Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve high temperature insulation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

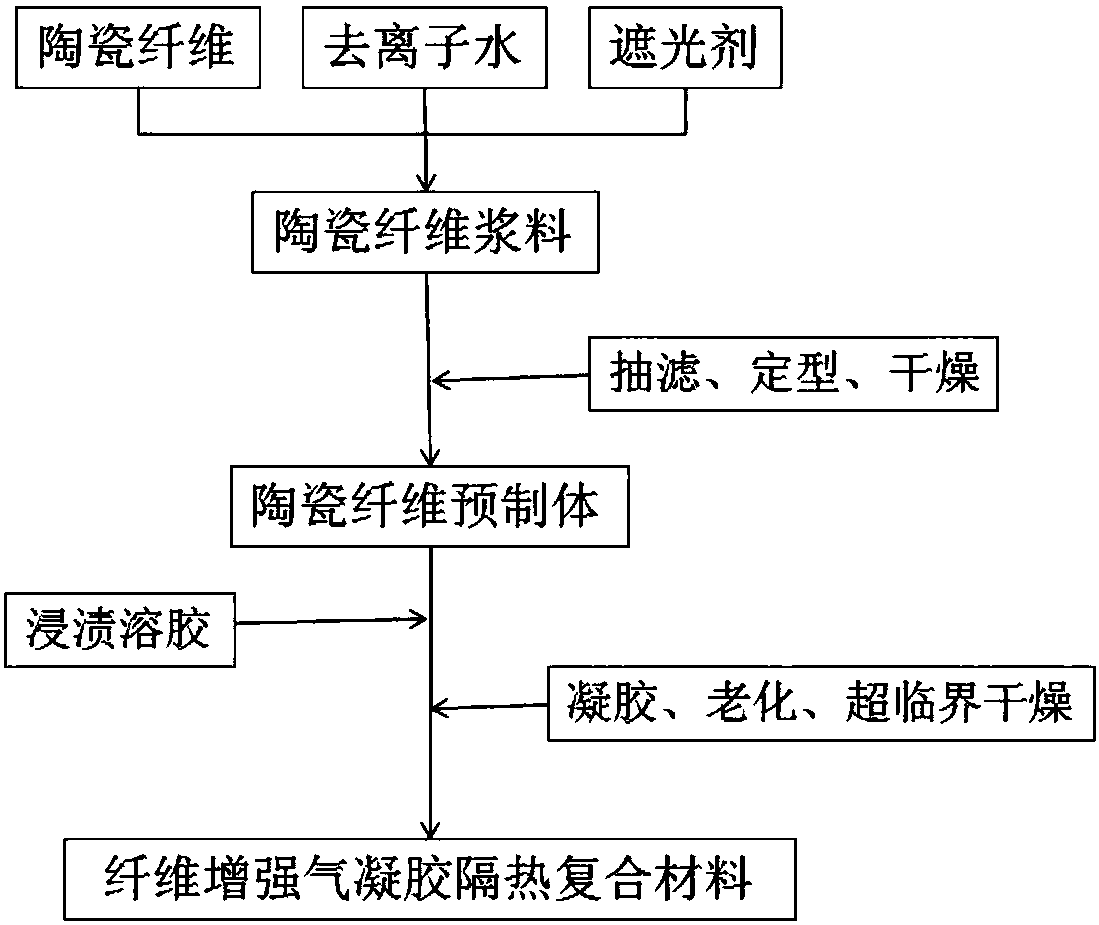

Fiber-preform-reinforced aerogel insulating composite material and preparation method thereof

InactiveCN108046739AEvenly dispersedImprove high temperature insulation performanceThermal stabilityMechanical property

The invention relates to a fiber-preform-reinforced aerogel insulating composite material. The fiber-preform-reinforced aerogel insulating composite material adopts ceramic fiber preform containing anopacifying agent as a reinforcement ,and adopts aerogel with nanopores as a matrix; a mass ratio of ceramic fiber in the ceramic fiber preform to the opacifying agent is 1:(0.1 to 0.5), and the opacifying agent is one or combination of TiO2, ZrO2, ZrSiO4, Cr2O3, Fe2O3 or SiC; the pore volume of the aerogel is larger than 2.5g / cm<3>. The fiber-preform-reinforced aerogel insulating composite material and the preparation method thereof have the beneficial effects that the high-temperature insulating property of the fiber-reinforced aerogel insulating material is obviously improved, and the highest use temperature of the material can reach 1200 DEG C, so that the heat stability is good; in addition, the fiber-preform-reinforced aerogel insulating composite material is good in mechanical property, and can be cut and machined into various member shapes to meet different use requirements.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

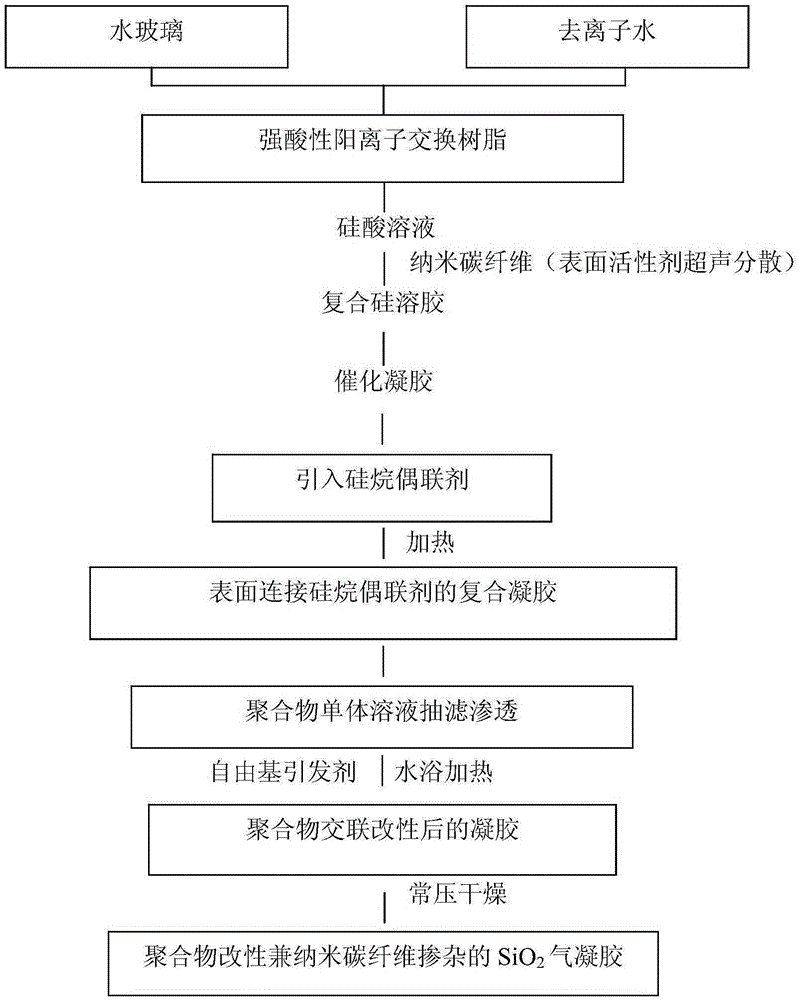

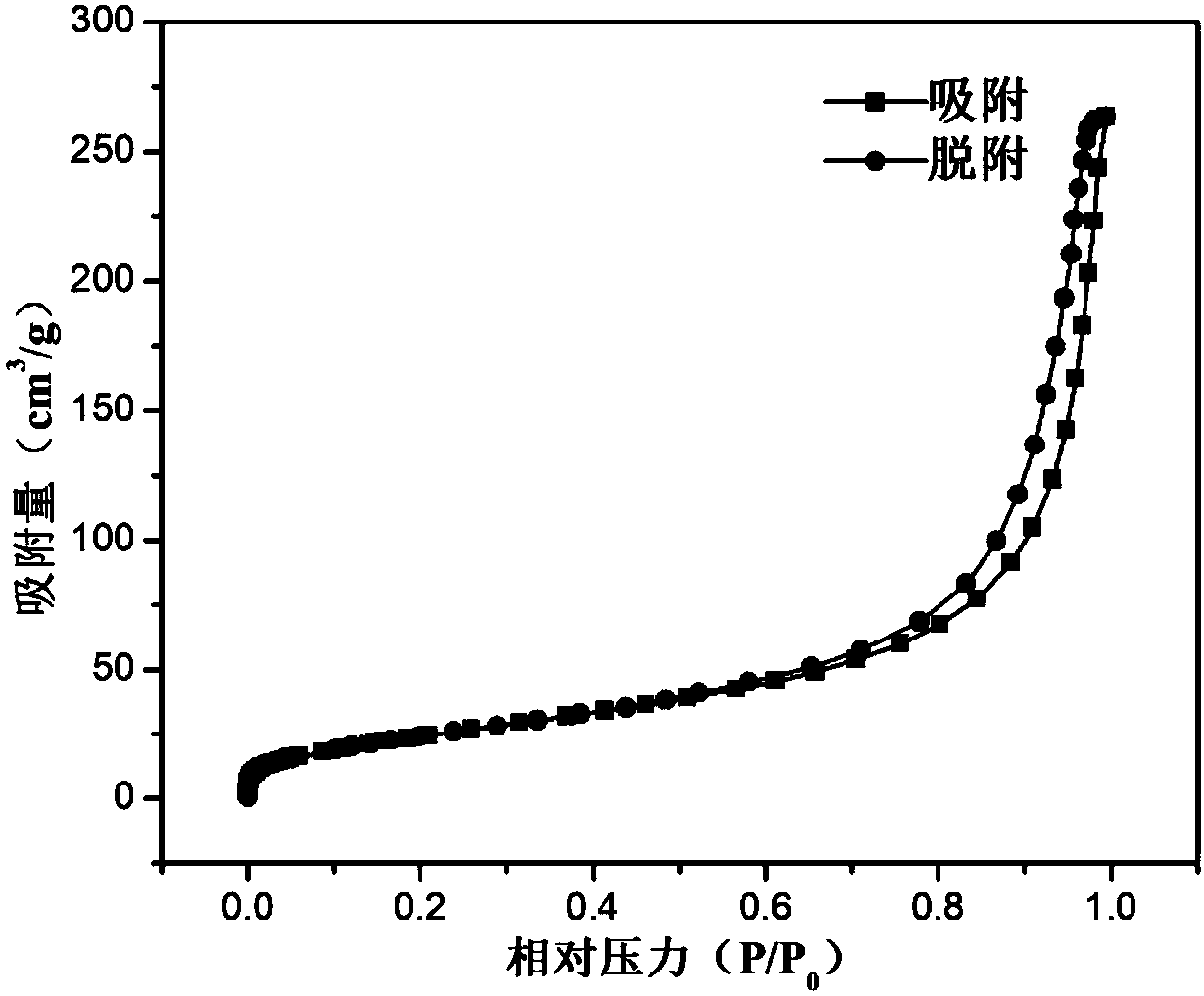

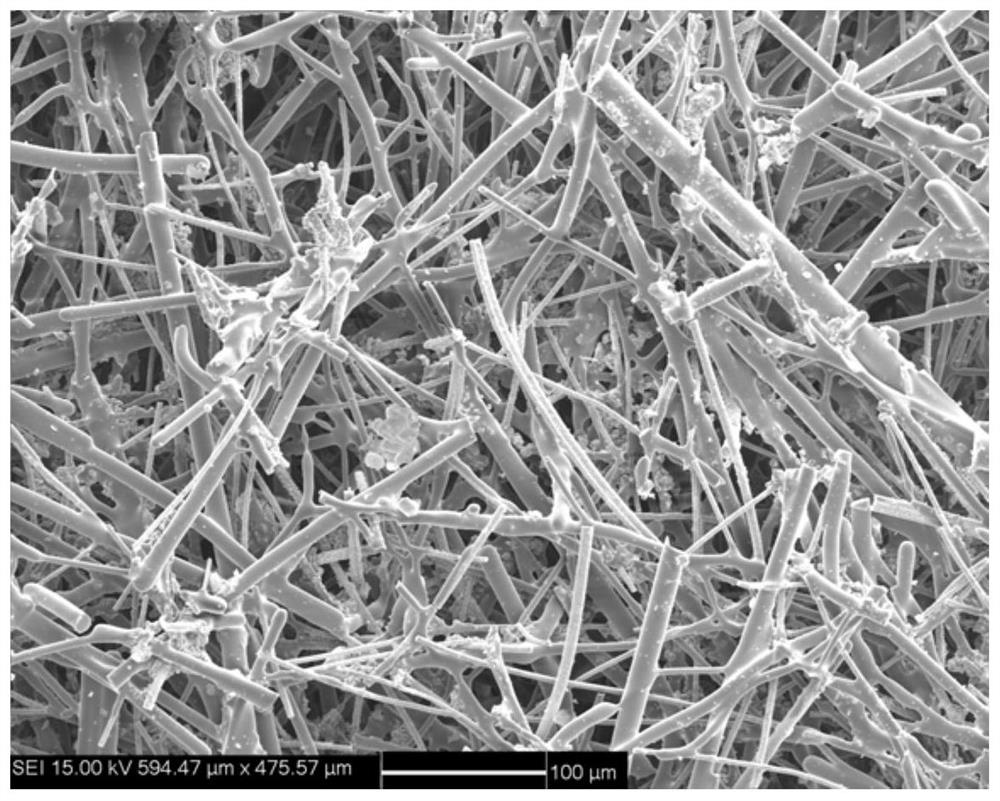

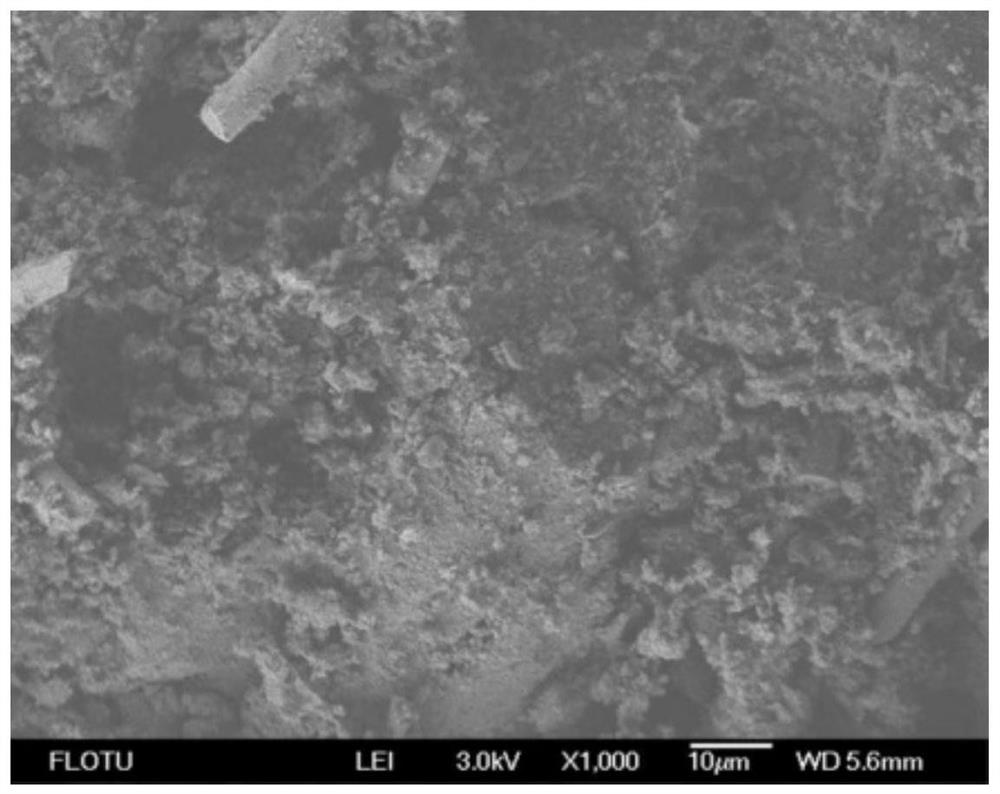

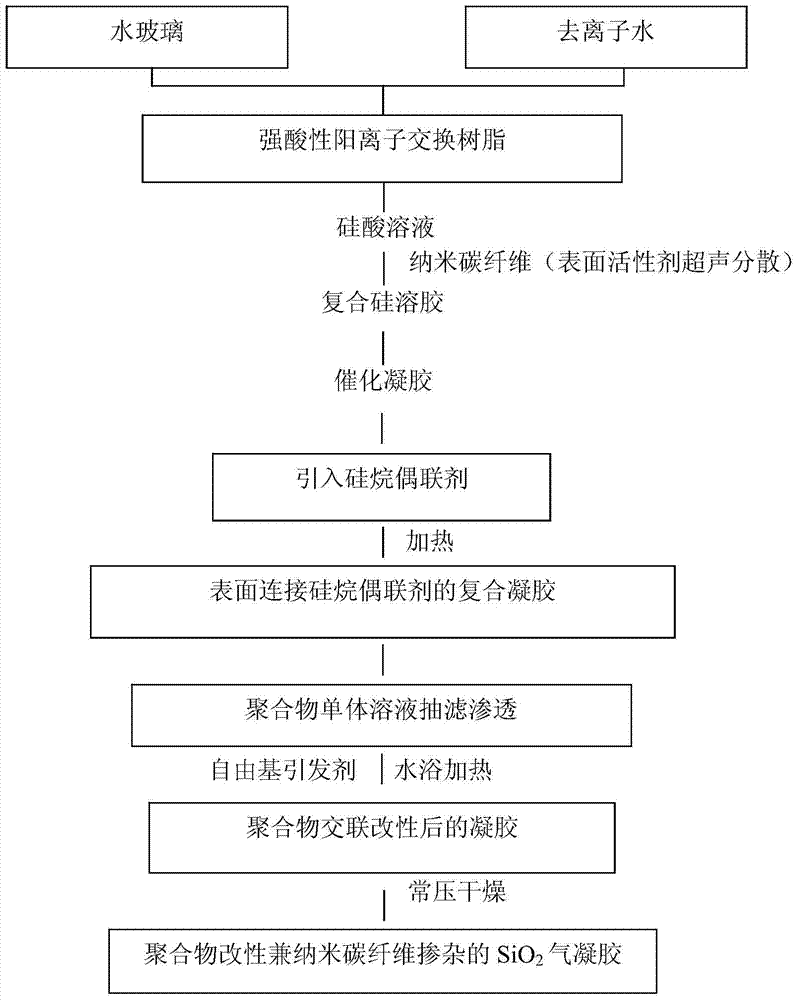

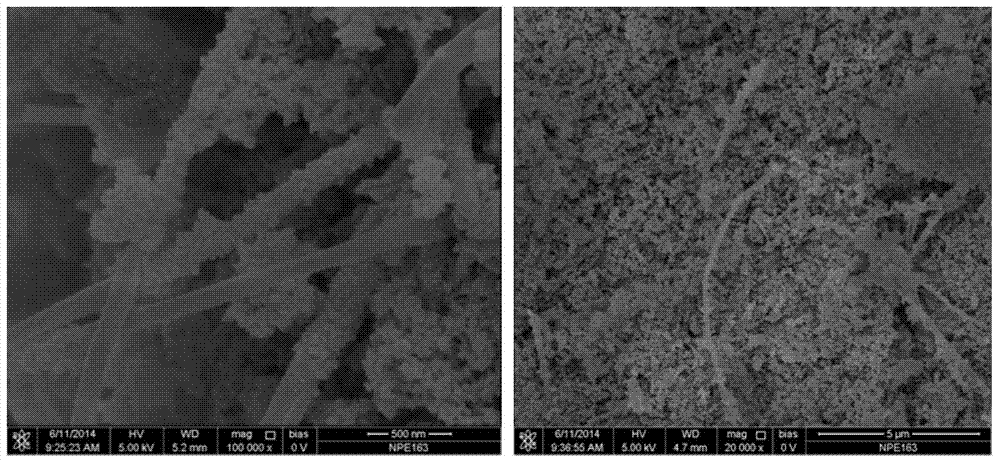

Polymer modified and nano-carbon fiber doped SiO2 aerogel and preparation method thereof

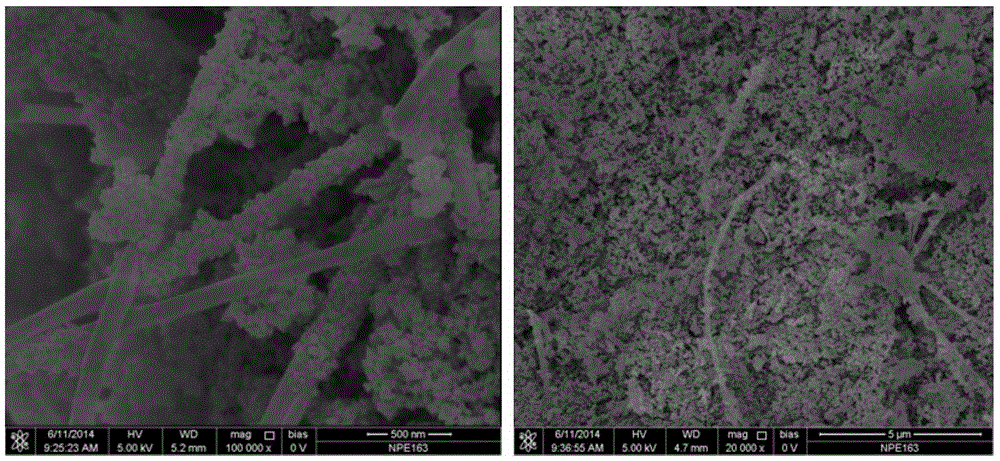

ActiveCN105236426AReduce internal defectsImprove high temperature insulation performanceSilicaFiberPolymer modified

The invention provides a polymer modified and nano-carbon fiber doped SiO2 aerogel and a preparation method thereof. The preparation method comprises: subjecting a water glass solution to ion exchange to obtain a silicic acid solution; dissolving a surfactant and nano-carbon fiber in the silicic acid solution, and carrying out ultrasonic dispersion to obtain nano-carbon fiber / SiO2 composite sol; adjusting the pH value of the composite sol, conducting standing at room temperature to obtain nano-carbon fiber / SiO2 gel; aging the gel at room temperature, and then transferring the gel into an aqueous solution of an organic solvent to conduct soaking; dissolving the soaked gel in an organic solvent of a silane coupling agent to carry out reaction under a heating condition; immersing the gel into a polymer monomer solution, conducting pumping filtering by a vacuum pump, and then carrying out polymerization reaction; and then performing washing and drying, thus obtaining the polymer modified and nano-carbon fiber doped SiO2 aerogel. The technical scheme provided by the invention has the advantages of safe operation and simple process, and the prepared SiO2 aerogel has excellent mechanical and thermal performance.

Owner:PETROCHINA CO LTD

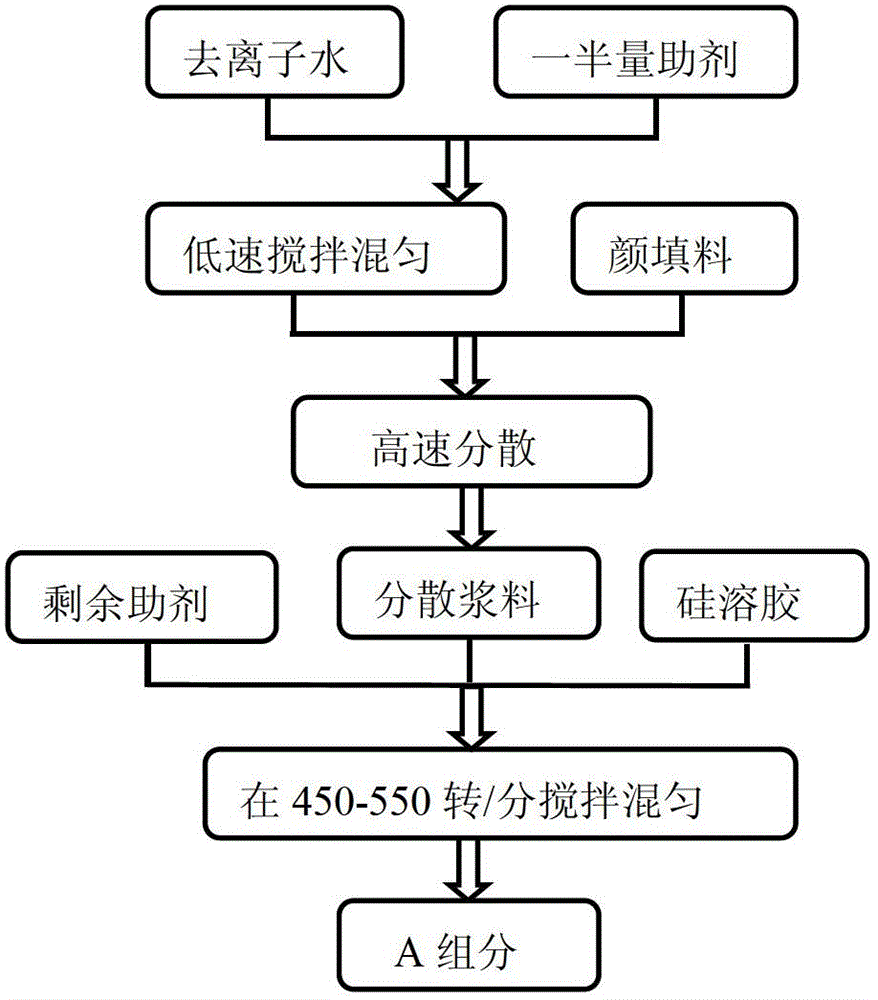

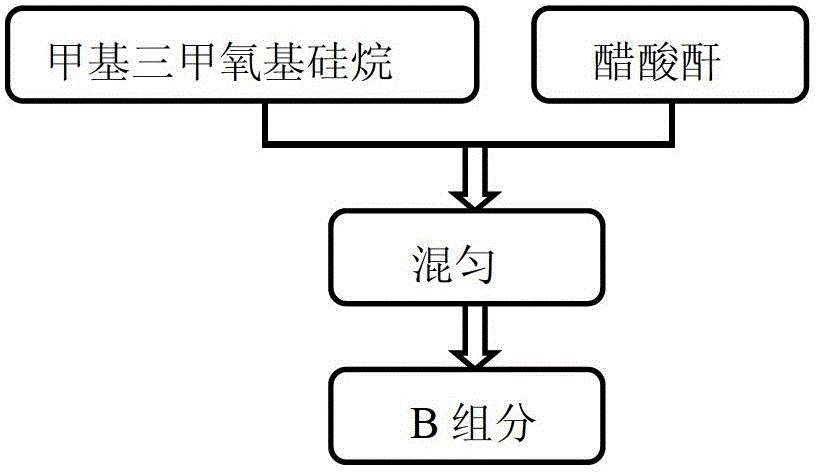

Environment-friendly high temperature-resistant inorganic insulated paint and preparation method thereof

InactiveCN102719120AExtend construction timeNo change in viscosityCoatingsEnvironmental resistanceAcetic anhydride

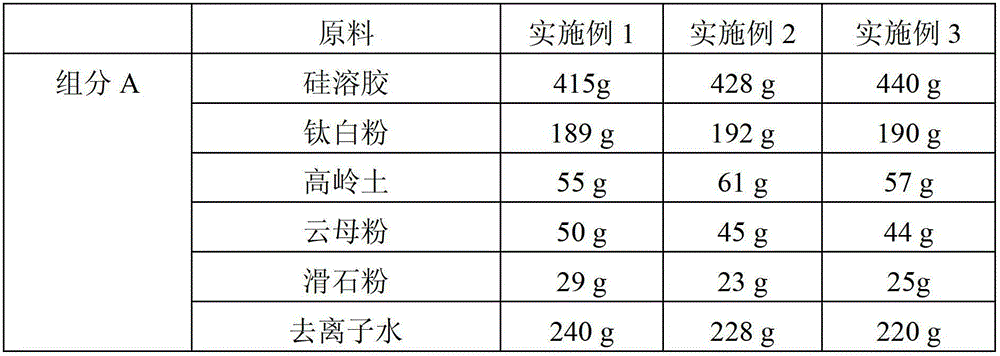

The invention relates to environment-friendly high temperature-resistant inorganic insulated paint and a preparation method thereof and belongs to the field of preparation of coatings. The environment-friendly high temperature-resistant inorganic insulated paint consists of a component A and a component B, wherein the component A consists of the flowing raw materials in percentage by mass: 41 to 44 percent of silica sol, 18.5 to 19.8 percent of inorganic pigment, 5.3 to 6.3 percent of kaolin, 4.4 to 5.0 percent of mica powder, 2.2 to 3.0 percent of talcpowder, 22 to 24 percent of deionized water, and 2.1 to 2.2 percent of aid; and the component B consists of the following raw materials in percentage by mass: 1.0 to 1.2 percent of acetic anhydride and 98.8 to 99.0 percent of methyltrimethoxysilane. During use, the component A and the component B are stirred and mixed in a ratio and cured; and then a mixture is subjected to air spraying onto metal base materials such as aluminum alloy, stainless steel and the like which are treated. The paint has the advantages of environment-friendliness, high temperature resistance and insulativity, acid and alkali resistance, long normal temperature quality guarantee period, long construction time and the like, and can be cured at normal temperature.

Owner:DALIAN JIAOTONG UNIVERSITY

High temperature thermal insulation material for tank number of torpedo cars

The invention relates to a thermal insulation material, and specially relates to a thermal insulation material of torpedo cars for iron and steel smelting. The invention provides a high temperature thermal insulation material for tank number of torpedo cars. The high temperature thermal insulation material comprises a nano thermal insulation layer and a strengthened layer, wherein the thermal insulation material mainly comprises the following raw materials: nano silica aerogels; fibrous alkali-free superfine glass or high silica glass fiber; quartz fiber; polycrystalline mullite fiber; ceramics; aluminium oxide aerogels; hydrophobic agent; one or more of potassium hexatitanate whiskers, silicon carbide, zirconium silicate and aluminum silicate; alumina; citric acid or sodium tripolyphosphate and gypsum; and the strengthened layer is formed by reinforced resin and fiber cloth. The nano high temperature thermal insulation material prepared according to the invention has excellent thermal insulation performance, higher strength and higher integrality, is polyporous, and can keep passing ability of electronic signals to the greatest extent without shielding.

Owner:HANGZHOU QIANJIANG WEIGHING TECH

Vermiculite and nanometer silica composite nanometer multi-hole heat insulation plate and manufacturing method thereof

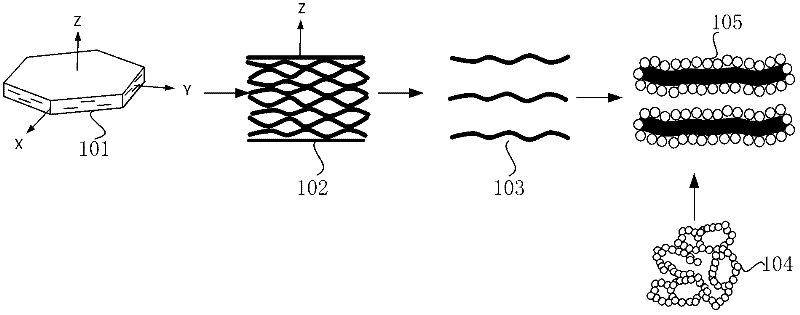

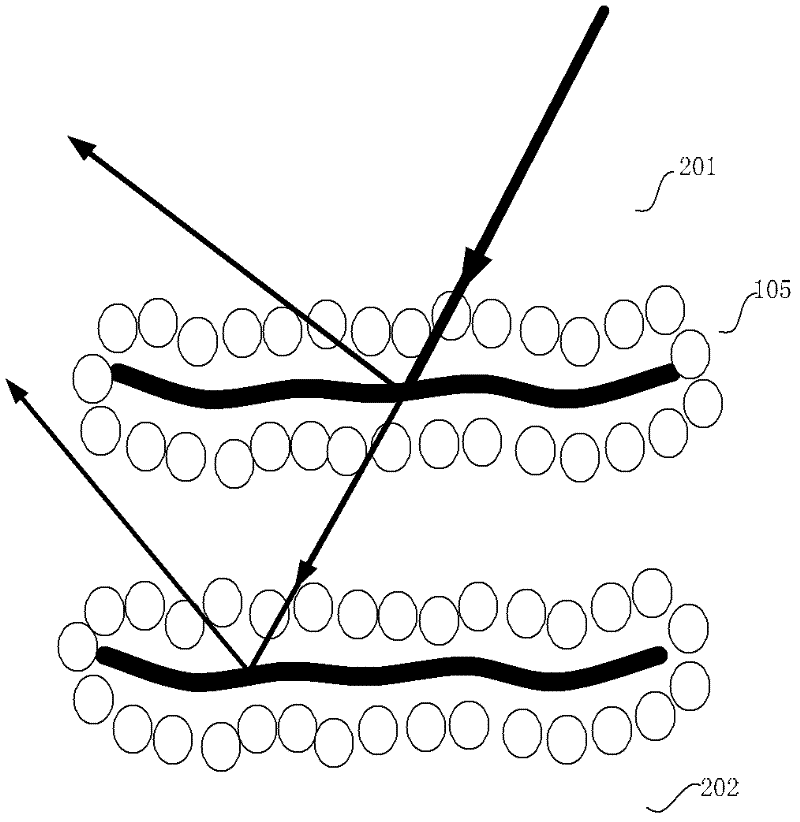

ActiveCN102503354AImprove high temperature insulation performanceImprove mechanical propertiesSilica particleThermal radiation

The invention relates to a vermiculite and nanometer silica composite nanometer multi-hole heat insulation plate and a manufacturing method thereof. The manufacturing method comprises the following steps: enabling primary mineral of the vermiculite to be heated and expanded in an expanding furnace to form expanded vermiculite; obtaining 30%-60% expanded vermiculite to be mixed with 40%-70% nanometer silica in a nanometer cladding machine; enabling the expanded vermiculite to be peeled into micro nanometer vermiculite slices which are wrapped by the nanometer silica simultaneously in a mixing process, enabling the micro nanometer vermiculite slices to be not contacted with each other, and obtaining mixing raw materials; and enabling the mixing raw materials to be pressed into heat insulation panels in a forming device. An embodiment providing the vermiculite and nanometer silica composite nanometer multi-hole heat insulation plate and the manufacturing method manufacture a novel heat insulation panel by compositing the vermiculite and the nanometer silica, and improve high temperature heat insulation performance by using the reflection effect of the micro nanometer vermiculite slices on high temperature thermal radiation. Simultaneously, the directional distribution of the micro nanometer vermiculite slices improves the mechanical property of materials.

Owner:SUZHOU SHENGBAOLONG NEW MATERIAL TECH

Preparation method of foam reinforced SiO2-TiO2 composite aerogel

InactiveCN110918008AReduce harmSimple processAerogel preparationColloidal chemistry detailsSupercritical dryingCatalytic method

The invention discloses a preparation method of foam reinforced SiO2-TiO2 composite aerogel. The preparation method comprises the steps: mixing tetraethyl orthosilicate and tetrabutyl titanate according to a certain proportion; sequentially adding absolute ethyl alcohol and deionized water, stirring, adding a catalyst after a period of time, dipping foam into the prepared SiO2-TiO2 colloidal solution, gelling and aging, and finally performing supercritical drying. The catalyst is only used once when the SiO2-TiO2 composite sol is prepared, so that the foam reinforced SiO2-TiO2 composite aerogel is prepared by a 'one-step catalytic method'. Moreover, TiO2 in the composite aerogel prepared by the method disclosed by the invention has excellent shading performance, and has a heat radiation prevention effect while insulating heat, so that the high-temperature heat conductivity of the aerogel can be effectively reduced. Meanwhile, the foam is used as a reinforcing body, so that the defect that the SiO2-TiO2 aerogel is fragile can be effectively overcome. Tests show that the normal-temperature thermal conductivity of the prepared foam reinforced SiO2-TiO2 composite aerogel is less than or equal to 0.015 W / (m*K).

Owner:航天海鹰(镇江)特种材料有限公司

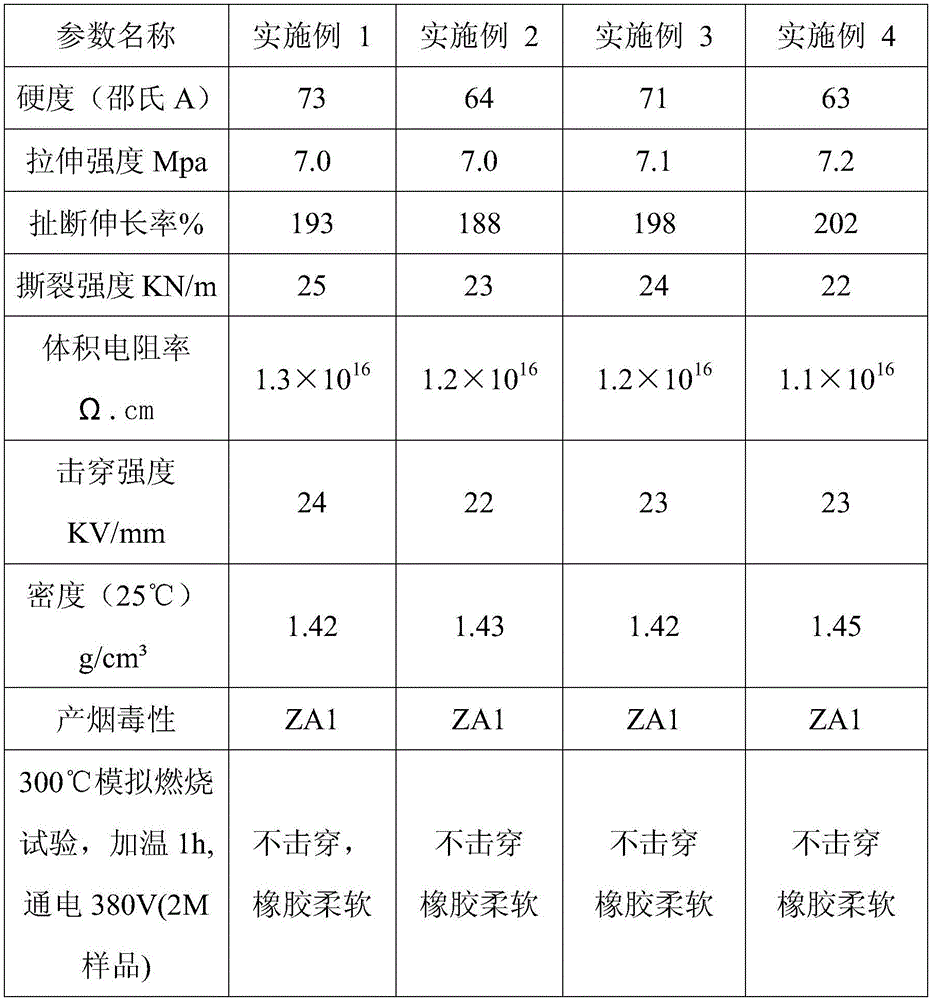

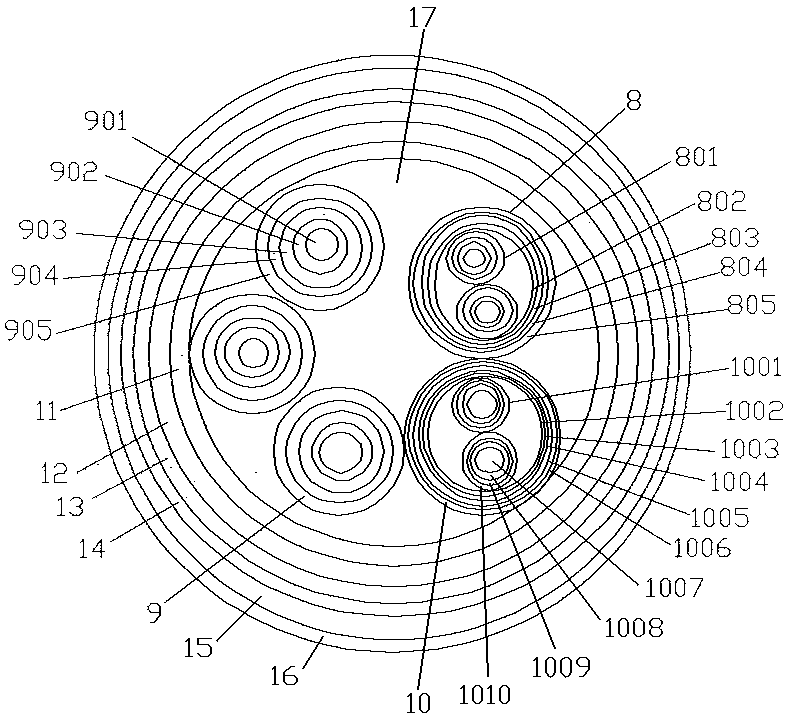

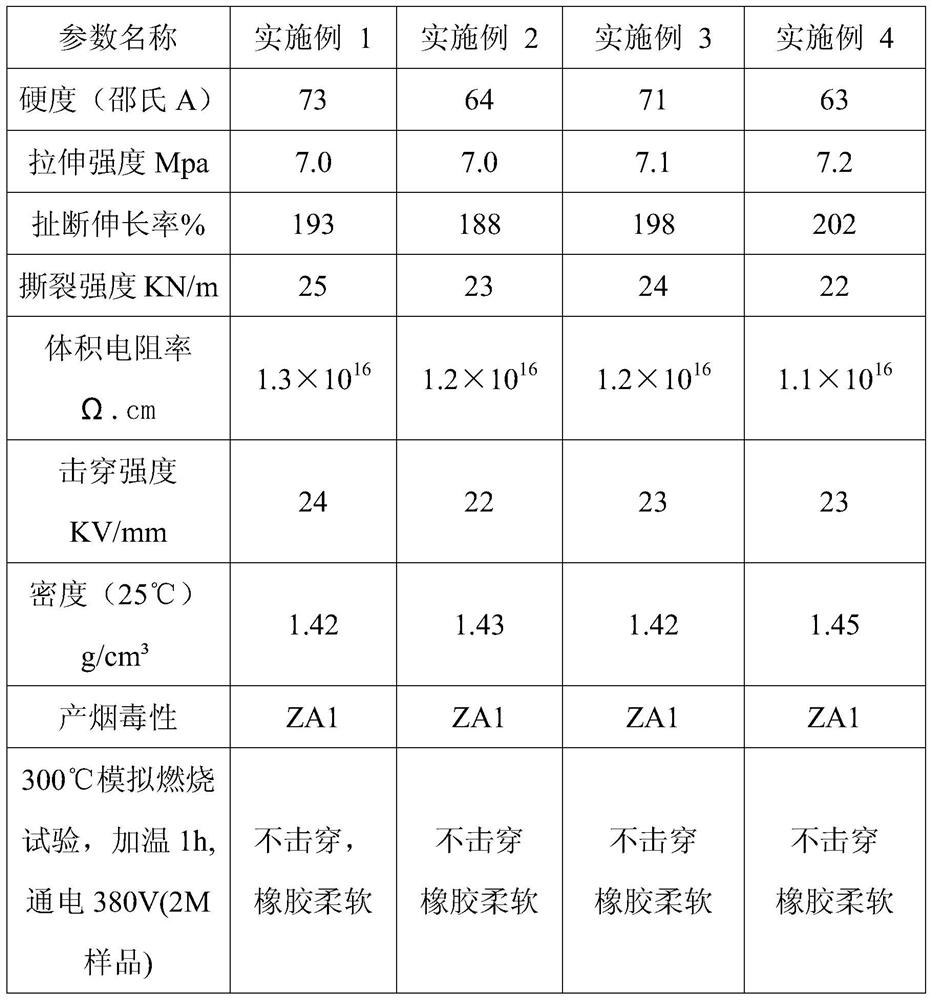

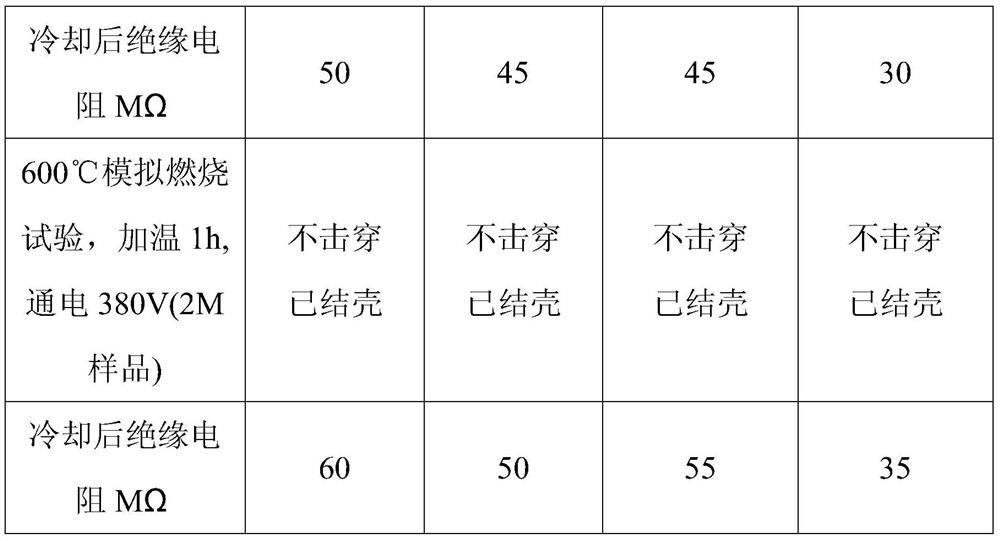

High insulation resistance refractory ceramic rubber for heating cable and preparing method thereof

ActiveCN105968820AHigh mechanical strengthImprove high temperature insulation performanceRubber insulatorsFiltrationVapor phase

The invention discloses high insulation resistance refractory ceramic rubber for a heating cable and a preparing method thereof. The ceramic rubber is mainly prepared from, by weight, 40-45 parts of silicone rubber, 20-25 pars of ceramic powder, 15-20 parts of glass powder, 5-10 parts of quartz powder, 8-10 parts of mica powder, 5-10 parts of vapor phase method white carbon black, 0.5-1 part of coupling agent, 2-5 parts of softening agent and 0.8-1 part of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane. The preparing method comprises the steps of placing the raw materials in a rubber mixing mill for mixing, wherein mixing temperature is controlled to be 50-60 DEG C, and mixing time is 15-20 min; then conducting filtration with a rubber filter to obtain the required ceramic rubber, wherein the rubber filter is provided with three layers of filter nets, which are the 20-mesh filter net, the 40-mesh filter net and the 60-mesh filter net from inside to outside in sequence. The ceramic rubber has the advantages of being high in insulation resistance refractory property, good in dampproof insulation effect and long in service life. The operating temperature of the heating cable with the ceramic rubber as an insulating layer can reach 600 DEG C, dampproof insulation effect is good, safety performance is high, and breakdown of the cable can not be caused even if an outer sheath is abraded or soaked.

Owner:沈兴线缆集团有限公司 +2

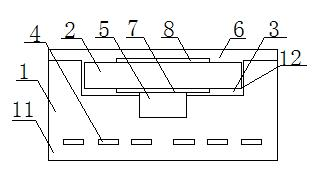

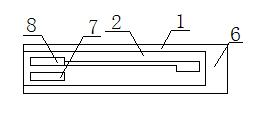

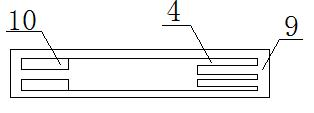

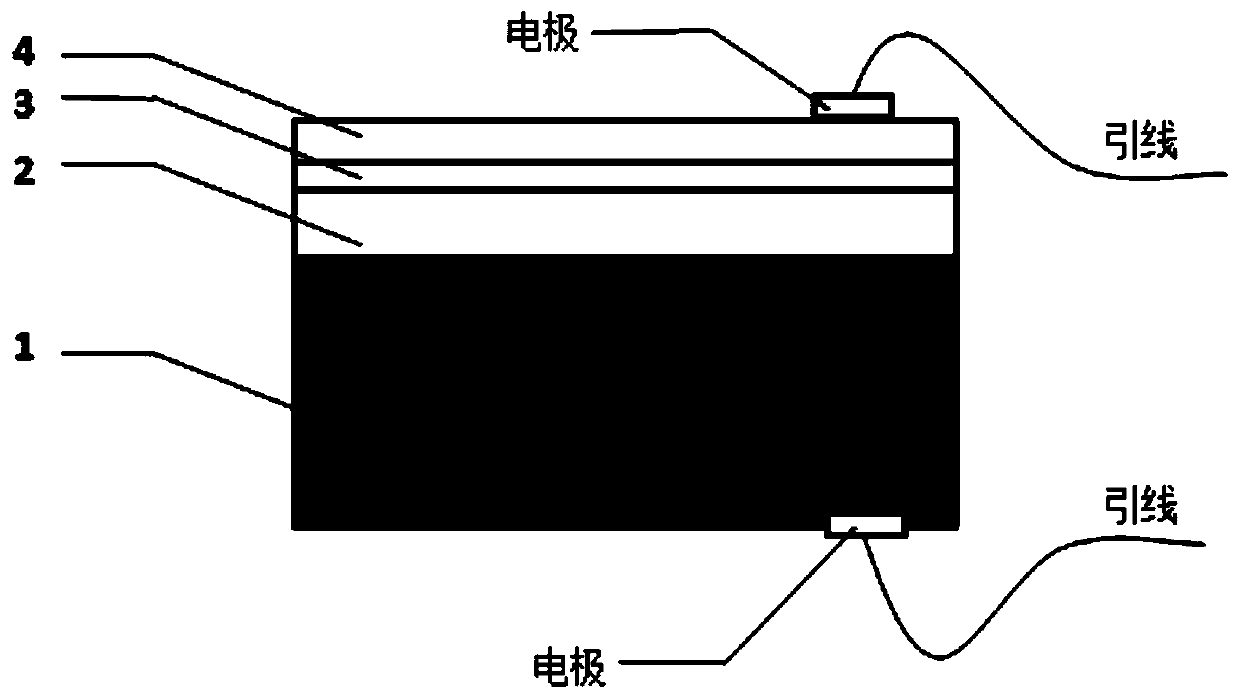

Inlaid plate-shaped oxygen sensor and preparation method thereof

InactiveCN102636527AQuick responseImprove high temperature insulation performanceMaterial electrochemical variablesEnergy consumptionZirconium dioxide

The invention relates to the technical field of a zirconium dioxide oxygen sensor for an automobile electric injection engine, in particular to an inlaid plate-shaped oxygen sensor and a preparation method thereof. The inlaid plate-shaped oxygen sensor comprises a ceramic heater, a zirconia sensitive element, a glass glaze sealing layer, a heating circuit, a reference gas channel, an alumina base body and a groove, wherein the zirconia sensitive element is arranged in the ceramic heater; the ceramic heater is connected with the zirconia sensitive element through the glass glaze sealing layer; the ceramic heater consists of the alumina base body and the groove; the groove is arranged on the upper surface of the alumina base body, and the heating circuit is arranged on the lower surface; and the reference gas channel is arranged between the zirconia sensitive element and the groove. The inlaid plate-shaped oxygen sensor provided by the invention improves the high-temperature insulation performance of the product, has fast response to electric signal, reduces the energy consumption and production cost, has long service life and is easy to popularize.

Owner:CHANGZHOU LAMBDA ELECTRONICS

Multicolor red phosphorus flame-retardant nylon composition and preparation method thereof

The invention discloses a multicolor red phosphorus flame-retardant nylon composition. The multicolor red phosphorus flame-retardant nylon composition is prepared from, by weight, 40%-70% of polyamide, 5%-20% of a red phosphorus flame retardant, 10%-35% of an enhanced component, 0.2%-5% of pigments, 0-3% of 4,4'-bismaleimide diphenylmethane, 0-3% of triallyl isocyanurate and 0.2%-3% of an auxiliary. According to the multicolor red phosphorus flame-retardant nylon composition, by adding the pigments, the multicolor red phosphorus flame-retardant composition can be supplied, and the current situation that an existing red phosphorus flame-retardant composition is single in color is changed; meanwhile, the specific weight percentage combination is adopted, therefore, the good flame retardant property, mechanical property and thermal property and multiple prepared colors are achieved, and the composition is mainly applied to electronic and electric industry and has the wide application prospect. The invention further provides a preparation method of the multicolor red phosphorus flame-retardant nylon composition, the preparation method can be achieved by adopting an existing double-screw extruder, preparation is easy, and industrialized production and implementation are easy to achieve.

Owner:CGN JUNER NEW MATERIALS +1

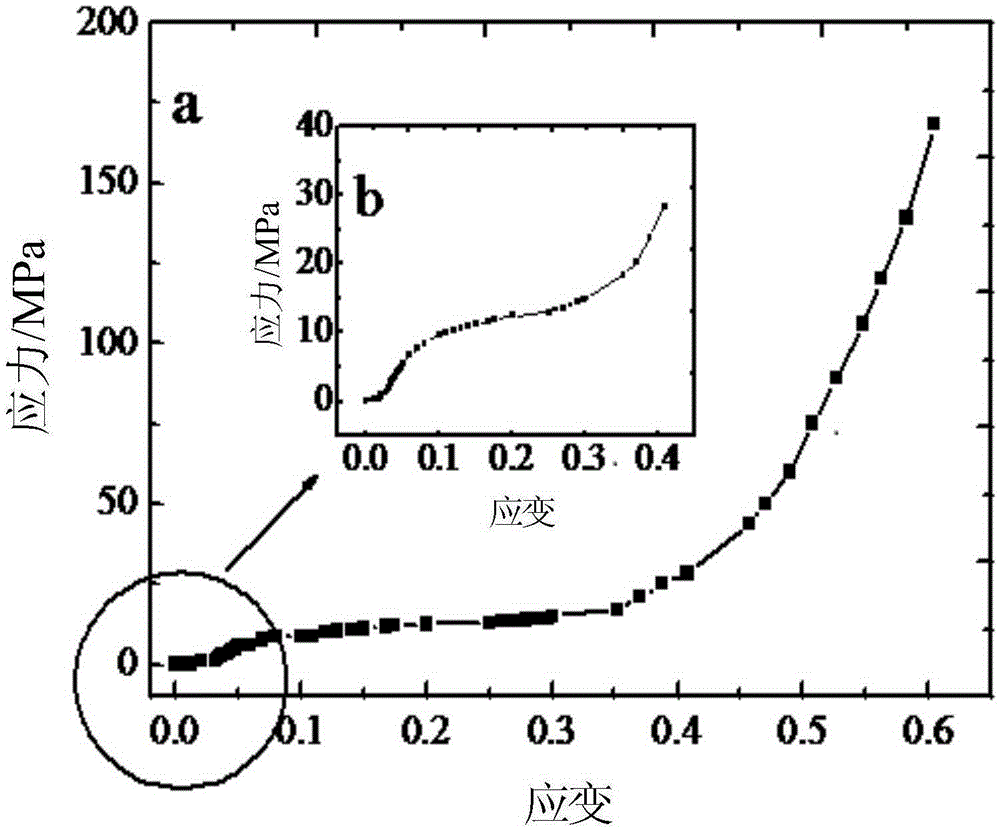

Preparation method for foaming-cement reinforced SiO2-TiO2 composite aerogel material

InactiveCN107746290AImprove high temperature insulation performanceImprove the blocking effectCeramicwareThermal insulationMolecular level

The invention relates to a preparation method for a foaming-cement reinforced SiO2-TiO2 composite aerogel material. The method comprises the following steps: firstly, preparing a silica sol and preparing a titanium sol, then compounding the above two sols, compounding foaming cement through a vacuum impregnation method, performing aging on a gel, and performing drying treatment to obtain the aerogel material. According to the invention, a synchronous sol process is used to realize mixing of a SiO2 aerogel component and a TiO2 aerogel component at the molecular level, and TiO2 is used as an opacifier to be uniformly compounded in a SiO2 aerogel system in situ, so that better shielding effects on infrared heat radiation under a high temperature are realized, and thermal insulation performance of an aerogel material under the high temperature is effectively improved; meanwhile, the foaming cement is used as a reinforcing phase to be compounded with a silicon-titanium binary aerogel, so that the defect that the aerogel material has no load-bearing capacity is overcome, and the thermal insulation effects, and especially the high temperature performance of the foaming cement material arefurther improved; and the prepared foaming-cement reinforced SiO2-TiO2 composite aerogel has a density of 0.32-0.86g / cm<3>, compressive strength of 0.56-3.62MPa, and a normal-temperature thermal conductivity coefficient of 0.038-0.146W*m<-1>*K<-1>.

Owner:NANJING UNIV OF TECH

Production process of heat-insulating breaking-resistant glass cup

InactiveCN107117795AReduce expansion and contraction deformationImprove heat stabilityGlass pressing apparatusDrinking vesselsSodium BentoniteSodium silicate

The invention relates to the field of glass cup manufacturing, in particular to a production process for heat-insulating and shatter-resistant glass cups. The raw materials required for this solution include: 10-15g of bentonite, 5-10g of polyacrylamide, 400-500g of sodium silicate powder, 5 ‑11g nano-graphite oxide, 40‑50gCaO, 30‑40gSiO2, 20‑30gSiC powder, rutile titanium dioxide powder equal to 10% of the sum of SiO2 and CaO mass, through heating and melting, extrusion molding, annealing, tempering, to obtain a Heat-insulating and shatter-resistant glass; the technical solution provided by the invention can effectively overcome the defects of the glass made in the prior art that the raw materials are poisonous and the heat insulation effect is poor, and it is worth popularizing.

Owner:安徽晶晶玻璃制品有限公司

Preparation method of silicon dioxide nanopore super thermal insulation material

InactiveCN107226710AHydroxyl activeUniform and stable dispersionCeramicwareOXALIC ACID DIHYDRATEThermal insulation

The invention discloses a preparation method of a silicon dioxide nanopore super thermal insulation material, and belongs to the technical field of heat preservation and thermal insulation materials. The preparation method is characterized in that firstly, tetraethyl orthosilicate and tetrabutyl titanate are used as raw materials; an oxalic acid solution and ammonium hydroxide are used as acid-base catalysts; after the raw materials are hydrolyzed in an absolute ethyl alcohol system, then solvent exchange and aging are performed; wet gel containing silicon dioxide and titanium dioxide is obtained; then, the dehydration condensation reaction is performed through heating by using terephthalic acid as a modifying agent and concentrated sulfuric acid as a catalyst; next, drying is performed after water washing, ethanol washing and normal hexane washing are sequentially performed; the silicon dioxide nanopore super thermal insulation material is obtained. The obtained product of the silicon dioxide nanopore super thermal insulation material disclosed by the invention has a good thermal insulation performance, an excellent mechanical performance and hydrophobicity; the use range of the silicon dioxide nanopore super thermal insulation material can be effectively expanded.

Owner:王景硕

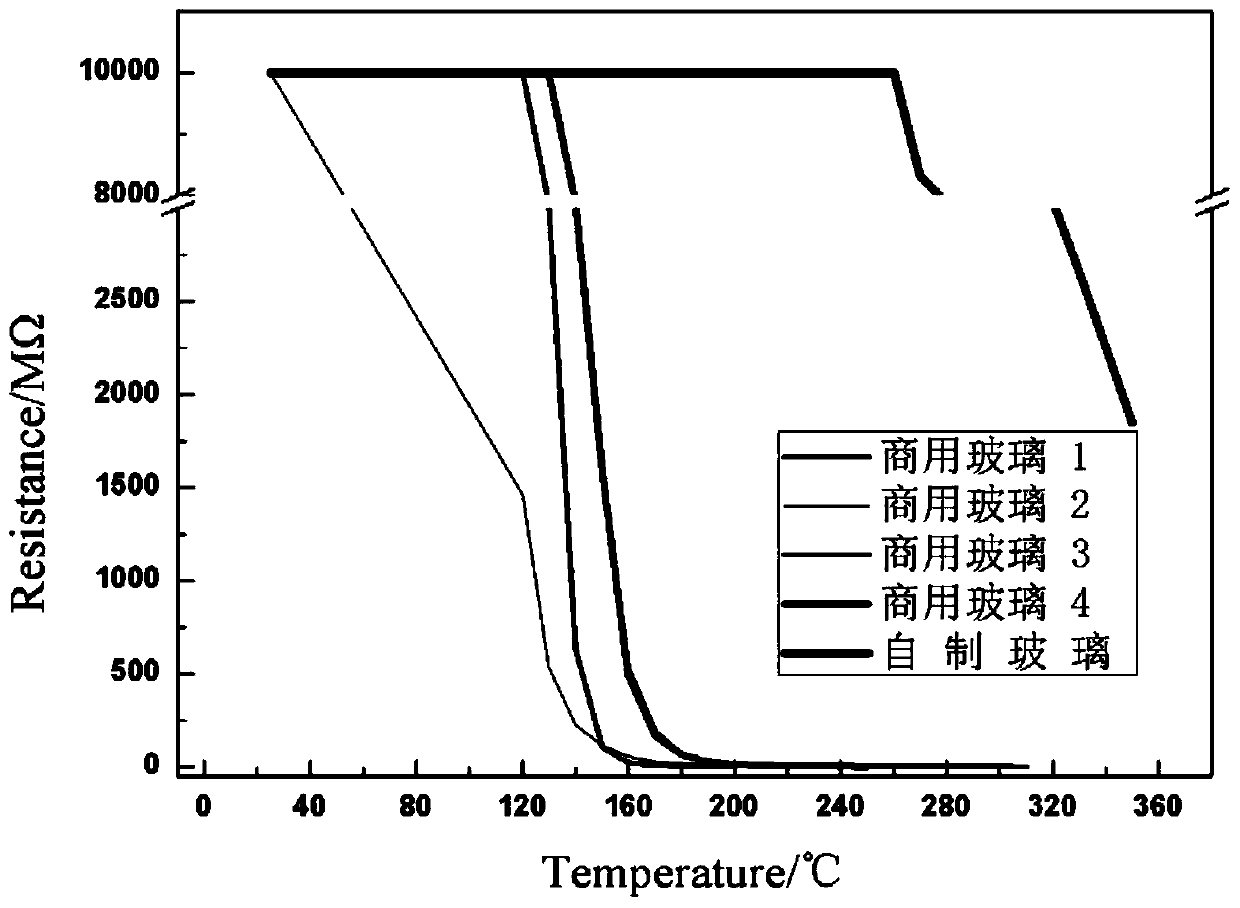

Preparation method and sealing process of sealing glass for high-temperature vibration acceleration sensor

ActiveCN114230181AGood seal matchingGood chemical stabilityGlass productionThermal dilatationVibration acceleration

The invention discloses a preparation method and a sealing process of sealing glass for a high-temperature vibration acceleration sensor, a SiO2-Al2O3-BaO-CaO system is selected, and the matching property of glass-metal sealing is changed by adding a metal oxide, carrying out controllable adjustment on glass components and improving the thermal expansion coefficient of the glass, so that the sealing performance of the glass-metal sealing is improved. Further, the high-temperature insulating property of the sealing glass is improved by adjusting the concentration of the components. According to the invention, the appearance of the sealing product is improved, the sealing process is simplified, and the consistency of the sealing product is high.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

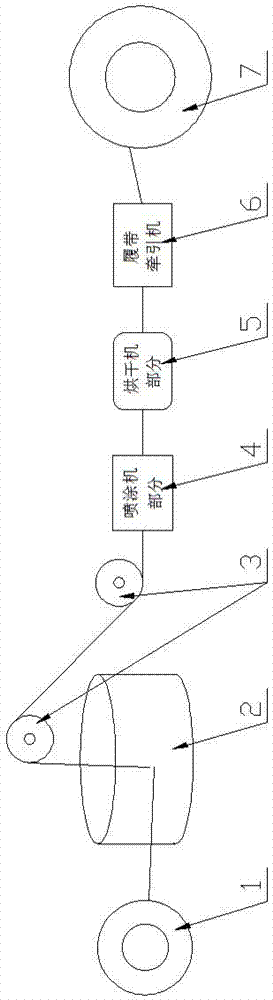

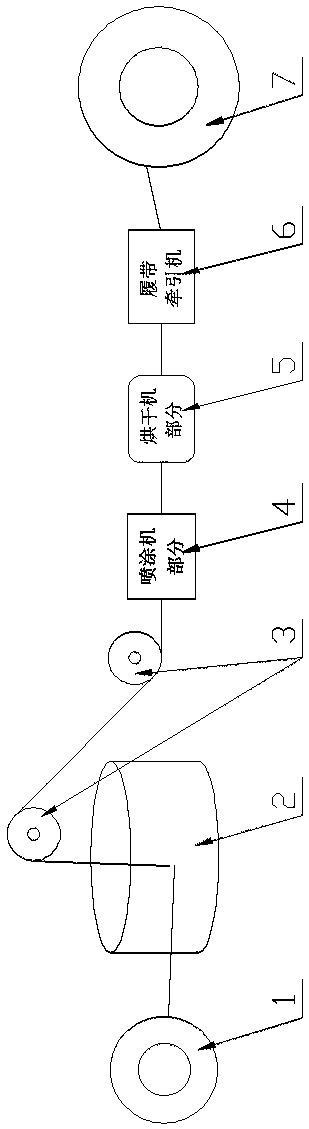

Manufacturing method of fireproof cable for multifunctional rail transit

ActiveCN107068290AImprove high temperature resistanceGood non burnInsulated cablesCable/conductor manufactureFiberAlkali free

The invention provides a manufacturing method of a fireproof cable for multifunctional rail transit, wherein the manufacturing method belongs to the technical field of wires and cables. The manufacturing method comprises a cable core manufacturing step, a cable core cabling step, and a step of combining a cable core with a housing. The cable core is obtained through cabling one functional cable or multiple functional cables. Each functional cable and / or housing at least comprises an alkali-free ceramic fiber yarn woven layer and a high-temperature-resistant nanometer coating which is arranged on the external surface of the alkali-free ceramic fiber yarn woven layer. The alkali-free ceramic fiber yarn woven layer and the high-temperature-resistant nanometer coating on the external surface form a flame-retardant protective tube. Electric conduction of the cable can be kept through function of the flame-retardant protective tube (with high temperature resistance, nonflammability and heat insulation). Signal connection can be kept by longer than three hours, thereby supplying reliable safe power, signal and the like for rescue. On the condition of the flame, the outer protective layer, the oxygen insulating layer and the insulating layer of the cable can be automatically solidified for protecting, thereby realizing fire resistance, water resistance, vibration resistance, no toxicity, environment-friendly performance, and high temperature resistance which reaches resistance to the higher temperature above 1000 DEG C. The manufacturing method can be simultaneously used in multiple fields.

Owner:山东中电通电缆科技有限公司

Vermiculite and nanometer silica composite nanometer multi-hole heat insulation plate and manufacturing method thereof

InactiveCN102503354BImprove high temperature insulation performanceImprove mechanical propertiesSilica particleThermal radiation

Owner:SUZHOU SHENGBAOLONG NEW MATERIAL TECH

A kind of thermal shock-resistant high-temperature composite insulation layer and its preparation method

InactiveCN107142477BImprove high temperature insulation performanceImprove stabilityVacuum evaporation coatingSputtering coatingThin film sensorInsulation layer

The invention belongs to the technical field of thin film sensors, and provides a thermal shock-resistant high-temperature composite insulating layer and a preparation method thereof; the composite insulating layer includes a two-layer structure, which is Al from bottom to top 2 o 3 ~ Al‑O‑N gradient layer and microcrystalline Al 2 o 3 thin film insulating layer; the Al 2 o 3 ~The bottom layer of the Al‑O‑N gradient layer is Al 2 o 3 layer, the top layer is an amorphous Al-O-N film layer, and along the film growth direction, the content of N element increases. The composite film insulating layer of the present invention can form uniform and dense coverage on different parts such as the plane, bending, and folding of special-shaped precision components, effectively improve the uniformity and high-temperature insulation performance of the insulating layer, and effectively ensure the reliability of the film sensor under high temperature conditions and stability; at the same time, the solution method is used to prepare, and the sol-gel method can easily complete the coating of larger workpieces, which is beneficial to the realization of batch production; and the sol-gel method is low in cost and easy to operate. These factors make the present invention provide Composite insulating layer has a broader application prospect.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

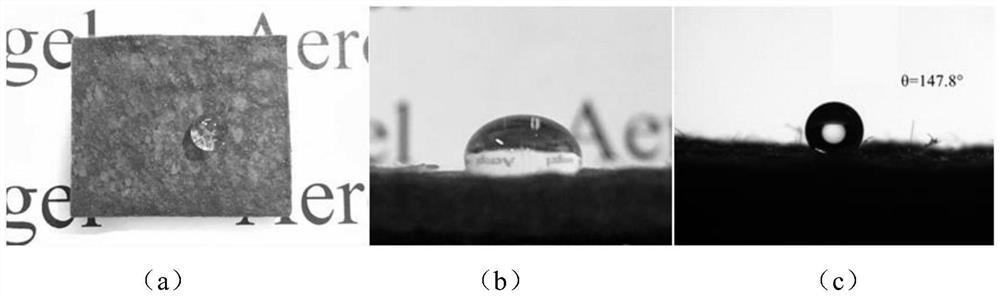

A kind of pan preoxygenated fiber felt/silica airgel composite material and preparation method thereof

The invention discloses a PAN pre-oxygen fiber felt / SiO 2 Aerogel composite material and preparation method thereof, the PAN pre-oxidized fiber felt / SiO 2 The aerogel composite material is composed of 100-120 parts by mass of PAN pre-oxygen fiber felt and 10-150 parts of SiO 2 The aerogel is prepared by a composite of two materials; among which SiO 2 Aerogel material is composed of silicon source, first auxiliary agent, sunscreen agent, chemical drying control additive, acid catalyst, basic catalyst, aging liquid, second auxiliary agent, surface hydrophobic modifier, and third auxiliary agent in parts by mass. The ratio is 25: (20‑80): (5‑30); (0.5‑10): (0.1‑10): (0.1‑10): (20‑80): (20‑80): (20‑ 80): (20-80) is obtained in preparation. PAN pre-oxygen fiber felt / SiO of the present invention 2 Aerogel felt has the advantages of excellent thermal insulation, stable chemical properties, superhydrophobicity, high toughness, high strength and long life. The invention can be widely used in the thermal insulation industry.

Owner:SHAANXI UNIV OF SCI & TECH

High temperature thermal insulation building material

InactiveCN104860589AImprove high temperature insulation performanceEasy constructionIron oxidePlasticizer

The invention discloses a high temperature thermal insulation building material, which is made from raw materials with parts by weight: acrylate 8-16 parts, talcum powder 2-4 parts, polyamide 12-23 parts, cementing materials 16-26 parts, areca sawdust 4-7 parts, mineral thermal insulation materials 15-26 parts, expanded pearl powder 6-8 parts, magnesium chloride water 14-22 parts, pthalic acid esters plasticizer 20-35 parts, nano-zinc oxide 2.5-3.6 parts, nano ferrum dioxide 3-6 parts, foam plastics 4-8 parts, calcium oxide 9-15 parts, perlite 12-28 parts and mica powder 3-5 parts. The high temperature thermal insulation building material has the beneficial effects that the high temperature thermal insulation building material enhances high temperature thermal insulation performance, is convenient to construct and has environmental protection effect.

Owner:青岛海蓝海洋复合功能材料科技有限公司

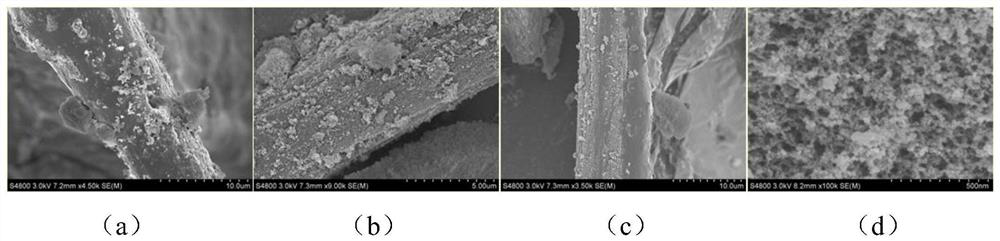

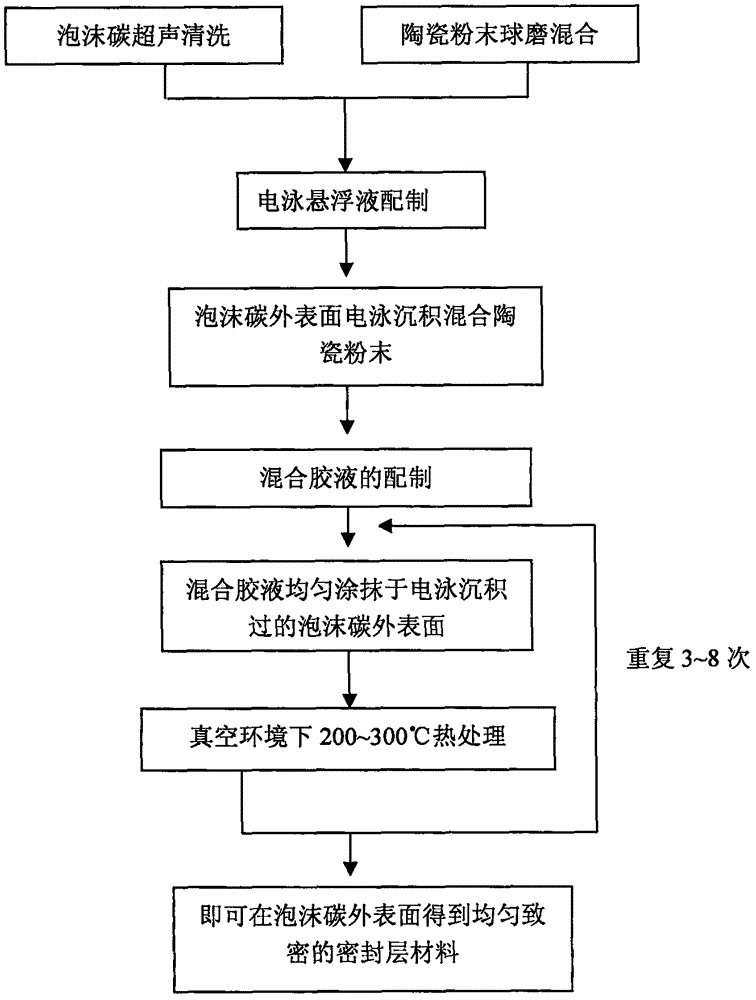

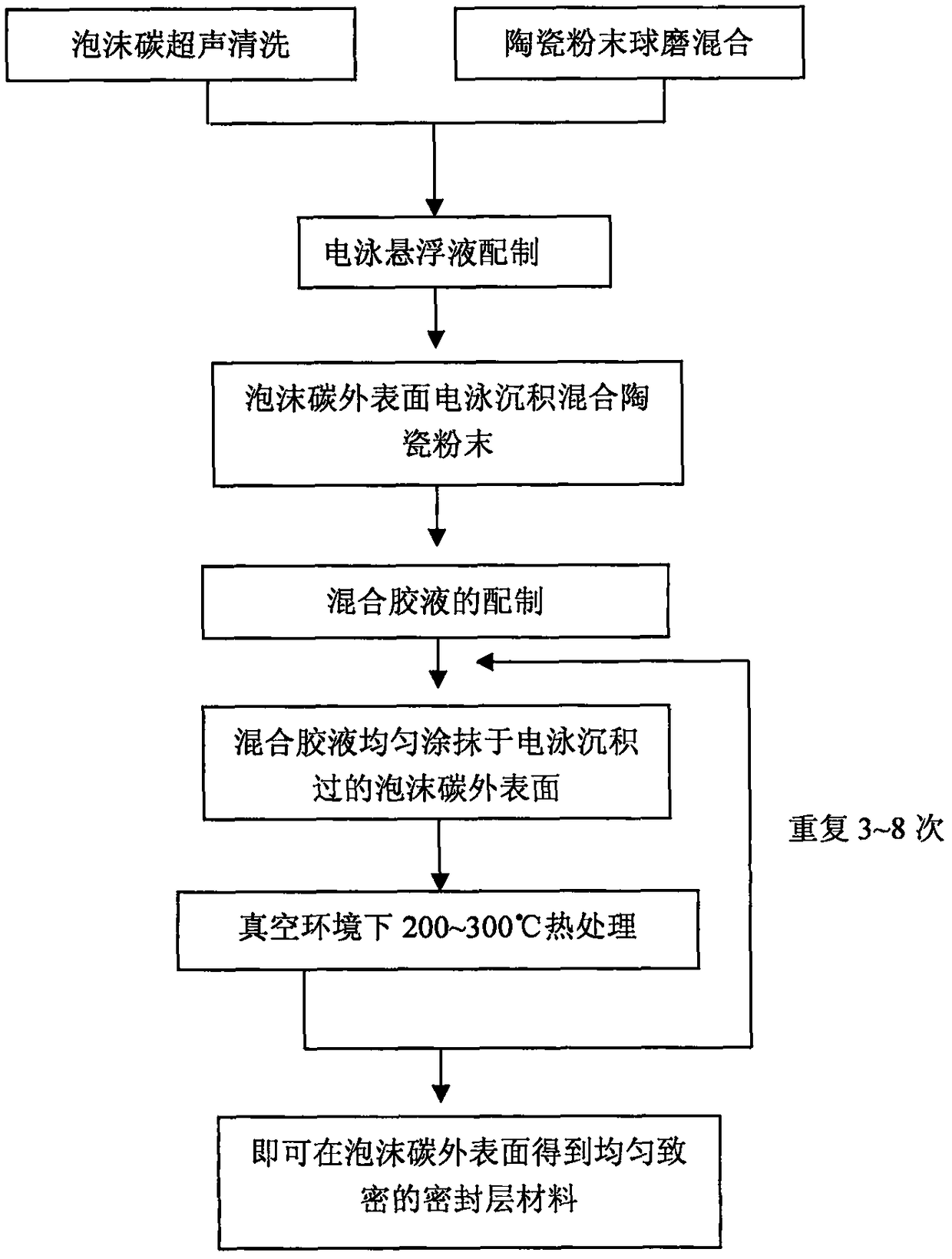

Preparation method of outer surface sealing layer of foamy carbon

ActiveCN106830995AImprove high temperature oxidation resistanceImprove high temperature insulation performanceCeramicwareAlcoholElectrophoresis

The invention relates to a preparation method of an outer surface sealing layer of foamy carbon. The preparation method is characterized by comprising the following steps: carrying out uniform ball-mill mixing on SiO2, ZrO2 and TiO2 ceramic powder in a molar ratio of 1 to (0.1-0.5) to (0-0.5), preparing suspension liquid, and depositing mixed ceramic powder on the outer surface of foamy carbon through electrophoretic deposition, wherein the concentration of mixed ceramic powder in the suspension liquid is 2g / L -10g / L; uniformly mixing a sodium polyacrylate solution, absolute ethyl alcohol and silica sol in a mass ratio of 1 to (1-5) to (10-20) to obtain mixed glue liquid, uniformly smearing the outer surface of a foamy carbon material being subjected to the electrophoretic deposition with the mixed glue liquid, carrying out thermal treatment at 200-300 DEG C in a vacuum environment, and repeatedly carrying out the step (6) for 3-8 times, so as to obtain a uniform and compact sealing layer material on the outer surface of foamy carbon. The preparation method has the advantages that (2) the sealing layer mainly consists of oxides, so that the high-temperature oxidation resistance of a composite material is improved; (2) a vacuum state is formed in the composite material, so that the high-temperature heat-insulating property of the composite material is improved; (3) the preparation temperature is low, the process is simple and rapid, and the cycle is short.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

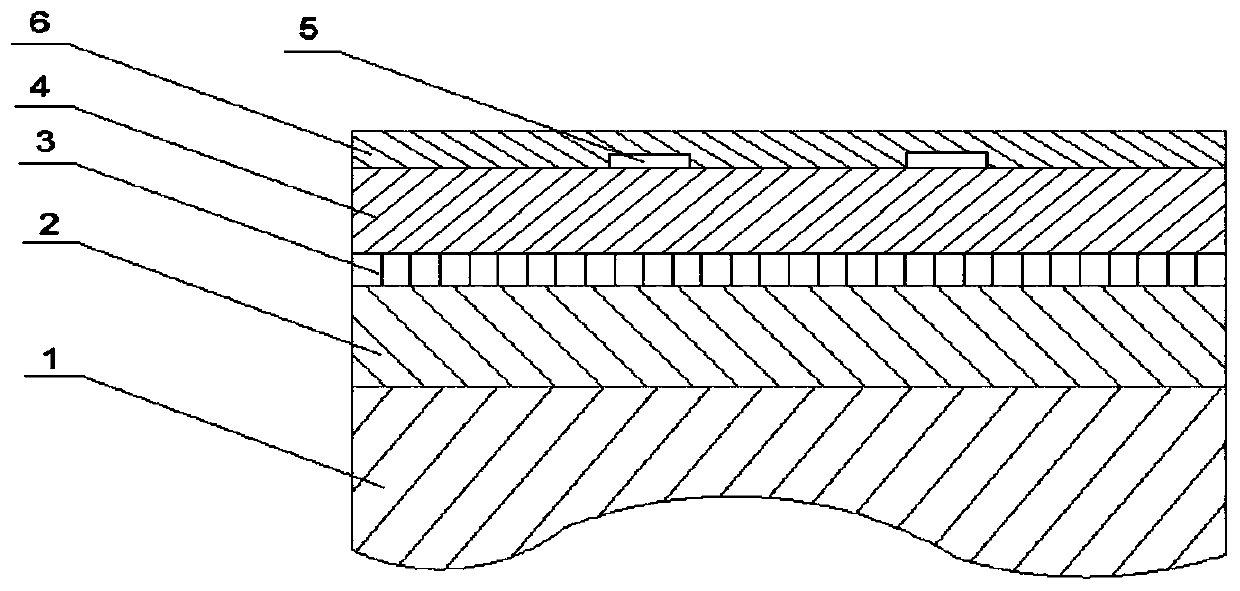

A high temperature heat insulation material for torpedo tanker tank number

The invention relates to a thermal insulation material, and specially relates to a thermal insulation material of torpedo cars for iron and steel smelting. The invention provides a high temperature thermal insulation material for tank number of torpedo cars. The high temperature thermal insulation material comprises a nano thermal insulation layer and a strengthened layer, wherein the thermal insulation material mainly comprises the following raw materials: nano silica aerogels; fibrous alkali-free superfine glass or high silica glass fiber; quartz fiber; polycrystalline mullite fiber; ceramics; aluminium oxide aerogels; hydrophobic agent; one or more of potassium hexatitanate whiskers, silicon carbide, zirconium silicate and aluminum silicate; alumina; citric acid or sodium tripolyphosphate and gypsum; and the strengthened layer is formed by reinforced resin and fiber cloth. The nano high temperature thermal insulation material prepared according to the invention has excellent thermal insulation performance, higher strength and higher integrality, is polyporous, and can keep passing ability of electronic signals to the greatest extent without shielding.

Owner:HANGZHOU QIANJIANG WEIGHING TECH

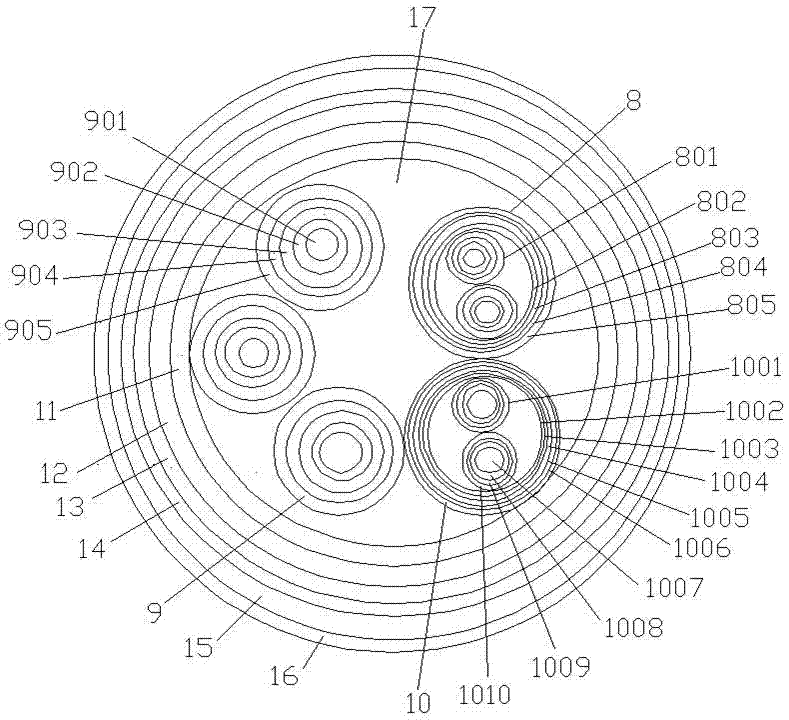

An airgel composite material for high temperature insulation

ActiveCN104177062BImprove high temperature insulation performanceIncrease temperaturePorosityOpacifier

The invention discloses a high-temperature-insulation aerogel composite material which comprises a SiO2 aerogel and doping opacifiers, wherein 3-5 opacifier doping layers are distributed inwards layer by layer from the outer surface of the SiO2 aerogel; the opacifier used by the first doping layer, which is arranged inwards from the outermost surface of the SiO2 aerogel, is carbon black with the particle size of 2.7-2.9 mu m, and the mass percent of the carbon black in the first doping layer is 42-45%; the opacifier used by the other doping layers is silicon carbide with the particle size of 2.5-3.5 mu m, and the mass percent of the silicon carbide in each doping layer is 75-85%; and from the second doping layer, the particle size of the silicon carbide doped in the layers decreases layer by layer, and the mass percent of the silicon carbide in the current doping layer increases. The high-temperature-insulation aerogel composite material still has higher porosity and larger specific area at 1200 DEG C, and is still available at 1200 DEG C, thereby further enhancing the application temperature of the SiO2-doped aerogel composite material.

Owner:浙江格洋新材料股份有限公司

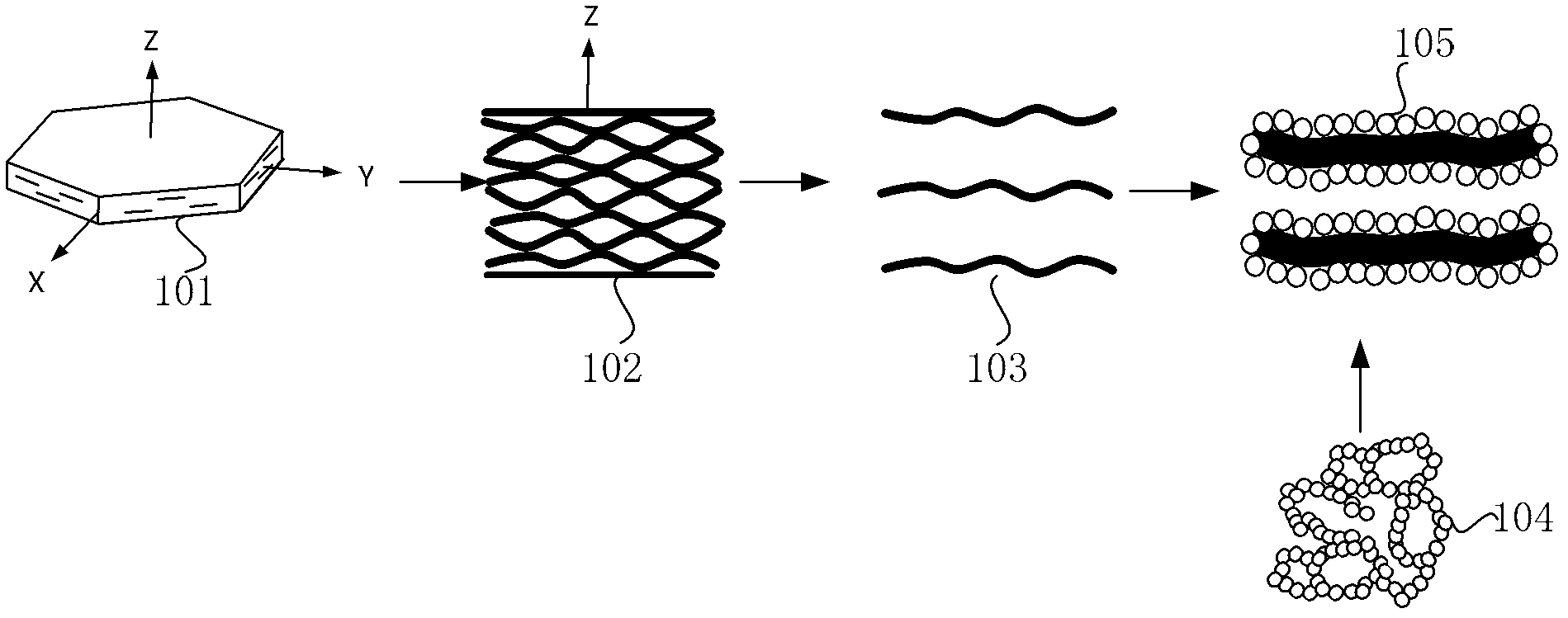

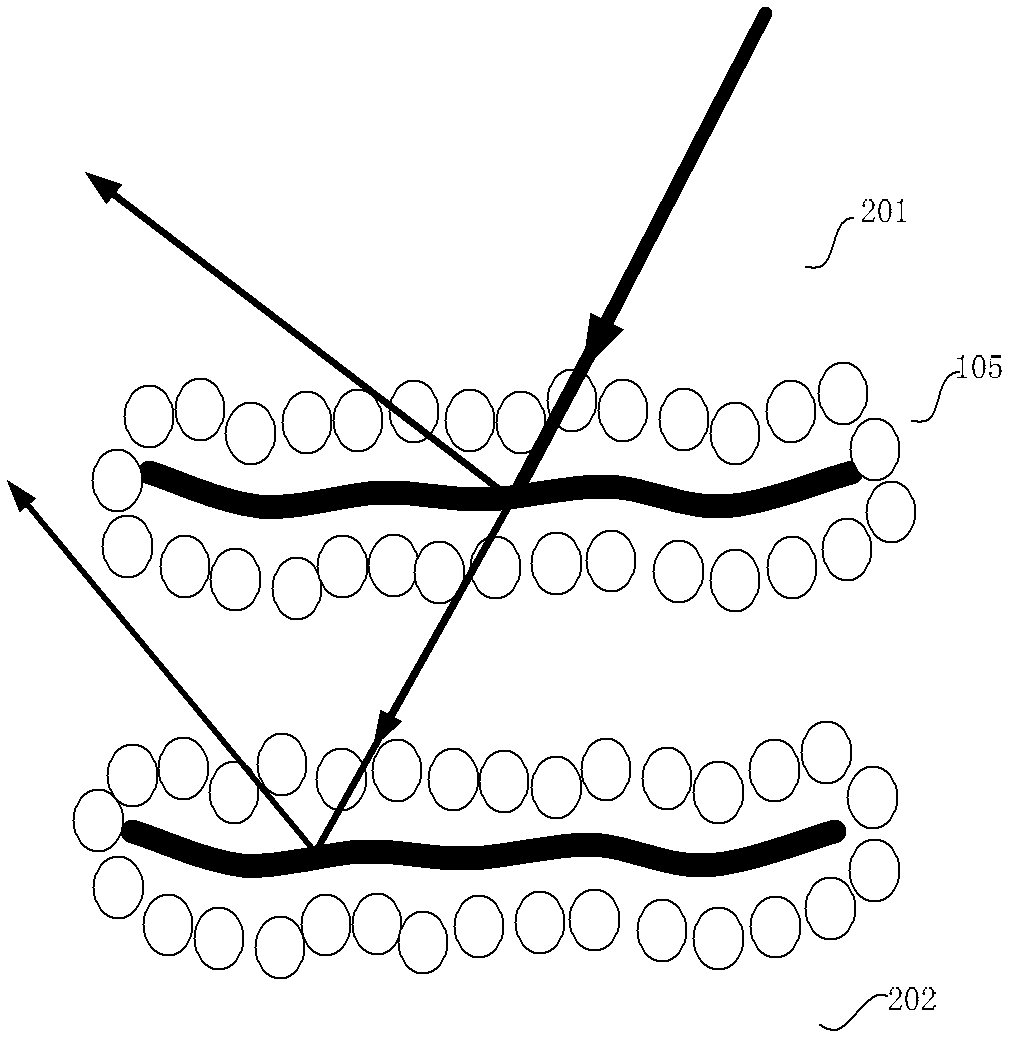

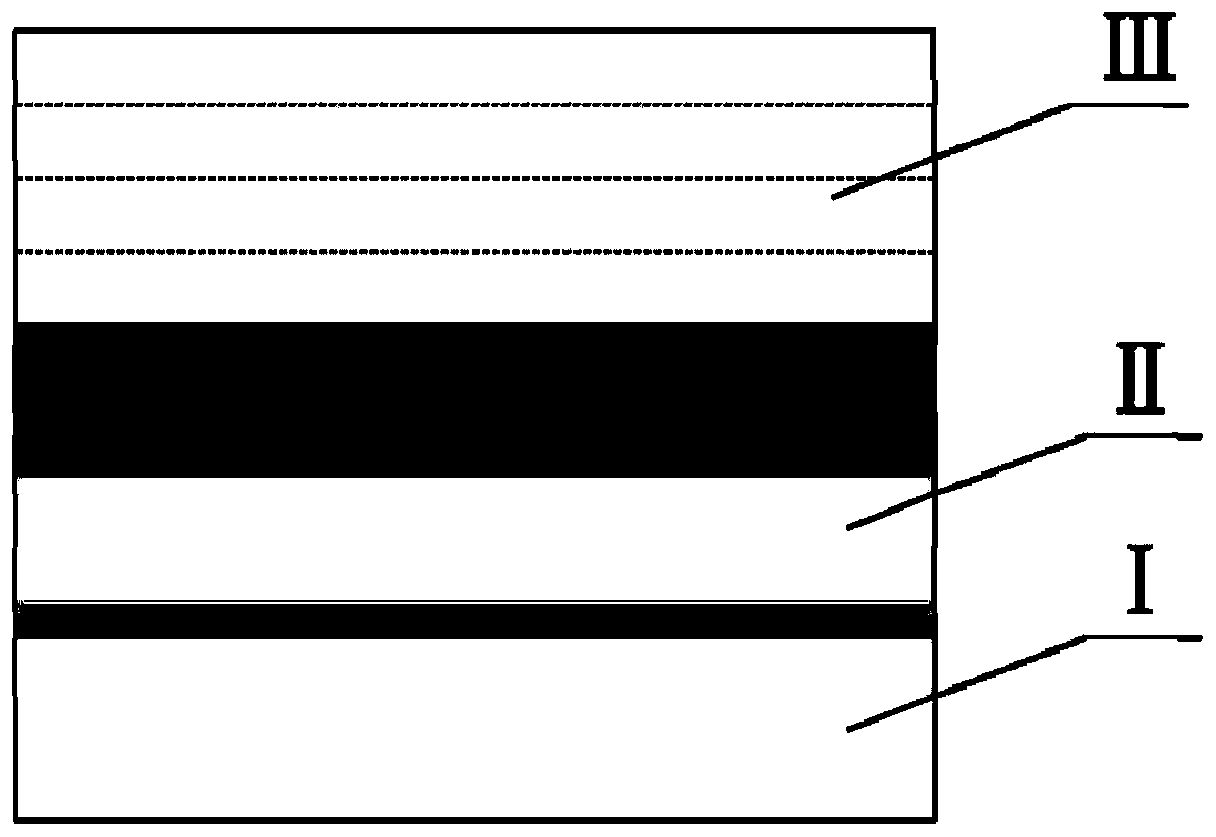

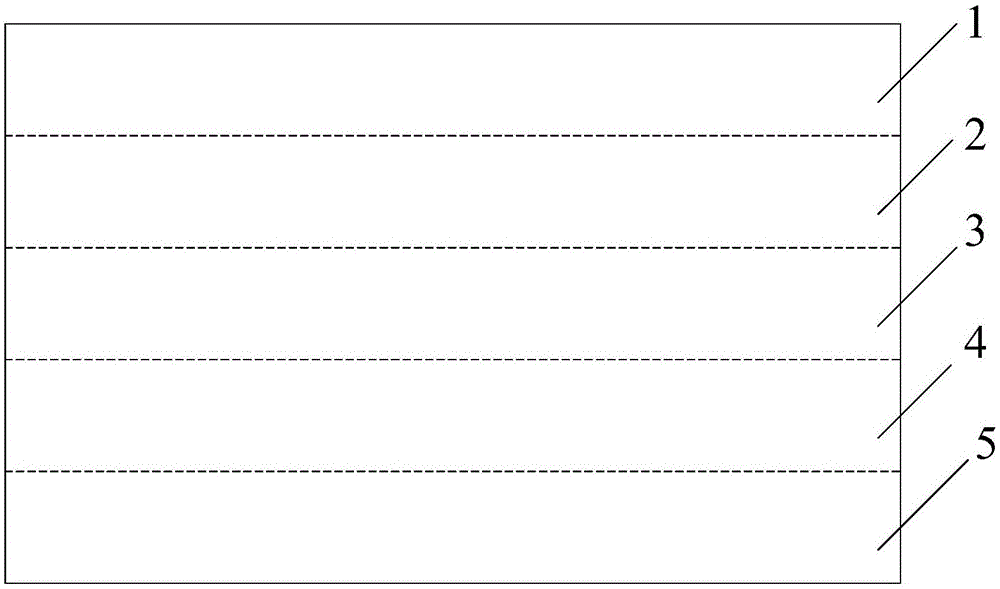

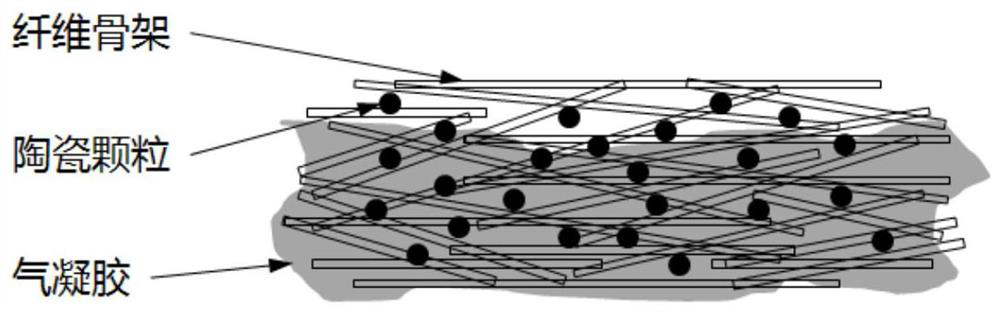

A high-temperature-resistant, heat-insulating, wave-transmitting functional integrated composite material and its preparation method

The invention relates to a high-temperature-resistant, heat-insulating and wave-transmitting function integrated composite material and a preparation method thereof, belonging to the technical field of inorganic materials. The prepared high-temperature-resistant, heat-insulating and wave-transmitting material has high temperature resistance, high strength, low thermal conductivity, and transparent The characteristics of good wave performance. The high-temperature-resistant, heat-insulating and wave-transmitting function integrated composite material composite material obtained in the present invention has a multi-layer structure in the thickness direction, the high-temperature layer is a fiber skeleton and ceramic particles, and the low-temperature layer is a fiber skeleton, ceramic particles and airgel, and each layer The thickness can be determined according to specific design requirements.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Sio with polymer modification and carbon nanofiber doping 2 Airgel and its preparation method

ActiveCN105236426BReduce internal defectsImprove high temperature insulation performanceSilicaFiberPolymer modified

Owner:PETROCHINA CO LTD

Method for preparing nano composite low melting point glass insulation coating

The process of preparing nanometer composite insulating low smelting point glass coating includes the following steps: 1. preparing mixed slurry through mixing low smelting point SiO2-B2O3 glass powder, nanometer ceramic powder, two or more of sodium silicate, silica sol, methyl cellulose and polyethylene glycol, and water in the weight ratio of 100 to 5-60 to 1-30 to 200-400 and ball milling for 5-10hr; 2. coating the slurry onto substrate, drying at 80-120 deg.c for 10-30 min, and heat treatment first at 350-450 deg.c for 30-60 and then at 500-700 deg.c for 5-30 min; and 3. repeating the step 2 by 3-10 times to prepare the nanometer composite insulating low smelting point glass coating. The preparation process has low cost and no environmental pollution, and the coating has relatively high heat expansion coefficient matching the metal substrate and excellent high temperature insulating performance.

Owner:宁波材料技术与工程研究所

Ceramic fiber wood plastic and manufacturing method thereof

The invention discloses a ceramic fiber wood plastic comprising in parts by weight: 35-60 parts of plant fibers, 15-20 parts of ceramic fibers, 10-15 parts of porous ceramic particles, 15-18 parts ofa thermoplastic resin, 5-7 parts of glass fibers, 3-5 parts of a flame retardant, 3-7 parts of a surface modifier, 2-4 parts of a stabilizer, 2-5 parts of a foaming agent, 1-3 parts of a foaming regulator and 1 part of a coupling agent. The beneficial effects are that: by utilizing the advantages of ceramic fibers, wood-plastic products containing the ceramic fiber component are excellent refractory materials; the heat insulation performance and the high-temperature heat insulation performance are good; the use safety is improved and the service life is prolonged; echo absorption and elimination performance of porous ceramic particles is achieved, the sound absorption and insulation performance of the wood-plastic products is improved, the suitable range is wider; at the same time, glass fiber material possesses excellent radiation resistance, so that the wood-plastic products possess radiation resistance; the advantages of simple and feasible process, convenient operation and control,easy realization of batch production, energy saving and environmental protection are achieved.

Owner:沈阳科洛环保科技有限公司

A kind of manufacturing method of fireproof cable for multifunctional rail transit

ActiveCN107068290BImprove high temperature resistanceGood non burnInsulated cablesCable/conductor manufactureYarnFiber

The invention provides a manufacturing method of a fireproof cable for multifunctional rail transit, wherein the manufacturing method belongs to the technical field of wires and cables. The manufacturing method comprises a cable core manufacturing step, a cable core cabling step, and a step of combining a cable core with a housing. The cable core is obtained through cabling one functional cable or multiple functional cables. Each functional cable and / or housing at least comprises an alkali-free ceramic fiber yarn woven layer and a high-temperature-resistant nanometer coating which is arranged on the external surface of the alkali-free ceramic fiber yarn woven layer. The alkali-free ceramic fiber yarn woven layer and the high-temperature-resistant nanometer coating on the external surface form a flame-retardant protective tube. Electric conduction of the cable can be kept through function of the flame-retardant protective tube (with high temperature resistance, nonflammability and heat insulation). Signal connection can be kept by longer than three hours, thereby supplying reliable safe power, signal and the like for rescue. On the condition of the flame, the outer protective layer, the oxygen insulating layer and the insulating layer of the cable can be automatically solidified for protecting, thereby realizing fire resistance, water resistance, vibration resistance, no toxicity, environment-friendly performance, and high temperature resistance which reaches resistance to the higher temperature above 1000 DEG C. The manufacturing method can be simultaneously used in multiple fields.

Owner:山东中电通电缆科技有限公司

High insulation resistance high temperature resistant ceramic rubber for heating cables and preparation method thereof

ActiveCN105968820BHigh mechanical strengthImprove high temperature insulation performanceRubber insulatorsSilicone rubberRaw material

Owner:沈兴线缆集团有限公司 +2

A kind of preparation method of foamed carbon outer surface sealing layer

ActiveCN106830995BImprove high temperature oxidation resistanceImprove high temperature insulation performanceCeramicwareAlcoholElectrophoresis

The invention relates to a preparation method of an outer surface sealing layer of foamy carbon. The preparation method is characterized by comprising the following steps: carrying out uniform ball-mill mixing on SiO2, ZrO2 and TiO2 ceramic powder in a molar ratio of 1 to (0.1-0.5) to (0-0.5), preparing suspension liquid, and depositing mixed ceramic powder on the outer surface of foamy carbon through electrophoretic deposition, wherein the concentration of mixed ceramic powder in the suspension liquid is 2g / L -10g / L; uniformly mixing a sodium polyacrylate solution, absolute ethyl alcohol and silica sol in a mass ratio of 1 to (1-5) to (10-20) to obtain mixed glue liquid, uniformly smearing the outer surface of a foamy carbon material being subjected to the electrophoretic deposition with the mixed glue liquid, carrying out thermal treatment at 200-300 DEG C in a vacuum environment, and repeatedly carrying out the step (6) for 3-8 times, so as to obtain a uniform and compact sealing layer material on the outer surface of foamy carbon. The preparation method has the advantages that (2) the sealing layer mainly consists of oxides, so that the high-temperature oxidation resistance of a composite material is improved; (2) a vacuum state is formed in the composite material, so that the high-temperature heat-insulating property of the composite material is improved; (3) the preparation temperature is low, the process is simple and rapid, and the cycle is short.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

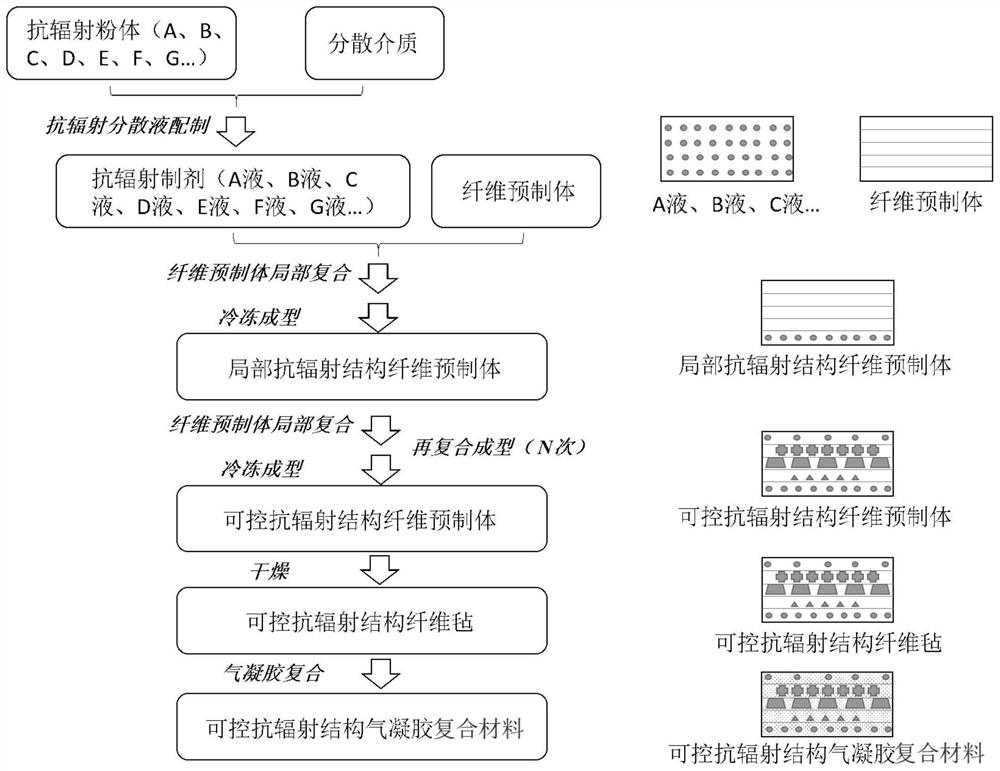

A controllable structure heat insulation material and its preparation method

ActiveCN112522852BImprove performanceRadiation Efficiency MaximizationFibre treatmentNon-woven fabricsInfraredFiber

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A kind of sealing glass powder for electric connector and its preparation method and sealing process

ActiveCN105859144BStable structureImprove high temperature insulation performanceContact member assembly/disassemblyPhysical chemistryNetwork structure

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com