High-strength and high-toughness light polyurethane rubber bridge deck paving material and preparation thereof

A polyurethane rubber and bridge deck pavement technology, which is applied in the field of bridge deck pavement materials, can solve the problems of unfavorable promotion and high cost, and achieve the effects of improving water stability, prolonging service life, and meeting energy conservation and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

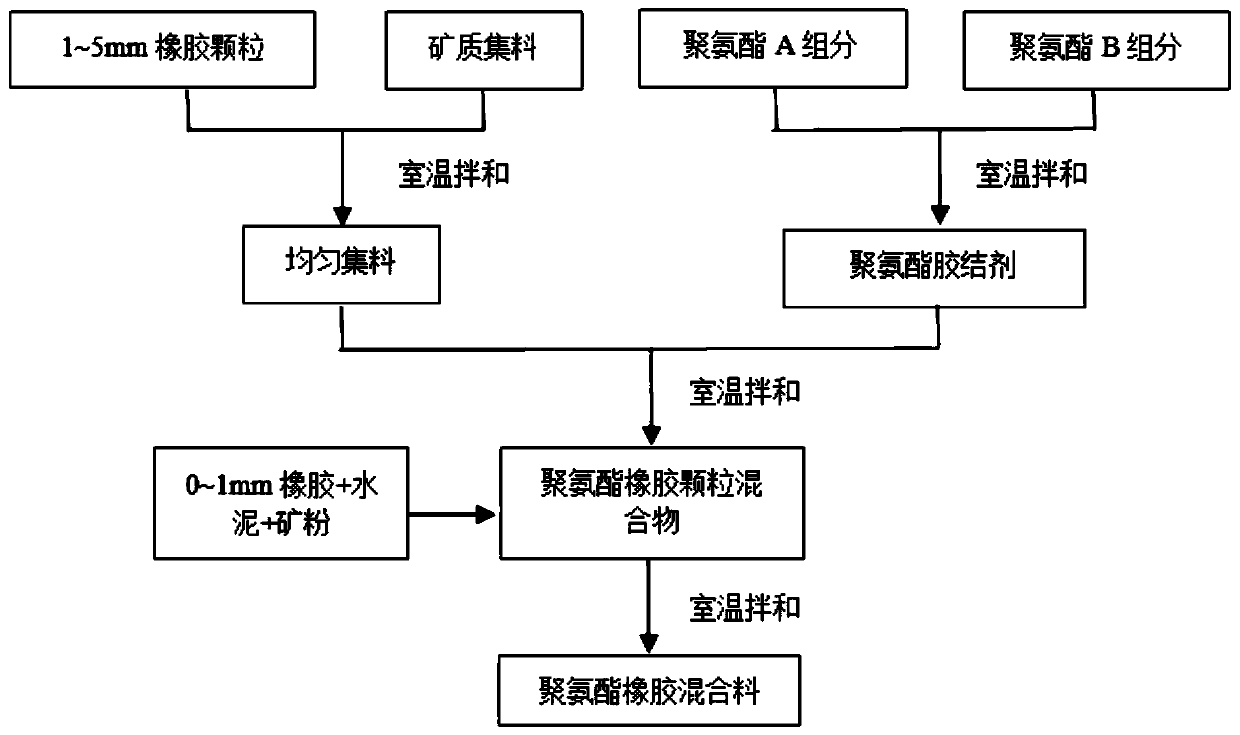

[0037] The present invention provides a kind of preparation method of the polyurethane rubber mixture that is used as bridge deck paving material, and its flow process sees figure 1 As shown, the specific steps are:

[0038] 1) Mix crushed stone aggregates with different particle sizes and rubber particles with a particle size of 1 to 5 mm at room temperature for 60 seconds according to a certain ratio to obtain uniformly mixed aggregates;

[0039] 2) Stir the two-component modified polyurethane component A and component B at room temperature for 120s to obtain a polyurethane cement;

[0040] 3) mixing the polyurethane cement into the uniform aggregate and stirring for 60s to obtain the polyurethane rubber particle mixture;

[0041] 4) Finally, rubber particles with a particle size of 0-1mm, cement and mineral powder were mixed into the mixture of polyurethane rubber particles and stirred for 90s, compacted and cured at room temperature for 48 hours to prepare a lightweight, hi...

Embodiment 1

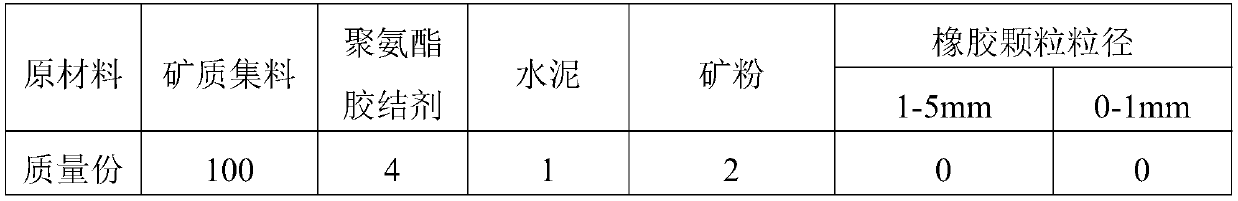

[0043] According to the polyurethane rubber compound embodiment 1 provided by the present invention, it contains the following materials and parts by mass of each material, as shown in Table 1 below:

[0044] Table 1

[0045]

[0046] Mineral aggregates are basalt crushed stone aggregates with a particle size of 10-15mm, basalt crushed stone aggregates with a particle size of 5-10mm, and limestone crushed stone aggregates with a particle size of no more than 5mm, and the ratios of the mass parts of the three aggregates are: 15:55:30, the mineral aggregates of various particle sizes meet the performance requirements of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004).

[0047] The preparation method of above-mentioned polyurethane rubber mixture, its process reference figure 1 In the process shown, the prepared polyurethane rubber mixture is compacted and molded at a temperature of 0-40°C, and the performance test is performed after 48 ...

Embodiment 2

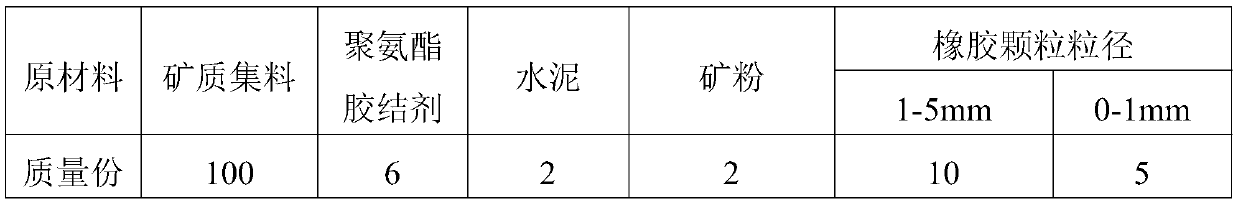

[0049] The polyurethane rubber mixture embodiment 2 provided according to the present invention contains the following materials and parts by mass of each material, as shown in Table 2 below:

[0050] Table 2

[0051]

[0052] Mineral aggregates are basalt crushed stone aggregates with a particle size of 10-15mm, basalt crushed stone aggregates with a particle size of 5-10mm, and limestone crushed stone aggregates with a particle size of 0-5mm, and the ratios of the mass parts of the three aggregates are: 10:50:40, mineral aggregates of various particle sizes meet "male Technical Specifications for Asphalt Pavement Construction (JTG F40-2004) performance requirements.

[0053] The preparation method of above-mentioned polyurethane rubber mixture, its process reference figure 1 In the process shown, the prepared polyurethane rubber mixture is compacted and molded at a temperature of 0-40°C, and the performance test is performed after 48 hours of curing. Refer to the "T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com