High-water resistance formaldehyde-free and environment-friendly wood adhesive and preparation method thereof

A technology for wood adhesives and water resistance, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor water resistance, achieve strong water resistance, glue stability, and improve low-temperature film formation The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

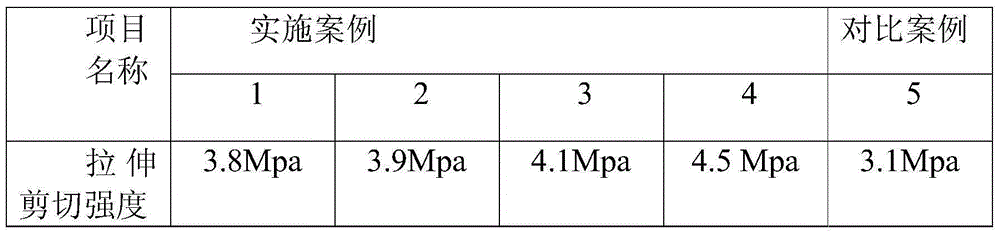

Embodiment example 1

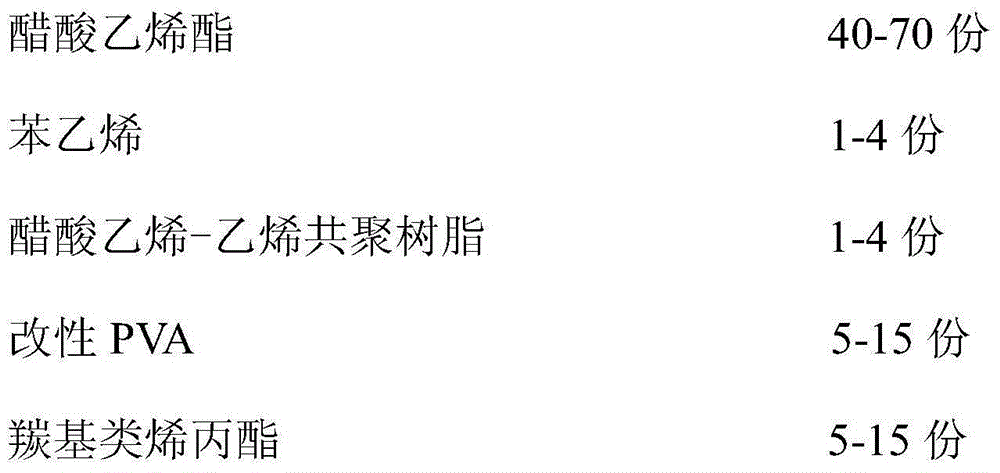

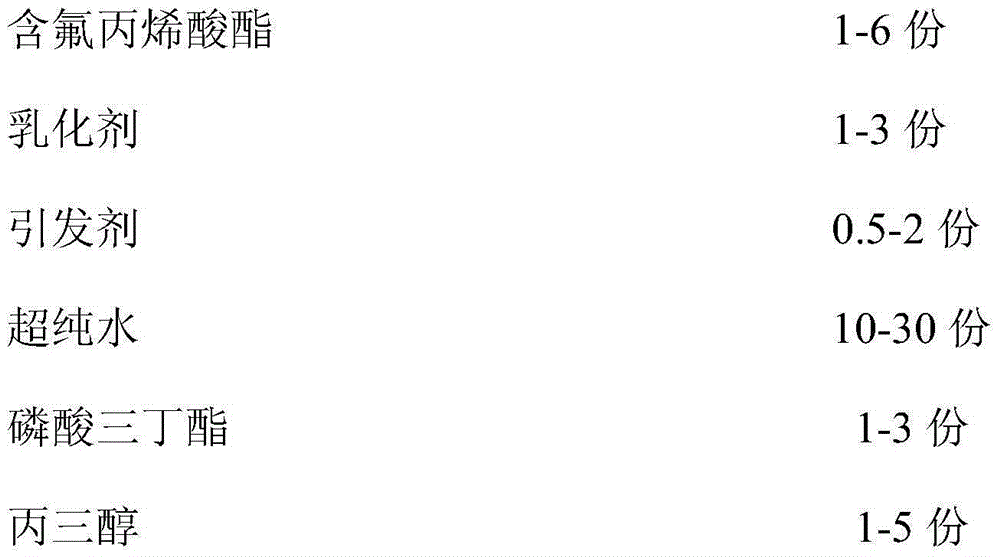

[0031] 45 parts of vinyl acetate; 1 part of styrene; 1 part of vinyl acetate-ethylene copolymer resin; 5 parts of PVA20885; 3 parts of ethylene glycol methacrylate acetoacetate; 2 parts; 0.3 parts of the mixture of alkylphenol polyoxyethylene ether and sodium lauryl sulfate; 0.3 parts of potassium persulfate; 40 parts of ultrapure water; 1 part of glycerol.

[0032] According to the ratio of weight fraction, add PVA2088 into the reaction kettle equipped with reflux condenser, drip hole and stirrer, and keep the stirring speed at 200-500 rpm, add ultra-pure water, heat until fully dissolved, and cool To 60-65 ℃, add emulsifier, defoamer, 2 / 3 potassium persulfate and hard shell monomer (acid vinyl-ethylene copolymer resin and styrene), after the reflux basically disappears, then heat up to 80 ℃; Add all remaining monomer mixtures (vinyl acetate, ethylene glycol methacrylate, dodecafluoroheptyl methacrylate) dropwise; then raise the temperature to 90°C and continue the reaction f...

Embodiment example 2

[0034] 45 parts of vinyl acetate; 1 part of styrene; 1 part of vinyl acetate-ethylene copolymer resin; 5 parts of acetoacetylated polyethylene glycol; 3 parts of acetoacetate methacrylate; 2 parts of tributyl phosphate; 0.3 parts of the mixture of phenol polyoxyethylene ether and sodium lauryl sulfate; 0.3 parts of potassium persulfate; 40 parts of ultrapure water; 1 part of glycerol.

[0035] According to the ratio by weight fraction, add acetoacetylated polyethylene glycol into the reaction kettle equipped with a reflux condenser, a drop hole and a stirrer, and keep the stirring speed at 200-500 rpm, add ultra-pure water, and heat until fully dissolved, cool to 60-65°C, add emulsifier, defoamer, 2 / 3 of potassium persulfate and hard shell monomer (acid vinyl-ethylene copolymer resin and styrene), after the reflux basically disappears, then Raise the temperature to 80°C; add all the remaining monomer mixture (vinyl acetate, allyl acetoacetate) dropwise; then raise the temperat...

Embodiment example 3

[0037] 48 parts of vinyl acetate; 1 part of styrene; 1 part of vinyl acetate-ethylene copolymer resin; 5 parts of acetoacetylated polyethylene glycol; 1 part of dodecafluoroheptyl methacrylate; 2 parts of tributyl phosphate; 0.3 parts of the mixture of phenol polyoxyethylene ether and sodium lauryl sulfate; 0.3 parts of potassium persulfate; 40 parts of ultrapure water; 1 part of glycerol.

[0038]According to the ratio of parts by weight, add acetoacetylated polyethylene glycol into the reaction kettle equipped with a reflux condenser, a drop hole and a stirrer, and add ultrapure water while maintaining the stirring speed at 200-500 rpm , heated to complete dissolution, cooled to 60-65°C, added emulsifier, defoamer, 2 / 3 of potassium persulfate and hard shell monomer (acid vinyl-ethylene copolymer resin and styrene), after the reflux basically disappeared , then raise the temperature to 80°C; drop all the remaining monomer mixture (vinyl acetate, dodecafluoroheptyl methacrylat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com