A toughened warm mix epoxy asphalt for steel bridge deck pavement

A technology of steel bridge deck and asphalt, applied in the field of transportation, can solve the problems of failure and damage, high brittleness of concrete, different chemical properties, etc., and achieve the effect of improving road performance and high temperature stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1 Steel bridge deck pavement binder preparation

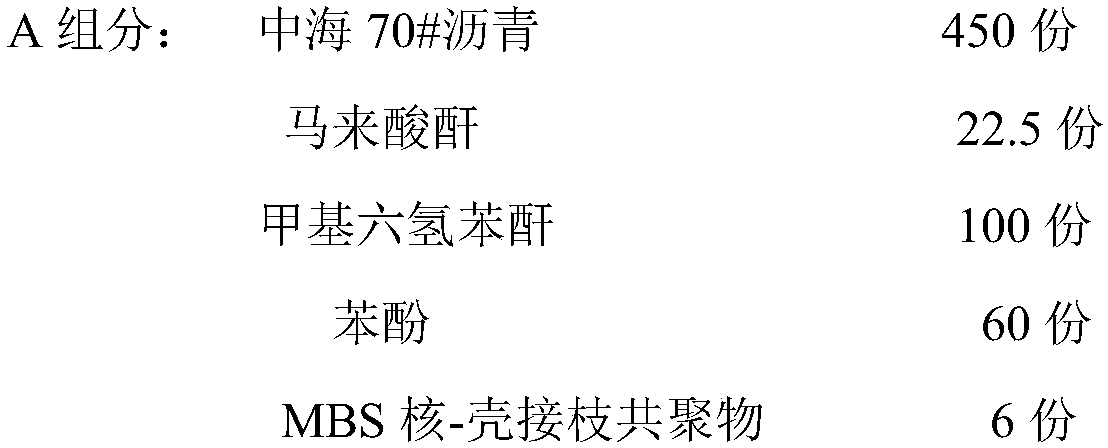

[0015] Accurately weigh the following materials by weight:

[0016]

[0017] B component: Bisphenol A type epoxy resin E51 100 parts

[0018] Propylene oxide butyl ether 2 parts

[0019] In component A, first mix asphalt and maleic anhydride at 120°C and mix evenly, when the maleic anhydride is completely incorporated into the asphalt, then add MBS elastomer to the asphalt at 120°C, keep stirring, and the stirring rate is controlled at 200 -250rpm, after the MBS elastomer is completely dissolved in the asphalt, add methyl hexahydrophthalic anhydride and phenol in turn, stir and mix, the stirring speed is controlled at 200-250rpm, and the stirring time is 20min.

[0020] In component B, add bisphenol A epoxy resin E51 to propylene oxide butyl ether at 50°C and stir evenly.

[0021] Mix components A and B according to the mass ratio A:B=1:6.08, and stir at 120°C for 2-3 minutes to prepare a binder.

Embodiment 2

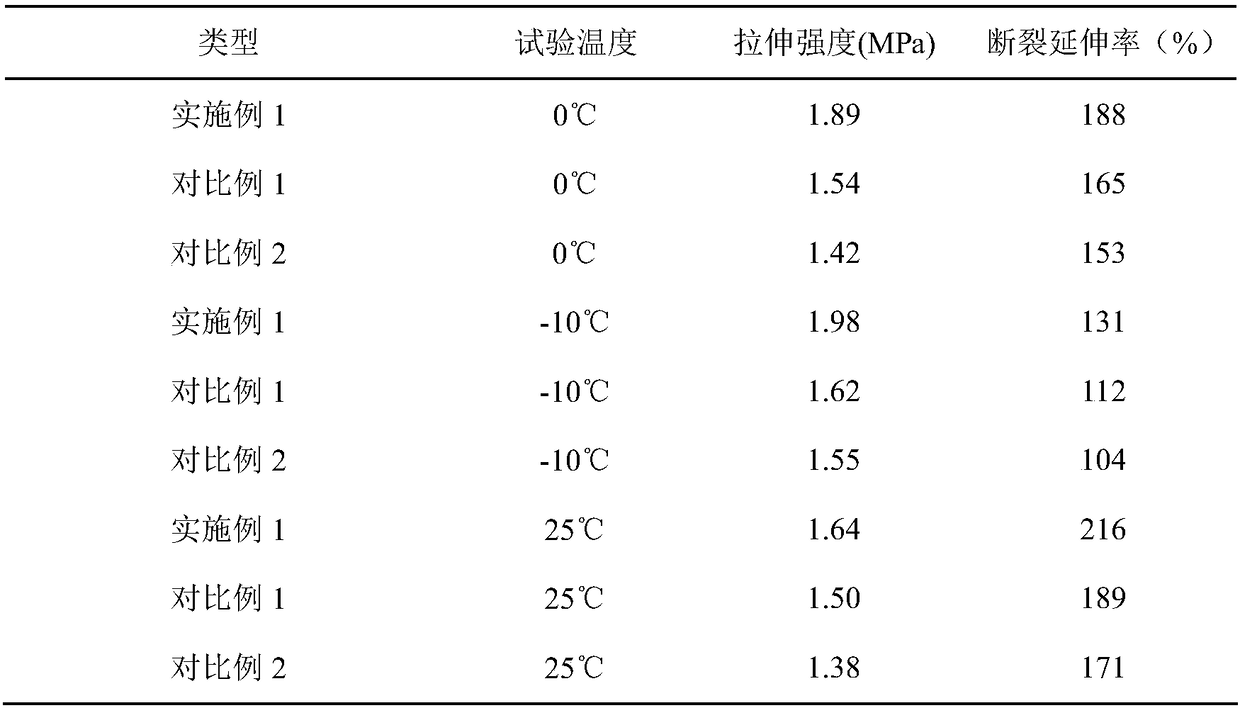

[0023] By preparing the binder mixed with MBS modification and the binder without MBS modification, and carried out the test of tensile strength and elongation at break, the standard specified in GB / T 16777-2008 "Test Methods for Building Waterproof Coatings" was adopted. Test piece production method Form the test piece. After the test piece is prepared, it is placed in an oven at 120 ° C for 4 hours. At this time, the test piece is completely cured. After the temperature of the specimen is stable, the tensile test is carried out. The whole test is carried out on a universal material testing machine, and the test tensile rate is 50±5mm / min. Six specimens were selected as a group for tensile test, and the average value of the results was taken as the test result.

[0024] The test results are as follows:

[0025] Table 1 Tensile strength and elongation at break of the binder under different test conditions

[0026]

Embodiment 3

[0030] The epoxy asphalt mixture was subjected to rutting test, low temperature bending test, freeze-thaw splitting test and fatigue test. The test process is as follows:

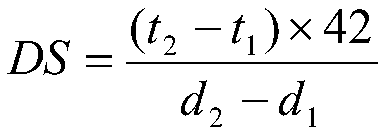

[0031] Rutting test: The rutting test in my country uses a 300mm×300mm×50mm rutting test mold, and the specimen is formed by a wheel mill according to the standard method stipulated in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011). The test wheel is a solid tire made of rubber, with a diameter of 200mm, a width of 50mm, a rubber layer thickness of 15mm, a wheel pressure of 0.7MPa, a test temperature of 70°C, and a running speed of the loading wheel at 42 times / min. The rutting test is usually carried out for 60 minutes or until the maximum deformation reaches 25mm, and the dynamic stability DS (times / mm) is calculated according to the formula:

[0032]

[0033] In the formula: d 1 is the load wheel action time t 1 (Generally 45min) permanent deformation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com