Inlaid plate-shaped oxygen sensor and preparation method thereof

An oxygen sensor and mosaic technology, applied in the field of mosaic plate oxygen sensor and its preparation, can solve the problems of high material cost, slow response speed, complex structure, etc., so as to improve high temperature insulation performance, prolong service life and reduce energy. consumption and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a mosaic plate-shaped oxygen sensor, the preparation method comprising the following steps:

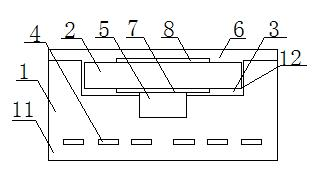

[0030] 1. The ceramic heater 1 is based on sintered and dense 95 alumina ceramics, and a groove 12 is opened on the surface of the alumina substrate 11, such as Figure 4 shown;

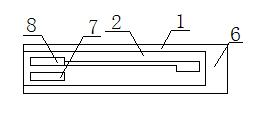

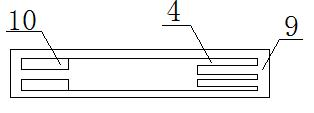

[0031] 2. Print the heating circuit 4 on the lower surface of the aluminum oxide substrate 11 with grooves 12 using a thick film screen printing process, print the glass glaze insulating layer 9 on the front of the heating circuit 4, and expose the rear to form two heating circuit pins 10, and then sintered in the air at 1200°C, and after cooling in the furnace, the heating circuit 4, the glass glaze insulating layer 9 and the alumina substrate 11 are tightly combined to form a whole, as in figure 2 shown;

[0032] 3. The zirconia sensitive element 2 is a strip-shaped sheet made of sintered dense 5-mole yttrium-stabilized zirconia as a matrix, and the thickness of the sheet i...

Embodiment

[0041] 1. Preparation of glass glaze powder: Accurately weigh each material according to the weight ratio of alumina: zirconia: silicon oxide: lithium oxide: bismuth oxide: zinc oxide = 29:27:32:4:5:3, add 50% water, using zirconia balls as the grinding medium, using a stirring ball mill for 2 hours, and forced drying after taking it out. The dried material powder is placed in a corundum crucible and melted at a high temperature of 1400°C. The molten glass is quenched by water to make a larger glass powder. The large glass powder is then ground by stirring and ball milling. The particle size of glass glaze powder is 1.5-2.5 microns;

[0042] 2. Preparation of organic solution: the organic solution material is a transparent viscous solution, composed of terpineol, polyvinyl butyral PVB and castor oil, according to the weight ratio terpineol: polyvinyl butyral PVB: castor oil The ratio of 79:15:6 is formulated into a viscous transparent solution, and its viscosity is 5000-6000m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com