High insulation resistance refractory ceramic rubber for heating cable and preparing method thereof

A technology of high-temperature-resistant ceramics and heating cables, which is applied in the field of ceramic rubber, can solve problems such as the downhole oil temperature is not reached, insulation wrapping is not moisture-proof and easy to break down, etc., achieves good moisture-proof insulation effect, improves mechanical properties and insulation performance, and high Effect of Insulation Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

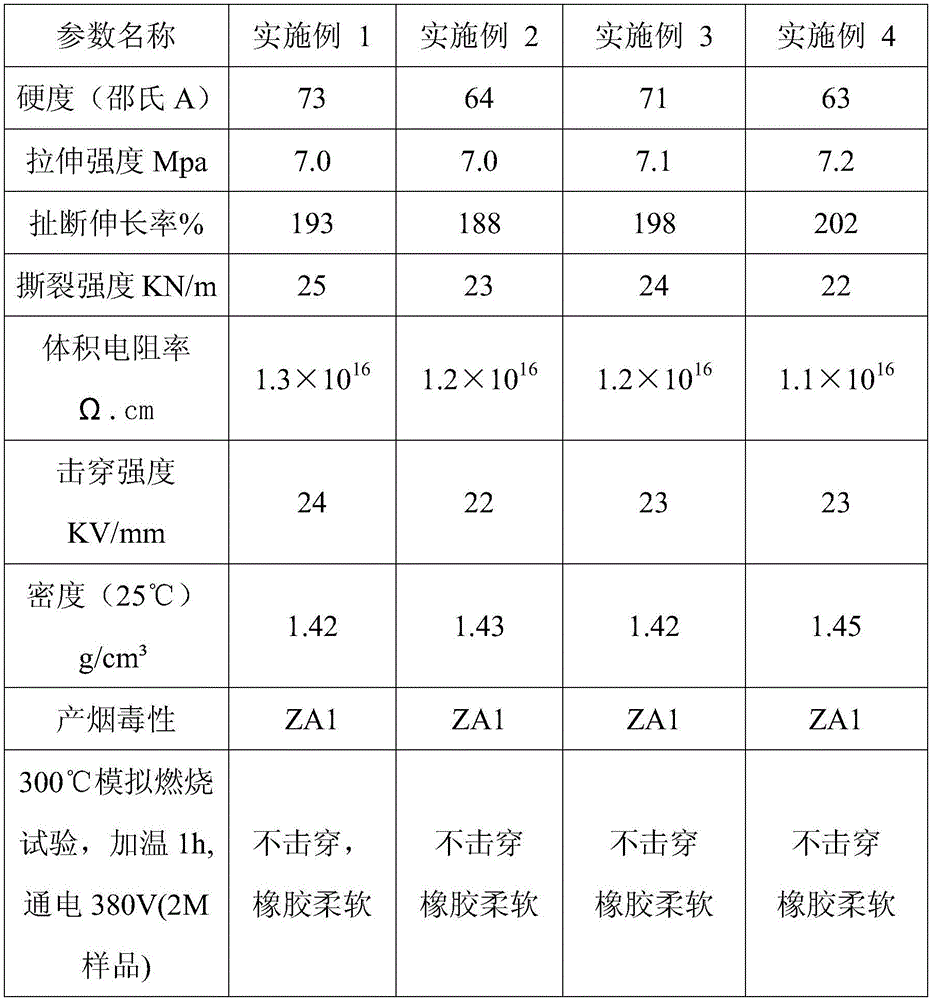

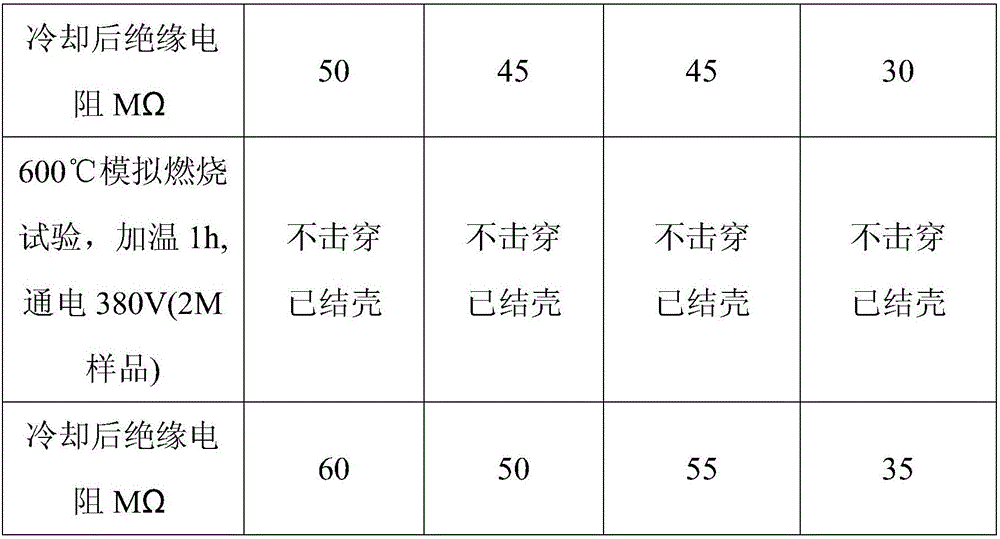

Examples

Embodiment 1

[0023] The invention relates to a high-insulation-resistance and high-temperature-resistant ceramic rubber for heating cables, the main components of which are as follows in parts by weight: 40 kg of silicon rubber, 25 kg of ceramic powder, 15 kg of glass powder, 10 kg of quartz powder, and mica powder 8 kg, 10 kg of fumed white carbon black, 0.5 kg of coupling agent, 5 kg of softener, and 0.8 kg of bis-pentasulfurizing agent.

[0024] The silicone rubber is preferably methyl silicone rubber, with a Mooney viscosity ML(1+4) of 30-35 at 180° C. and an ethylene content of 63%. Its function is as the main material, which has the characteristics of low temperature resistance of -50°C and high temperature of 180°C, and does not produce carbides at high temperatures above 300°C, so as to achieve the cable performance required by the present invention.

[0025] The ceramic powder has a particle size of 3000 mesh and a temperature resistance of 1200°C. The ceramic powder mainly plays...

Embodiment 2

[0033] The invention relates to a high-insulation-resistance and high-temperature-resistant ceramic rubber for heating cables, the main components of which are as follows in parts by weight: 45 kg of silicon rubber, 20 kg of ceramic powder, 20 kg of glass powder, 5 kg of quartz powder, and mica powder 10 kg, 5 kg of fumed white carbon black, 1 kg of coupling agent, 2 kg of softener, and 1 kg of bis-pentasulfurizing agent.

[0034] The silicone rubber is preferably methyl silicone rubber, with a Mooney viscosity ML(1+4) of 30-35 at 180° C. and an ethylene content of 63%. Its function is as the main material, which has the characteristics of low temperature resistance of -50°C and high temperature of 180°C, and does not produce carbides at high temperatures above 300°C, so as to achieve the cable performance required by the present invention.

[0035] The ceramic powder has a particle size of 3000 mesh and a temperature resistance of 1200°C. The ceramic powder mainly plays the ...

Embodiment 3

[0043] The invention relates to a high-insulation-resistance and high-temperature-resistant ceramic rubber for heating cables, the main components of which are as follows in parts by weight: 40 kg of silicon rubber, 25 kg of ceramic powder, 15 kg of glass powder, 10 kg of quartz powder, and mica powder 8 kg, 10 kg of fumed white carbon black, 0.5 kg of coupling agent, 5 kg of softener, 0.8 kg of bis-pentasulfurizing agent, 3 kg of anti-aging agent and 2 kg of active agent.

[0044] The silicone rubber is preferably methyl silicone rubber, with a Mooney viscosity ML(1+4) of 30-35 at 180° C. and an ethylene content of 63%. Its function is as the main material, which has the characteristics of low temperature resistance of -50°C and high temperature of 180°C, and does not produce carbides at high temperatures above 300°C, so as to achieve the cable performance required by the present invention.

[0045] The ceramic powder has a particle size of 3000 mesh and a temperature resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com