A kind of thermal shock-resistant high-temperature composite insulation layer and its preparation method

A technology of composite insulation and thermal shock resistance, applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problems of inability to form a uniform and dense insulating layer, unsatisfactory actual effect, and high energy of metal atoms, and achieve The composite insulation layer is uniform and dense, avoiding cracking and falling off, and improving the effect of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the drawings and embodiments

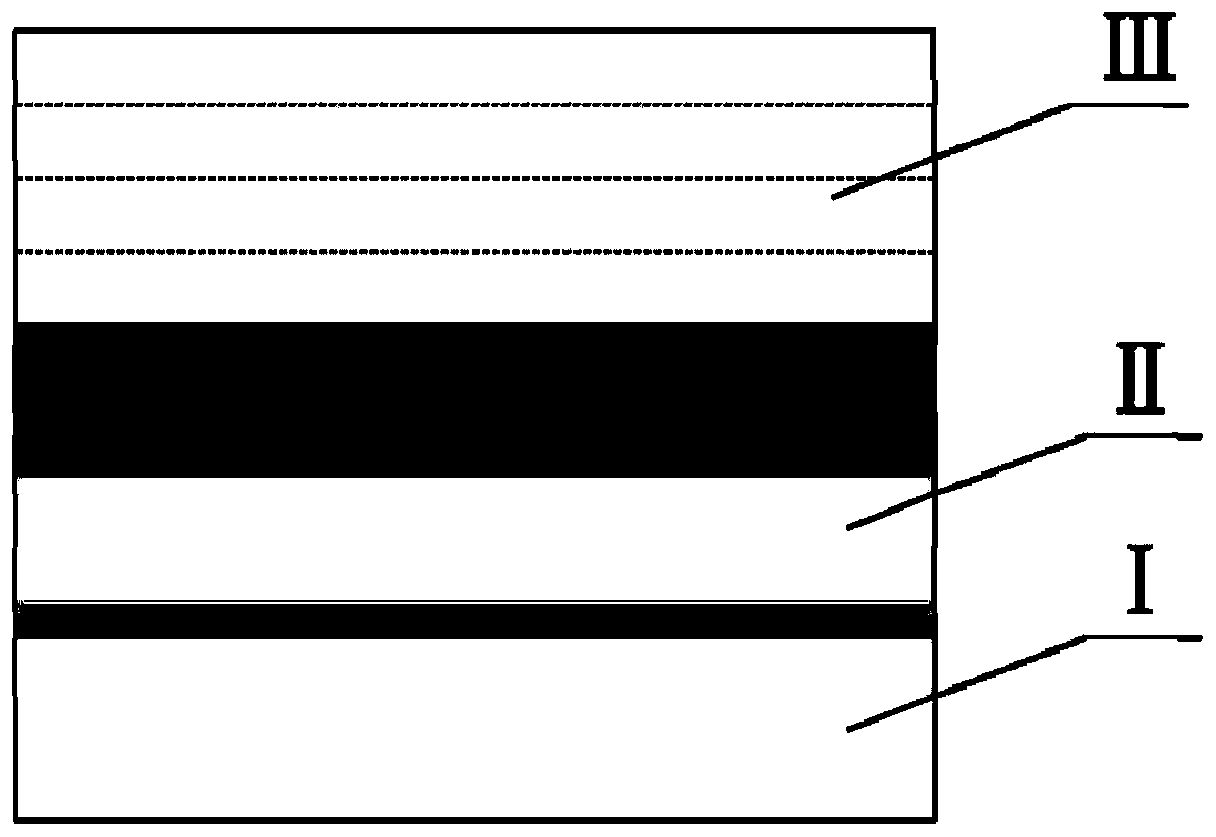

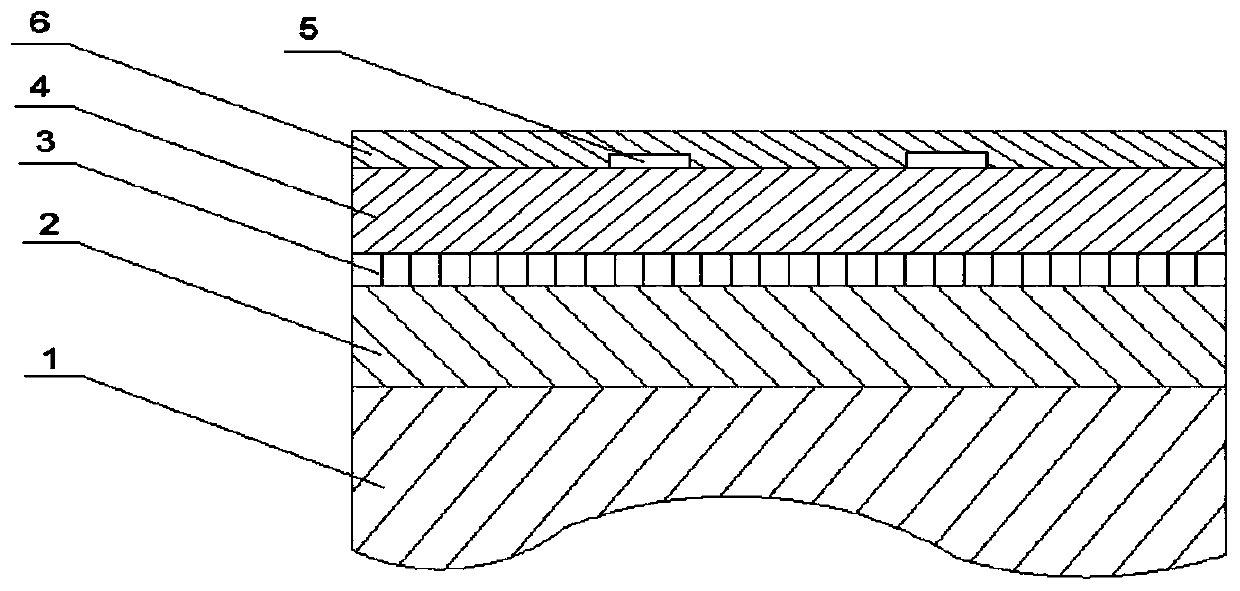

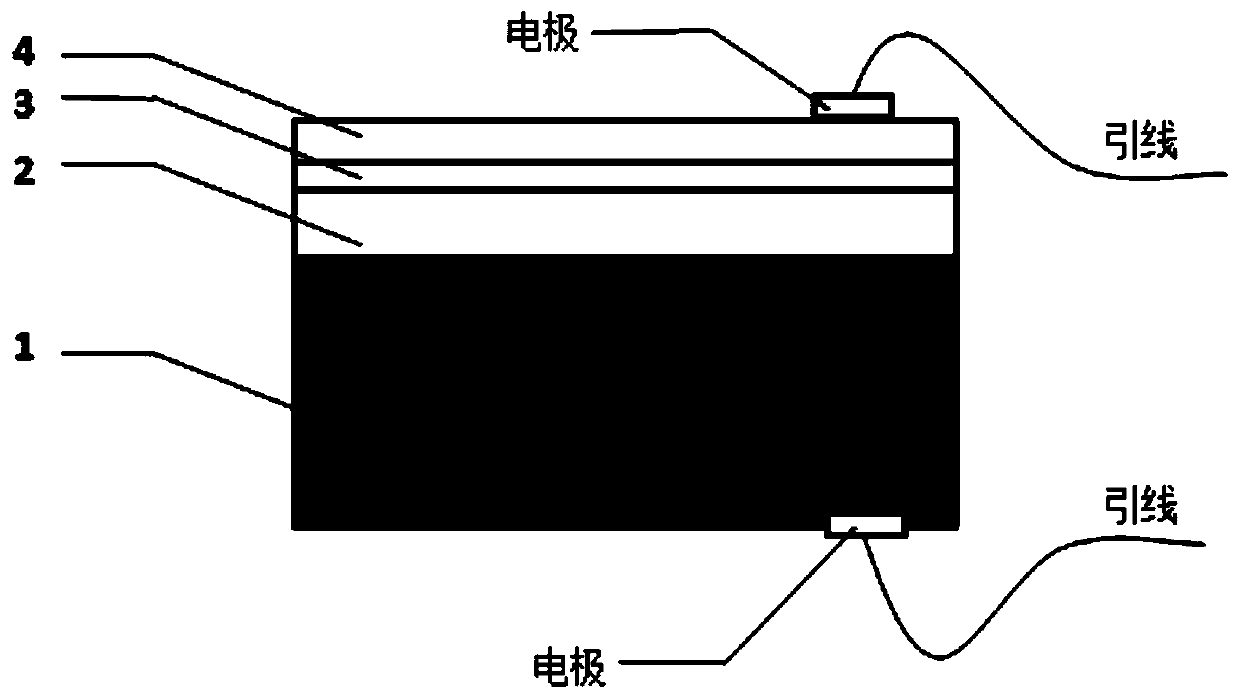

[0023] The invention provides a high-temperature composite insulating layer resistant to thermal shock, such as figure 1 As shown, it includes a two-layer structure, with Al from bottom to top 2 O 3 ~Al-O-N gradient layer and microcrystalline Al 2 O 3 Thin film insulating layer; the Al 2 O 3 ~The bottom layer of the Al-O-N gradient layer is Al 2 O 3 The top layer is an amorphous Al-O-N film layer, and the N element content increases along the film growth direction. The thin film sensor using the composite insulating layer includes a six-layer structure, such as figure 2 As shown, from bottom to top, alloy substrate 1, NiCrAlY alloy transition layer 2, thermally grown Al 2 O 3 Layer 3, composite insulating layer 4, sensitive functional layer 5 and Al 2 O 3 Protective layer 6; the preparation method of the thin-film sensor includes the following steps:

[0024] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com