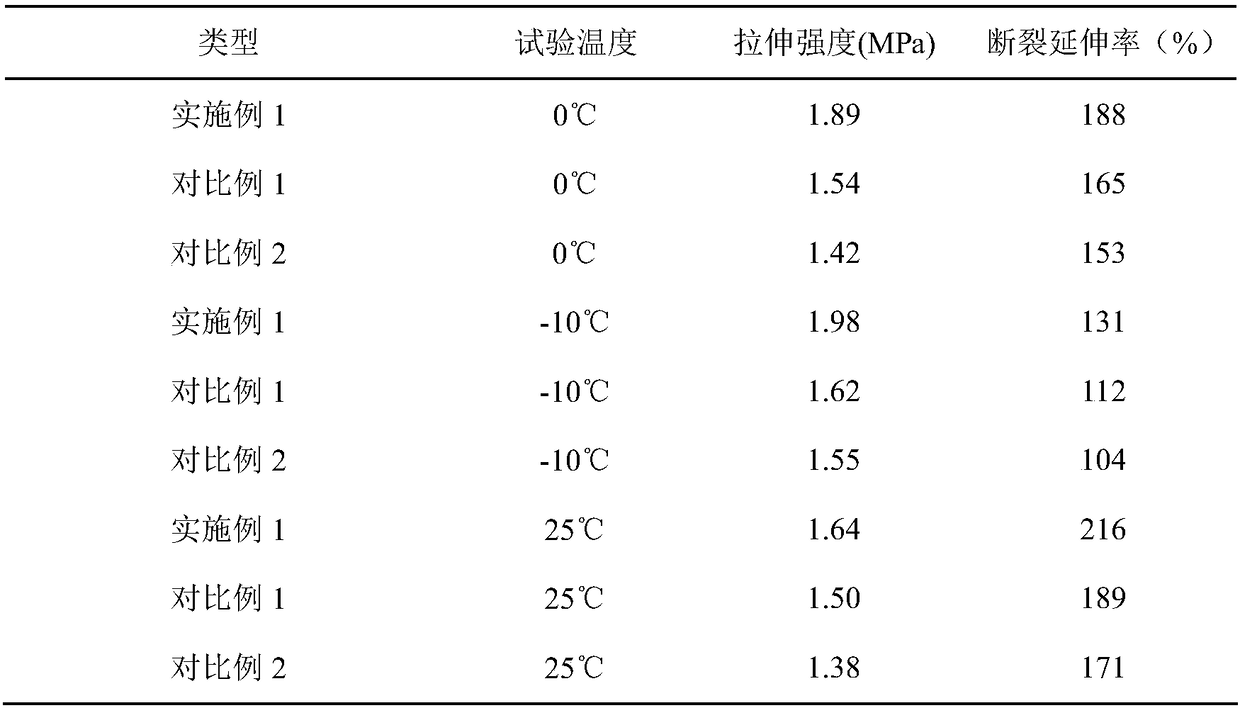

Toughened warm-mixed epoxy asphalt for steel bridge deck pavement

ActiveCN105838094AImprove high temperature stabilityImprove road performanceClimate change adaptationBuilding insulationsThird phaseBituminous materials

The invention belongs to the technical field of traffic, and discloses a novel material which is mainly used for steel bridge deck pavement to improve the pavement performance of steel bridge deck pavement. The asphalt material is softened and toughened by adopting a MBS core-shell grafted copolymer as a toughening agent and adopting a phenolic compound as a compatibilizing agent through the characteristics that the flexibility of the MBS core-shell grafted copolymer is good at low temperature and the MBS core-shell grafted copolymer can be soluble with asphalt, the interfacial tension between the asphalt and epoxy resin is decreased by serving the phenolic compound as a third phase through the characteristic that the phenolic compound can be soluble with the asphalt and the epoxy resin, and then the purpose that the blend system is stable is achieved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Waterproof crack-resisting coating and preparation method thereof

InactiveCN107987647AHigh elongationResponsiveAntifouling/underwater paintsPaints with biocidesCelluloseCrack resistance

The invention discloses a waterproof crack-resisting coating and a preparation method thereof, and relates to the field of coating materials. The waterproof crack-resisting coating is prepared from the following components in parts by weight: 40 to 80 parts of elastic emulsion, 15 to 20 parts of ZnO-CeO2 particles, 10 to 30 parts of Portland cement, 20 to 40 parts of quartz sand, 10 to 30 parts ofcomplexing agent, 10 to 30 parts of cellulose, 10 to 30 parts of water reducing agent, 3 to 5 parts of defoaming agent, 3 to 5 parts of dispersing agent, 3 to 5 parts of leveling agent and 3 to 5 parts of thickening agent. The waterproof crack-resisting coating provided by the invention has the advantages of excellent waterproof and crack resistance, scrubbing resistance, pulverization resistance, stain resistance, weather fastness, good aging resistance, storage stability, low cost, greenness and environment friendliness.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

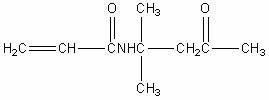

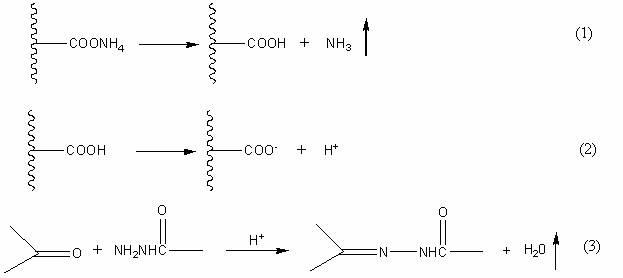

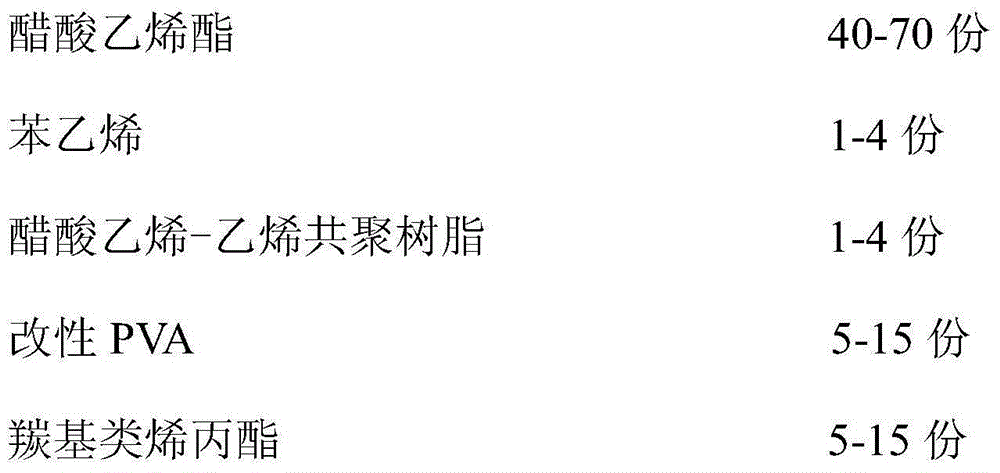

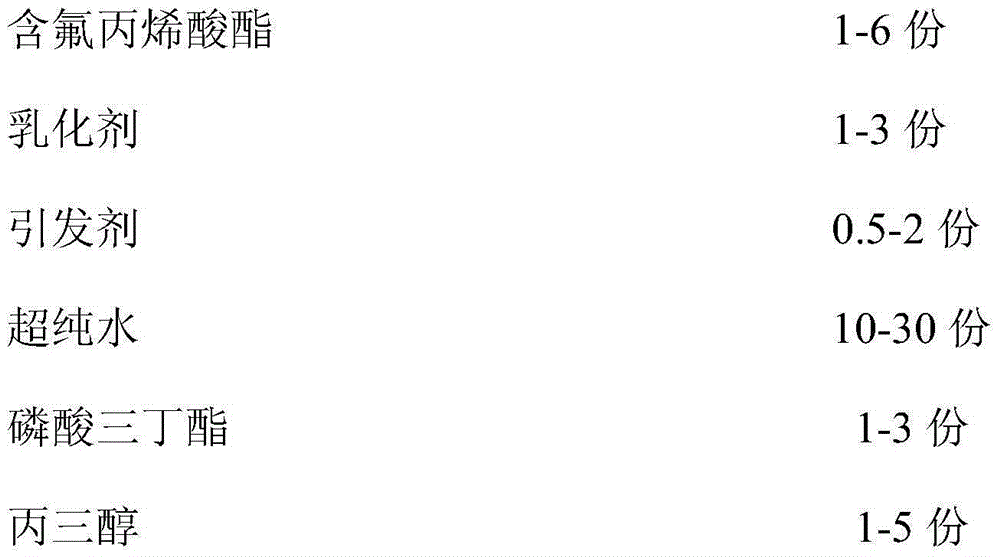

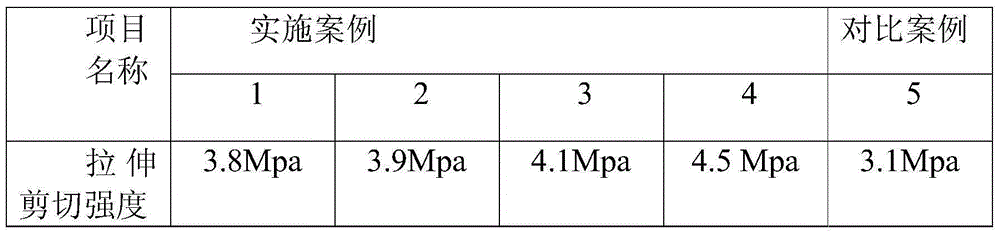

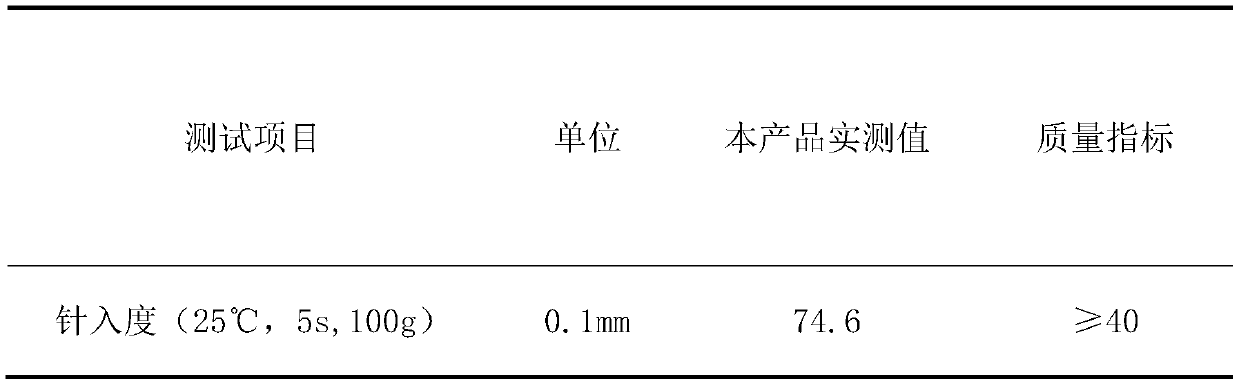

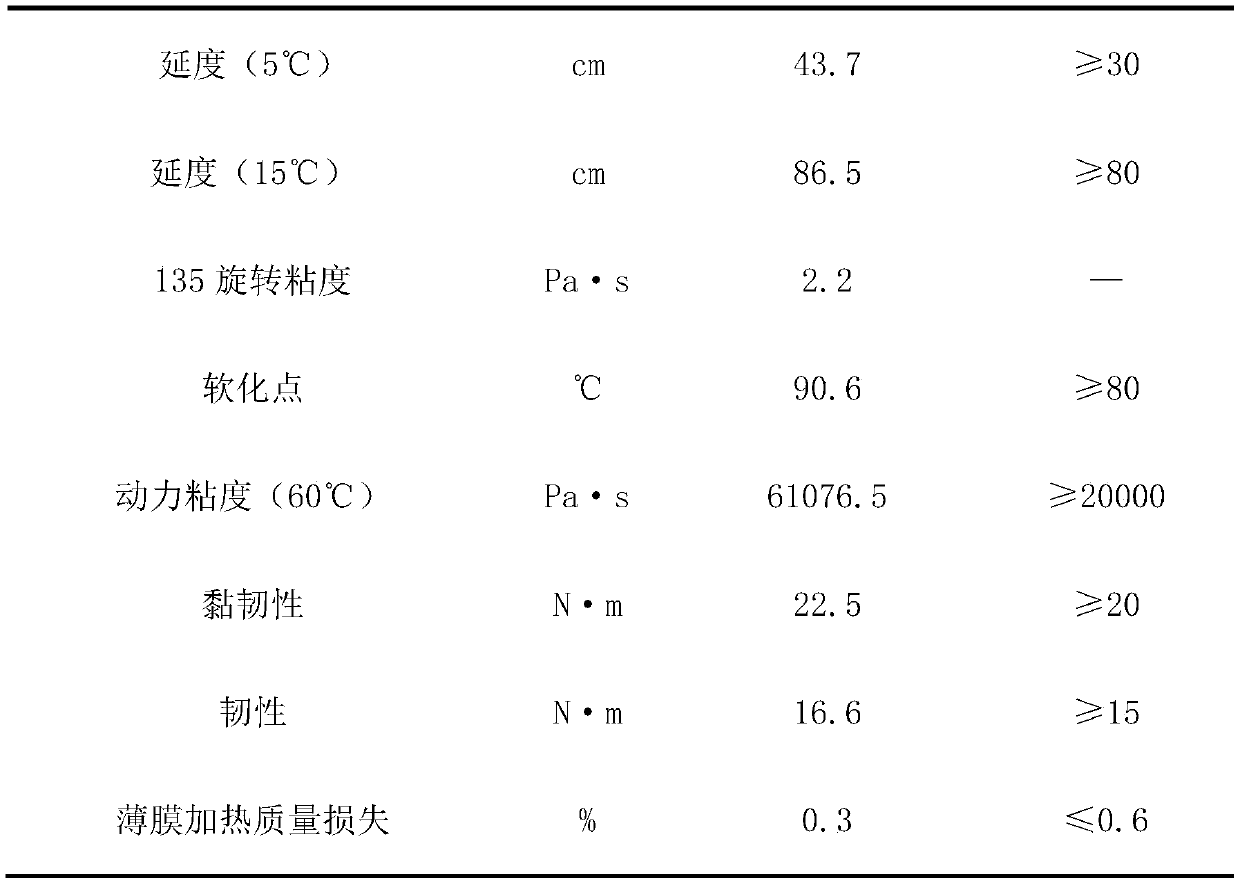

High-water resistance formaldehyde-free and environment-friendly wood adhesive and preparation method thereof

ActiveCN105086892AHigh mechanical strengthImprove water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesFunctional monomerCarvacryl acetate

The invention relates to a high-water resistance formaldehyde-free and environment-friendly wood adhesive and a preparation method thereof. The adhesive is prepared through adopting modified PVA as a protective agent, and carrying out core-shell emulsion polymerization on vinyl acetate monomers and functional monomers. The adhesive comprises the following main components: modified PVA, vinyl acetate, styrene, vinyl acetate-ethylene copolymer resin, carbonyl allyl ester, fluorinated acrylate, an emulgator, an initiator, ultrapure water, an antifreezing agent, and the like. Compared with like products at home and abroad, the prepared emulsion prepared through adopting core-shell emulsion polymerization is better in mechanical strength; besides, the stability and water resistance of the product can be improved through adding the novel protective agent; further, the water resistance, storage stability, freezing resistance, and the like, of the prepared emulsion can be significantly improved through adding the functional monomers.

Owner:厦门诺维特环保科技有限公司

High-adhesion modified asphalt and preparation method thereof

InactiveCN109852085AIncreased durabilityImprove engineering structureBuilding insulationsPolyesterPolymer science

The invention discloses high-adhesion modified asphalt and a preparation method thereof, and belongs to the technical field of road engineering materials. The raw materials of the high-adhesion modified asphalt comprises 500 parts of base asphalt, 300-400 parts of an additive and 10-20 parts of composite reinforcing fibers, and the composite reinforcing fibers are prepared by compounding basalt fibers and polyester fibers and then being coated with base asphalt thin films. When preparing the high-adhesion modified asphalt, the composite reinforcing fibers are added, so that the adhesion, high-temperature stability, fatigue durability of asphalt pavements are greatly improved, and the asphalt has the properties of low-temperature crack prevention and reflection crack prevention. The tensile, shear, compressive and impact strength are effectively improved, and the thermal stability and low temperature resistance of the asphalt are improved.

Owner:河北长大交通科技有限公司

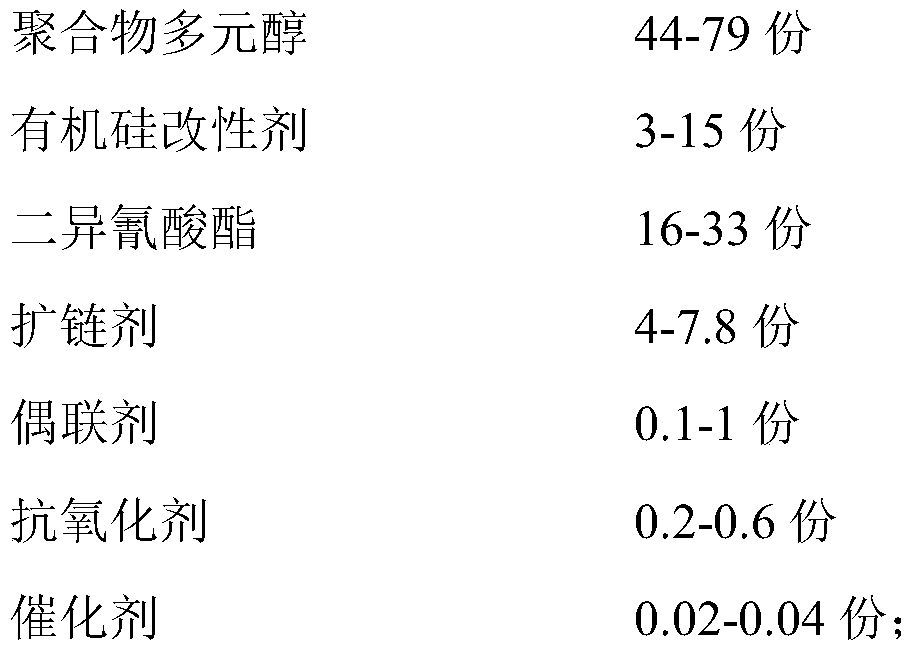

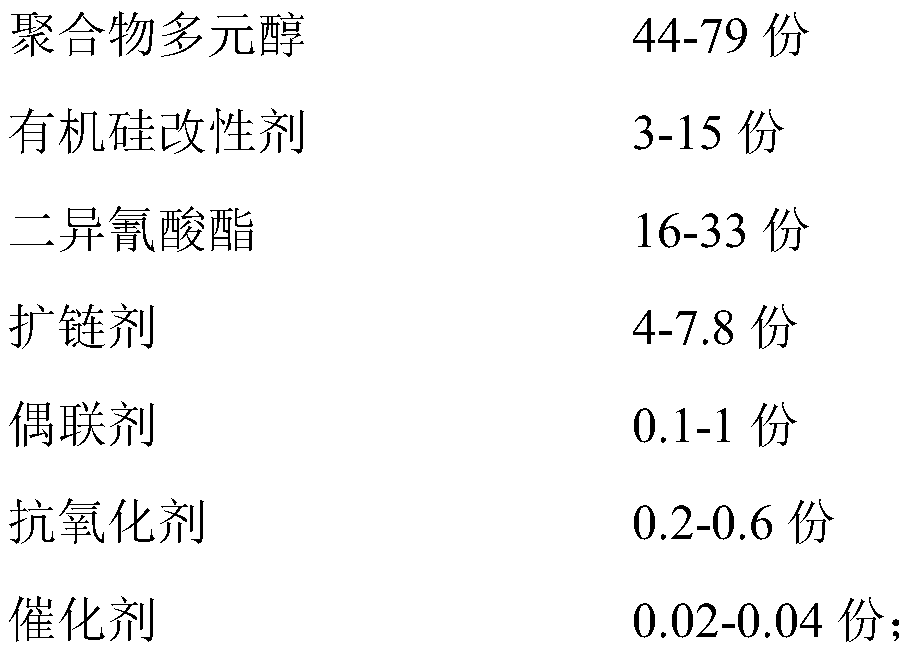

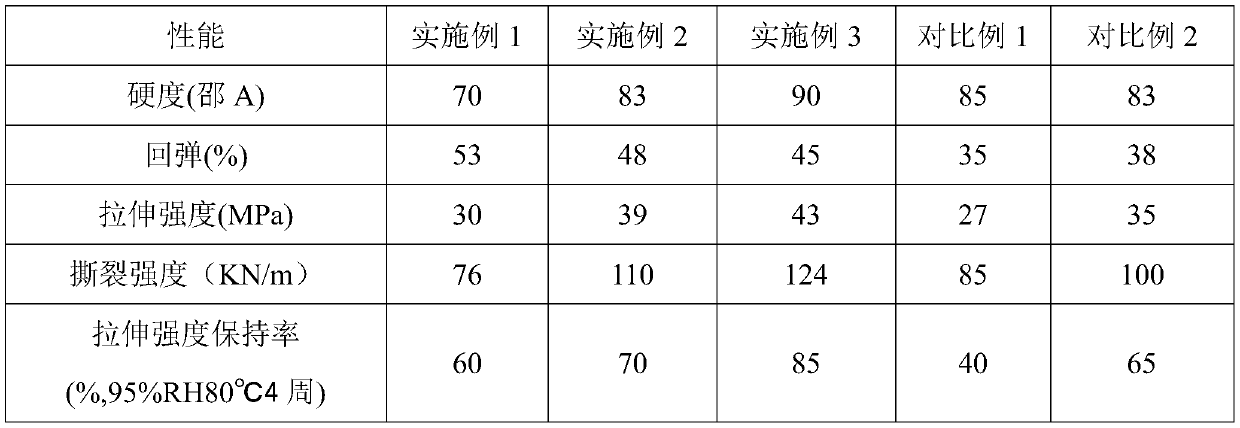

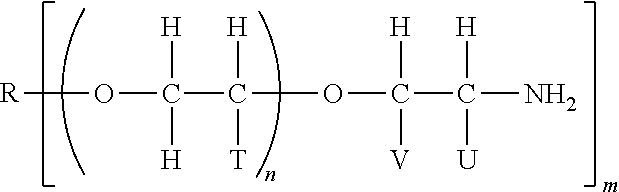

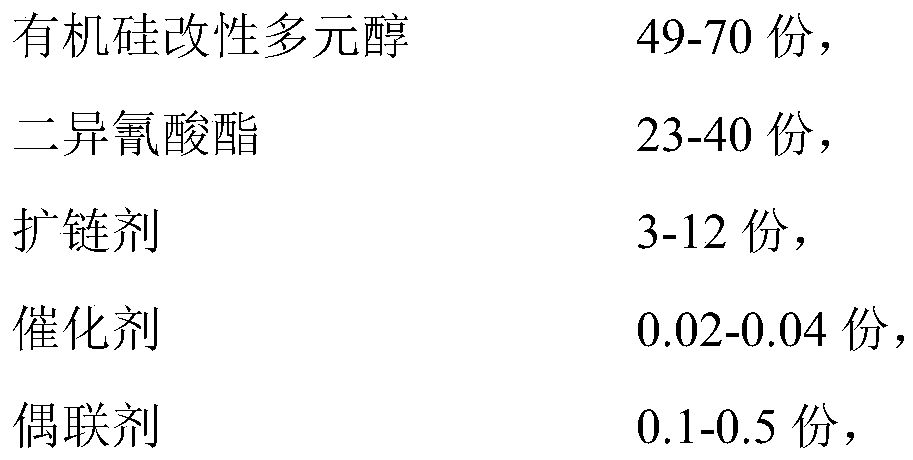

Thermoplastic organosilicon polyurethane elastomer material and preparation method thereof

The invention specifically relates to a thermoplastic organosilicon polyurethane elastomer material and a preparation method thereof, belonging to the technical field of polyurethane elastomers. The thermoplastic organosilicon polyurethane elastomer material is composed of the following raw materials by mass: 44 to 79 parts of polymer polyol, 3 to 15 parts of an organosilicon modifier, 16 to 33 parts of diisocyanate, 4 to 7.8 parts of a chain extender, 0.1 to 1 part of a coupling agent, 0.2 to 0.6 part of an antioxidant and 0.02 to 0.04 part of a catalyst, wherein the organosilicon modifier isa siloxane-polyester compound with a hydroxyalkyl group as a terminal functional group or a siloxane-polyether compound with a hydroxyalkyl group as a terminal functional group. The thermoplastic organosilicon polyurethane elastomer material of the invention has improved low-temperature flexibility, water resistance, smoothness, tear resistance and other properties, and overcomes the problem of organosilicon migration. The preparation method provided by the invention is simple in process and easy to operate.

Owner:SHANDONG INOV POLYURETHANE

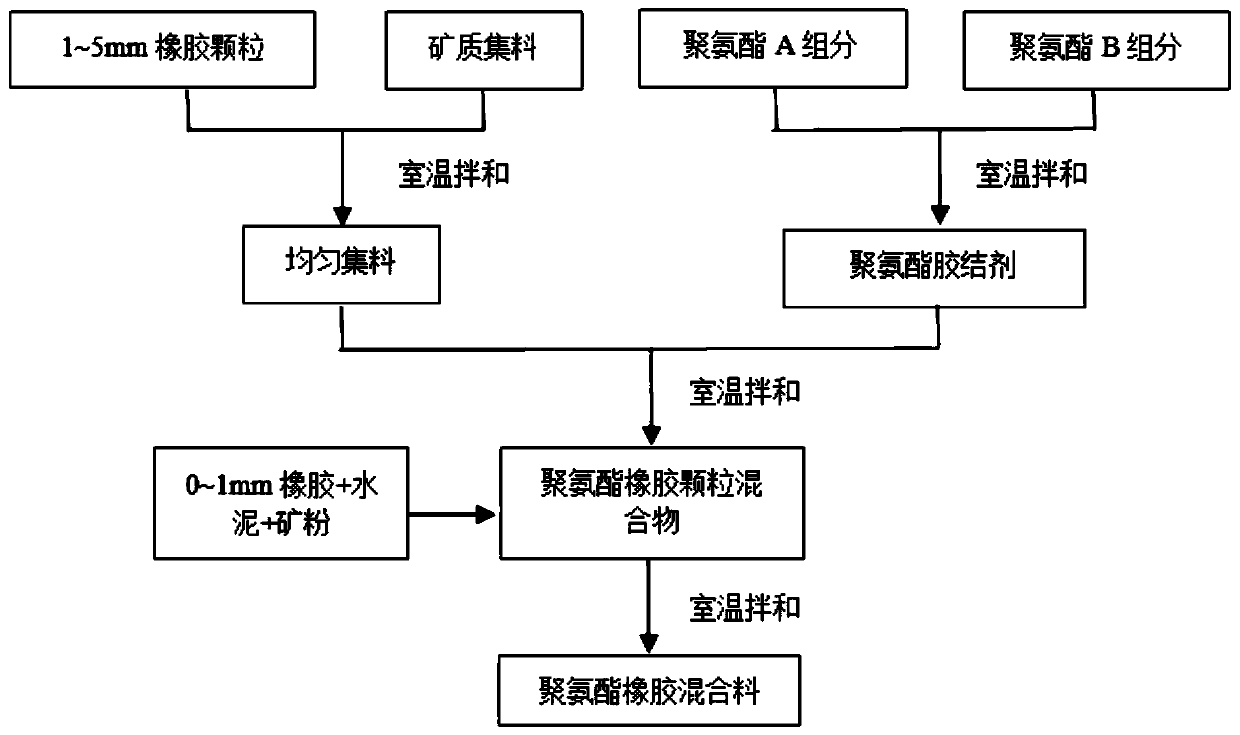

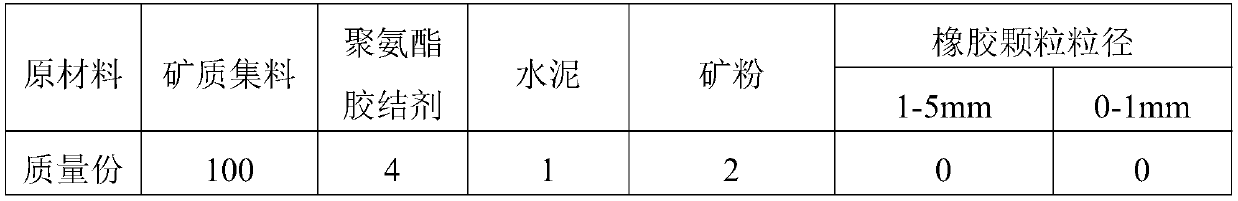

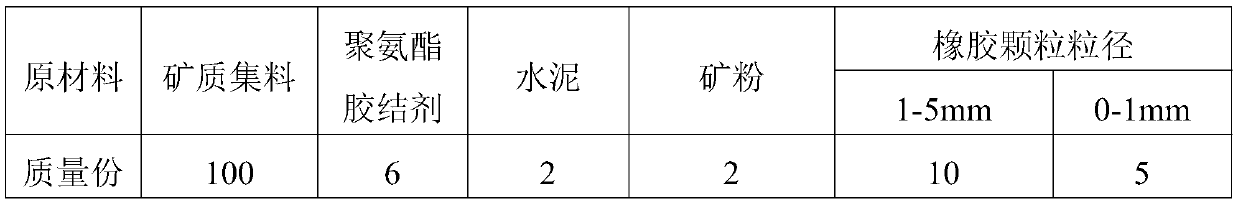

High-strength and high-toughness light polyurethane rubber bridge deck paving material and preparation thereof

The invention relates to a high-strength and high-toughness light polyurethane rubber bridge deck paving material and preparation thereof. According to the formula, the bridge deck paving material isspecifically prepared from the components in parts by weight: 100 parts of mineral aggregate, 3-15 parts of a polyurethane cementing agent, 0-5 parts of cement, 0-5 parts of mineral powder, 0-40 partsof rubber particles with a grain size of 1-5 mm and 0-20 parts of rubber particles with a grain size of less than 1 mm. Compared with the prior art, the high-toughness polyurethane is utilized as thecementing agent, the high-strength and high-toughness light polyurethane rubber bridge deck paving material has high strength, high toughness and fatigue resistance and has a compact structure and good coordination ability with bridge deck deformation, and the occurrence of bridge deck cracks can be prevented; mixed rubber granules can not only prepare light mixtures, but also control the relative bulk density of the mixture to be 1.8-2.5 g / cm<3>, the waste rubber can be effectively utilized, and a new concept of green roads is met.

Owner:TONGJI UNIV

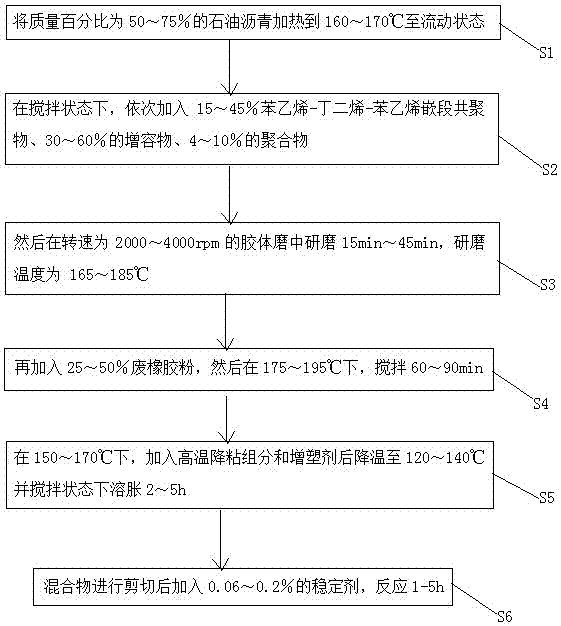

Preparation method of pavement joint sealant

InactiveCN107201213AImprove high temperature stabilityImprove low temperature flexibilityNon-macromolecular adhesive additivesOil/fat/wax adhesivesPolymer scienceWaste rubber

The invention discloses a preparation method of road surface joint glue. The petroleum asphalt with a mass percentage of 50-75% is heated to 160-170°C to a flow state; in the stirring state, 15-45% styrene-butadiene is sequentially added ethylene-styrene block copolymer, 30-60% compatibilizer, 4-10% polymer; then grind in a colloid mill with a rotation speed of 2000-4000rpm for 15min-45min, and the grinding temperature is 165-185°C; Then add 25-50% waste rubber powder, then stir at 175-195°C for 60-90 minutes; then at 150-170°C, add high-temperature viscosity-reducing components and plasticizers, cool down to 120-140°C and stir Swell in the state for 2-5 hours; finally cut the mixture, add 0.06-0.2% stabilizer, and react for 1-5 hours to prepare the road surface joint glue. This improves high temperature stability, low temperature flexibility, elastic recovery and fatigue resistance, and is suitable for pavement crack treatment in cold and extremely cold climates.

Owner:山西宝路加交通科技有限公司

Method for preparing double-component nano polyaniline-epoxy acrylate resin/polyurethane interpenetrating network conductive anticorrosive paint

InactiveCN105778750AImprove low temperature flexibilityImprove appearanceAnti-corrosive paintsPolyurea/polyurethane coatingsEnvironmental resistanceChemical reaction

The invention relates to a method for preparing double-component nano polyaniline-epoxy acrylate resin / polyurethane interpenetrating network conductive anticorrosive paint. According to the method, a conductive interpenetrating network polymer coating is prepared through chemical reaction of a component A, that is, a nano polyaniline-epoxy acrylate resin system, and a component B, that is, a castor oil polyurethane prepolymer containing an isocyanate end group under the action of an initiator and a catalyst, wherein the component A is prepared by drying a mixture obtained through in-situ emulsion polymerization of aniline in epoxy acrylate resin, adding an allyl monomer, a catalyst, a polymerization inhibitor, a preservative, a light stabilizer, packing and the like, and by uniformly stirring the components; the component B, that is, the polyurethane prepolymer, is prepared by enabling castor oil and diisocyanate to react, adding an initiator, a promoter and a proper amount of a solvent, and by uniformly stirring the components. The paint is simple in process equipment, convenient to operate, beneficial to large-scale industrial production, high in solid content, stable in anticorrosion property and very good in mechanical property, aging resistance, chemical corrosion resistance and environmental friendliness.

Owner:HUBEI QILI NEW MATERIAL CO LTD

Method for preparing stretchable bending-resistant PVC hose

InactiveCN109251442AImprove low temperature tensile propertiesImprove low temperature flexibilityDecompositionPlasticizer

The invention discloses a method for preparing a stretchable bending-resistant PVC hose, which belongs to the technical field of preparation of a PVC material. The main raw material of the PVC hose ofthe invention is polyvinyl chloride, and the polyvinyl chloride is mechanically modified by EPDM raw rubber, and the ethylene content of the used EPDM raw rubber is 50-55%, the EPDM can effectively improve the low temperature tensile properties and low temperature flexibility of polyvinyl chloride, and can effectively solve the problem of large changes in the low temperature tensile properties ofthe finished products caused by the use of a plasticizer, the EPDM easily absorbs the accumulated and modified zeolite powder surface, oriented and orderly arranged crystallization can be differentlygenerated, hydrogen chloride due to heat and photodegradation can be rapidly absorbed, so that the continuous decomposition of polyvinyl chloride can be blocked, the aging resistance performance of polyvinyl chloride is increased and is stable, and the method has wide application prospect.

Owner:FOSHAN CHANCHENG DISTRICT NUOGAO ENVIRONMENTAL PROTECTION TECH CO LTD

Hot mixed asphalt mixture seam plaster for alleviating pavement cracks and preparation method thereof

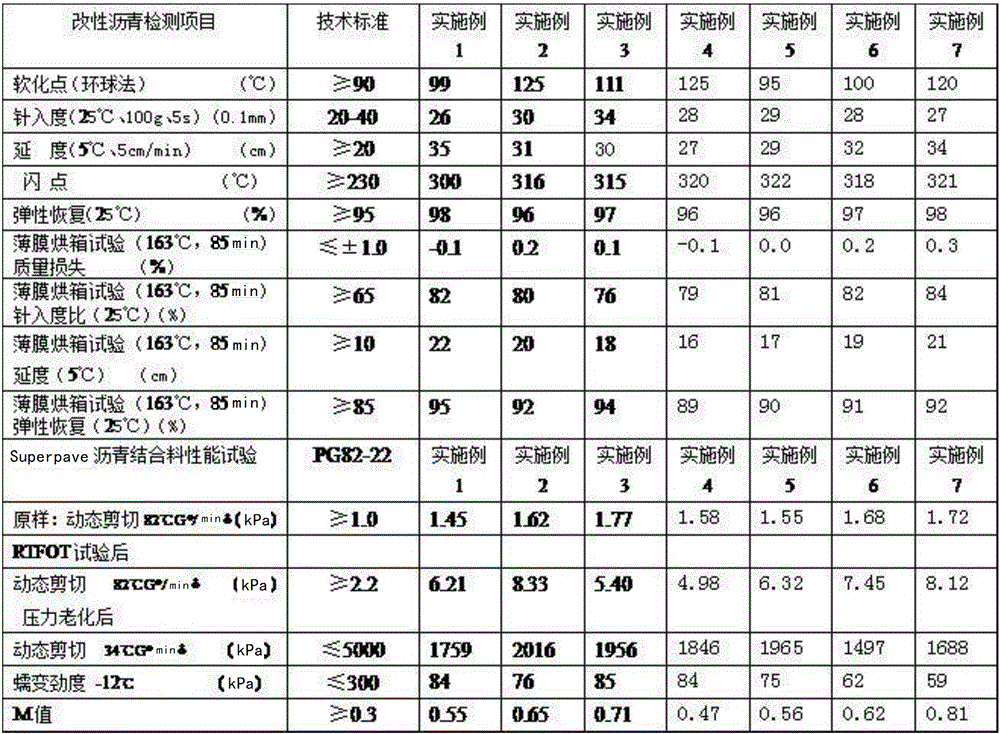

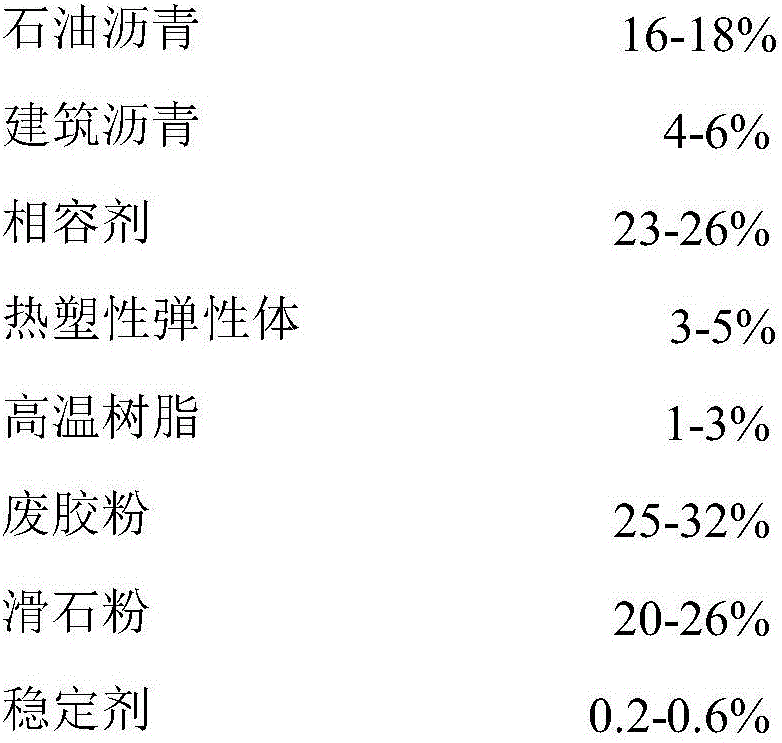

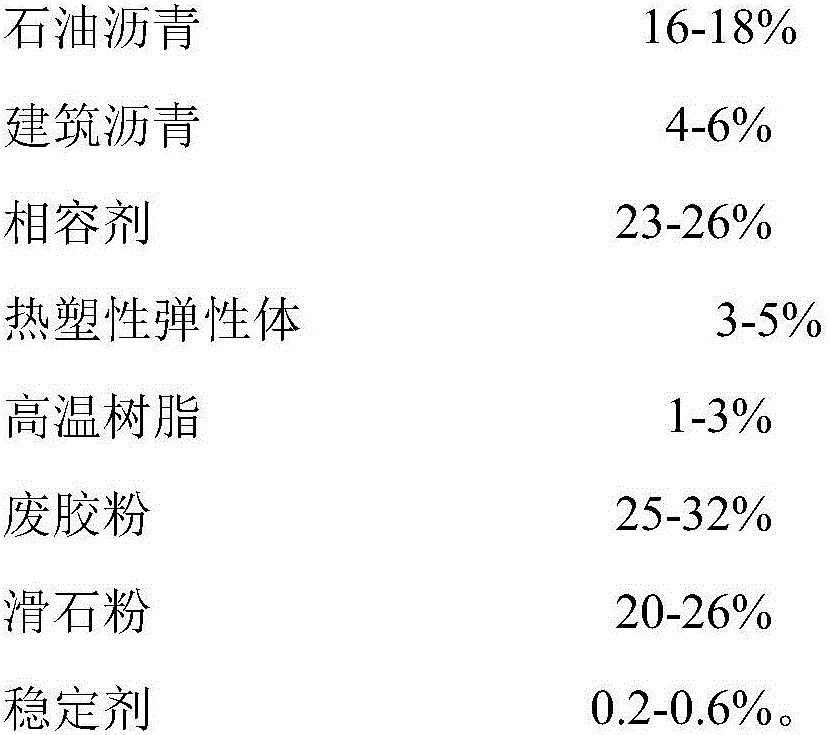

ActiveCN106336545ASignificant strengthening effectImprove high temperature performanceBuilding insulationsCrack resistanceWaste rubber

The invention discloses an asphalt mixture seam plaster for alleviating pavement cracks and a preparation method thereof, and the asphalt mixture seam plaster comprises the components of 16-18% of petroleum asphalt, 4-6% of building asphalt, 23-26% of a compatilizer, 3-5% of a thermoplastic elastomer, 1-3% of high temperature resin, 25-32% of waster rubber powder, 20-26% of talcum powder and 0.2-0.6% of a stabilizer. The preparation method is as follows: heating the petroleum asphalt, then adding the petroleum asphalt into the building asphalt for even mixing, after heating, beating into a working tank, and adding the compatibilizer; adding the thermoplastic elastomer and the high temperature resin, and shearing and finely grinding by a colloid mill while stirring to obtain a mixture; beating the mixture into a development horizontal tank, adding the waste rubber powder, the talcum powder and the stabilizer, stirring at 165-185 DEG C for development for 3-4H to obtain a cementing material; extruding for molding the cementing material and packing. The asphalt mixture seam plaster has the advantages of strong adhesion and self restoring deformation ability, can greatly improve high temperature deformation resistance, low temperature cracking resistance and fatigue resistance of asphalt pavements, reduces effectively alleviates asphalt pavement cracks, increases driving comfort, and reduces road construction investment frequency.

Owner:HUBEI GUOCHUANG HI TECH MATERIAL

Ultrasoft high-transparency flame-retardant heat-resistant polyvinyl chloride material and preparation method thereof

ActiveCN106188975AImprove low-temperature softnessHigh transparencyDiisodecyl phthalateFlame resistance

The invention relates to an ultrasoft high-transparency flame-retardant heat-resistant polyvinyl chloride material which is composed of the following raw materials in parts by weight: 50-80 parts of polyvinyl chloride resin WS-1300, 30-40 parts of polyvinyl chloride resin SH-200, 5-10 parts of ethylene-vinyl acetate carbonyl copolymer E / VA / CO, 30-40 parts of trioctyl trimellitate, 10-15 parts of diisodecyl phthalate, 5-8 parts of epoxy soybean oil, 8-10 parts of flame retardant, 1.3-1.9 parts of stabilizer, 0.3-0.5 part of lubricant and 0.8-1 part of antioxidant. The preparation method comprises the following steps: blending the raw materials, and carrying out extrusion granulation in a double-screw extrusion granulator set. The polyvinyl chloride material has the advantages of favorable transparency, favorable flexibility, favorable flame retardancy and favorable heat resistance.

Owner:HUBEI YANGTIAN PLASTIC PROD CO LTD

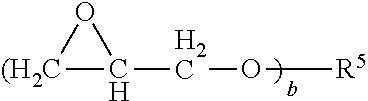

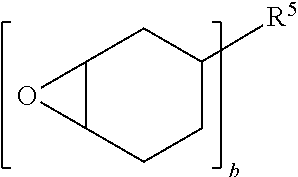

Elastomeric epoxy materials and the use thereof

ActiveUS20130211017A1Improve low temperature flexibilityGood low temperature flexibilityPrepolymerEpoxide

Thermoset elastomer compositions are disclosed. Such elastomers are the reaction product of (a) an ambient temperature liquid epoxy-terminated prepolymer formed by reacting a polyoxyalkyleneamine having a molecular weight of from 3000 to 20,000 with an excess of epoxide, wherein the polyoxyalkyleneamine has at least 3 active hydrogen atoms and (b) a curing agent comprising at least one amine or polyamine having an equivalent weight of less than 200 and having 2 to 5 active hydrogen atoms. Such elastomers can be used in applications such as for sealants, adhesives, coatings, gaskets, jointing and cast elastomers.

Owner:DOW GLOBAL TECH LLC

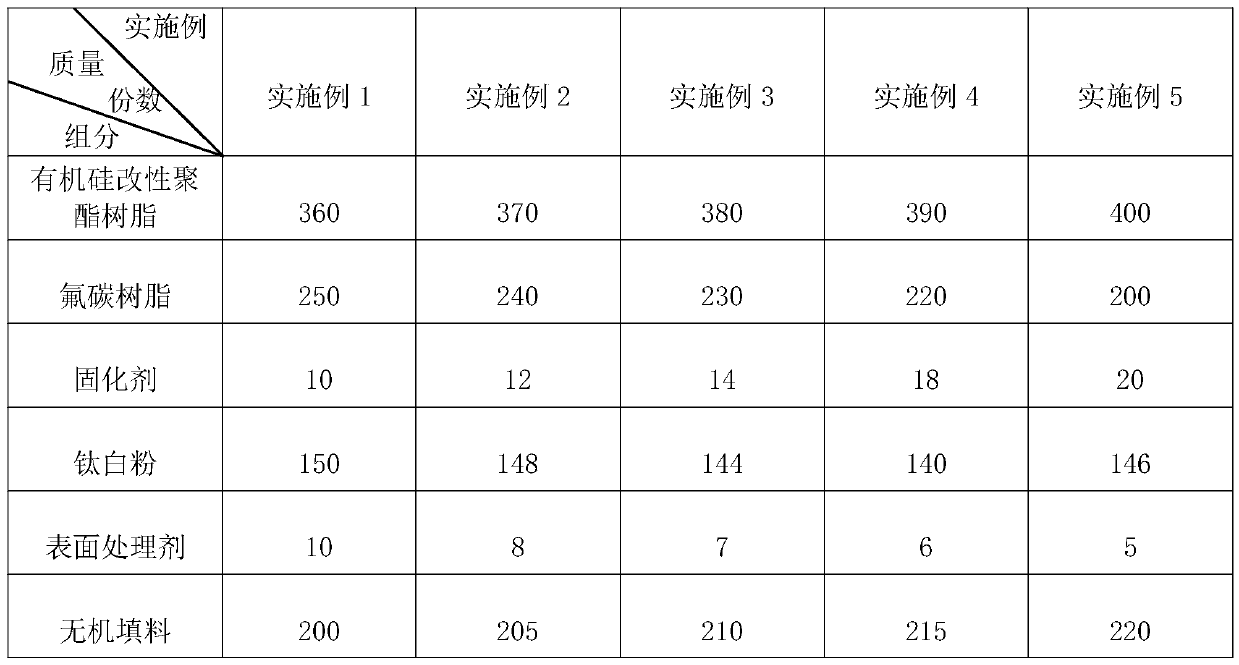

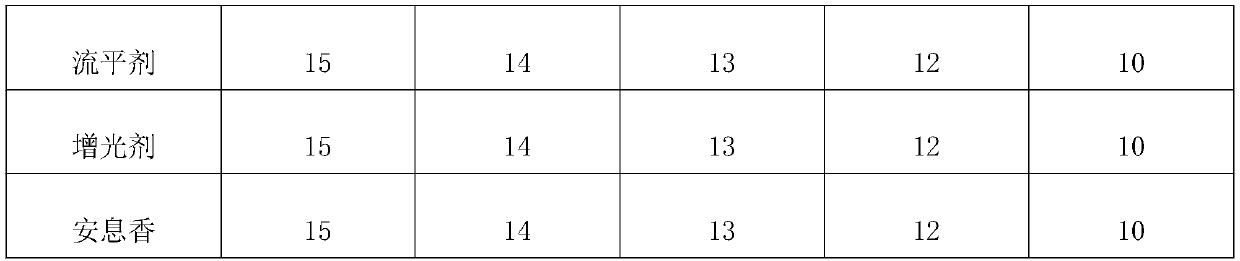

High weather resistant powder coating and production process thereof

InactiveCN110373109AReduce coefficient of frictionIncrease smoothnessPowdery paintsTurbidityUnsaturated polyester

The invention discloses a high weather resistant powder coating and a production process thereof, and belongs to the technical field of powder coating production. The high weather resistant powder coating is prepared from the following components in parts by weight: 360-400 parts of organic silicon modified polyester resin, 200-250 parts of fluorocarbon resin, 10-20 parts of a curing agent, 140-150 parts of titanium dioxide, 5-10 parts of a surface treatment agent, 200-220 parts of inorganic filler, 10-15 parts of a leveling agent, 10-15 parts of an optical brightener, and 10-15 parts of benzoin. The preparation method of the organic silicon modified polyester resin comprises the steps of putting a chloro unsaturated polyester resin raw material into a four port flask, heating to 100-120DEG C to conduct a condensation reaction, when the acid value drops to 6-6.5, vacuumizing to remove water and other micromolecules in a system, then reducing a reaction system to 35-38DEG C, adding an organosilicon prepolymer and tetrabutyl titanate, warming up to 75-80DEG C to conduct a condensation reaction, and changing the reaction system from turbidity to complete transparency to make the organic silicon modified polyester resin. The production process has the advantages of improving weather resistance performance of the powder coating and making the powder coating suitable for high weatherresistance occasions.

Owner:厦门国丽静电粉末有限公司

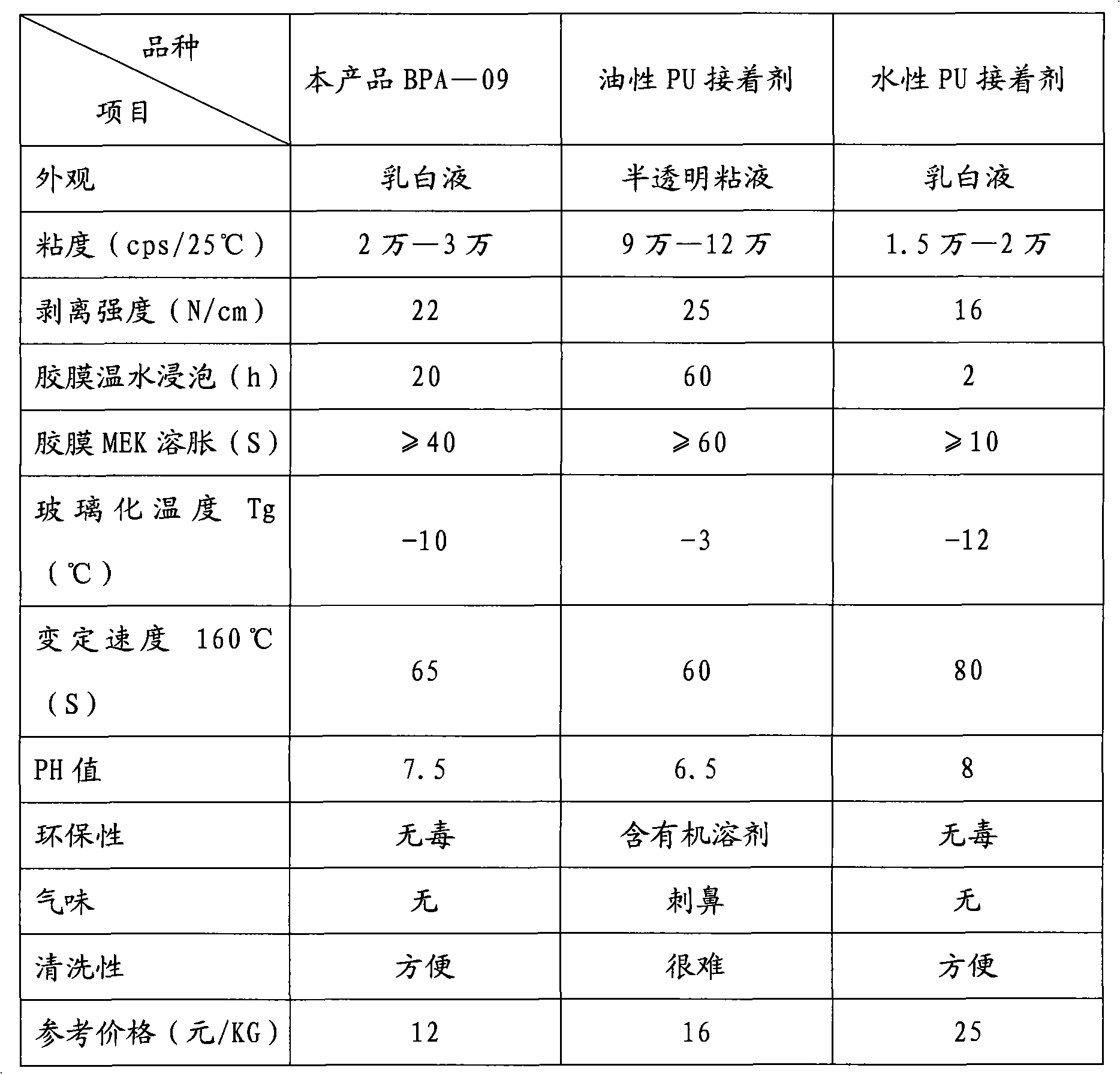

Bonding adhesive for leather, preparation method thereof and application of bonding adhesive in leather making process

InactiveCN101649172ASolve the defects of oil resistance and high temperature resistanceImprove adhesionNitrile polymer adhesivesAmide/imide polymer adhesivesHigh resistanceFunctional monomer

The invention discloses a leather bonding adhesive, a preparation method thereof and application of the bonding adhesive in the leather making process. By adopting a molecule design method, the invention grafts (methyl) n-butyl acrylate with a flexible molecular chain and a polar group to silicone oil, introduces a polar functional monomer to a silicone oil molecular chain so as to obtain a modified compound monomer, a side chain of which is provided with carboxyl, and improve the adhesive force of the silicone oil on materials; meanwhile, the oil slick phenomenon which is common in silicon-acrylic emulsion is avoided, the problem that silicone oil slicks out of common silicon-acrylic emulsion to influence the bonding strength is solved, the internal plasticization is carried out successfully, the vitrification temperature is reduced and the low-temperature flexibility of an adhesive film is increased. Meanwhile, through block copolymerization of Acrylonitrile, the invention overcomesthe defects of no oil resistance and no high temperature resistance of the conventional silicon-acrylic emulsion. Through adjusting the ratio of a soft monomer to a hard monomer and the consumption and the mode of an emulsifying agent, the invention ensures that the composite indicator reaches the optimal value, which cannot be achieved by the common silicon-acrylic emulsion.

Owner:FUJIAN POLYTECH TECH CO LTD

Hot-melt pressure-sensitive adhesive for gas-permeable membrane and preparation method of hot-melt pressure-sensitive adhesive

InactiveCN111732918AImprove heat stabilityImprove low temperature flexibilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesEpoxyElastomer

The invention relates to a hot-melt pressure-sensitive adhesive for a breathable film and a preparation method of the hot-melt pressure-sensitive adhesive. The hot-melt pressure-sensitive adhesive isprepared from the following raw materials in parts by weight: 20-45 parts of a thermoplastic elastomer, 8-20 parts of toughened epoxy resin, 20-35 parts of tackifying resin, 0.5-5 parts of functionalized modified graphene, 0.1-1 part of an antioxidant and 1-5 parts of a cross-linking agent. The preparation process is simple in steps and good in controllability, and the prepared hot-melt pressure-sensitive adhesive is good in temperature resistance, has stable cohesiveness with polyethylene materials, is high in initial adhesion and good in permanent adhesion, and has a very good application prospect.

Owner:嘉好(太仓)新材料股份有限公司

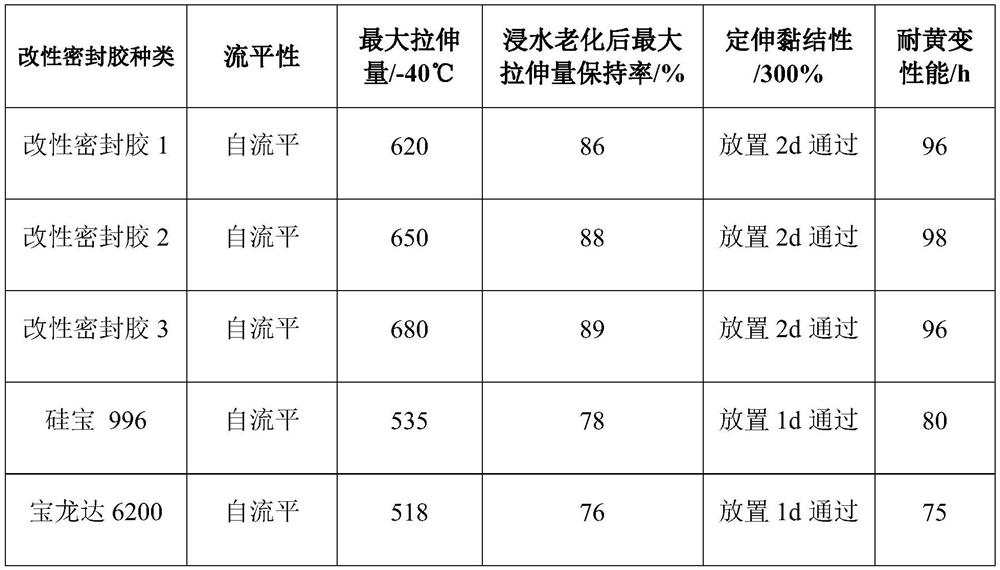

Modified silicone sealant for asphalt pavement crack treatment and preparation method thereof

ActiveCN112226197AUniform and stable dispersionGood compatibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesRubber materialPolymer science

The invention provides a modified silicone sealant for asphalt pavement crack treatment, which comprises the following components in parts by weight: 10-30 parts of modified polyurethane prepolymer, 10-30 parts of modified acrylic resin prepolymer, 50-70 parts of silicone sealant, 2-4 parts of dimethyl silicone oil, 3-8 parts of coupling agent, 2-4 parts of hydroxyl radical scavenger and 2-4 partsof cross-linking agent. The compatibility between the modified polyurethane prepolymer, the modified acrylic acid prepolymer and the silicone sealant is better, so that the polyurethane prepolymer and the acrylic acid prepolymer can be better modified and added into the silicone sealant, and the polyurethane prepolymer and the acrylic acid prepolymer can be uniformly and stably dispersed in a reaction system; and the binding force between the rubber materials is improved, so that the elongation, the low-temperature tensile strength and the storage stability of the rubber body are improved, and the modified silicone sealant provided by the invention can be effectively used for treating asphalt pavement cracks.

Owner:CHONGQING ZONJO RENEWABLE RESOURCES DEV CO LTD

Graphene-containing wear-resistant rubber and plastic foam shoe material and preparation method thereof

InactiveCN110724298AGood effectImprove low temperature flexibilitySolesPolymer scienceSodium phosphates

The invention relates to the field of rubber and plastic foam materials, and concretely relates to a wear-resistant rubber and plastic foam shoe material and a preparation method thereof. The preparation method comprises the following steps: graphene and aluminum powder are mixed according to a mass ratio of 5:1, and the obtained mixture is smelted and mixed evenly at a high temperature of 660-680DEG C, and then is sprayed to obtain flaky nanoscale graphene / aluminum powder; polycarbonate diol is uniformly mixed with 4,4'-diphenylmethane diisocyanate and stannous octoate, then graphene / aluminum powder and sodium hexametaphosphate are added, and the obtained mixture is stirred and reacted at 80-100 DEG C so as to obtain a polyurethane elastomer; the polyurethane elastomer is mixed with EVA,NR rubber, an inorganic filler, a lubricant, sulfur, an AC foaming agent and an anti-aging agent in an internal mixer at 90-100 DEG C for 4-6 min, and then a sheet is discharged; and the sheet is cut, is implanted in a mold pressing machine and is foamed at 170-200 DEG C for 180-240 s to obtain the graphene-containing wear-resistant rubber and plastic foam shoe material. The shoe material has good low-temperature wear resistance.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Light-cured single-component waterborne epoxide, waterproof material and preparation method of waterproof material

ActiveCN107652414APromote ring-opening cross-linking reactionImprove stabilityBuilding insulationsEpoxyEther

The invention discloses a light-cured single-component waterborne epoxide, a waterproof material and a preparation method of the waterproof material. The light-cured single-component waterborne epoxide is prepared from the following components in parts by mass: 40 to 60 parts of epoxy resin, 1 to 5 parts of acrylic acid, 0.2 to 0.6 part of polymerization inhibitor, 3 to 6 parts of diethylaminoethanol, 4 to 8 parts of ethylene glycol monobutyl ether, 2 to 4 parts of unsaturated anhydride, 1 to 2 parts of waterborne light initiator and 30 to 60 parts of water. The light-cured single-component waterborne epoxide adopts self-made modified emulsified asphalt of a light-cured waterborne epoxide system, is different from an existing double-component epoxy curing agent and a latent epoxy curing agent, has the advantages of being good in long-time room-temperature light-shielding storage stability and long in storage time; the room-temperature light-shielding storage can reach 6 months; the waterborne light initiator is added in the light-cured single-component waterborne epoxide; the curing-agent waterborne epoxide is enabled to be quick in curing speed under the action of natural light; the construction is convenient and the construction period is shortened.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD

Production method of foamed sheet

ActiveCN107236187AIncrease elasticityImprove degradation rateFlat articlesPolymer scienceVulcanization

The invention discloses a production method of a foamed sheet and aims to provide the production method of the degradable foamed sheet with high thermal insulation performance and low production cost. According to the technical scheme, the production method of the foamed sheet comprises the steps as follows: firstly, preparation: the foamed sheet is prepared from raw materials in parts by weight as follows: 50-70 parts of polypropylene, 20-40 parts of stone powder, 10-20 parts of polylactic acid, 20 parts of fluorocarbon resin, 5 parts of triacetin, 5 parts of methyl silicone oil, 10 parts of aluminum potassium sulfate dodecahydrate, 3 parts of a processing aid, 5-20 parts of a foaming aid, 2-5 parts of a toughening agent and 1-2 parts of a crosslinking agent; secondly, rubber mixing; thirdly, sheet pressing: mixed rubber is fed into an extruder to be extruded into base sheets; fourthly, shaping and laminating: surfaces of the base sheets are flattened, and a plurality of the base sheets are laminated together; fifthly, foaming: the laminated base sheets are placed in a rubber foaming forming machine for vulcanization foaming forming; sixthly, coiling. The production method is applicable to the technical field of plastic foaming.

Owner:台州道麒新材料股份有限公司

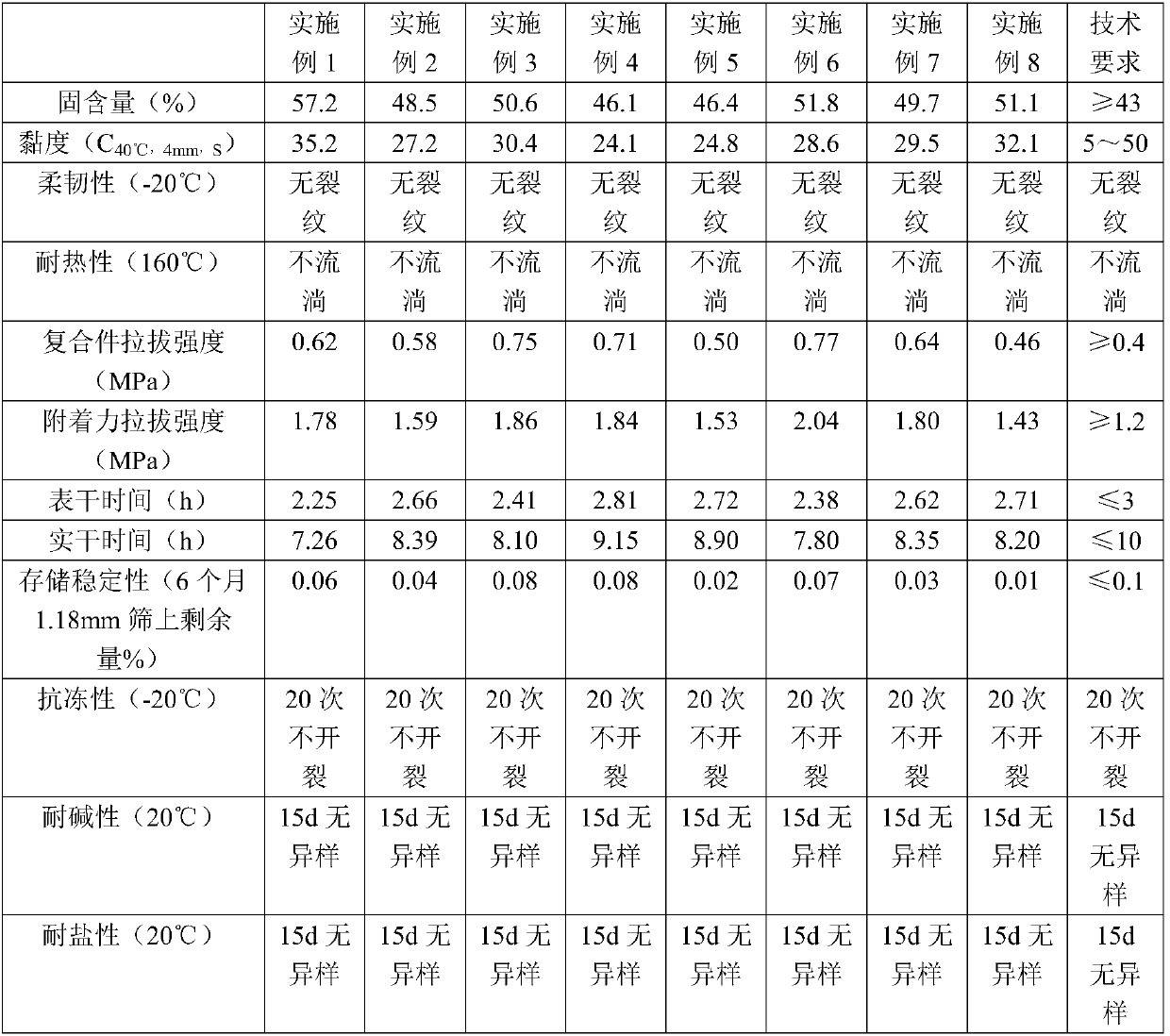

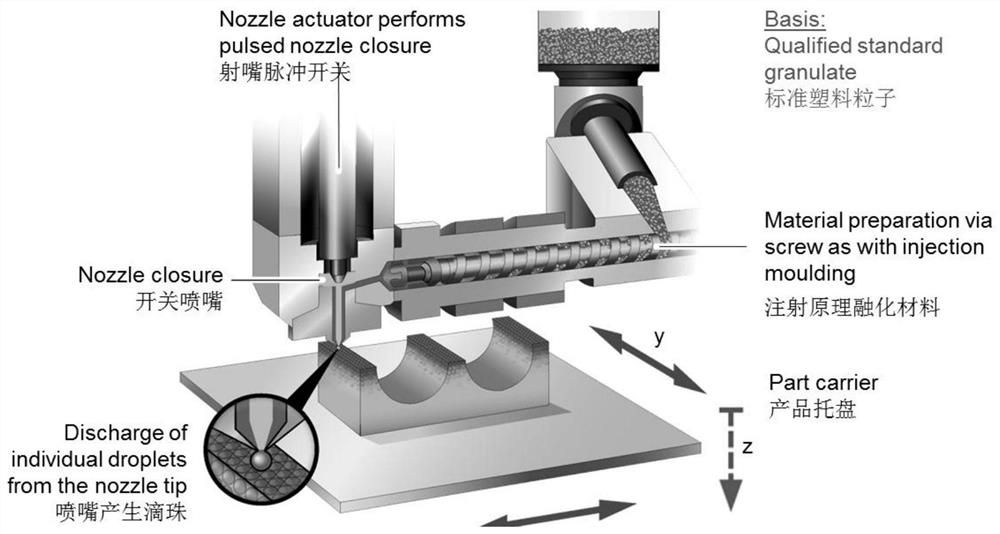

3D printing method of TPU 9370AU plastic particles

PendingCN112109320AImprove material propertiesGood moisture permeabilityAdditive manufacturing apparatus3D object support structuresInformation processingComputer printing

The invention discloses a 3D printing method of TPU 9370AU plastic particles. The 3D printing method comprises the steps that a target three-dimensional CAD model is layered through a computer, and the section information is processed; then, the section data are input into a 3D printer with an APF technology; and droplets generated by melting TPU 9370 AU plastic particles are stacked layer by layer through the 3D printer according to the section data, so that a TPU 9370 AU product with the designed structural shape is obtained. According to the 3D printing method, domestication of the TPU 9370AU plastic particles and precision forming of additive manufacturing are achieved, and the closed-loop system construction from product design to manufacturing of the TPU 9370AU plastic particles special for the APF technology to the product printing and forming process is achieved; intermediate links are omitted, and the material cost is saved; and the batch production is achieved, and the research and development speed and the industrialization speed are increased.

Owner:北京恒尚科技有限公司

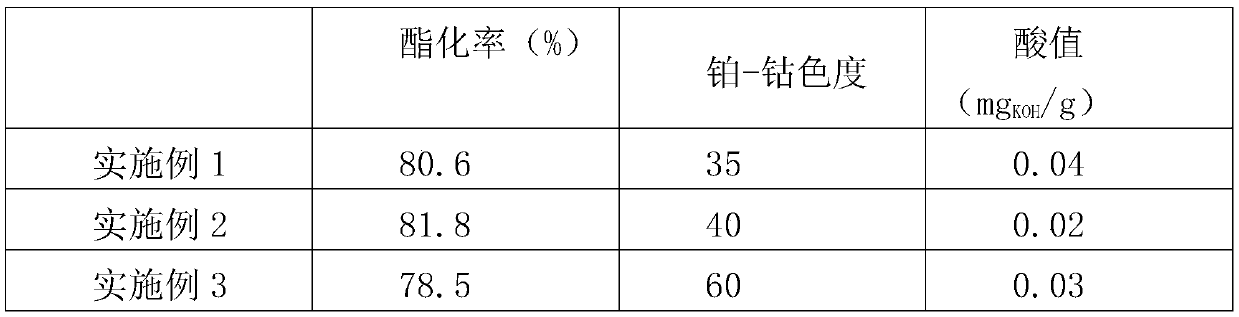

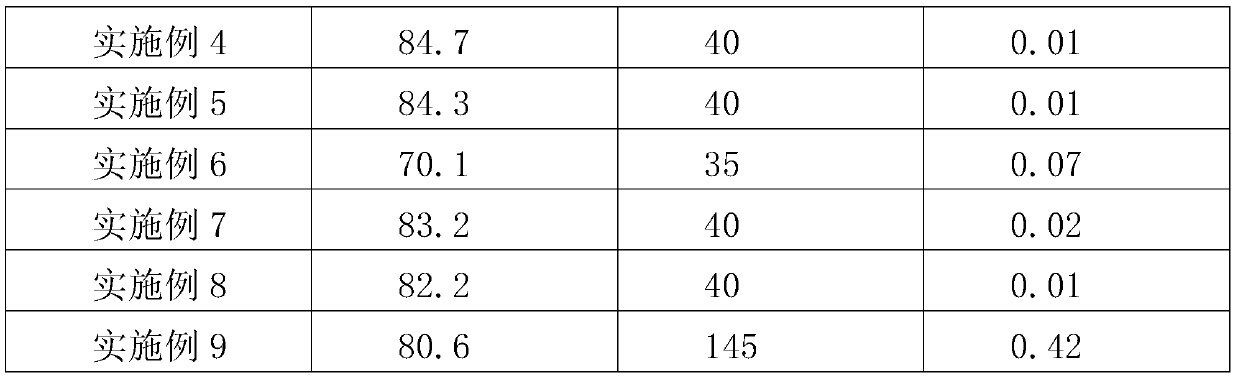

Treatment method of mixture containing long-chain dicarboxylic acid, long-chain dicarboxylic acid dibutyl ester mixture and application thereof

PendingCN111269113ASolve the waste of resourcesImprove low temperature flexibilityOrganic compound preparationCarboxylic acid esters preparationPlasticizerDicarboxylic acid

The invention provides a treatment method of a mixture containing long-chain dicarboxylic acid, a long-chain dicarboxylic acid dibutyl ester mixture and application thereof. The treatment method comprises the step of carrying out butyl esterification on the mixture containing the long-chain dicarboxylic acid to obtain mixed long-chain dicarboxylic acid dibutyl ester. The mixture containing the long-chain dicarboxylic acid, which is discharged in the process of extracting and refining the long-chain dicarboxylic acid from the long-chain dicarboxylic acid fermentation liquor, is effectively utilized, so that resource waste is avoided. The long-chain dicarboxylic acid dibutyl ester mixture obtained after the mixture containing long-chain dicarboxylic acid is subjected to a butyl esterification reaction and purification is low in chromaticity, can be directly applied to a cold-resistant plasticizer, and can effectively improve the low-temperature flexibility of a polymer. The treatment method of the mixture containing the long-chain dicarboxylic acid is suitable for industrial large-scale production, has low requirements on equipment, is simple and convenient to operate, solves the problem of treatment and reutilization of discharge in the production process of the long-chain dicarboxylic acid, and has economic value.

Owner:CATHAY R&D CENT CO LTD +1

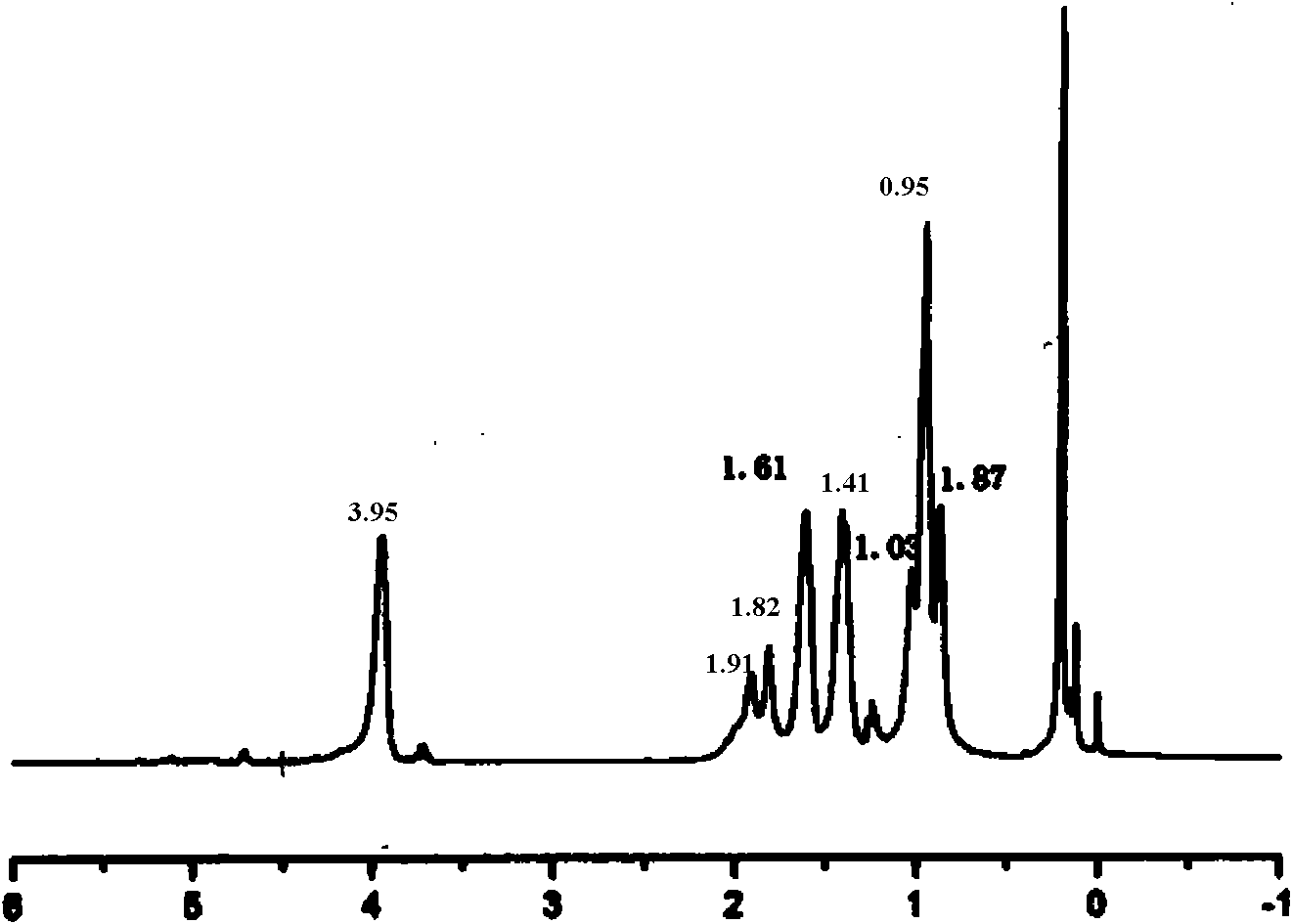

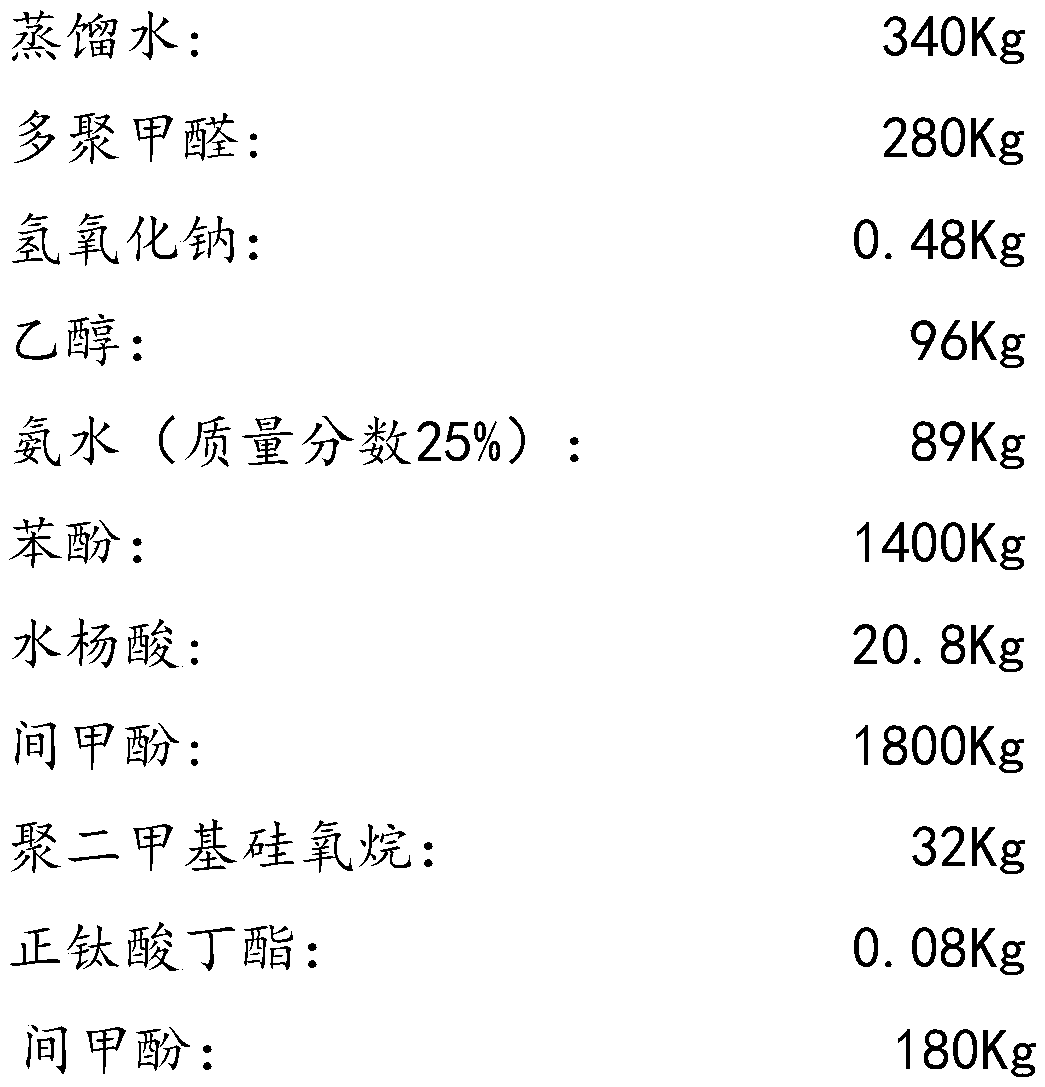

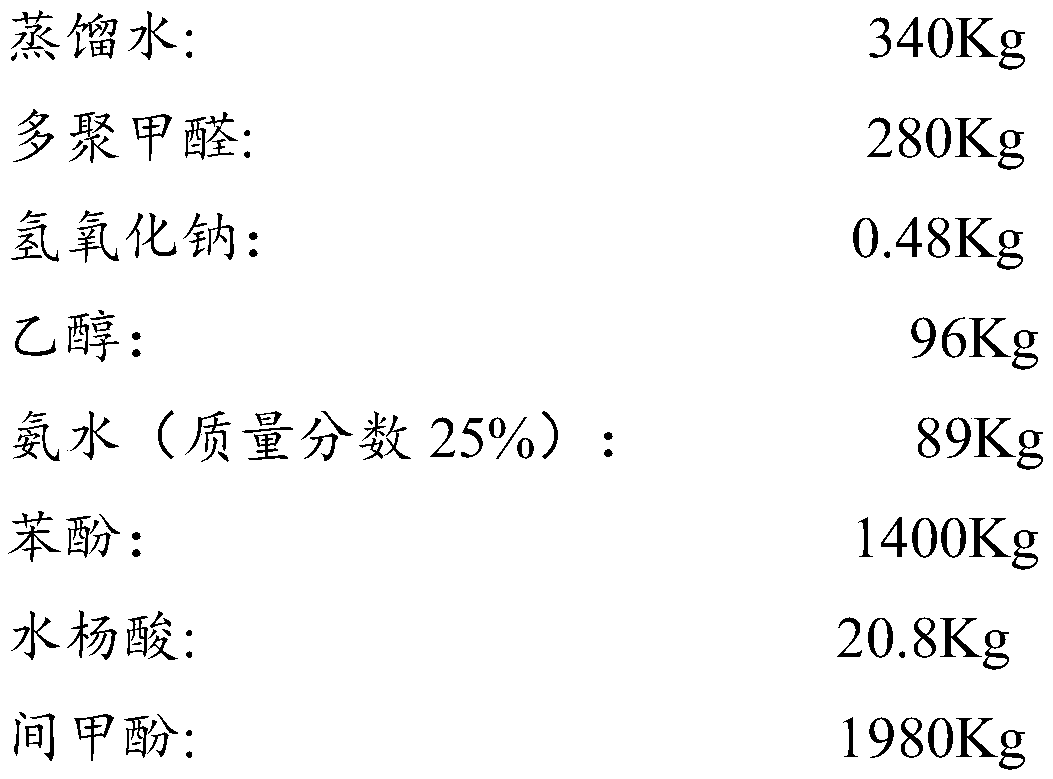

Modified phenolic resin and preparation method thereof

The invention relates to the field of chemical product preparation, particularly discloses a modified phenolic resin and a preparation method thereof. The preparation method comprises following steps:conveying distilled water, paraformaldehyde, sodium hydroxide and ethanol sequentially into a reaction kettle to be stirred, heated and subjected to heat preservation; after the heat preservation isfinished, cooling and dropwise adding a catalyst into the reaction kettle; after dropwise adding is finished, adding molten phenol and carrying out heating reaction; cooling after reaction, adding salicylic acid and m-cresol, carrying out first reduced-pressure dehydration, after dehydration, adding polydimethylsiloxane and tetrabutyl titanate, heating to carry out secondary reaction, reducing thekettle temperature after reaction, carrying out second reduced-pressure dehydration until the viscosity reaches a set range, and finally adding m-cresol to dilute and adjust the viscosity, thereby obtaining a modified phenolic resin solution; adding polydimethylsiloxane, so that the thermal stability and low-temperature flexibility of the phenolic resin are improved. Adding of the modified phenolic resin into varnished wires is capable of improving the scratch resistance and impact resistance of the varnished wires, and improving coating film surface leveling property, smoothness and gloss.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

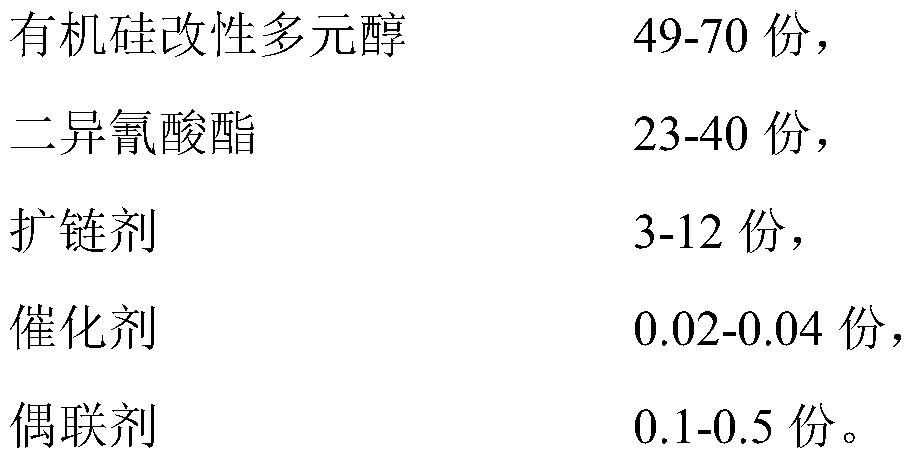

Organic silicon modified TPU medical catheter and preparation method thereof

PendingCN111303618AImprove low temperature flexibilityAvoid Silicone MigrationCatheterOrganosiliconPoly ethylene

The invention belongs to the technical field of polyurethane elastomers, and particularly relates to an organic silicon modified TPU medical catheter and a preparation method thereof. The organic silicon modified TPU medical catheter comprises a TPU material and a polyvinylpyrrolidone coating, wherein the TPU material is prepared from the following raw materials in parts by mass: 49 to 70 parts oforganic silicon modified polyol, 23 to 40 parts of diisocyanate, 3 to 12 parts of a chain extender, 0.02 to 0.04 part of a catalyst and 0.1 to 0.5 part of a coupling agent. The organic silicon modified TPU medical catheter has excellent mechanical performance and biocompatibility and high low-temperature flexibility, water resistance and hydrophilic lubricity, participates in a reaction in initial raw material synthesis, and avoids the problem of migration. The invention further provides a preparation method which is simple in process and easy and convenient to operate.

Owner:SHANDONG INOV POLYURETHANE

A toughened warm mix epoxy asphalt for steel bridge deck pavement

ActiveCN105838094BImprove low temperature flexibilityImprove high temperature stabilityClimate change adaptationBuilding insulationsEpoxyBridge deck

The invention belongs to the technical field of traffic, and discloses a novel material which is mainly used for steel bridge deck pavement to improve the pavement performance of steel bridge deck pavement. The asphalt material is softened and toughened by adopting a MBS core-shell grafted copolymer as a toughening agent and adopting a phenolic compound as a compatibilizing agent through the characteristics that the flexibility of the MBS core-shell grafted copolymer is good at low temperature and the MBS core-shell grafted copolymer can be soluble with asphalt, the interfacial tension between the asphalt and epoxy resin is decreased by serving the phenolic compound as a third phase through the characteristic that the phenolic compound can be soluble with the asphalt and the epoxy resin, and then the purpose that the blend system is stable is achieved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Ultrathin color sealing layer material and preparation method thereof

PendingCN111410456AIncrease elasticityImprove low temperature flexibilityRoad surfaceWear resistance

The invention discloses an ultrathin color sealing layer material and a preparation method thereof. The ultrathin color seal material comprises the following raw material components in parts by weight: 5-85 parts of a color cementing material, 50-180 parts of water, 0.1-4.5 parts of an emulsifier, 1-12 parts of a stabilizer, 0.1-8 parts of a modifier and 25-110 parts of aggregate. The ultrathin color sealing layer material provided by the invention is used for a pavement, has the characteristics of high-temperature stability, good ductility, difficulty in embrittlement and excellent waterproofness and wear resistance, is used for a paving sealing layer of the pavement and is thinner, and the thickness of the ultrathin color sealing layer material is not more than 2mm.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com