Fissure cementation glue for pavement, and preparation method for fissure cementation glue

A technology of joint glue and test method, which is applied in the direction of roads, roads, pavement details, etc., can solve the problems of high maintenance cost, high price of imported materials, and difficulty in meeting the needs of joint filling in cold regions, and achieve high temperature stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First, heat No. 90 petroleum asphalt with 64.4% mass percentage to 185-195°C to a fluid state, and add 4.5% polymer under stirring (the polymer includes 40% star SBS and 60% linear SBS) Grinding by a colloid mill with a rotating speed of 3500RPM, adding 11% reverse furfural extract oil, 7% mineral oil, and then adding 13% waste rubber powder, then swelling for 5 hours under stirring, and then adding 0.1% Sulfur powder was reacted for another 1 hour to obtain the pavement joint glue product.

Embodiment 2

[0032] At first the No. 110 petroleum pitch that mass percent is 67.9% is heated to 185~195 ℃ to flow state, 5% polymer (polymer comprises 35% star SBS, 65% linear SBS) under stirring state, Grind by a colloid mill with a rotation speed of 3000RPM, add 12% reverse furfural extract oil, 5% mineral oil, and 10% waste rubber powder in sequence, then swell for 5 hours under stirring, and then add 0.1% sulfur powder , and then reacted for 2 hours to obtain a pavement joint glue product.

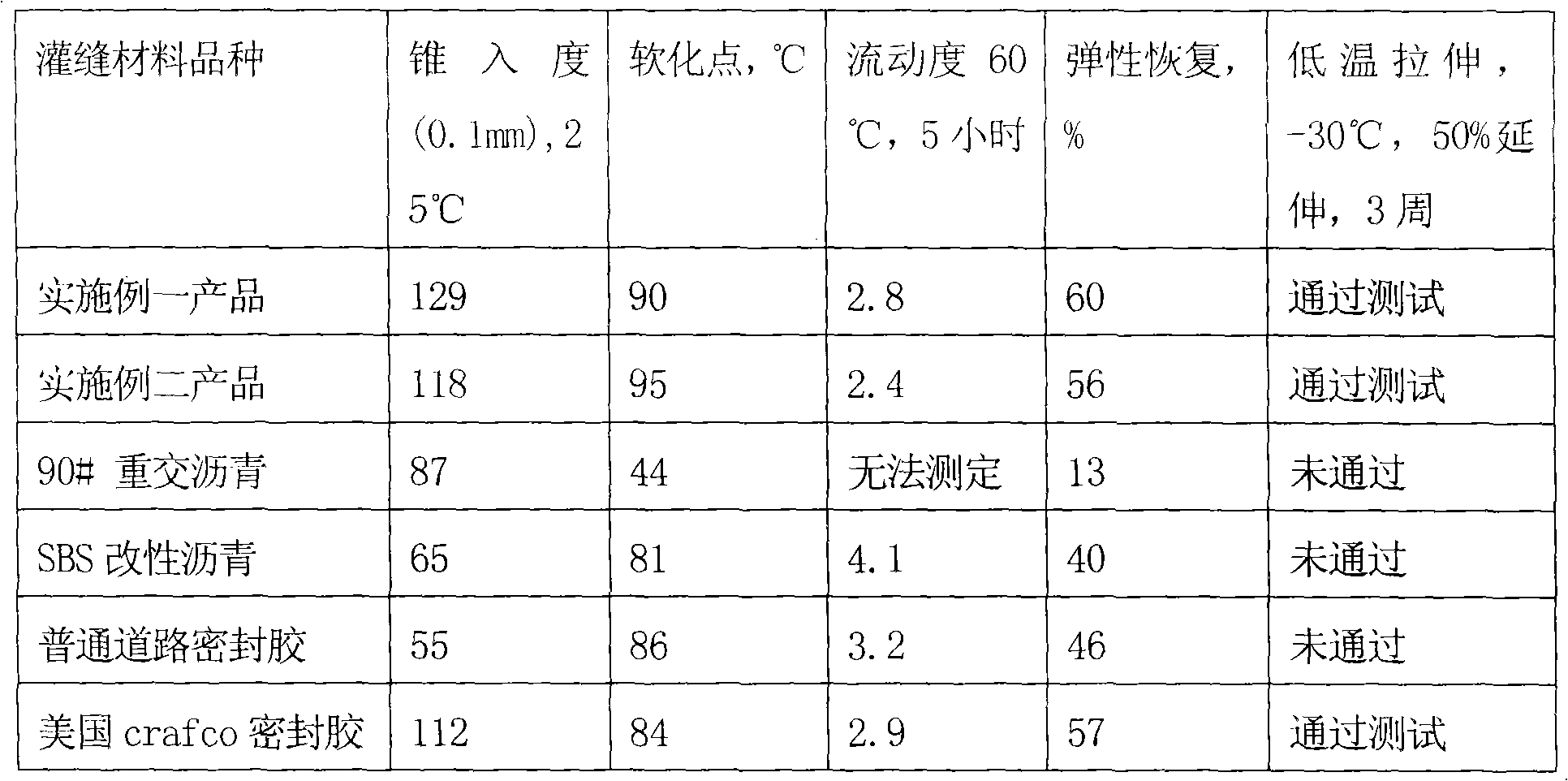

[0033] Table 1 shows the comparison of technical indicators between the products of the above examples and other joint filling materials.

[0034] Table 1 Comparison of technical indicators of joint filling materials

[0035]

[0036] It can be seen from the above table 1 that the joint glue has outstanding advantages in terms of high temperature performance, low temperature performance, elasticity and flexibility, and most materials are difficult to meet the requirements under low temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com