Preparation method of outer surface sealing layer of foamy carbon

A carbon foam and outer surface technology, which is applied to ceramic products, other household utensils, household utensils, etc., can solve the problems of the stability of foam carbon materials in high-temperature aerobic environments, reduce the thermal conductivity of composite materials, etc., and achieve high temperature resistance. Effects of oxidation ability, short cycle time and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

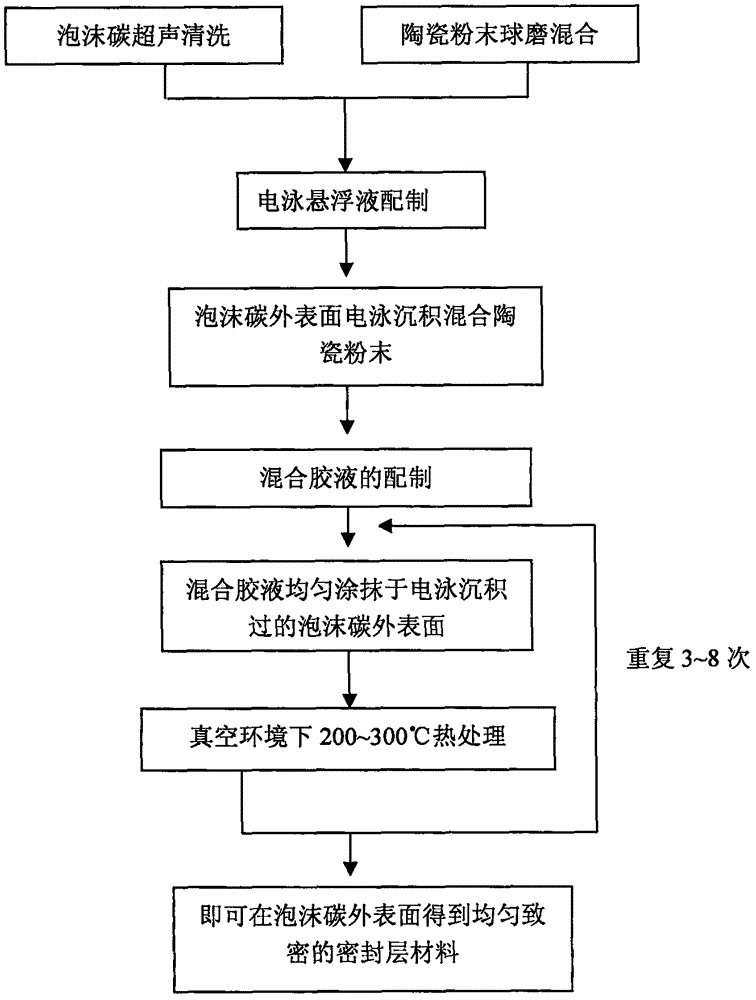

Method used

Image

Examples

Embodiment 1

[0018] Doped TiO on the outer surface of carbon foam 2 Preparation method of sealing layer:

[0019] (1) Immerse the carbon foam in absolute ethanol, clean it with ultrasonic vibration for 20 minutes, take it out and dry it in an oven at 110°C for later use;

[0020] (2) SiO 2 , ZrO 2 、TiO 2 The ceramic powder is mixed evenly by ball milling according to the molar ratio of 1:0.5:0.5, the ball milling speed is 500r / min, and the ball milling time is 24h;

[0021] (3) Magnesium chloride hexahydrate is added in the mixed powder that step (2) obtains, magnesium chloride hexahydrate: mixed powder=1: 10, after mixing according to mass ratio, join in the organic solvent and be made into suspension, in the suspension The solid-liquid concentration is 5g / L, and the organic solvent can choose absolute ethanol and acetone;

[0022] (4) the carbon foam of step (1) is used as the negative electrode, and graphite is used as the positive electrode material, and the mixed ceramic powder i...

Embodiment 2

[0027] The outer surface of carbon foam is not doped with TiO 2 Preparation method of sealing layer:

[0028] (1) Immerse the carbon foam in absolute ethanol, clean it with ultrasonic vibration for 30 minutes, take it out and dry it in an oven at 100°C for later use;

[0029] (2) SiO 2 , ZrO 2 、TiO 2 The ceramic powder is mixed evenly by ball milling according to the molar ratio of 1:0.5:0, the ball milling speed is 500r / min, and the ball milling time is 24h;

[0030] (3) Magnesium chloride hexahydrate is added in the mixed powder that step (2) obtains, magnesium chloride hexahydrate: mixed powder=1: 10, after mixing according to mass ratio, join in the organic solvent and be made into suspension, in the suspension The solid-liquid concentration is 5g / L, and the organic solvent can choose absolute ethanol and acetone;

[0031] (4) the carbon foam of step (1) is used as the negative electrode, and graphite is used as the positive electrode material, and the mixed ceramic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com