Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Improve graphics quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

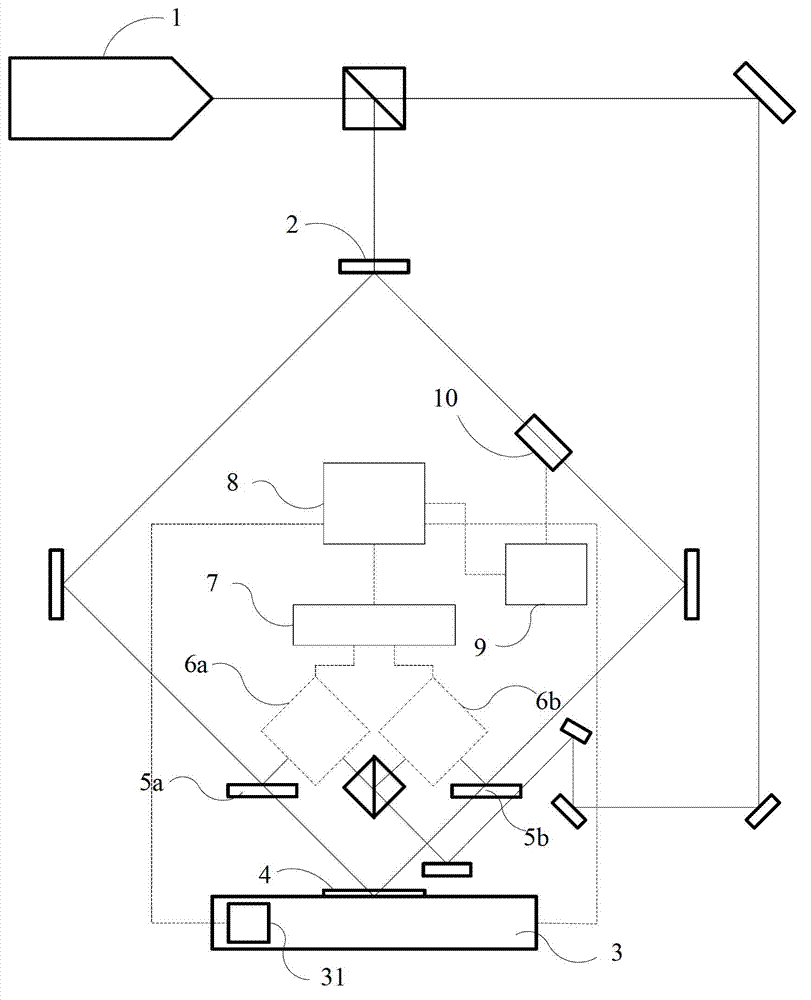

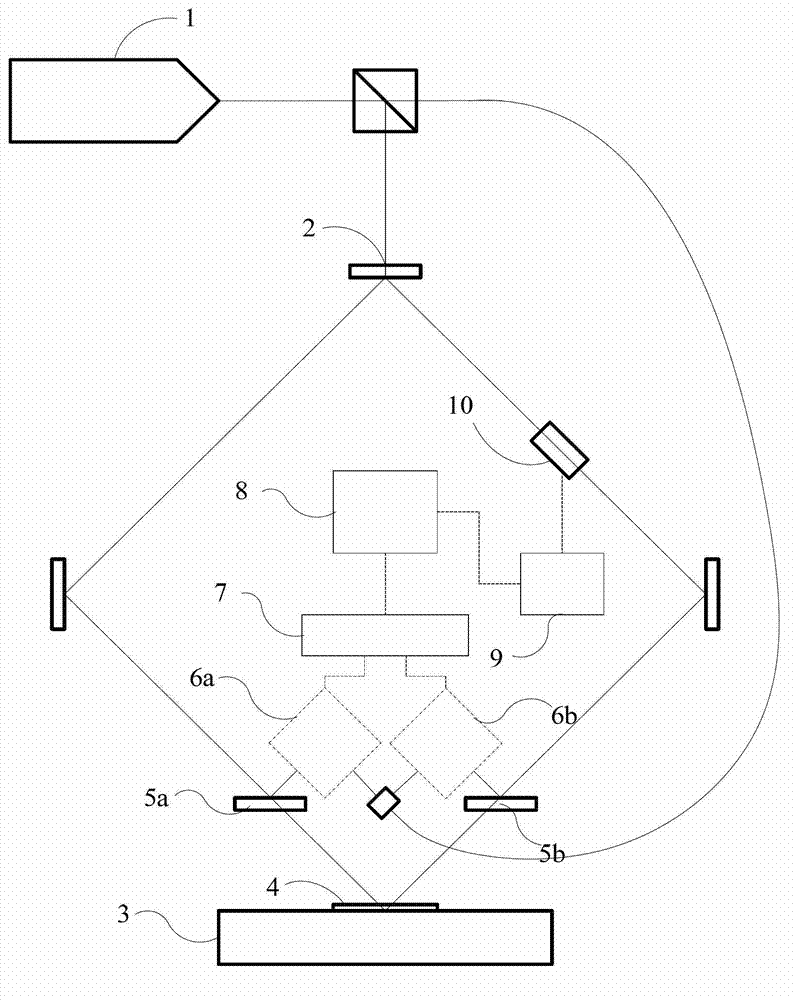

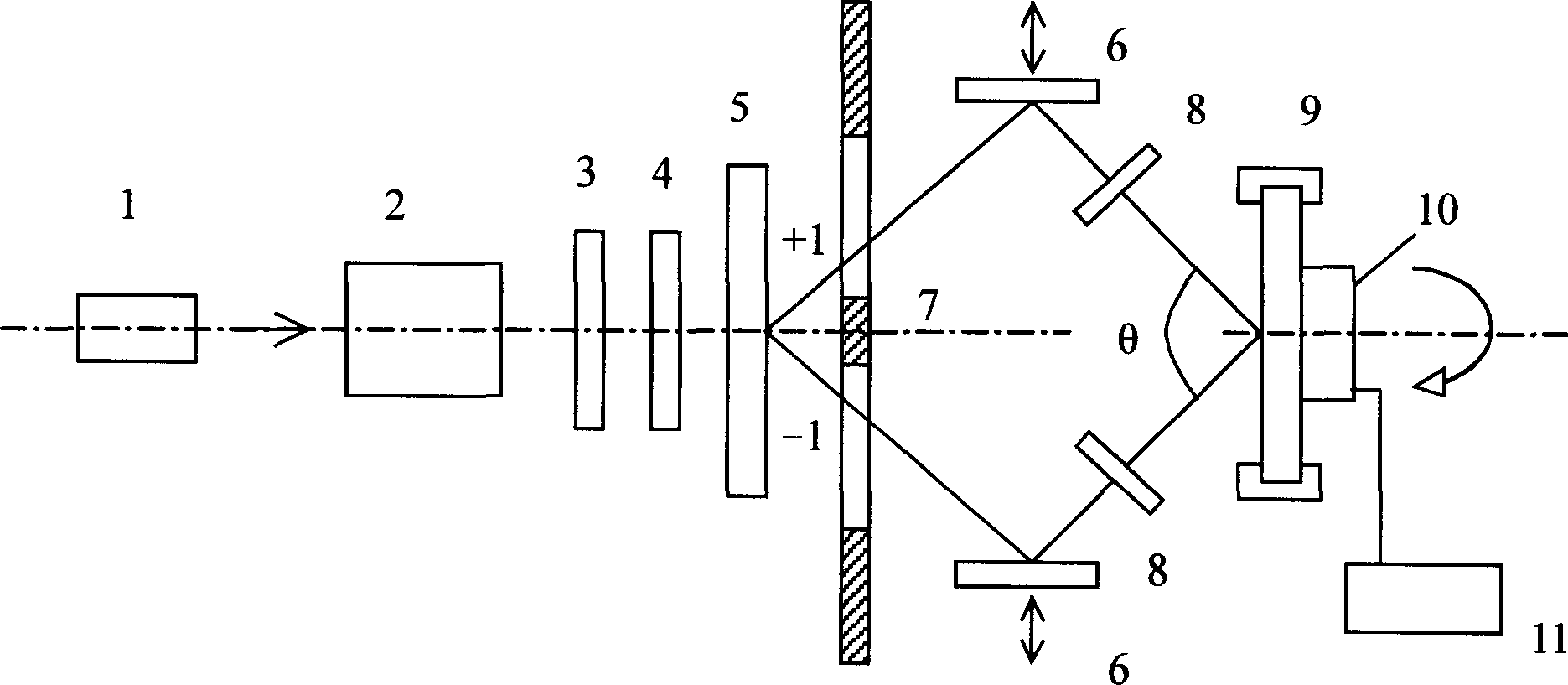

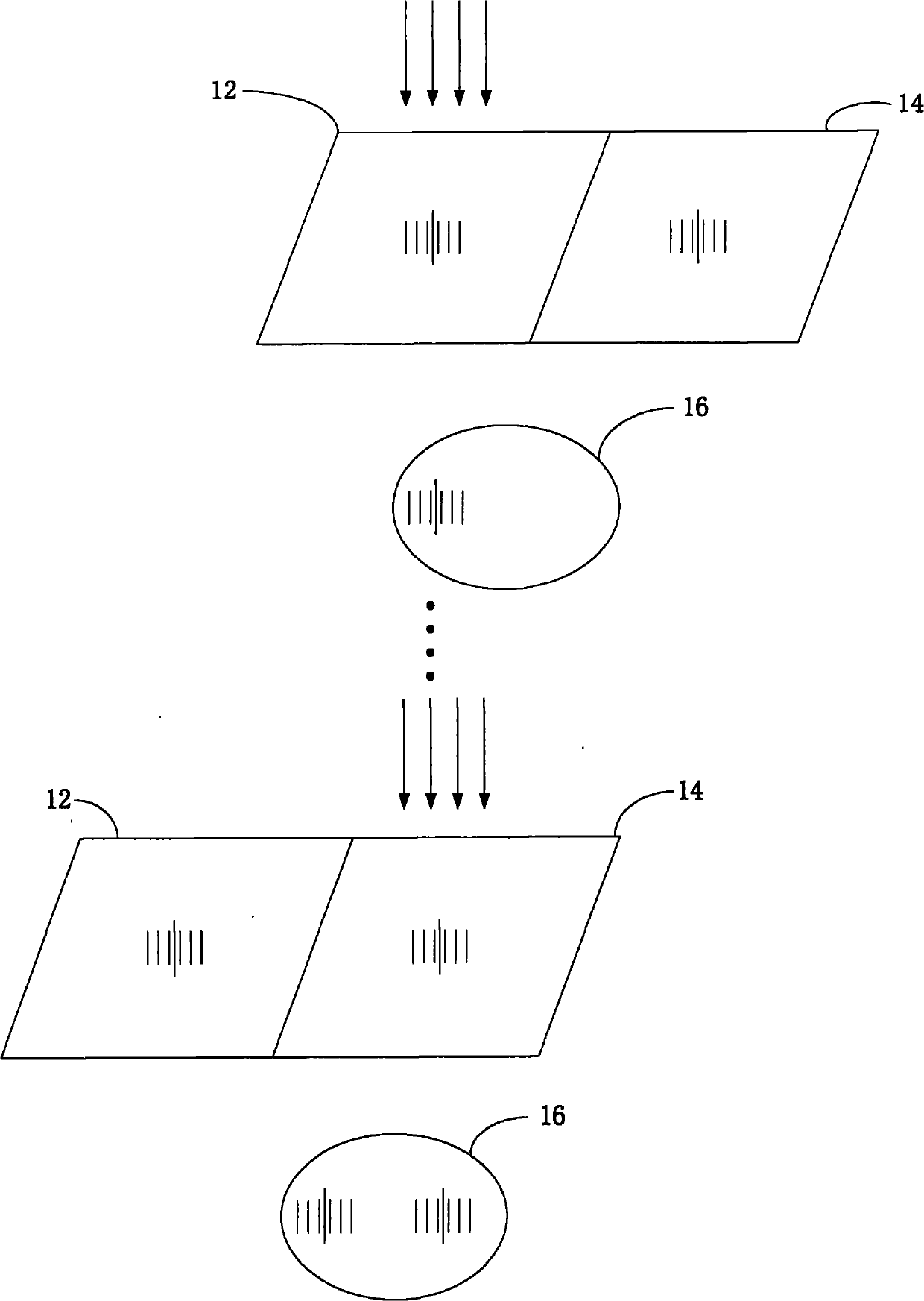

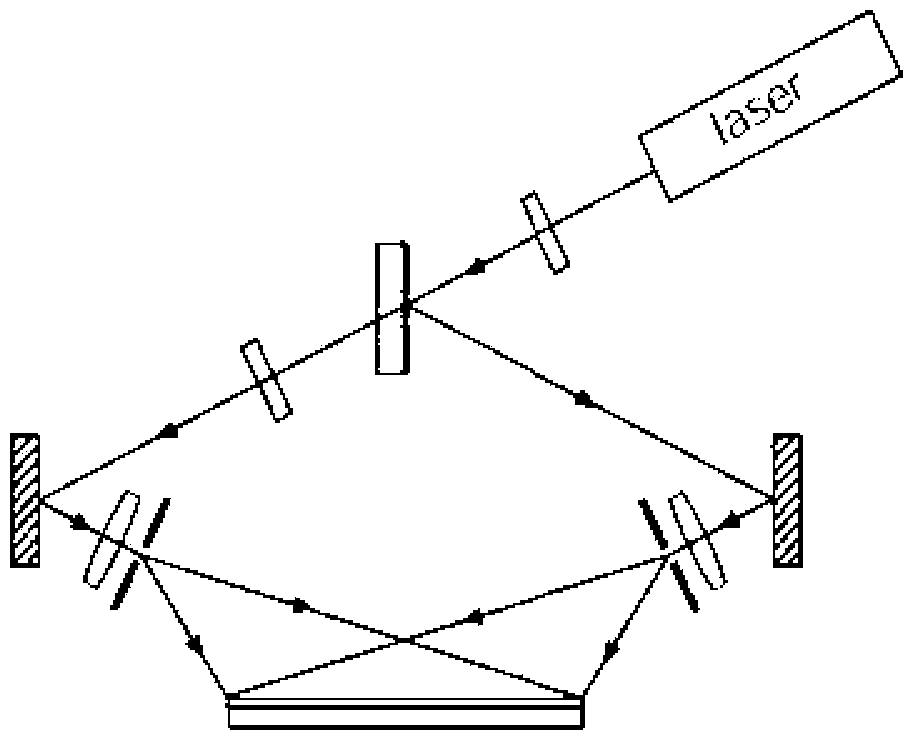

Laser interference lithography system with pattern locking function

ActiveCN103092002AWith graphics lock functionLock high speedPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingBeam splitter

A laser interference lithography system with a pattern locking function comprises a laser, a reflector, a beam splitter, a substrate stage, a substrate and a pattern locking device. A laser beam emitted by the laser is split into an exposure beam and a reference beam by a spectroscope; the exposure beam passes through the beam splitter, and is reflected to the substrate on the substrate stage by the reflector to realize interference; the interference patterns can realize pattern record transfer by exposing the substrate; and the patterns are locked by the pattern locking device to prevent pattern drift during exposure. The pattern locking device includes a null phase meter, an electronic signal processing component, a controller, a driver and a phase modulation executing, wherein the null phase meter is used for measuring pattern phase drift; the pattern phase drift is fed back to the controller through the signal processing component; and the controller controls the phase modulation executer to realize phase locking through the driver. The laser interference lithography system provided by the invention has the advantages of simple structure, high pattern locking accuracy and the like, and is a key system for realizing large-area high-accuracy grating fabrication.

Owner:TSINGHUA UNIV +1

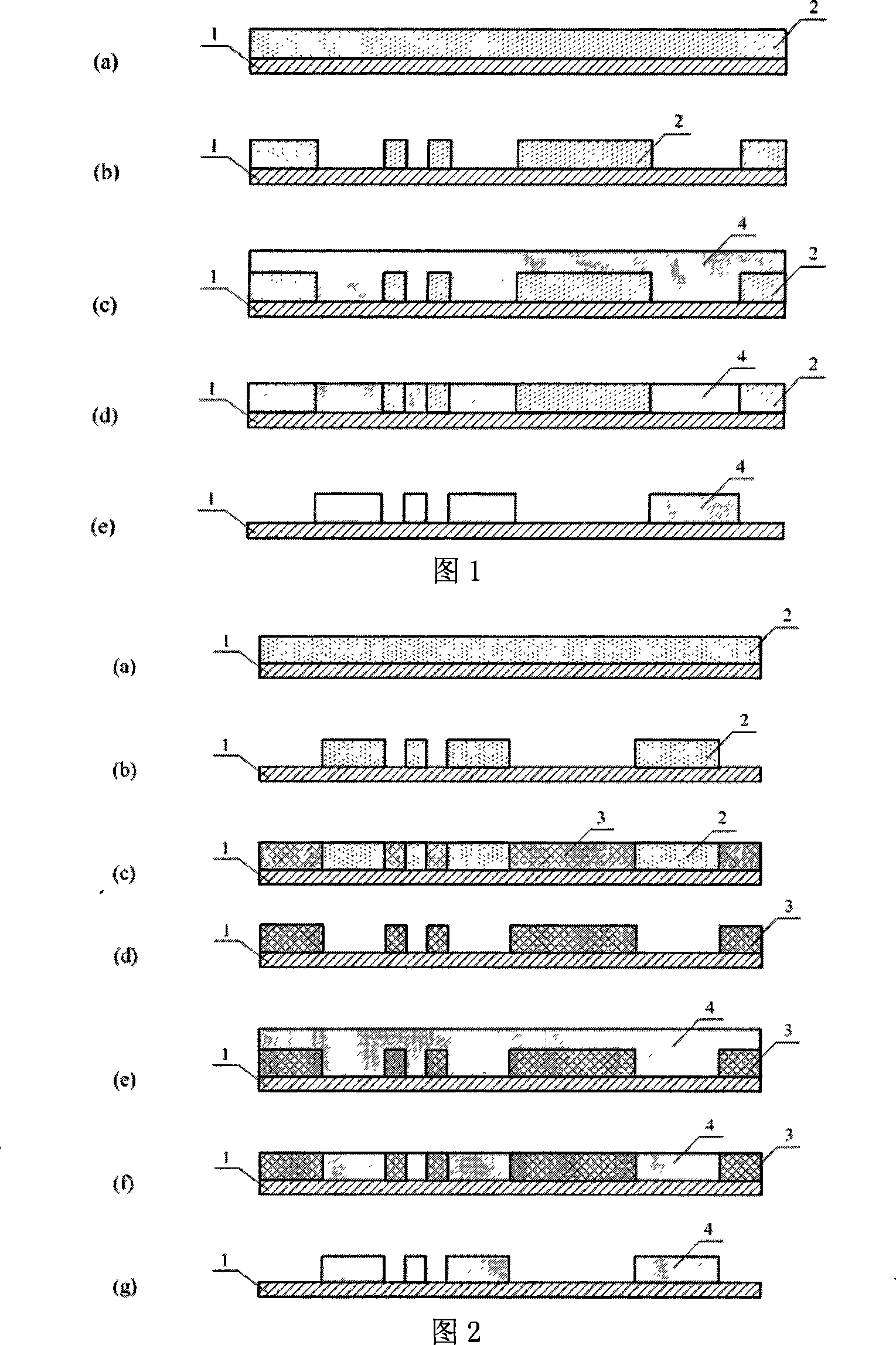

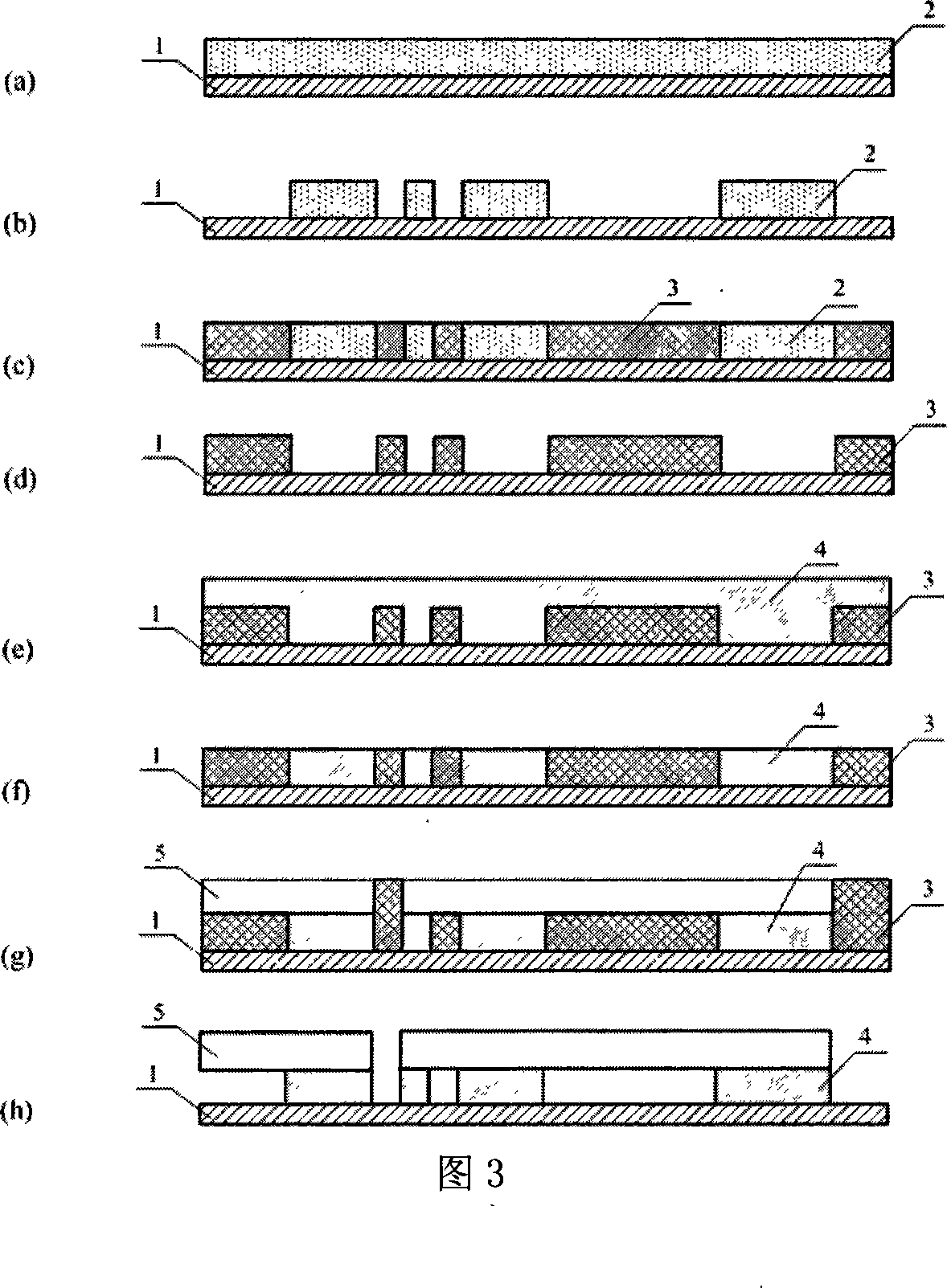

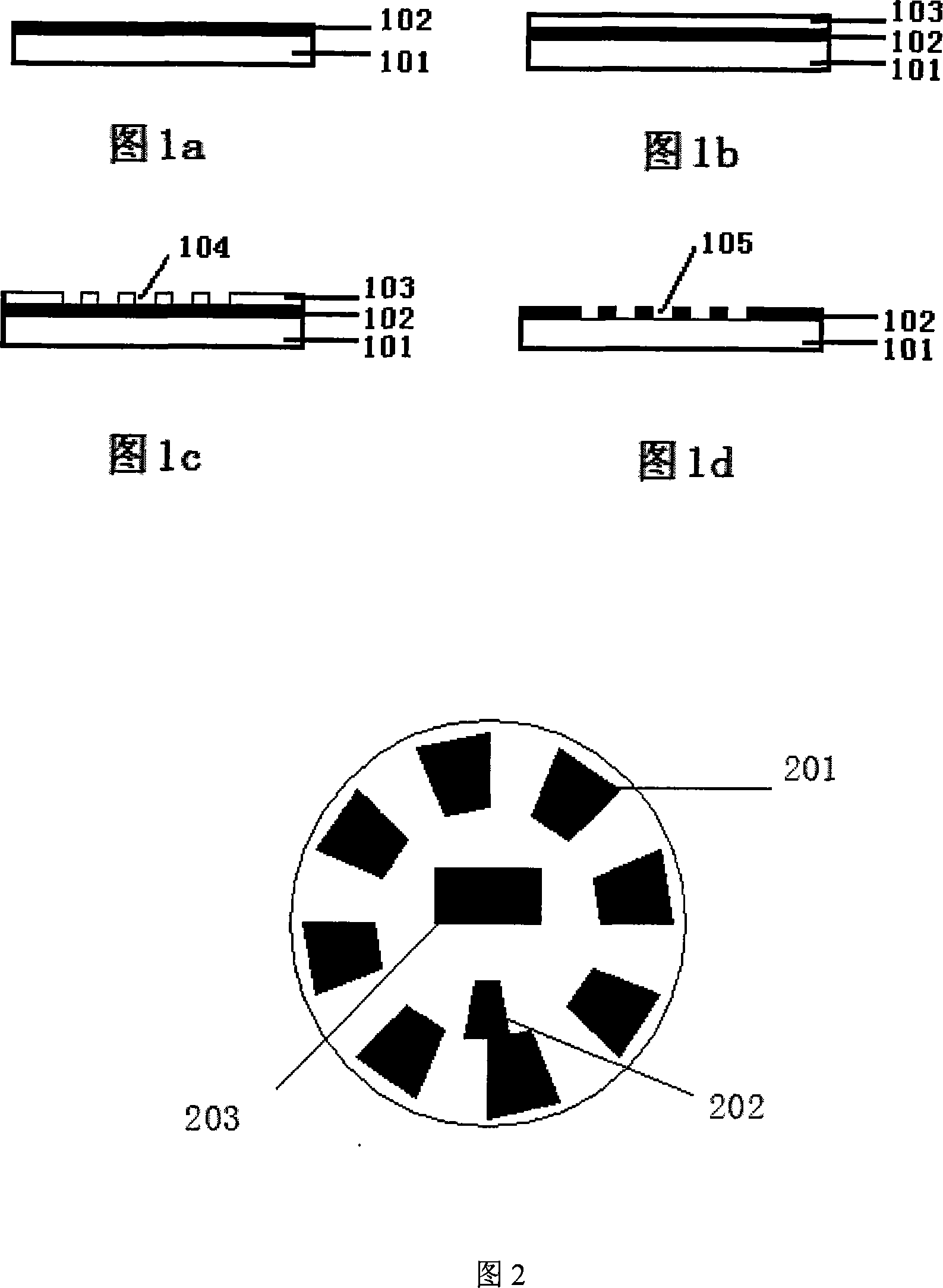

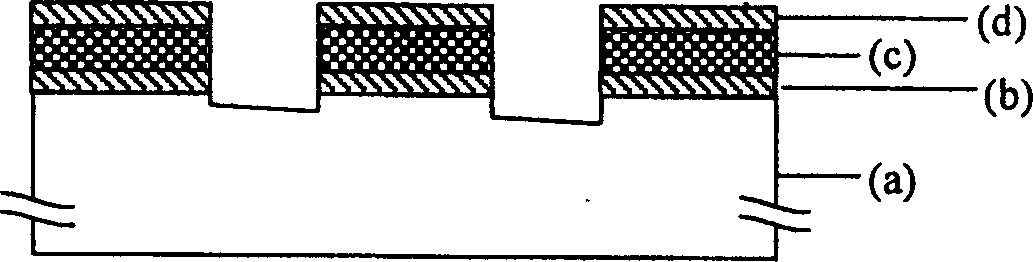

Universal film material graphics method

InactiveCN101143699AVersatilityImprove graphics qualityDecorative surface effectsChemical vapor deposition coatingGraphicsMicro structure

The invention discloses a graphic method for a universal film material in the technical field of micro machine processing. The invention prepares a disposable plane micro mould on a basal by photolithograph or mask plating; the film material is deposited on the whole basal, to fill the gap of the micro mould; the redundant part of the film which is higher than the micro mould is removed by grinding, and the film is reduced to be as thick as required; the disposable plane micro mould is removed selectively, to obtain the required micro structure. The invention can manufacture not only manufacture single structures but also laminated structures; can integrate with the sacrificial layer process to manufacture a suspend structure; is not restrained by the material, thickness and deposition method of the film and the substrate material, and is universal; solves the problem that conventional methods of some film materials cannot manufacture quite thick and neat boundary micro structures; has simple process and quite high graphic quality; is compatible with conventional micro processing technologies; does not need special processes and equipments; and is easy to be promoted.

Owner:SHANGHAI JIAO TONG UNIV

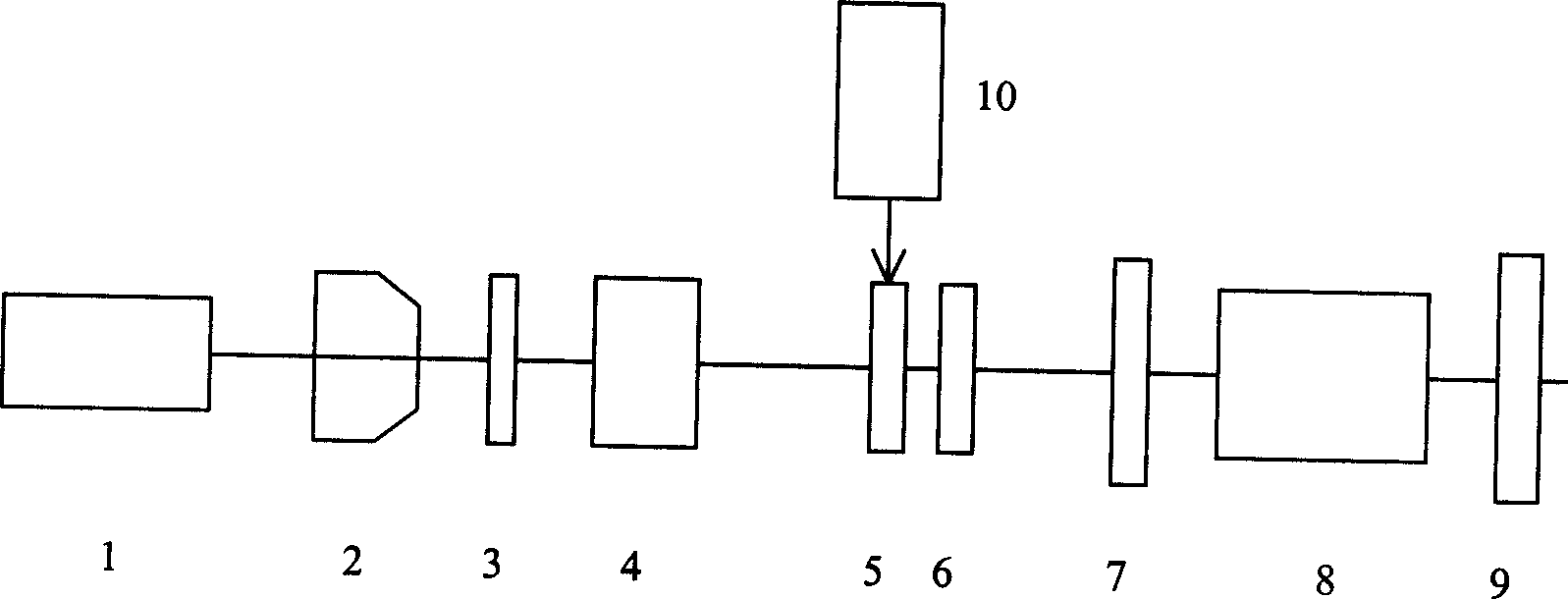

Laser interference photo etching method adopting holographic optical elements and photo etching system

InactiveCN1690857AEasy to manufactureImprove adaptabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingWavelength

The laser interference photo-etching method with holographic optical element is characterized in that: use holographic optical element as beam amplitude division element to divide the laser beam to two beams of almost equal strength and angle divided; reflect to make them intersect; on the intersect overlap area, expose the resister basal plate to produce high resolution grating, form minuteness interference image; holographic optical element is element that can produce tri-beam, quad-beam, or quint-beam, or holographic image produced by computer, or diffraction optic element; laser interference photo-etching system realized aforementioned method comprises a laser of ª™-wave, beam expand collimating device, timer shutter, variable density neutral color filter, holographic optical element, adjustable diaphragm, holophote, optical attenuator, basal plate and electric control roller. As the preparation of holographic optical element is easy, with light weight, and can made with low cost according to different angle to adjust different needs, this invention can decrease size, weight and cost of the system, of far reaching importance and application future.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

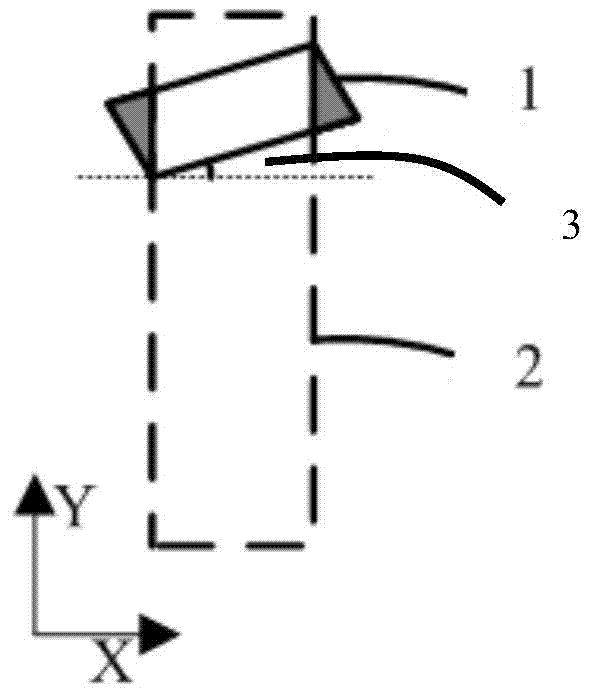

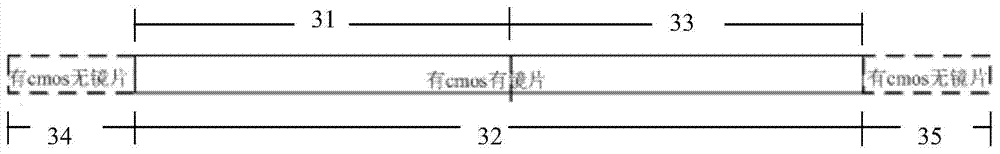

Inclined scanning stitching method of write-through lithography system

InactiveCN104281013AEasy splicingIncrease profitPhotomechanical exposure apparatusMicrolithography exposure apparatusGraphicsLithographic artist

The invention discloses digital micromirror device-based (Digital Micromirror Device, DMD) write-through lithography equipment, and provides a method for improving a stitching effect. Existing write-through lithography equipment adopts an inclined scanning mode, so that two unemployed triangular regions are formed on a DMD in the left and right directions. Effective patterns are filled into the triangular regions, and the physical characteristics of 64 CMOSs without lenses in front of and behind the DMD are combined, so that the grey superposition effect is generated on the edges of the adjacent strips. Compared with the prior art, stitching between the strips is improved, the pattern quality is improved, and meanwhile, the utilization rate of the lenses is increased, and popularization and application in industry are facilitated.

Owner:TIANJIN JINXIN MICROELECTRONICS TECH CO LTD

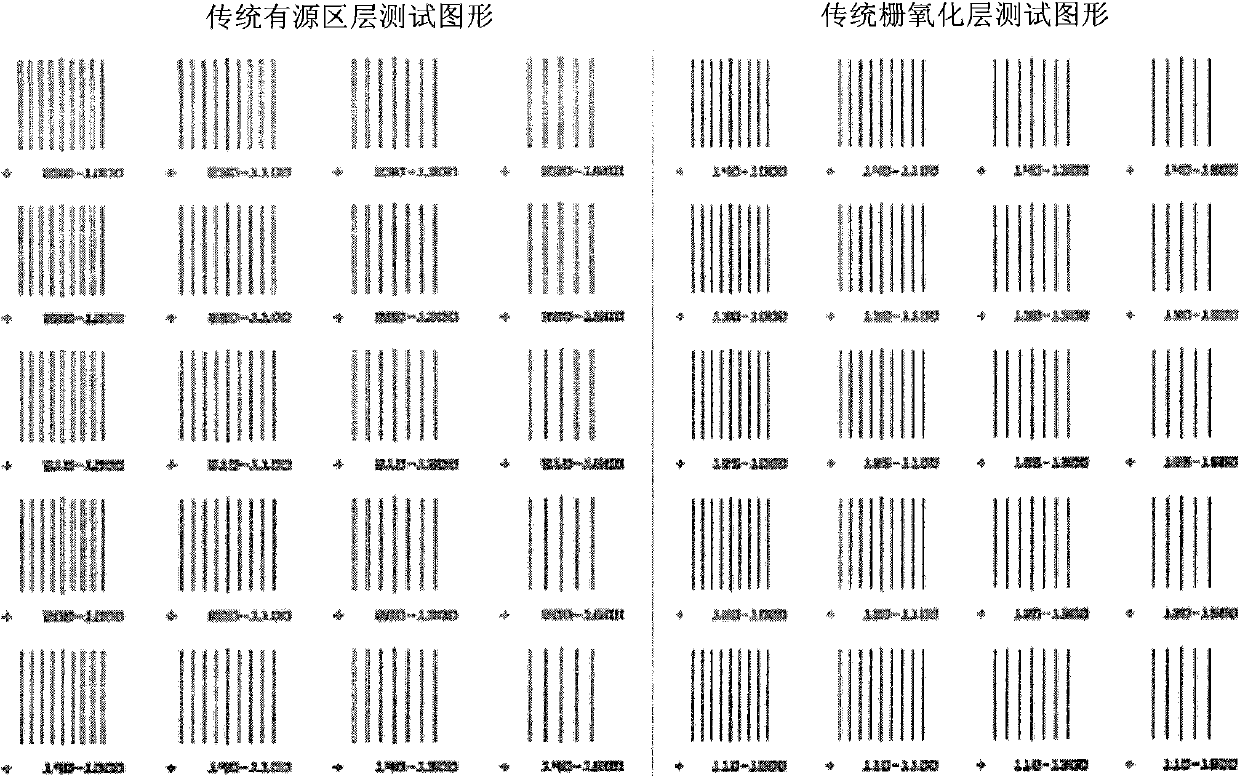

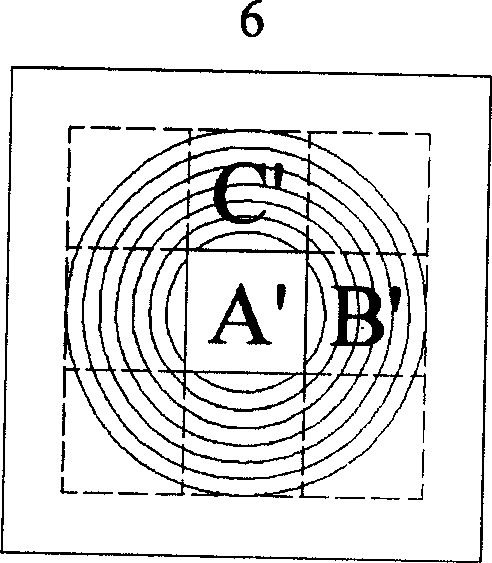

Optical proximity effect corrective modeling method and generating method of test pattern

ActiveCN102087469AImprove graphics qualityOriginals for photomechanical treatmentSpecial data processing applicationsLithographic artistGate oxide

The invention relates to a generating method of a test pattern of optical proximity effect, and the method includes steps of: amplifying each layer of the original test pattern to obtain an amplified pattern; photoetching the original test pattern and the amplified pattern on a mask plate to form an original pattern region and an amplified pattern region respectively; and photoetching the original pattern region and the amplified pattern region which are on the mask plate on a wafer. The invention also relates to a model based optical proximity effect corrective modeling method of a test pattern generated by the above method. The invention truly simulates the condition that gate oxide covers on a layer of active region, and truly reflects optical proximity effect of overlapping lithography between gate oxide and the layer of active region. Patterns with very good quality are obtained on the wafer, and thus high quality optical proximity effect correction can be carried out.

Owner:CSMC TECH FAB2 CO LTD

Projection system of photoetching machine and method for eliminating smear generated in exposure process

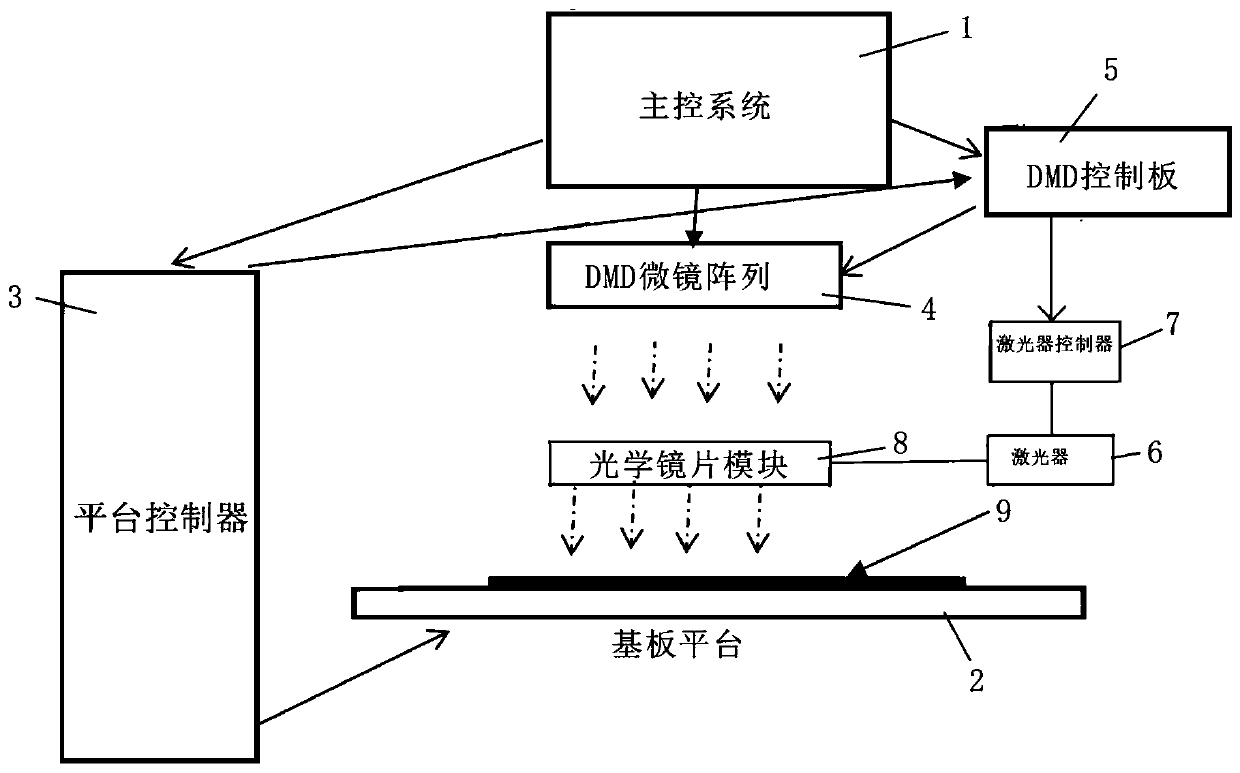

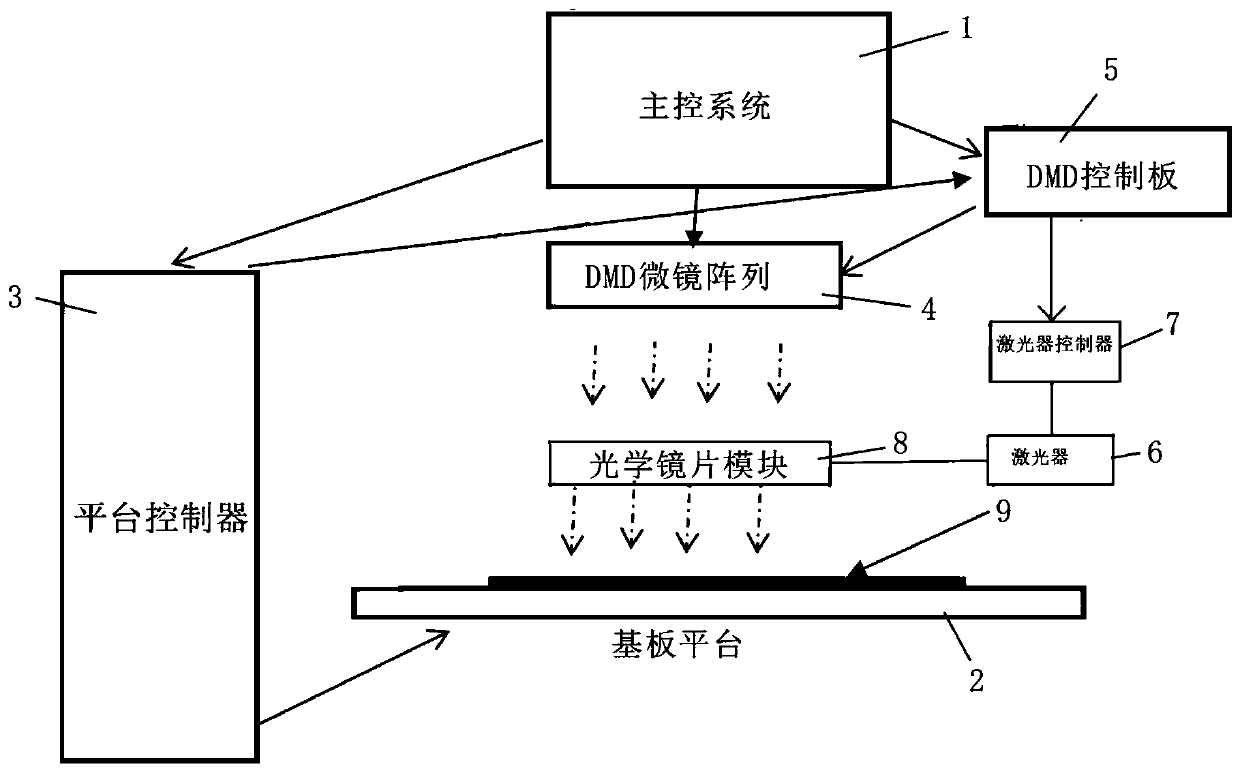

InactiveCN109960113AClear linesSharp linesPhotomechanical exposure apparatusMicrolithography exposure apparatusProjection systemMicromirror array

The invention provides a projection system of a photoetching machine, and also provides a method for eliminating smear generated in an exposure process by adopting the projection system of the photoetching machine. While a DMD control panel sends a projection synchronization pulse signal to control a DMD micromirror array to overturn, the image projection synchronous pulse signal is synchronouslysent to a laser controller, and the laser controller synchronously controls laser emission according to the image projection synchronous pulse signal, so that an obtained exposed image is clear and sharp, and the exposure quality is good.

Owner:SUZHOU YUANZHUO OPTOELECTRONICS TECH CO LTD

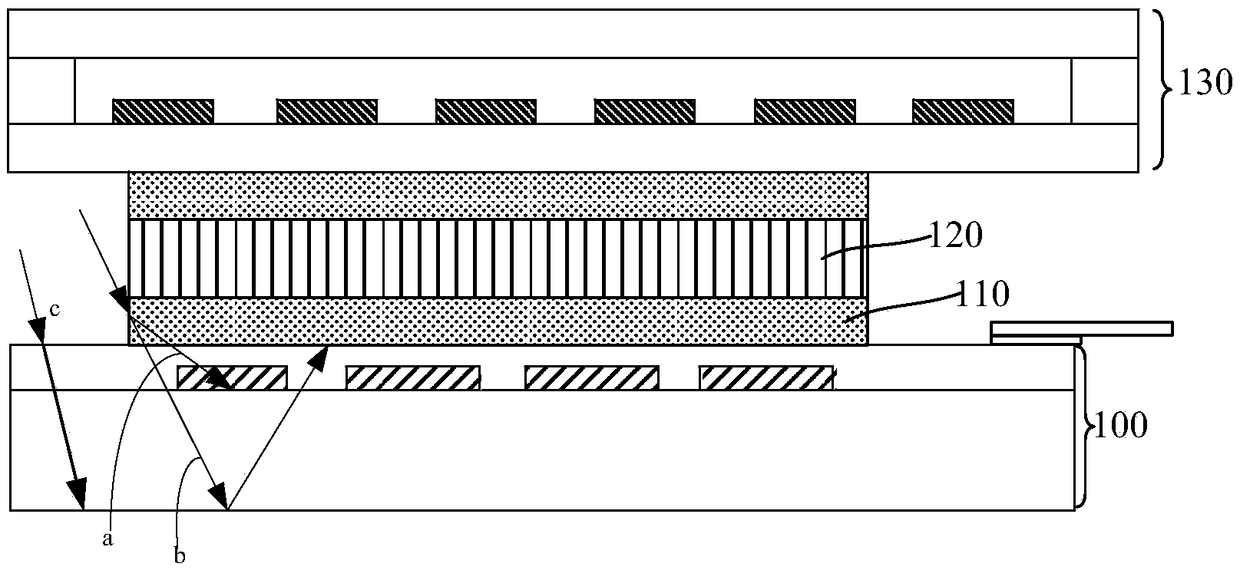

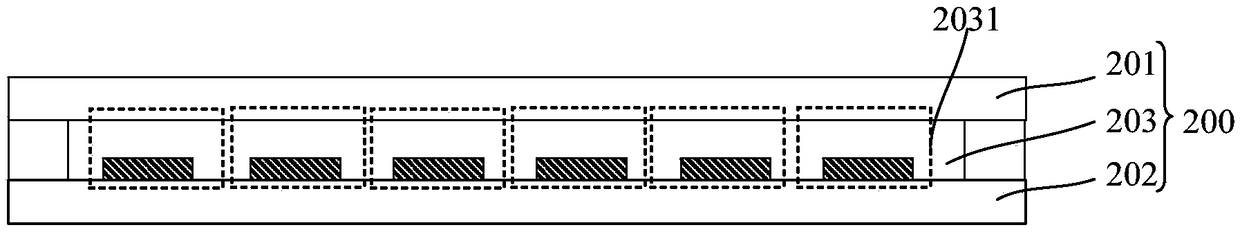

Optical fingerprint sensor module and forming method thereof

An optical fingerprint sensor module and a method for forming the same. The optical fingerprint sensor module comprises a self-luminous display panel; Optical fingerprint sensor, the optical fingerprint sensor comprises a sensor light-transmitting substrate and a fingerprint sensing circuit layer located on the surface of the sensor light-transmitting substrate, The fingerprint sensing circuit layer includes a first pixel region and a first peripheral region located around the first pixel region, the fingerprint sensing circuit layer includes a first sensing surface, the first sensing surfacefacing away from the sensor light transmitting substrate; A light collimator layer positioned between the optical fingerprint sensor and the self-luminescent display panel, the light collimator layerfacing a first sensing surface of a first pixel region; A light absorbing layer located at a first sensing surface of the first peripheral region. The performance of the optical fingerprint sensor module is improved.

Owner:SHANGHAI OXI TECH

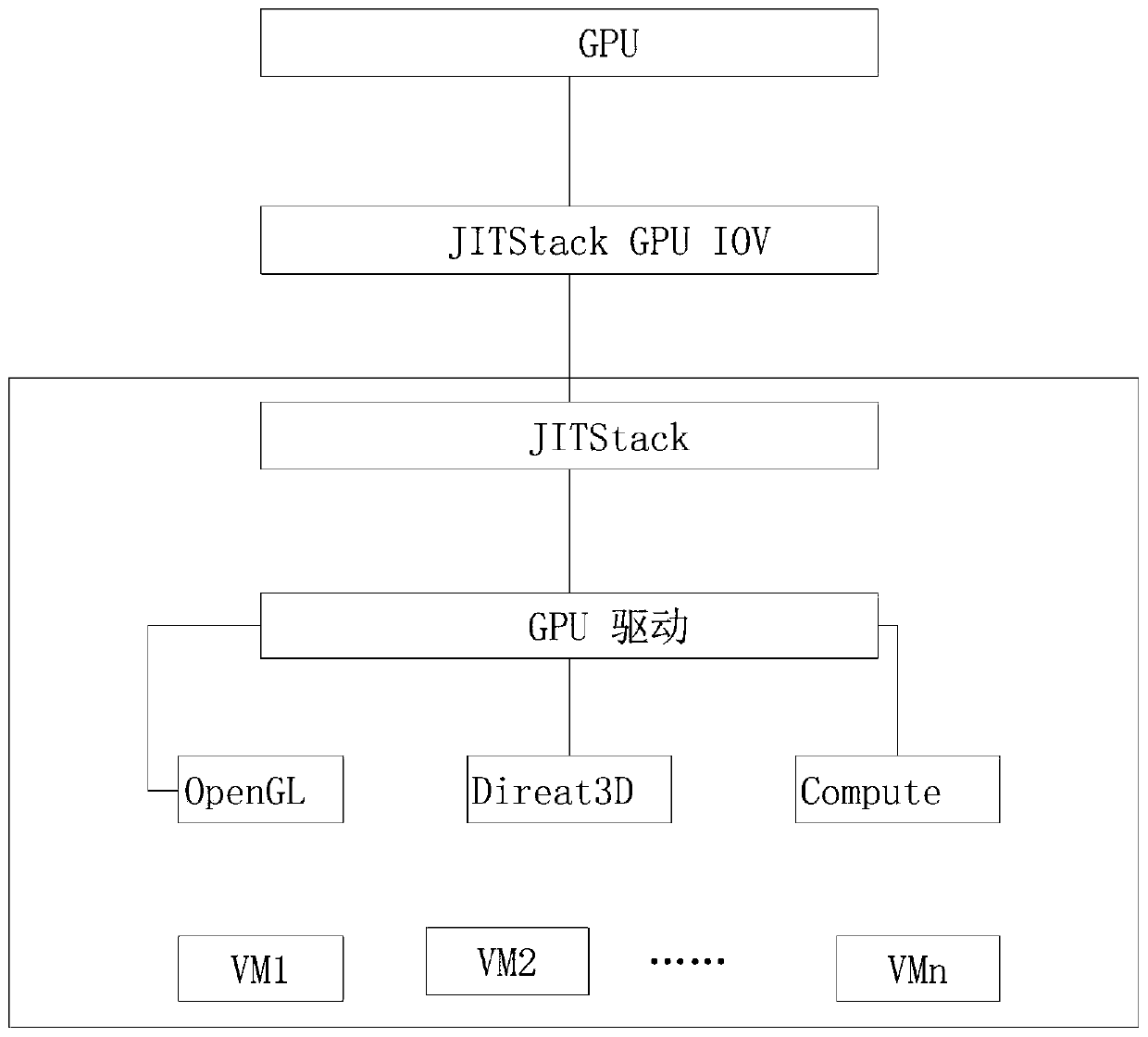

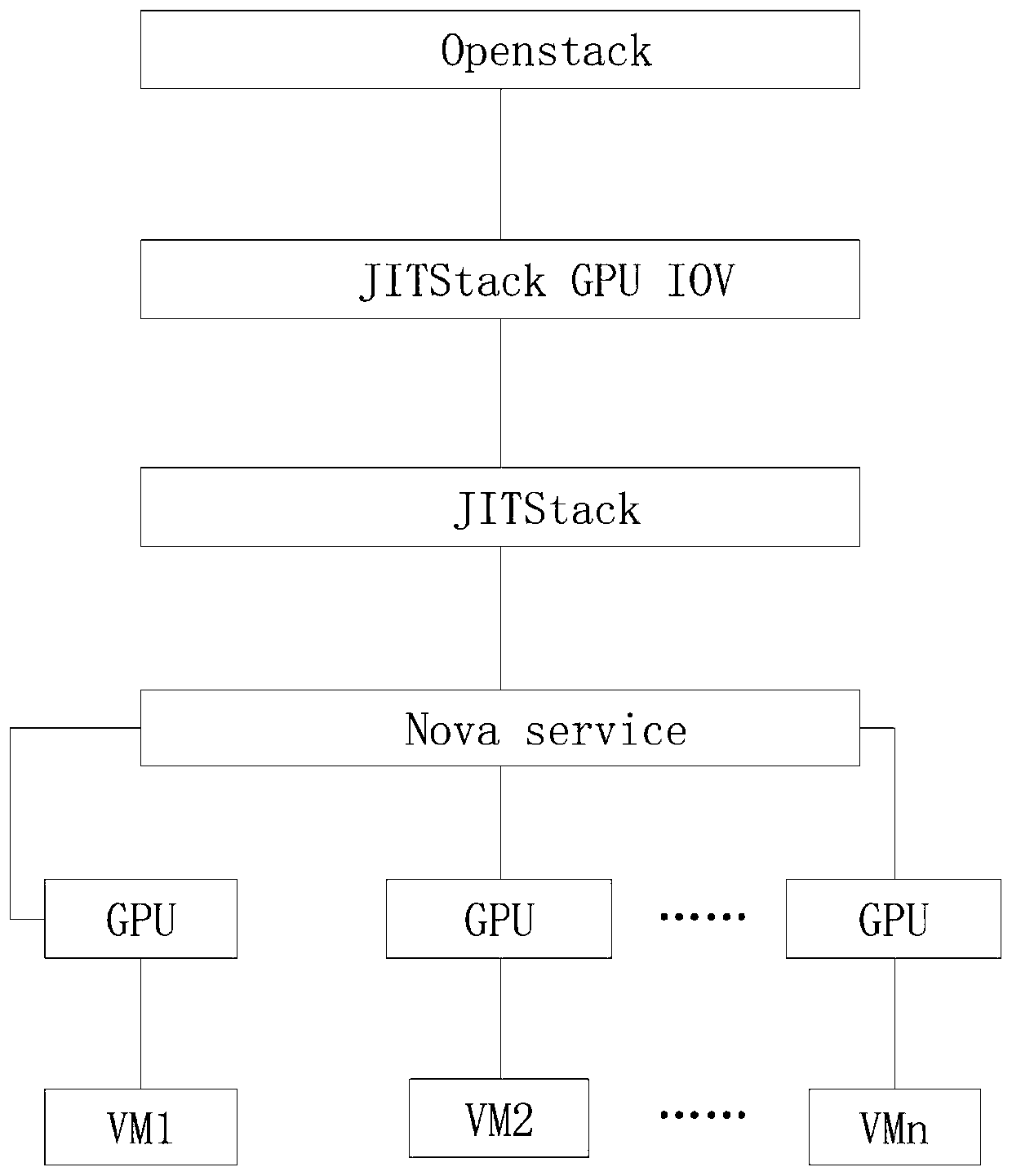

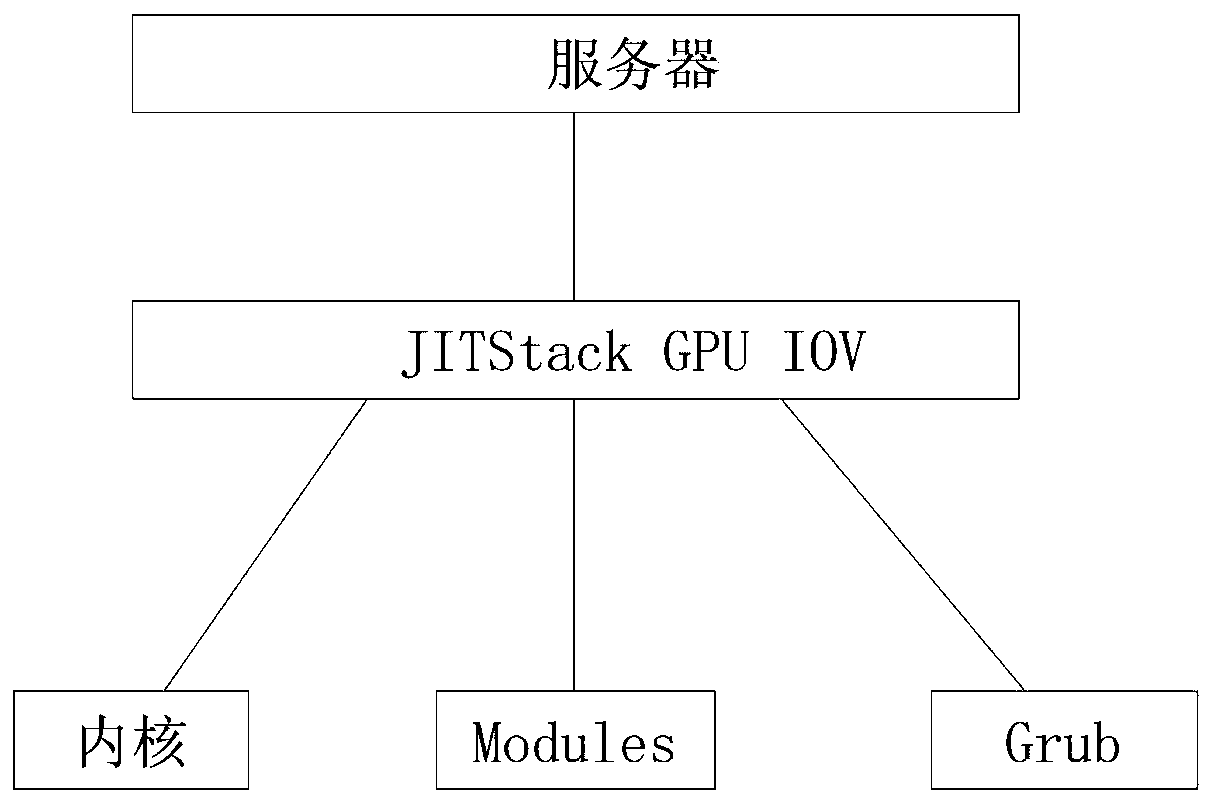

GPU component extension application method and system based on flat holder

PendingCN110727502AEnable direct applicationImprove GPU capabilitiesBootstrappingSoftware simulation/interpretation/emulationGraphicsGraphic card

The invention provides a GPU component extension application method and system based on a flat holder, and the method comprises the steps: obtaining a server which comprises a Linux system installed on the server, at least one GPU card, a GPU component, and a cloud management platform JITStack operating based on the Linux system; the cloud management platform JITStack being used for creating a plurality of virtual machines; the cloud management platform JITStack reading information corresponding to at least one GPU card through the GPU component; the GPU component being used for updating the kernel of the Linux system and updating the Modules and the Grub according to the information corresponding to the GPU card; the cloud management platform JITStack enabling the configurable GPUs to correspond to the virtual machines, determining GPU drivers corresponding to the selected GPUs are installed after the selected GPUs, and distributing the GPUs to the virtual machines through graphics card penetration, so that terminals connected with the virtual machines directly apply the GPUs. By applying the embodiment of the invention, through an autonomously developed dynamic display card scheduling technology, the display card can be scheduled and used among a plurality of virtual machines, and the resource utilization efficiency is improved.

Owner:上海思询信息科技有限公司

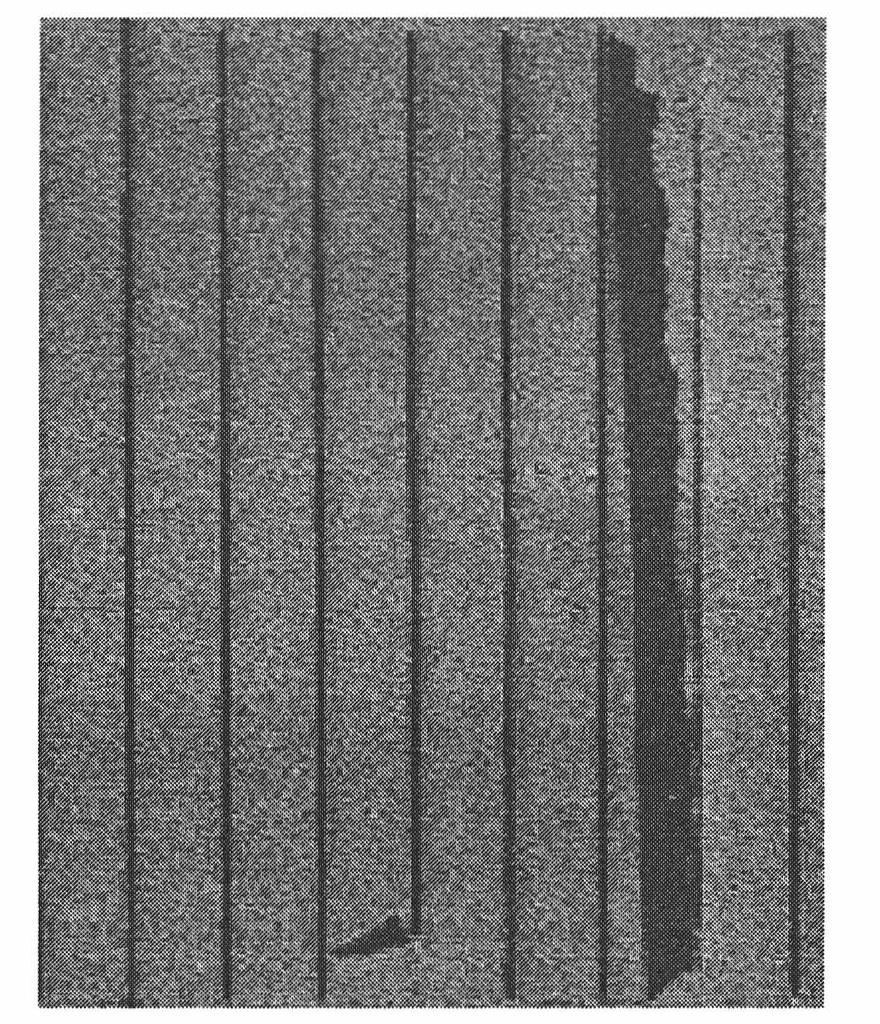

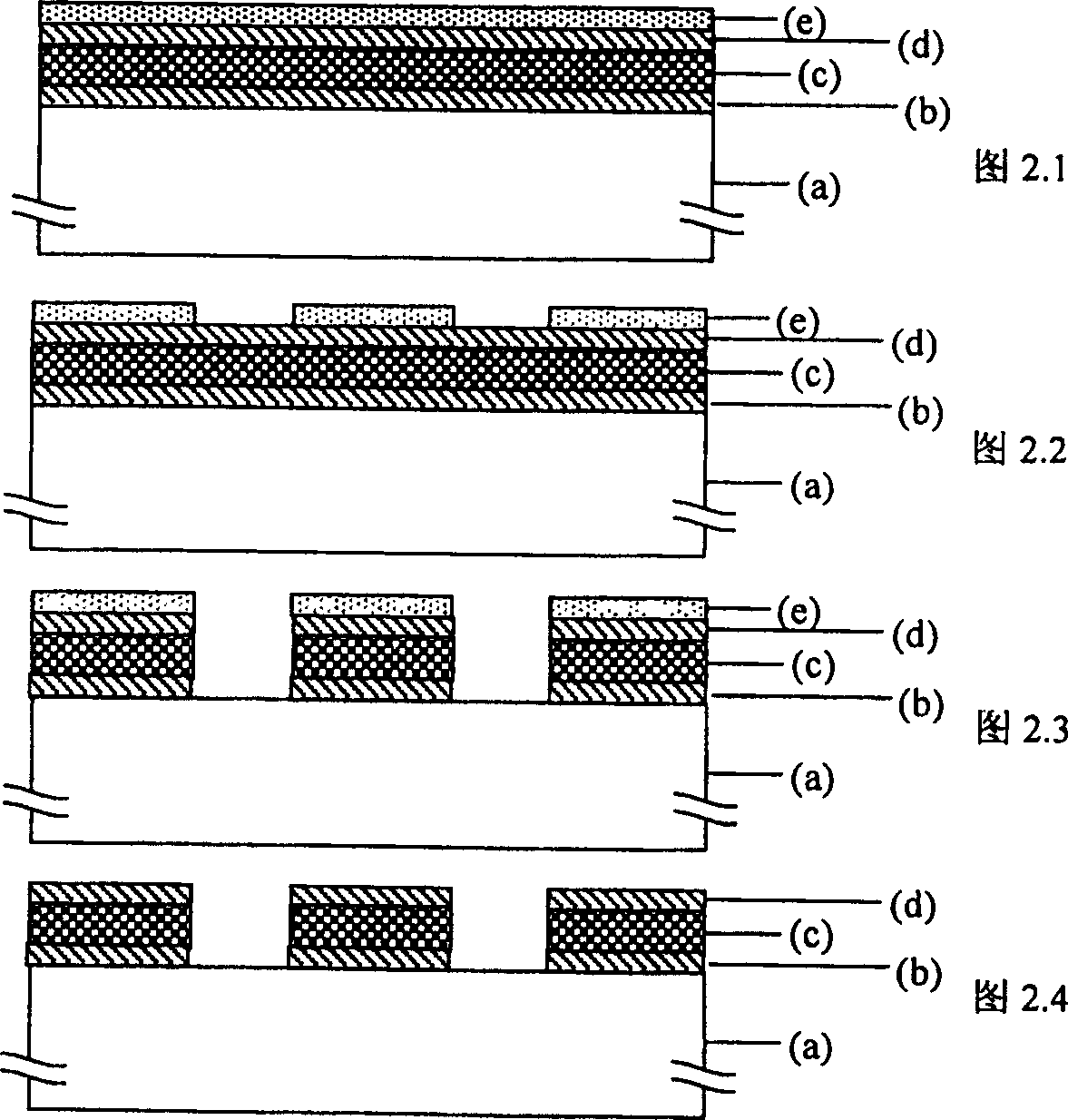

Super-resolution dry-method surface plasma photo-etching method

ActiveCN102636965ASmall molecular weightStrong absorption capacityPhotomechanical exposure apparatusPhotosensitive material processingCooking & bakingEtching

The invention discloses a super-resolution dry-method surface plasma photo-etching method, comprising the following steps of: 1) washing a substrate; 2) plating a layer of inorganic photoresist TeOx on the substrate; 3) plating a layer of metal thin film on a TeOx film layer; 3) repeatedly plating for a plurality of periods and finally plating one layer of inorganic photoresist; 5) placing a multi-layer film below a mask plate with a certain pattern and exposing; 6) carrying out dry-method developing on the exposed multi-layer film; and 7) finally removing the residual Ag layer. The super-resolution dry-method surface plasma photo-etching method disclosed by the invention has the advantages that a dry method is used to develop the inorganic photoresist so as to obtain the pattern with a regular and steep edge, the problems of the traditional inorganic photoresist that the edge of the pattern is irregular due to the solvent expansion effect and pattern lines are easy to collapse due to post-baking can be solved; and furthermore, a metal layer can amplify the transmission of development vector waves and reduce the light diffraction effect in the exposing process. Therefore, the quality of an SP photo-etched pattern is improved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

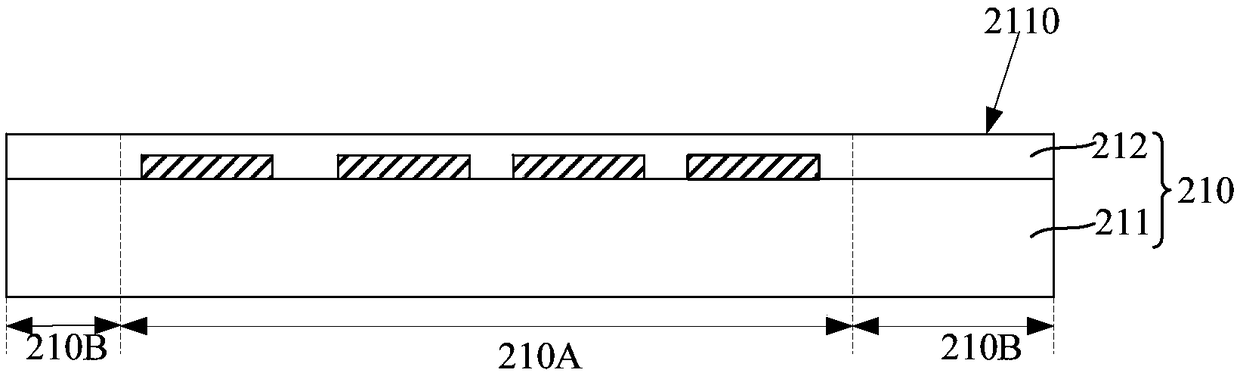

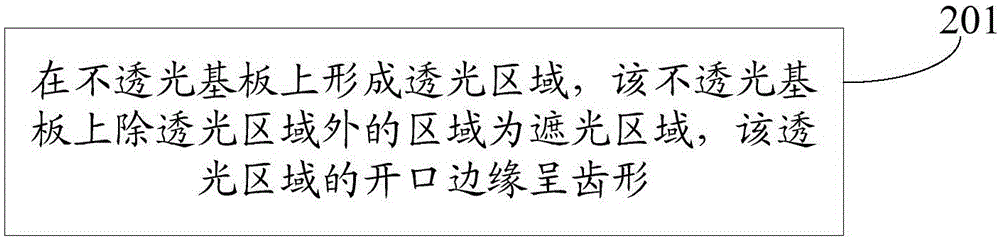

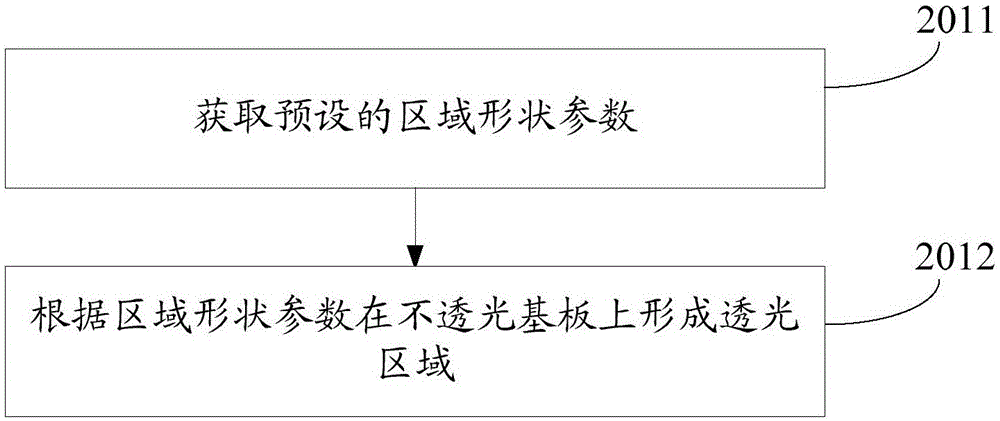

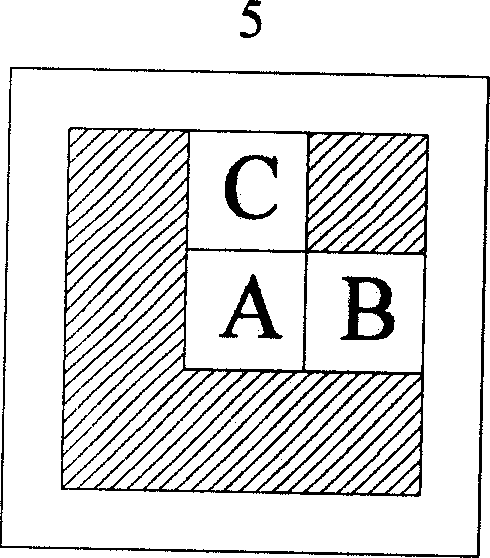

Mask plate, manufacturing method and device of mask plate and using method of mask plate

ActiveCN105137709AImprove clarityImprove graphics qualityOriginals for photomechanical treatmentDisplay deviceYield rate

The invention discloses a mask plate, a manufacturing method and device of the mask plate and a using method of the mask plate, and belongs to the display technical field. The manufacturing method includes the step that a light transmitting area is formed on a light-proof substrate, the area, except the light transmitting area, of the light-proof substrate is a light blocking area, and the edge of an opening of the light transmitting area is in a tooth shape. The problem that the yield rate of products is low is solved, the effect of increasing the yield rate of the products is achieved, and the mask plate, the manufacturing method and device of the mask plate and the using method of the mask plate are used for a display device.

Owner:BOE TECH GRP CO LTD +1

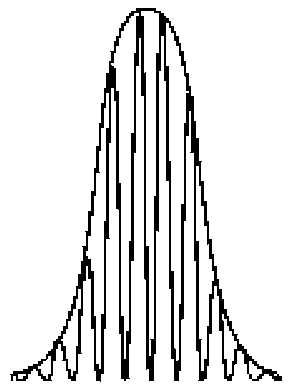

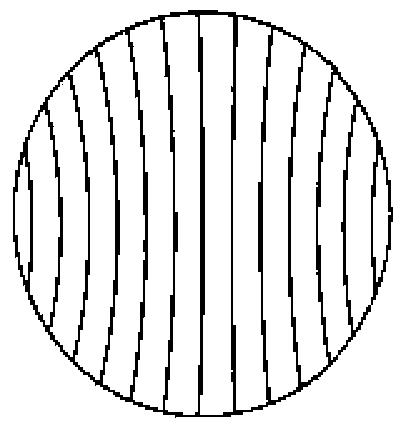

Image interference photoetching method using circular grating and gated optical shutter and its system

InactiveCN1752848AAchieve triple exposureAchieve exposureDiffraction gratingsPhotomechanical exposure apparatusGratingImage resolution

The present invention relates to an imaging interference photoetching method by adopting circular grating and gated shutter. It is characterized by that it adopts circular grating and gated shutter device to provide illumination perpendicular to mask plane, X-directional bias illumination and Y-directional bias illumination for triple exposure imaging interference photoetching process so as to implement triple exposure required for imaging interference photoetching process.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Production method for novel gyroscope signal reading graph

InactiveCN101126641ANo damageHigh precisionNavigation by speed/acceleration measurementsSemiconductor/solid-state device manufacturingGraphicsGyroscope

The utility model relates to a producing method for new gyroscope signal reading graphics, which achieves a micron-level signal reading graphic by a sputtering deposition, a photolithography and an ion beam etching. The utility model has the following processing steps: 1. gaining the metal film by sputtering on the top flat surface of the gyroscope rotor plane; 2. spin coating photoresist on the metal film; 3. gaining photoresist graphics by UV exposure and development; 4. conducting ion beam etching with an incident angle of 15 to 30 degrees to remove residual photoresist, and signifying metal signal reading graphics in the rotor.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

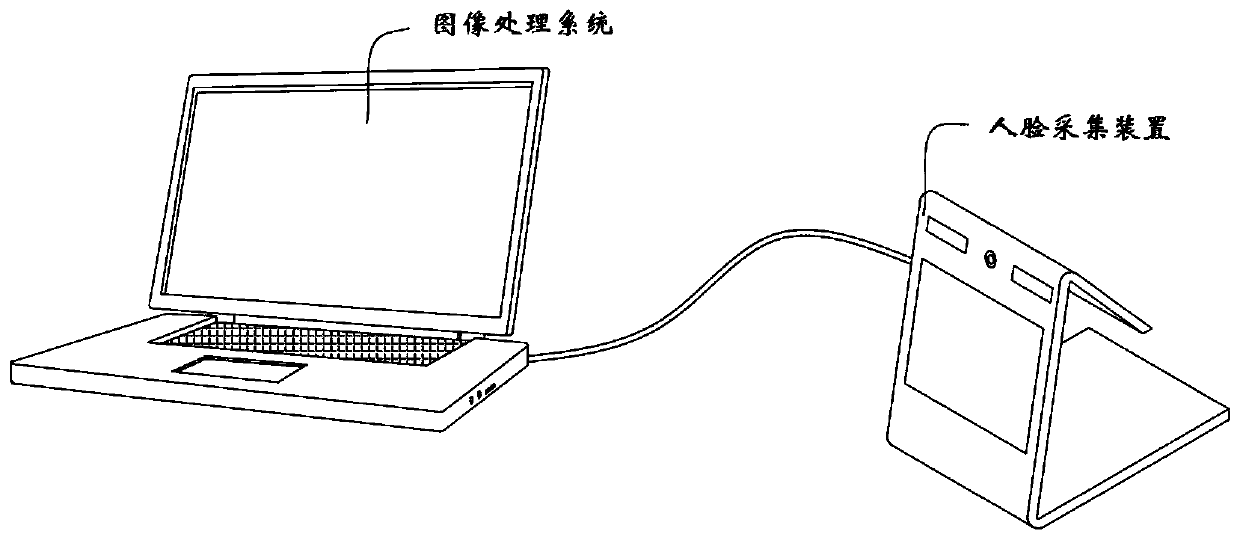

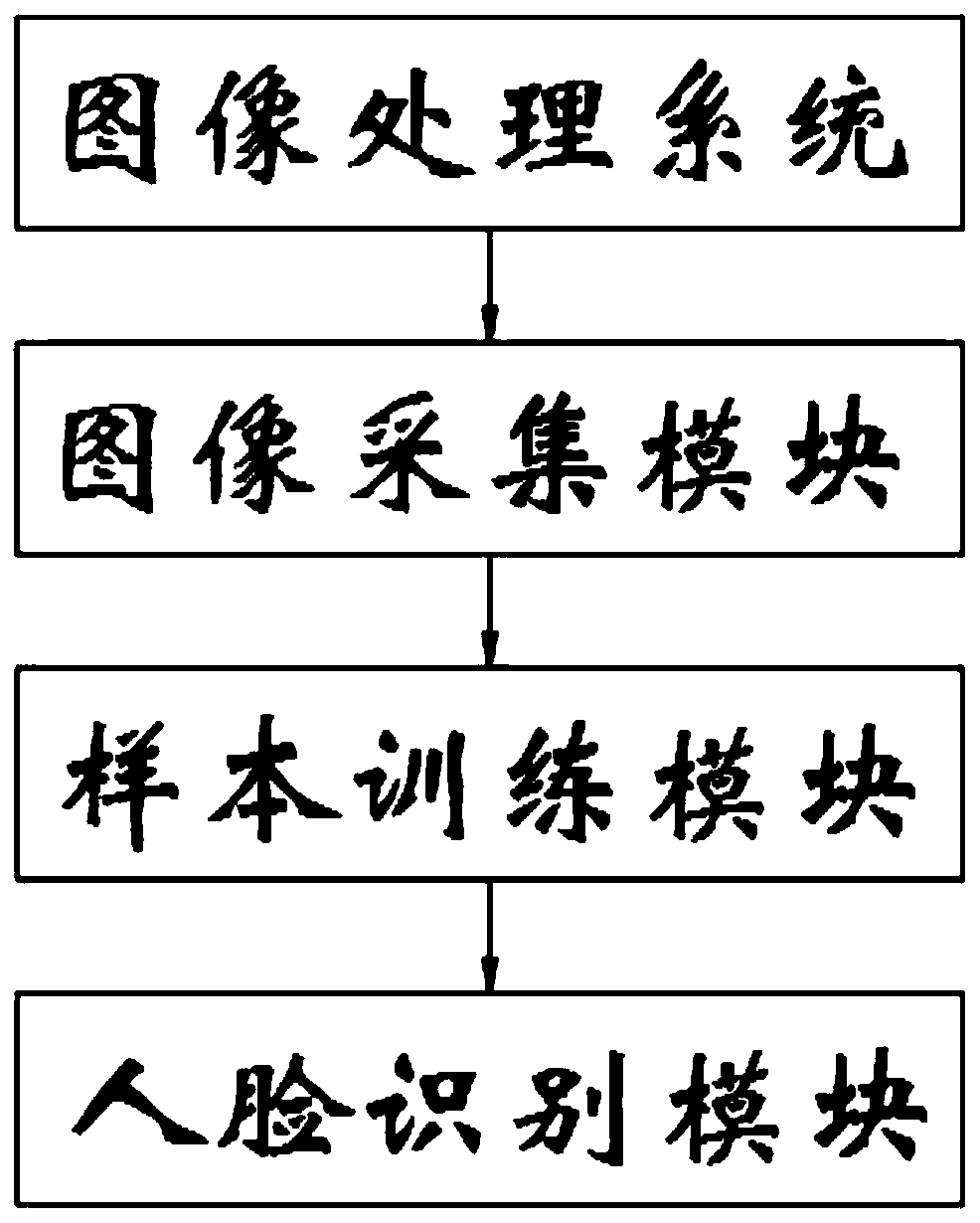

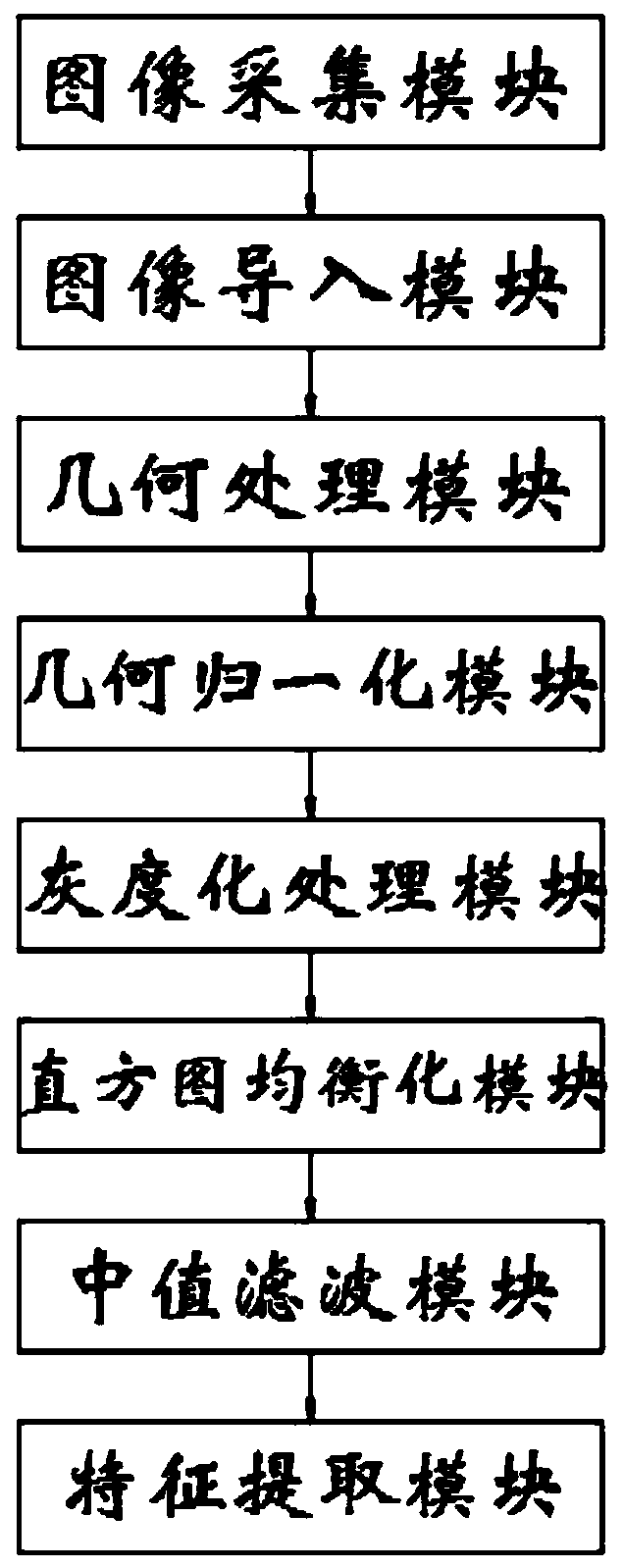

Face recognition device and method

InactiveCN110188684AAccurate extractionProcessing speedCharacter and pattern recognitionColor imageGraphics

The invention relates to the technical field of face recognition, in particular to a face recognition device and method. The face recognition device comprises a face collection device which is used for collecting face images, and an image processing system which is used for processing the collected face images. In the face recognition device and method, an image acquisition module is set to acquire face images; a color image is converted into a gray level image through a graying processing module, so as to accelerate the processing speed; the gray level distribution of the image is adjusted through a histogram equalization module, so as to improve graphics quality; interference noise in the image is removed through a weighted value filtering module, so that image feature extraction is accurate, and recognition precision is improved; collected face images are matched with extracted feature information through a face recognition module; and a threshold judgment module is set to determinewhether the face images to be recognized are the collected face images or not, thus reducing the judgment error probability, and improving recognition accuracy.

Owner:HUNAN CITY UNIV

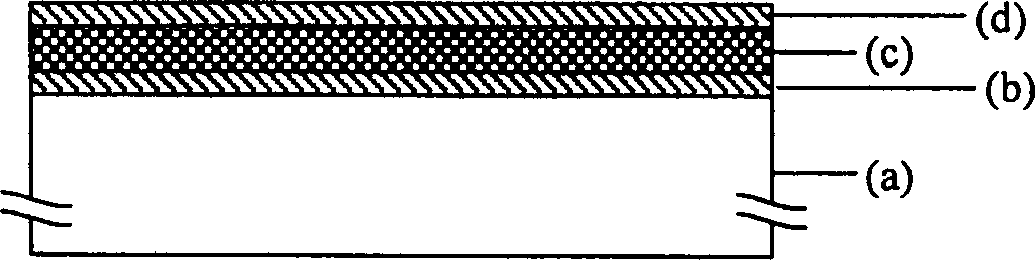

Dry and wet combined etching method for multilayer film

InactiveCN1617229ADoes not affect etchingReducing the need for etch rate uniformity over large areasManufacture of flux-sensitive headsGalvano-magnetic device manufacture/treatmentPermalloyDry etching

The present invention relates to combined dry and wet etching process for multilayer film, especially in anisotropic magnetic resistance effect (AMR) sensor manufacture. The process includes dry etching the protecting layer of AMR film; wet etching the permalloy (NiFe) layer of the AMR film; and dry etching the transition layer of the AMR film. The AMR film is multilayer Ta / NiFe / Ta film. Compared with traditional technology, the present invention has the advantages of shortened etching time, raised etching efficiency, regular edge of resistance stripes and high graph quality.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

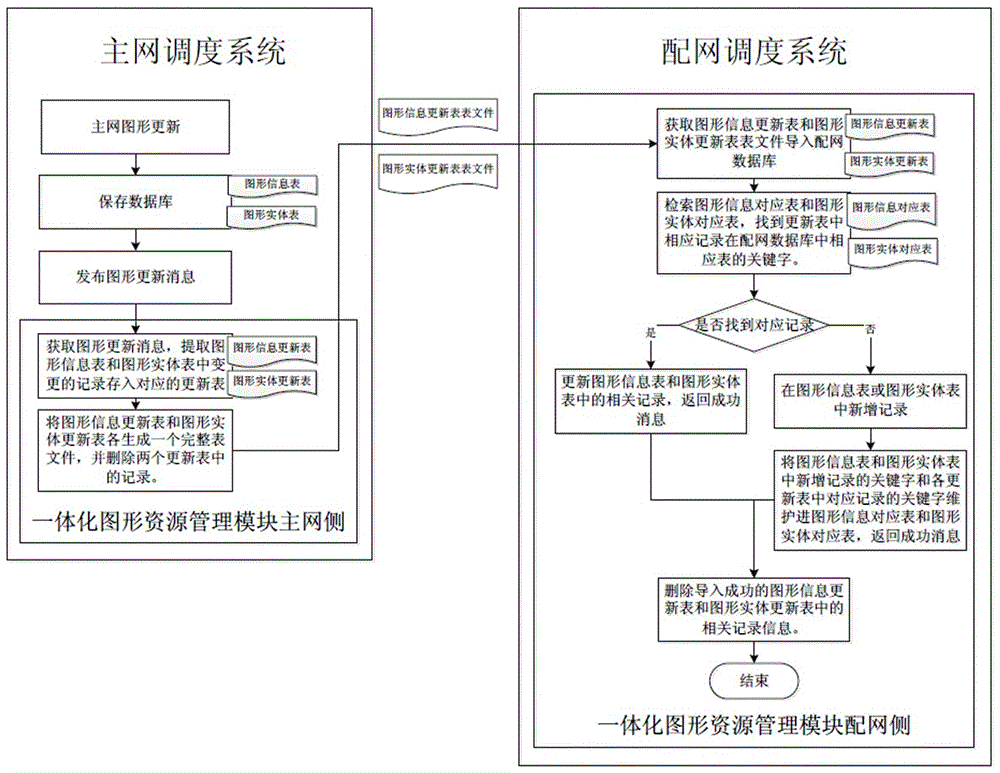

Integrated graphic resource sharing method for master and distribution networks

ActiveCN106096824AAutomatically match recordsIncrease profitResourcesSpecial data processing applicationsGraphicsDistributed computing

The invention discloses an integrated graphic resource sharing method for master and distribution networks. According to the method, various graphic resources of the master network can be shared to a distribution network scheduling system in time, and corresponding graphic database records are automatically matched and automatically updated on a distribution network side; and in addition, background automatic processing can be realized, and the quality of an imported graph is high, so that a large amount of manual maintenance work is reduced, the utilization rate of the graphic resources is increased, and the scheduling operation and maintenance level is improved.

Owner:NARI TECH CO LTD +4

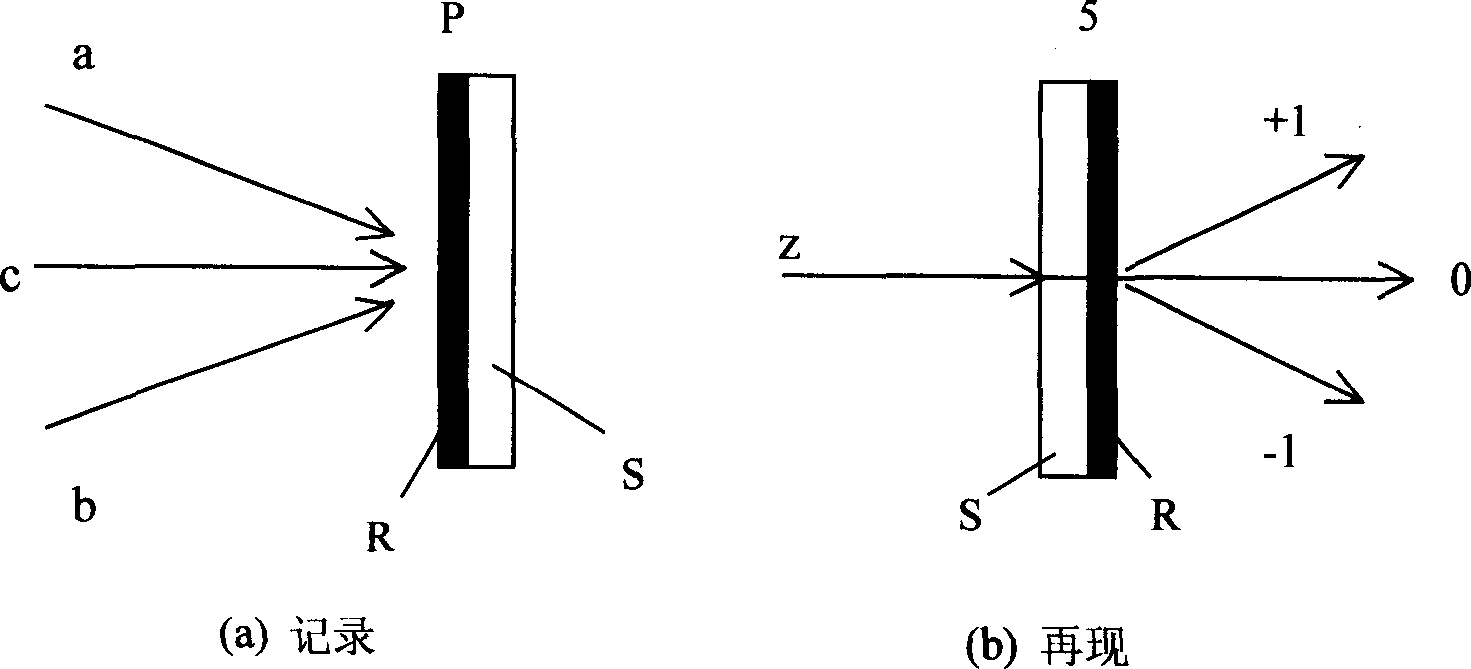

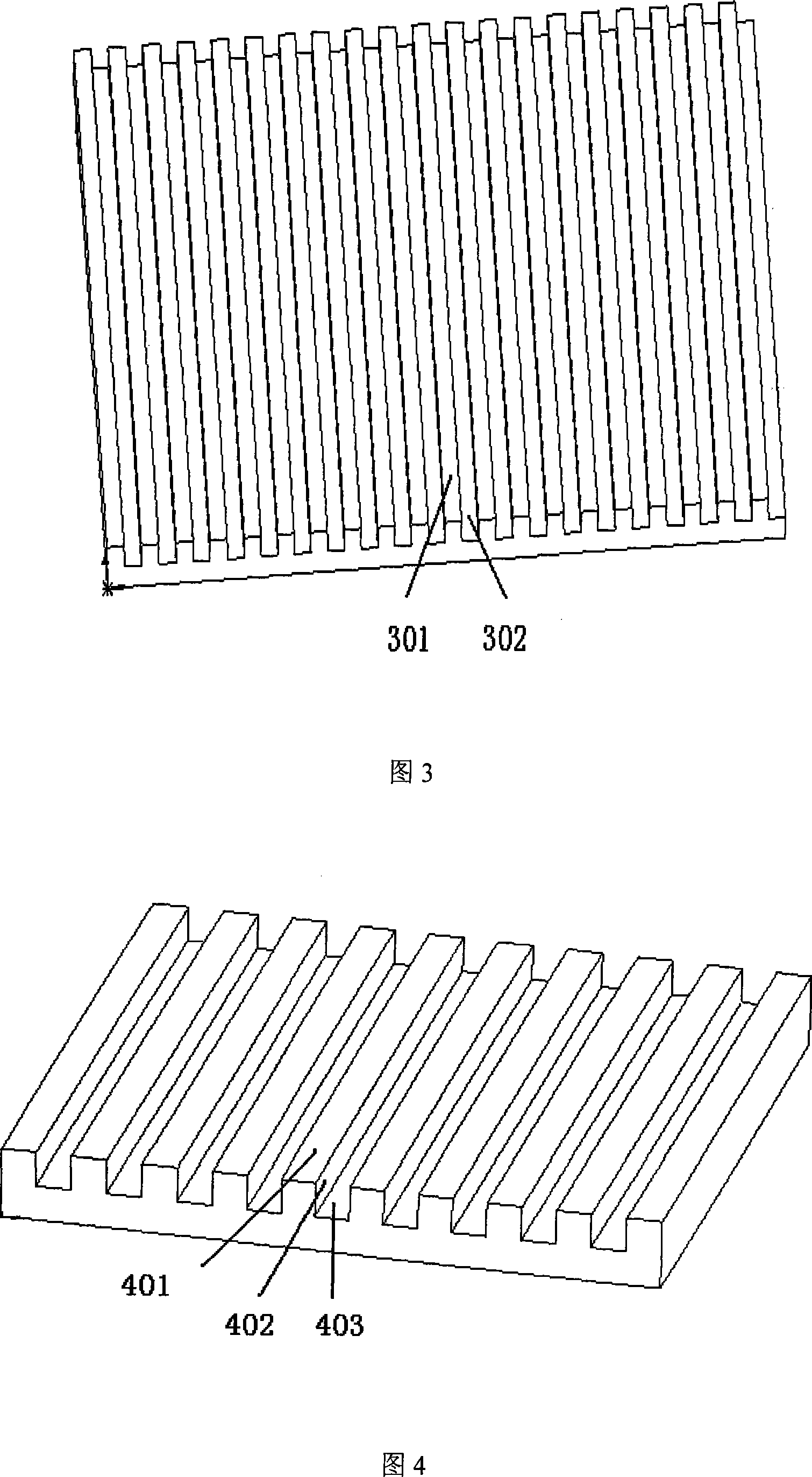

Transmission-type spectro-grating and interference lithography system

InactiveCN103424794AHigh diffraction efficiencyImprove uniformityDiffraction gratingsPhotomechanical exposure apparatusGratingHigh energy

Provided are a transmission-type spectro-grating and an interference lithography system. The transmission-type spectro-grating comprises a grating groove-shaped area placed on an incident plane and a light blocking area placed on the periphery of the grating groove-shaped area. The grating groove-shaped area comprises a stair-shaped grating structure, and the stair-shaped grating structure is provided with a transmission stair plane and a non-transmission area. The transmission-type spectro-grating can achieve maximum modulation to + / -1 level light, beam splitting light which is transmitted out is made to have the highest energy utilization rate, and an interference pattern obtained through the transmission-type spectro-grating has good border quality, is capable of achieving conducting of precise splicing patterns, and enables a large-size interference lithography technology to be improved obviously.

Owner:SUZHOU UNIV

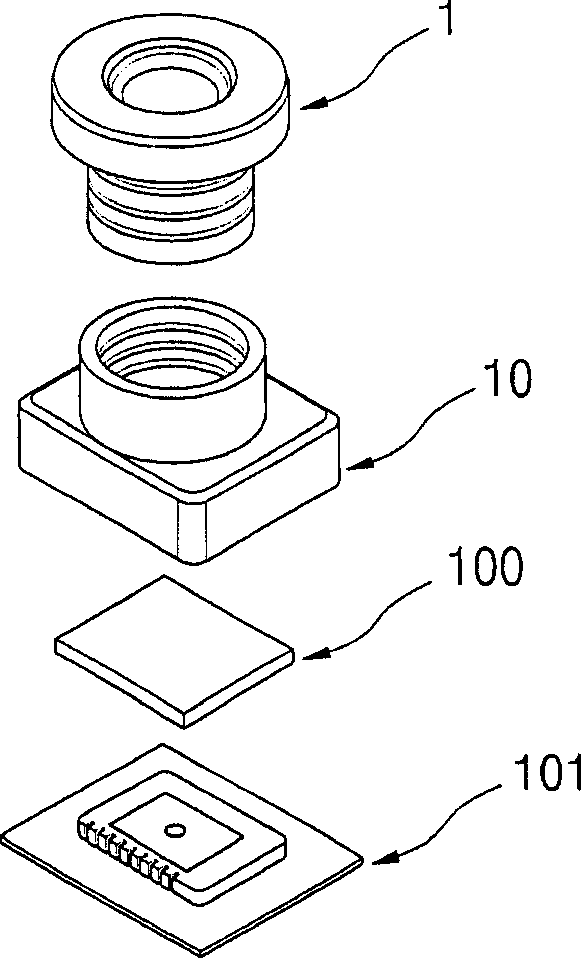

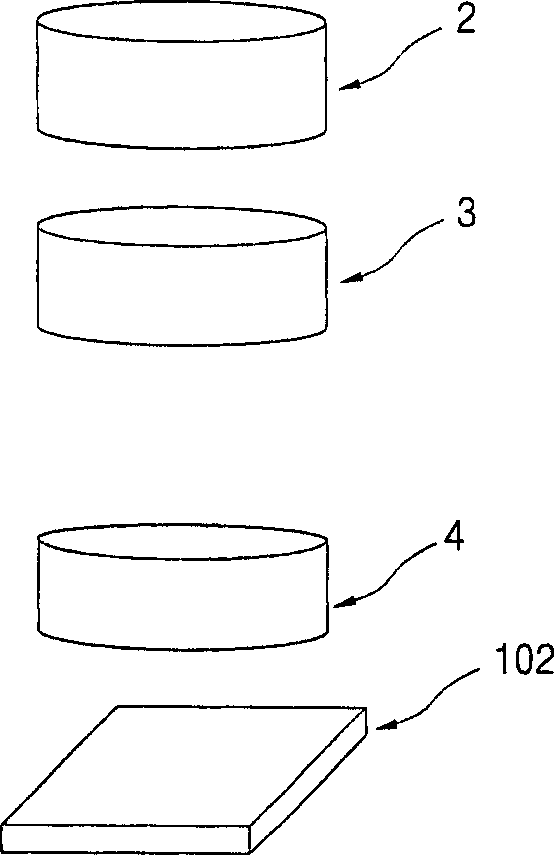

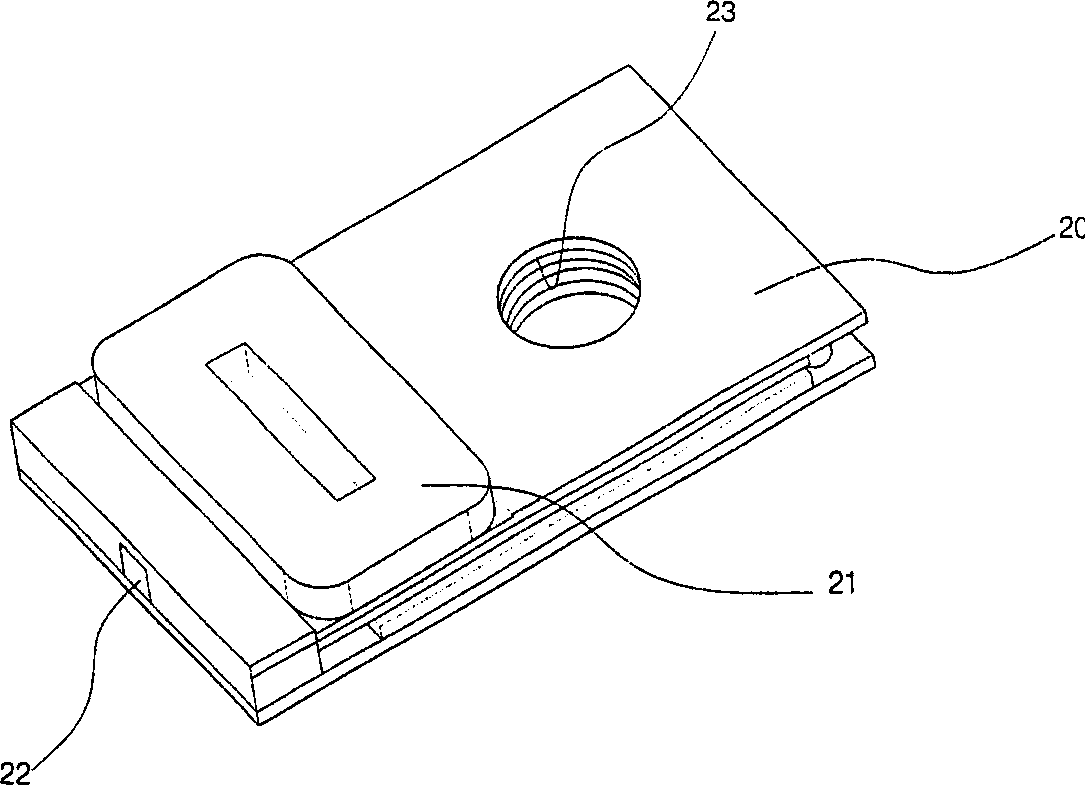

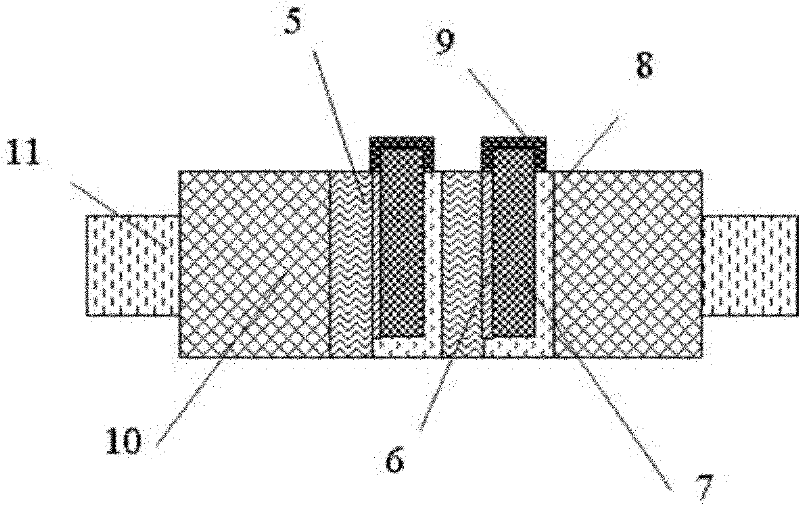

Small form factor camera module with mechanical iris and shutter

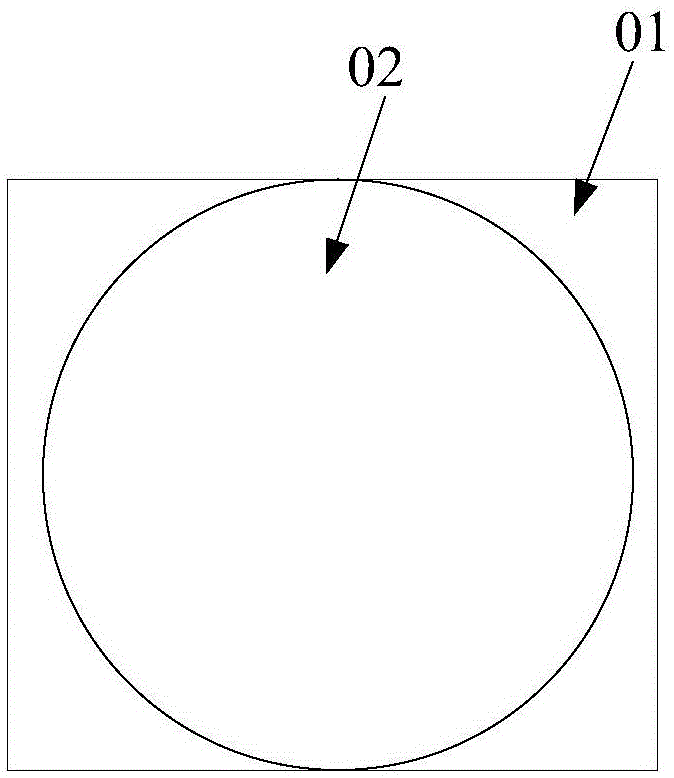

InactiveCN1854879AImprove graphics qualityTelevision system detailsColor television detailsElectronic shutterImaging quality

The present invention relates to a small form factor camera module, more particularly, to a small form factor camera module having a mechanical iris and a shutter not only to improve an image quality by adjusting an amount of a light entering an image sensor but also to remarkably reduce a volume of the entire system by using an electromagnetic force and therefore to be applied to various applications which require for a small form factor camera module including a handheld terminal and so on, contrary to the existing electronic shutter. In order to obtain the object of the present invention, the small form factor camera module having a lens assembling body consisting of more than one lens for obtaining an image of an object, an image sensor for transforming the image passed through the lens into an electric signal and a peripheral circuit unit connected with the image sensor, further comprising: a light amount adjustment device capable of adjusting a light amount of an image reaching an image sensor through the lens assembling body by controlling an incidence area and an incidence time.

Owner:LG ELECTRONICS INC

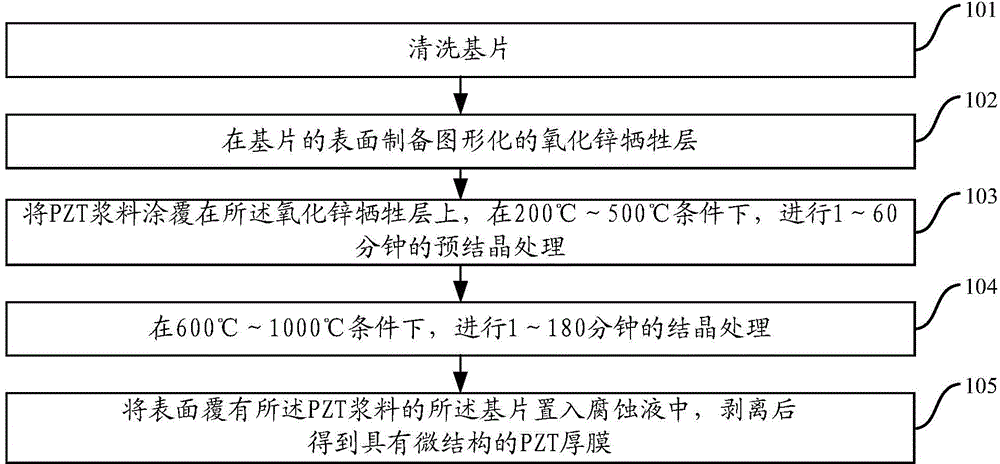

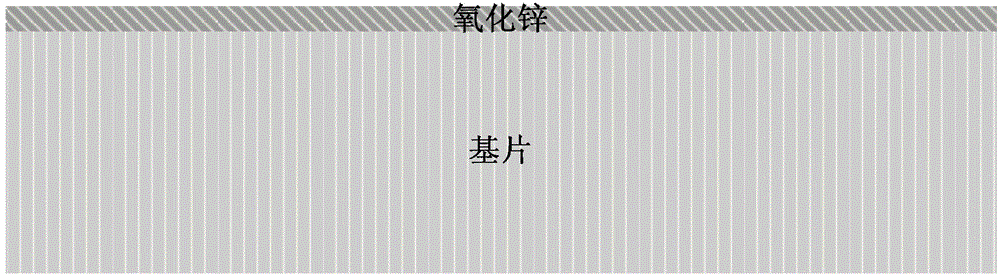

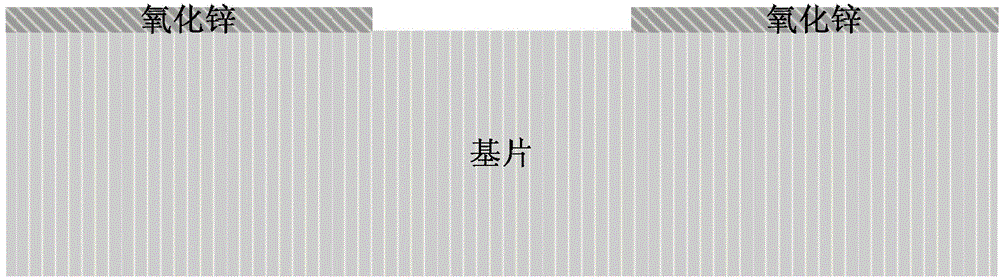

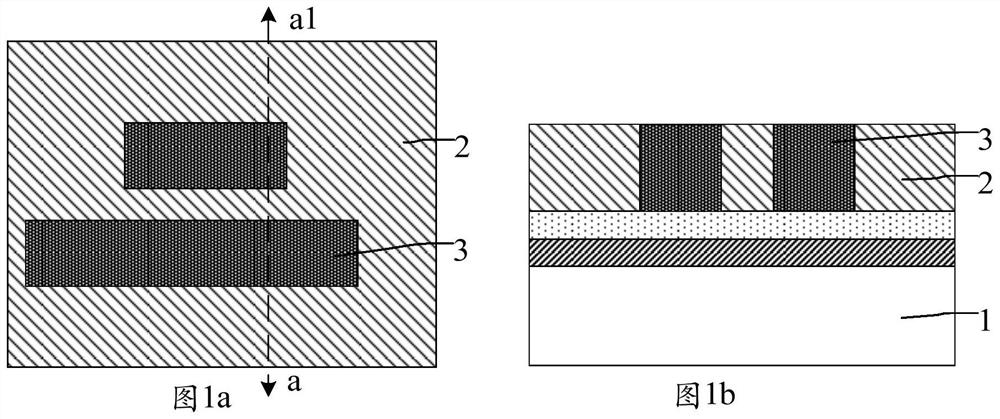

Preparation method of piezoelectric ceramic transducer (PZT) thick film with micro structure

InactiveCN104311007AImprove surface smoothness and densityOvercoming Difficulty in Clean EtchingThermal treatmentZinc

The invention provides a preparation method of a piezoelectric ceramic transducer (PZT) thick film with a micro structure. The preparation method is characterized by comprising the following steps: preparing a graphical zinc oxide sacrificial layer on the surface of a substrate; coating the zinc oxide sacrificial layer with PZT slurry, performing pre-crystallization treatment for 1-60 minutes at 200-500 DEG C; at 600-1000 DEG C, performing crystallization treatment for 1-180 minutes; and putting the substrate, surface of which is coated with the PZT slurry, into a corrosive liquid, and then stripping to obtain the PZT thick film with the micro structure. By adopting a process of improving the slurry and the thermal treatment, the preparation method disclosed by the invention can be used for obviously improving the surface evenness and the density of the PZT thick film. And meanwhile, by virtue of a stripping technology that adopts the zinc oxide as the sacrificial layer, the problem that the PZT thick film is difficult to etch completely can be overcome.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

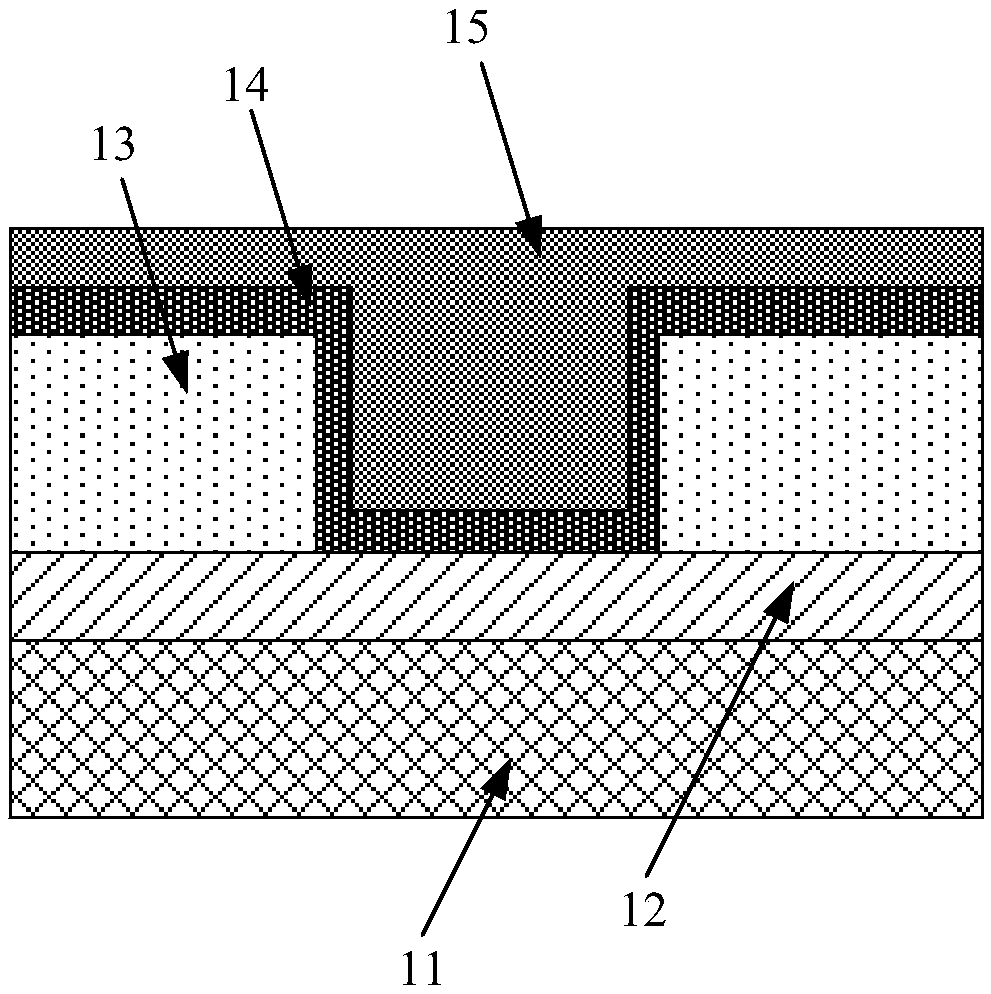

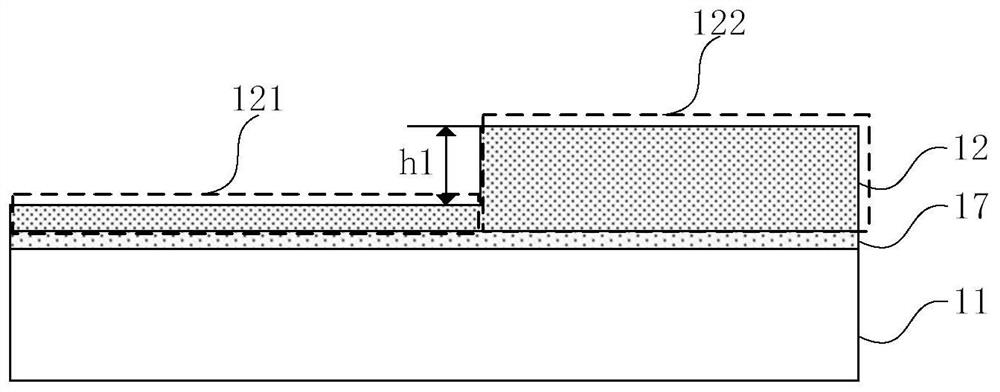

Semiconductor structure and forming method thereof

PendingCN112713087AIncreased etch resistanceReduce the probability of misetchingSemiconductor/solid-state device manufacturingSemiconductor structureEngineering

The invention discloses a semiconductor structure and a forming method thereof. The forming method comprises the steps of providing a substrate, and forming a to-be-etched layer on the substrate, forming a core layer and a plurality of sacrificial layers located in the core layer on the to-be-etched layer, and enabling the sacrificial layers to be arranged at intervals, removing part of the core layer between the adjacent sacrificial layers to form a first groove penetrating through the core layer, and exposing the sacrificial layers from the side wall of the first groove, carrying out first ion doping treatment on the core layer of the side wall of the first groove, wherein the first ion doping treatment is suitable for increasing the etching resistance of the core layer of the side wall of the first groove, forming a side wall on the side wall of the first groove, after first ion doping processing and side wall forming are carried out, removing the sacrificial layer, forming a second groove penetrating through the core layer, and isolating the second groove and the first groove by a side wall, and etching the to-be-etched layers at the bottoms of the first groove and the second groove by taking the core layer and the side walls as masks. According to the embodiment of the invention, the probability that the core layer on the side wall of the first groove is mistakenly etched in the step of removing the sacrificial layer is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

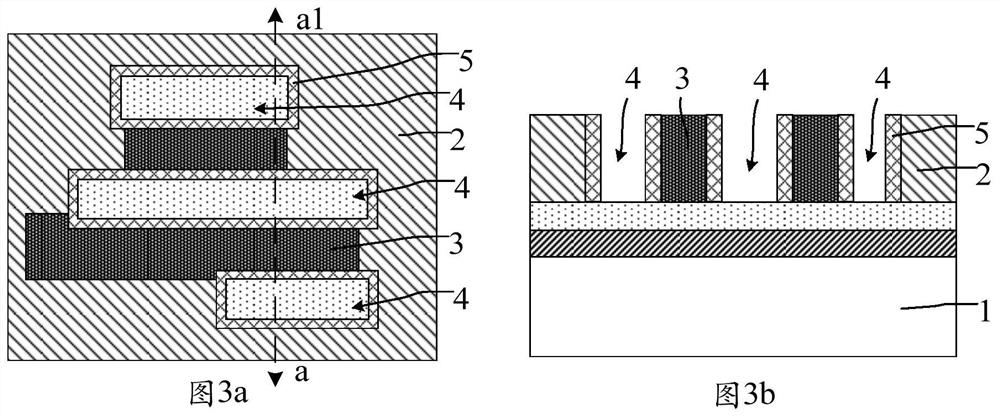

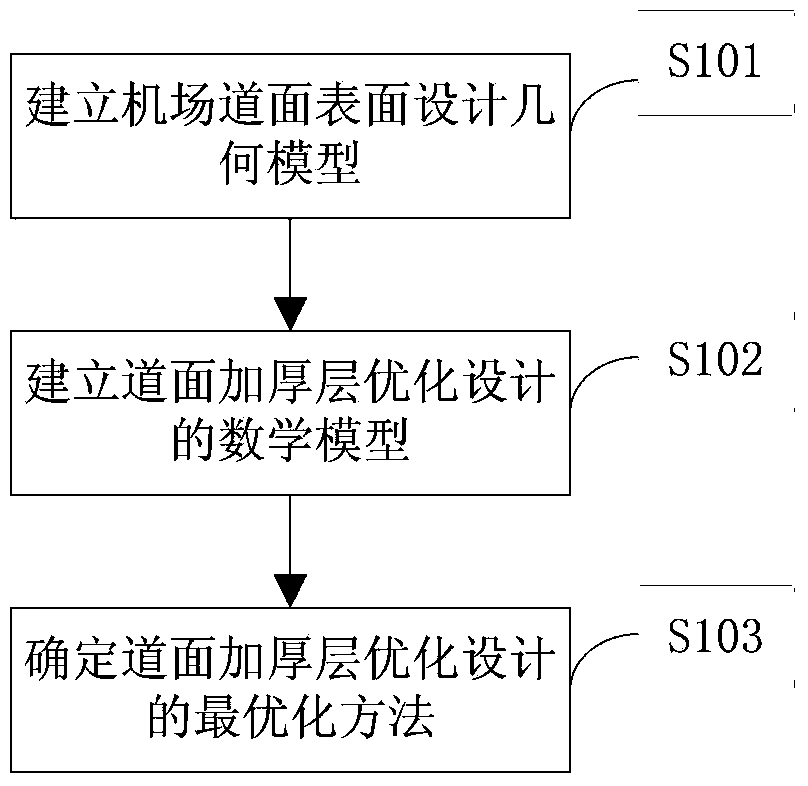

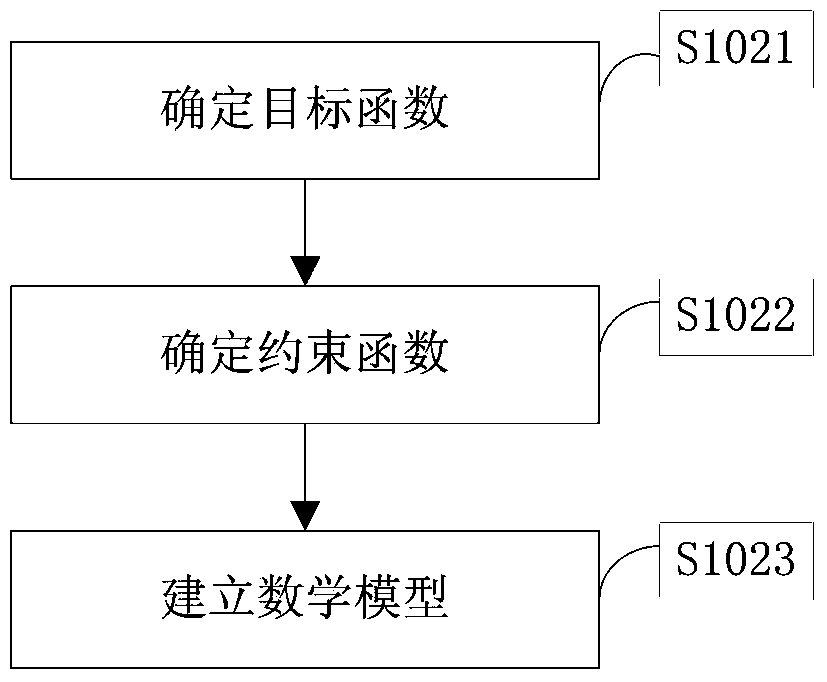

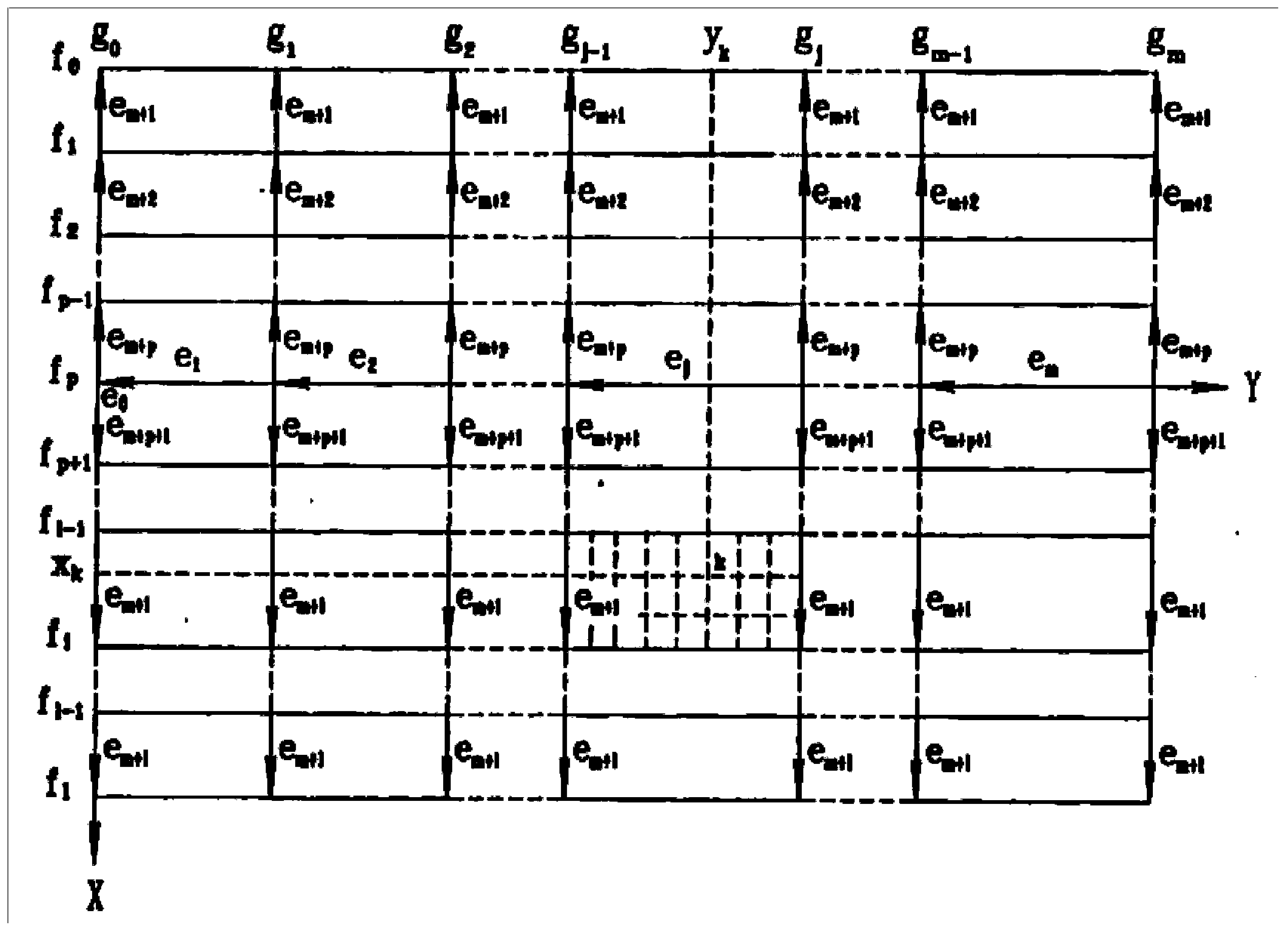

System and method for optimally designing thickening layers of airport pavements

InactiveCN103761373AReliable calculationEasy to useSpecial data processing applicationsMathematical modelGeometric modeling

The invention discloses a system and a method for optimally designing thickening layers of airport pavements. The system for optimally designing the thickening layers of the airport pavements comprises an automatic optimizing unit, an automatic computing unit, an interactive unit and an automatic drawing unit. The method for optimally designing the thickening layers of the airport pavements includes steps of using spatial curved surfaces as the surfaces of the pavements with the thickening layers and designing geometrical models; building mathematical models for optimally designing the thickening layers of the pavements by means of using design grade and elevation of control points as design variables; creating constraint conditions which conform to relevant specifications of current military aviation and civil aviation; providing the optimal process for optimally designing the thickening layers of the pavements. The system and the method have the advantages that the system and the method are applied to designing more than ten rebuilt or expanded airports such as the Baita airport in Hohhot, the concrete thickening layer engineering quantity can be saved by about 5%, all design drawing can be implemented, an acquired design scheme completely conforms to technical standards, and the design period can be shortened and is about 10 days.

Owner:AIR FORCE UNIV PLA

Method for processing optical character recognition (OCR) output data, wherein the output data comprises double printed character images

InactiveUS8320677B2Improve performanceImprove graphics qualityCharacter recognitionCharacter recognitionOptical character recognition

The present invention is related to a method of processing of output data from an Optical Character Recognition (OCR) system, wherein the output data comprises images of double printed characters. The method identifies the respective members of a suspected double printed character image by first providing a set of single character template images from images of characters identified in the text being processed by the OCR system, then combining the single character templates providing candidate models for the suspected double printed character image. Correlation between each respective candidate model and the suspected double printed character image provides an indication of which pair of modelled single template character images that most probable are the correct identification of the respective character images in the double printed character image.

Owner:LUMEX AS (NO)

Flexible substrate MEMS technology-based electroencephalogram dry electrode array and preparation method thereof

InactiveCN101973508BImprove graphics qualityQuality improvementDecorative surface effectsDiagnostic recording/measuringImaging qualityBiocompatibility Testing

The invention relates to a flexible substrate MEMS technology-based electroencephalogram dry electrode array and a preparation method thereof, belonging to the technical field of micro electro mechanical system. The electrode array comprises a stationary fixture and a plurality of electroencephalogram dry electrodes fixed in the stationary fixture; wherein the electroencephalogram dry electrode comprises a metal electrode micro needle and a circuit layer as well as a second metal seed layer and a second polyimide layer which are arranged at the two sides thereof, the surface of the metal electrode micro needle is coated with an inertia metal layer, and a first polyimide layer is flexible substrate of electroencephalogram dry electrode. The invention has simple process and high yield; the position of electrode can be changed according to application requirement; metal is adopted as electrode main body, mechanical strength is high, resistance is small, imaging quality of flexible substrate is high, and biocompatibility is good; multilayer packaging of electrode is adopted and fixture is used for fixing, and the prepared electrode stereoscopic array is easy to fix and has good shielding characteristic.

Owner:SHANGHAI JIAO TONG UNIV

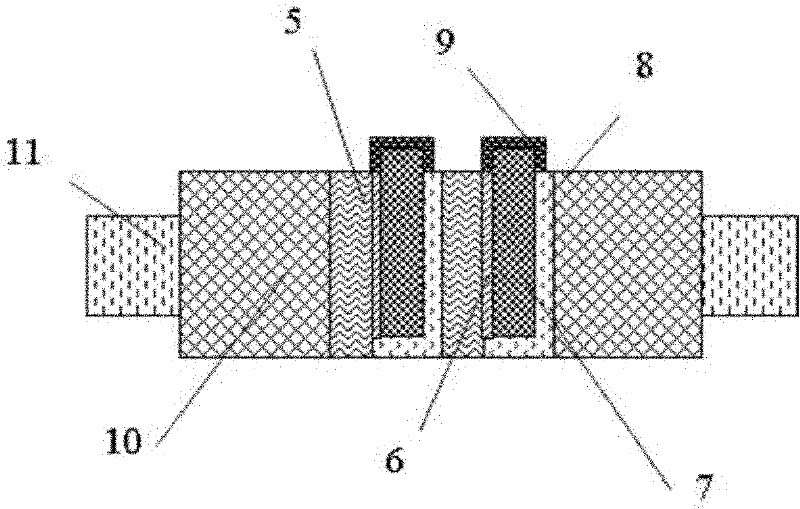

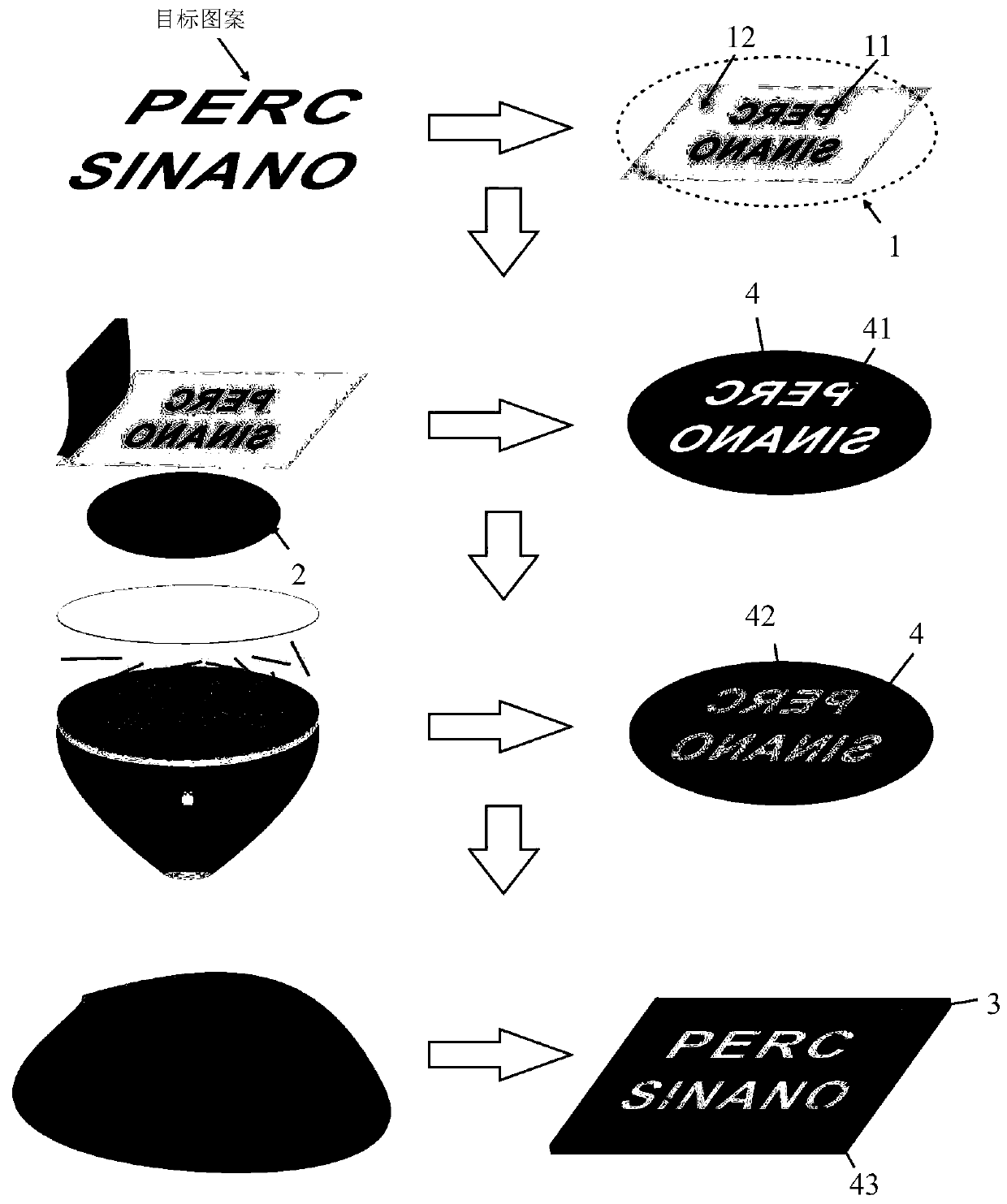

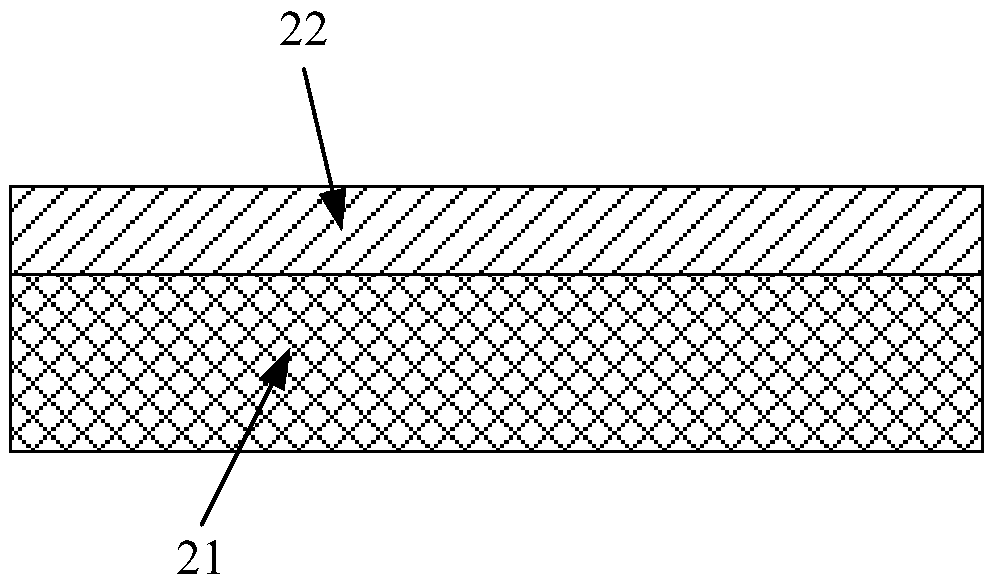

Patterning methods for nanomaterials

ActiveCN108263106BGraphicalImprove graphics qualityNanotechnologyOther printing apparatusScreen printingComputer graphics (images)

The invention discloses a method for patterning nanometer materials. The patterning method includes the following steps: providing a net plate, a filter membrane and a substrate; covering the net plate on the filter membrane; Printing polymer slurry to form a patterned polymer slurry layer on the surface of the filter membrane; depositing nanomaterials on the patterned area of the polymer slurry layer to form a nanomaterial structure; The structure is transferred onto the substrate. In the method for patterning nanomaterials provided by the present invention, an imaged polymer slurry layer is formed by screen printing, and then nanomaterials are deposited on the patterned region of the polymer slurry layer to form a patterned nanomaterial structure; Finally, the nanomaterial structure is transferred onto the substrate. The imaging method can effectively realize the patterning of nanomaterials and improve the patterning quality of nanomaterials.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

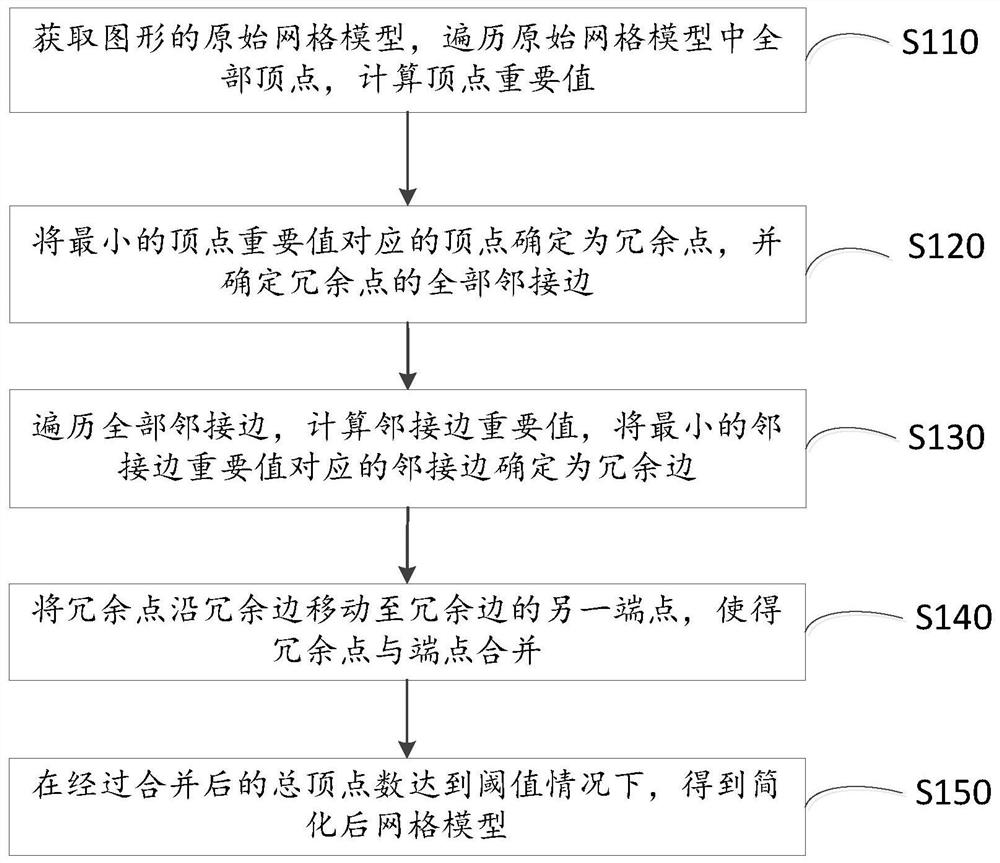

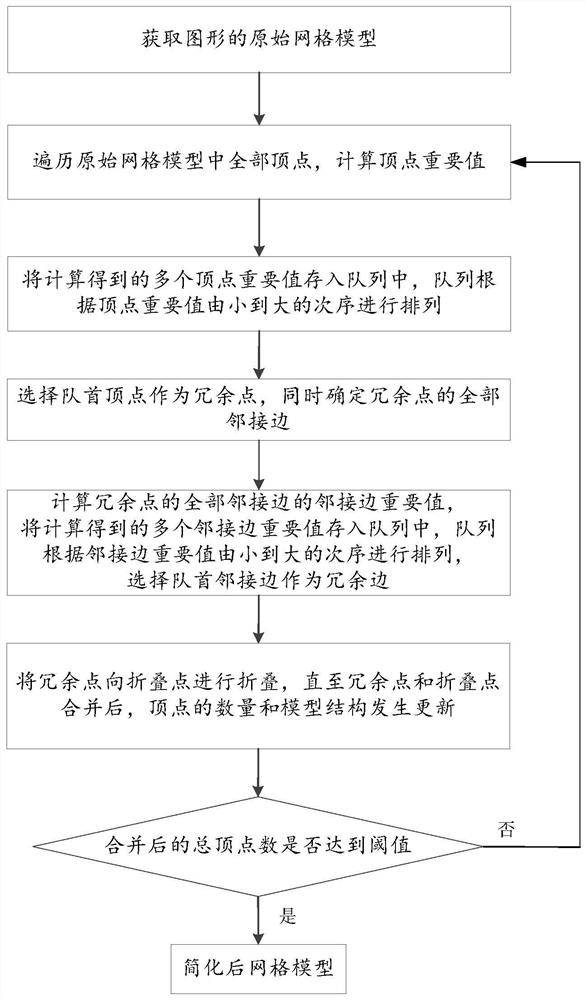

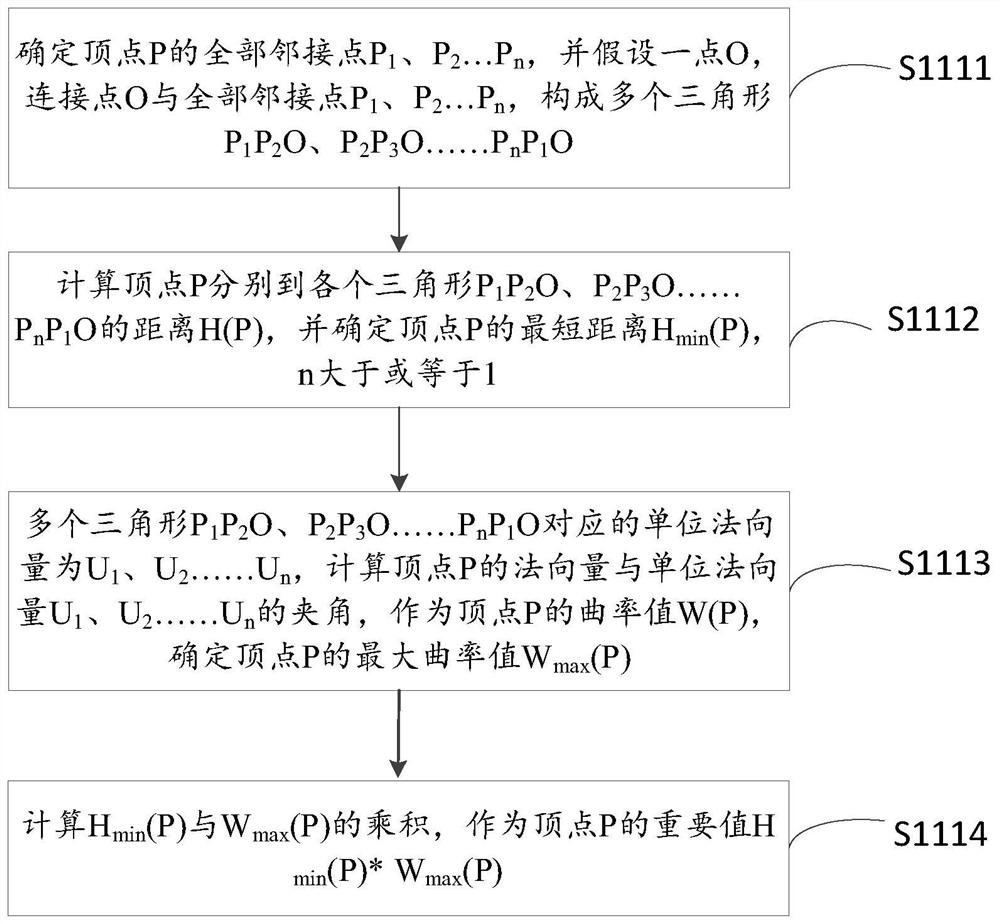

Grid model simplifying method and device

PendingCN112465985AReduce operating costsImprove graphics qualityDesign optimisation/simulationSpecial data processing applicationsDot matrixAlgorithm

The invention discloses a grid model simplifying method and device. The specific implementation scheme is that the method comprises the steps: acquiring an original grid model of a graph, traversing all vertexes in the original grid model, and calculating vertex importance values; determining the vertex corresponding to the minimum vertex importance value as a redundant point, and determining alladjacent edges of the redundant point; traversing all adjacent edges, calculating important values of the adjacent edges, and determining the adjacent edge corresponding to the smallest important value of the adjacent edge as a redundant edge; moving the redundant point to the other end point of the redundant edge along the redundant edge to merge the redundant point and the end point; and under the condition that the combined total vertex number reaches a threshold value, obtaining a simplified grid model. According to the method, the vertexes which have small influence on the grid model aregradually reduced, the vertexes which have large influence on the grid model are reserved, the obtained simplified grid model can display the best-quality graph by using the minimum dot matrix data, the operation cost of the simplified graph is saved, and the graph quality is improved.

Owner:CHINA UNIONPAY

Resistive random access memory and manufacturing method thereof

ActiveCN109411601AImprove reliabilityAvoid the problem of uneven electric fieldElectrical apparatusStatic random-access memoryRandom access memory

The technical scheme of the invention discloses a resistive random access memory and a manufacturing method thereof. According to the technical scheme, a functional layer located outside a through hole is removed; and one side surface, deviating from a substrate, of an insulating dielectric layer does not cover the functional layer, so that the problem that the electric field is uneven due to thefact that the function layer is arranged outside the through hole is avoided, and the reliability of the resistive random access memory is improved.

Owner:ZHUHAI CHUANGFEIXIN TECH CO LTD

Method for manufacturing layers required by integrated circuit layout registration

InactiveCN104376178AEasy to makeReduce stitching workloadSpecial data processing applicationsGraphicsElectronic document

The invention discloses a method for manufacturing layers required by integrated circuit layout registration. The method includes the following steps that a data file of the gds format of an integrated circuit layout is introduced into planishing; a certain layer with process features is selected, and the layer is printed to form an electronic document file; the page margins of pages of picture files are set sequentially, graphs unrelated to the layout graphs are removed, only the layout graphs are reserved, and the adjacent layout graphs to be spliced are made to be right aligned with the page margins and are converted into a plurality of files of the jpeg format of the layer; the files of the jpeg format of the layer are selected, shapes of chip layouts are compared, the corresponding positions of the files of the jpeg format are set and are spliced into a graphic file; the spliced graphic file is evaluated; the manufactured files of all the layers are gathered to one file, and the layer files for the integrated circuit layout registration are formed. By means of the method, the splicing workload is lowered, the splicing accuracy is improved, and the requirement for layer manufacturing is met.

Owner:SUZHOU R&D CENT OF NO 214 RES INST OF CHINA NORTH IND GRP

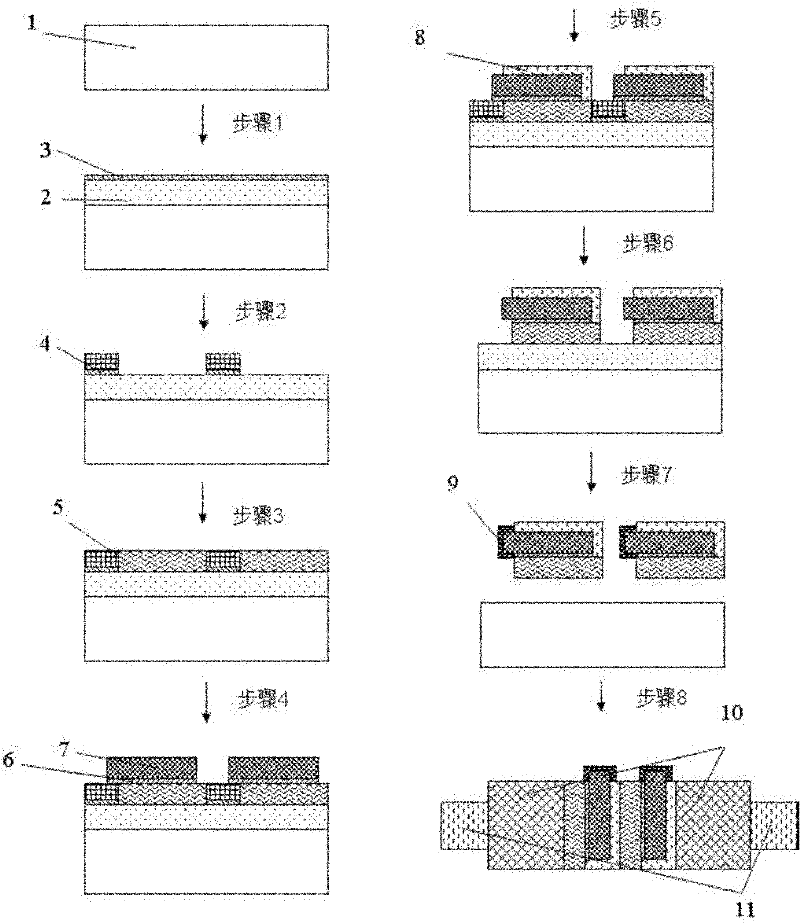

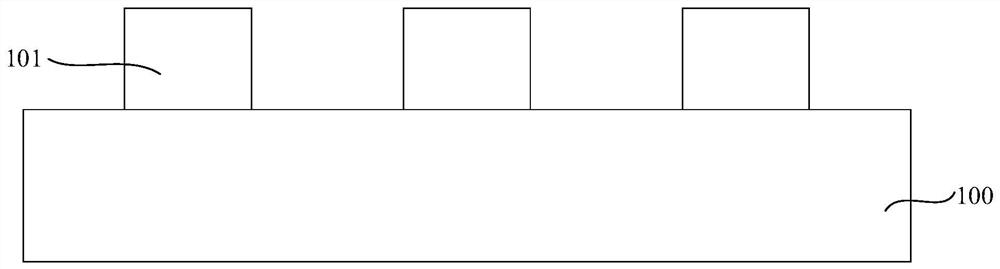

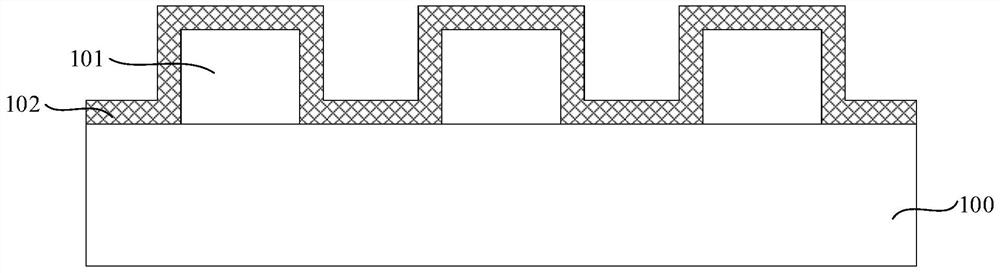

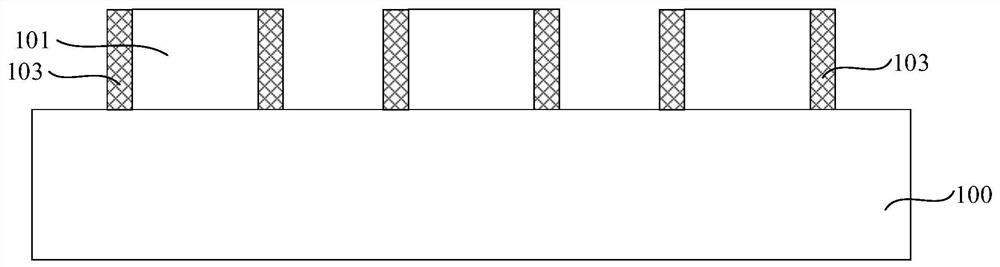

Semiconductor structure forming method and semiconductor structure

PendingCN111785613APrevent tipping or collapsingImprove graphics qualitySemiconductor/solid-state device manufacturingPhysicsChemistry

The embodiment of the invention relates to a forming method of a semiconductor structure, and the semiconductor structure. The forming method comprises the steps: providing a substrate, and forming aplurality of discrete sacrificial layers on the substrate; forming a buffer layer on the surface of the side wall of the sacrificial layer, wherein the material of the buffer layer contains organic groups and inorganic components; forming a side wall layer on the surface of the buffer layer, wherein the buffer layer is located between the side wall layer and the sacrificial layer; after the side wall layer is formed, removing the sacrificial layer; and after the sacrificial layer is removed, etching the substrate by taking the side wall layer and the buffer layer as masks. According to the invention, the pattern quality of the self-aligned pattern can be improved, and the semiconductor production yield is improved.

Owner:CHANGXIN MEMORY TECH INC

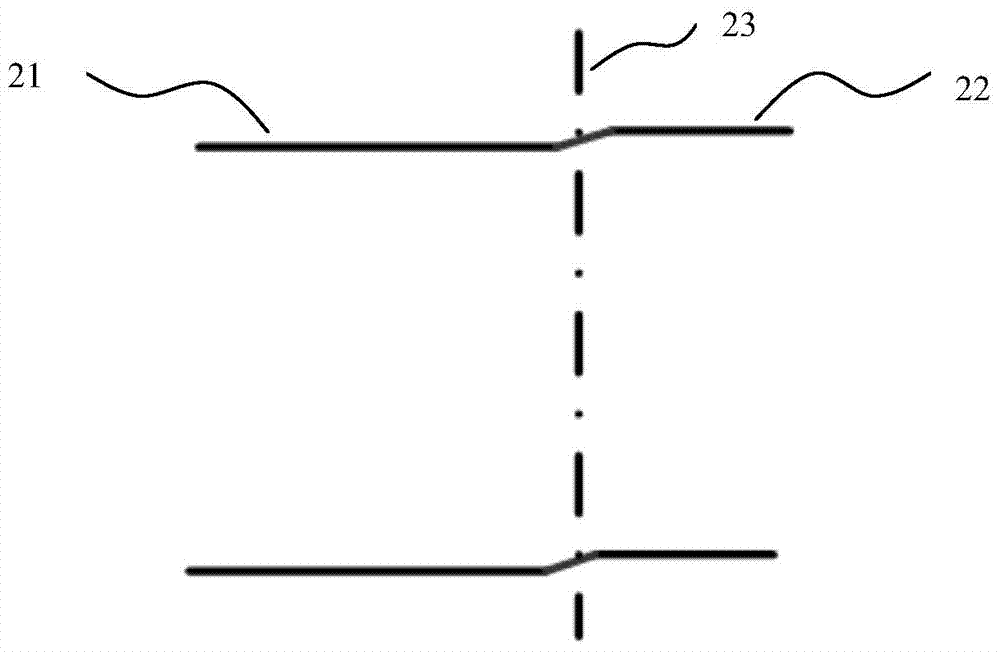

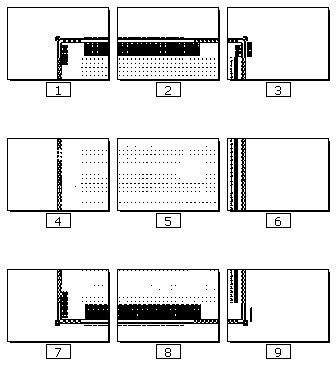

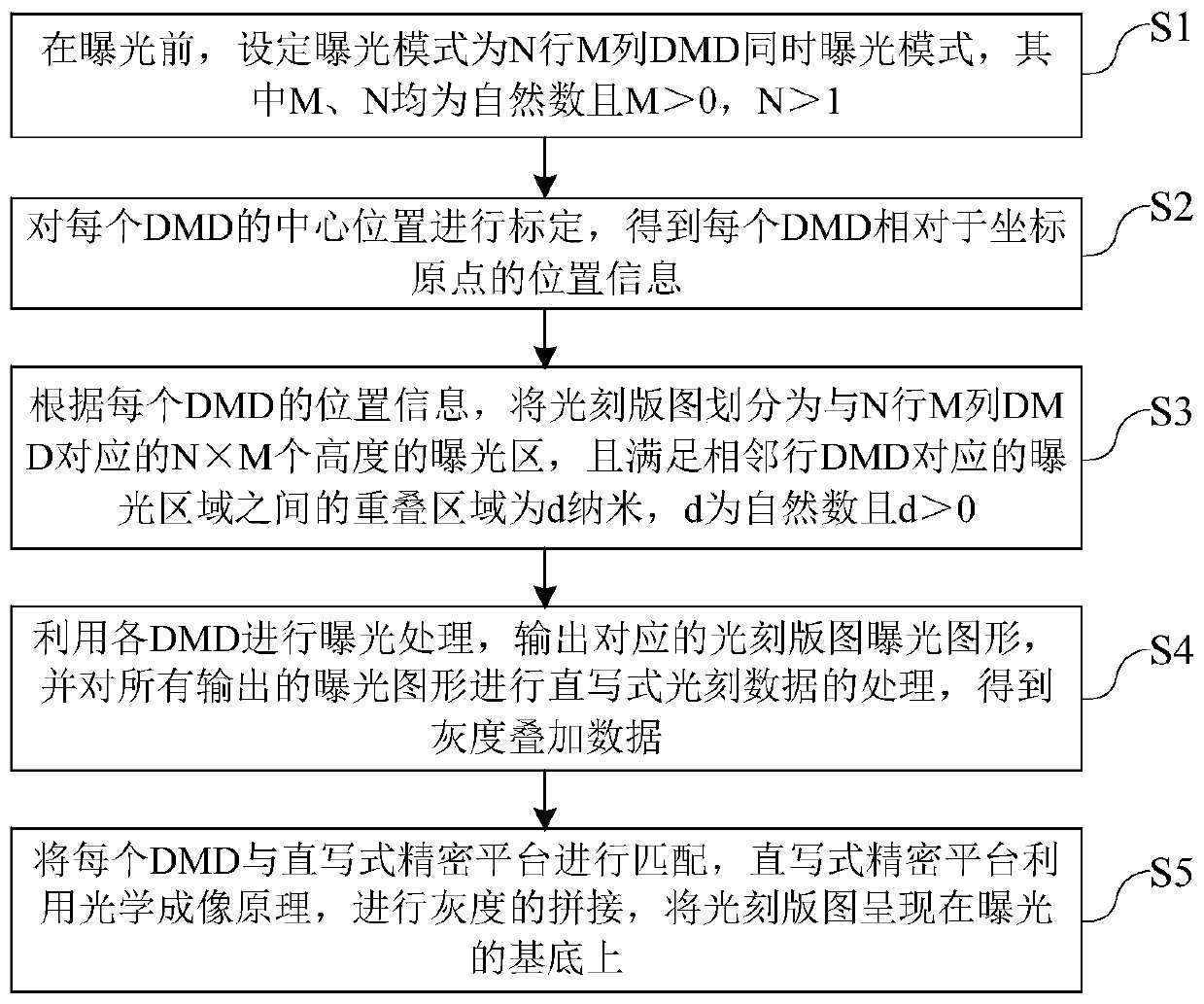

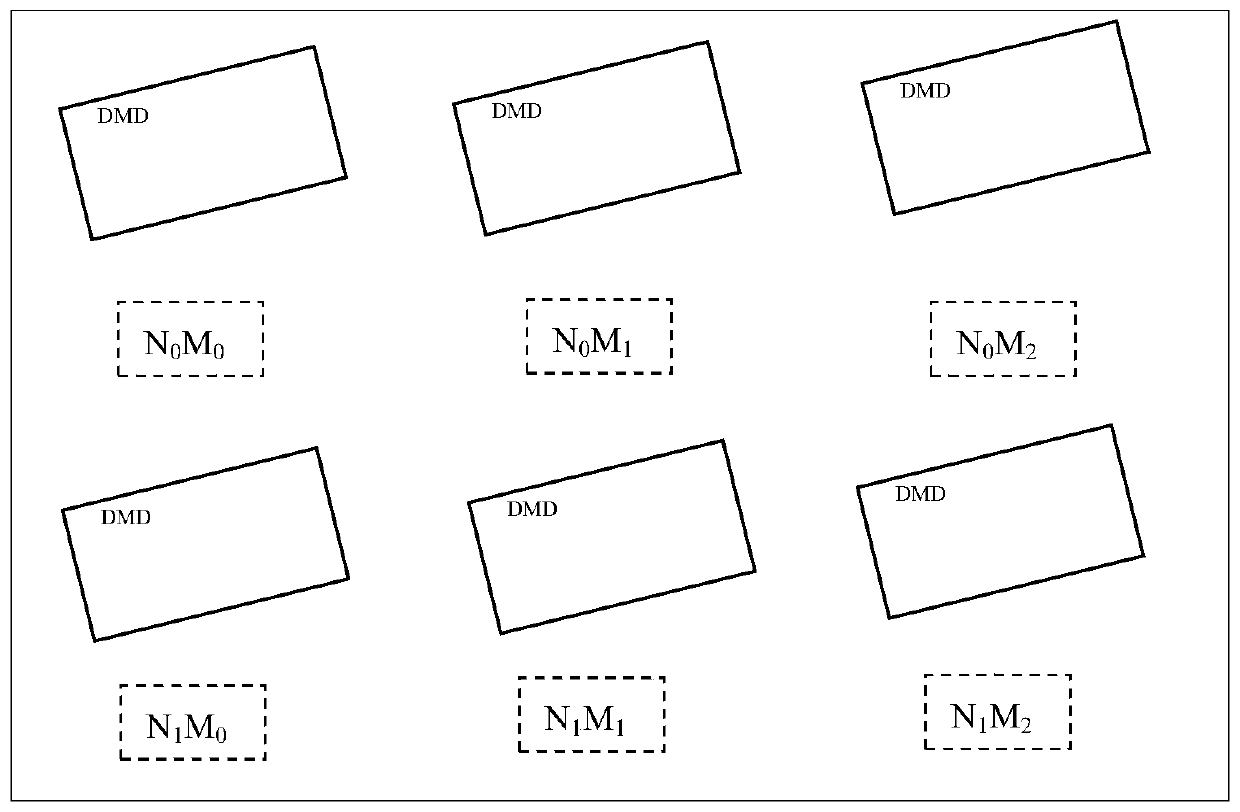

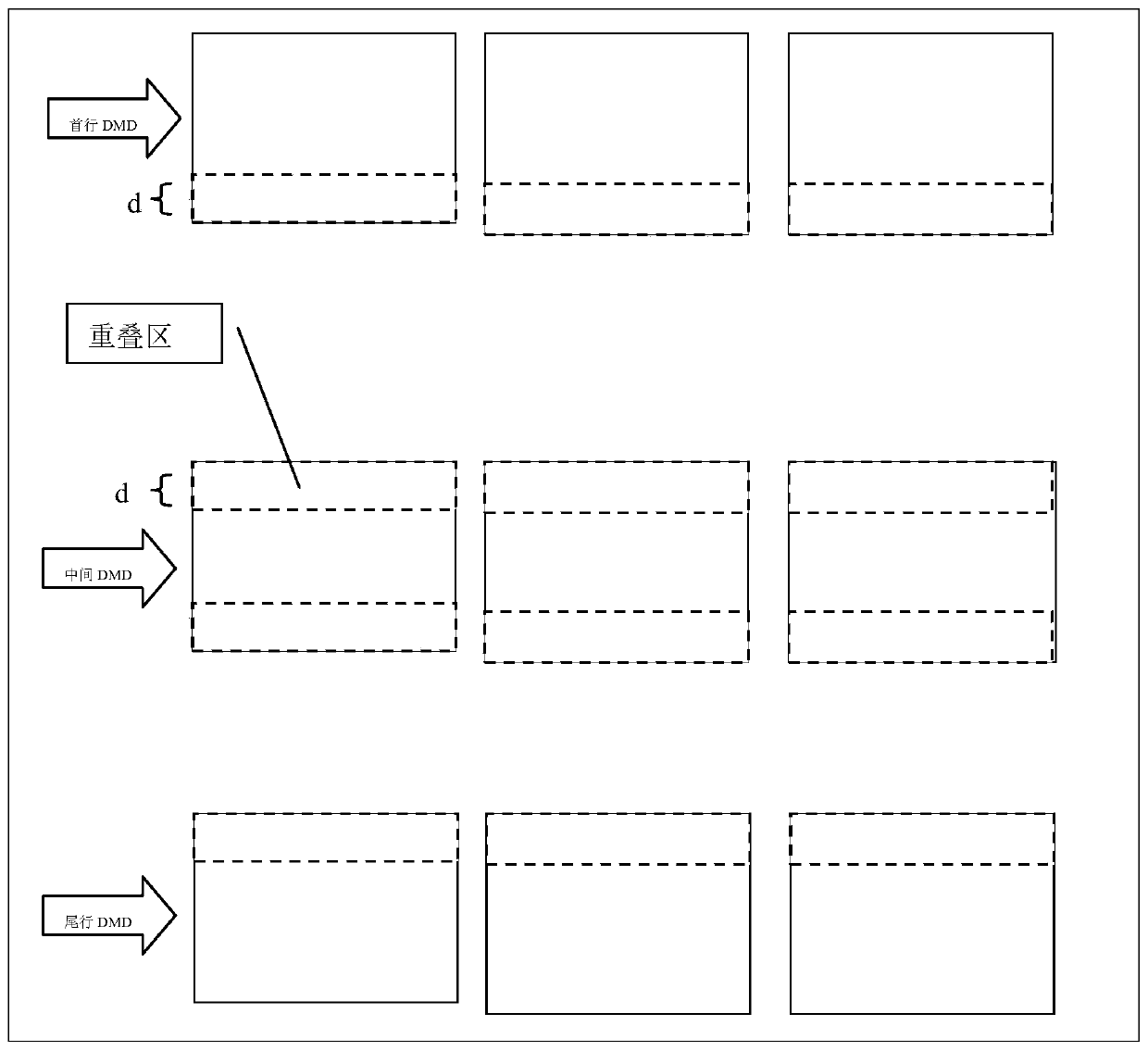

Direct-writing photoetching machine splicing method

InactiveCN110531590AReduce the need for self-precisionPossibility to achieve segmented exposurePhotomechanical exposure apparatusMicrolithography exposure apparatusGraphicsImaging processing

The invention discloses a direct-writing photoetching machine splicing method, and belongs to the semiconductor photoetching machine graph and image processing and splicing technology field. The method comprises the following steps of before exposure, setting an exposure mode as an N-row M-column DMD simultaneous exposure mode; dividing a photoetching layout into N * M height exposure areas corresponding to the N-row M-column DMD, wherein an overlapping area between the exposure areas corresponding to adjacent rows of DMDs is d nanometers; carrying out exposure processing by using each DMD, and carrying out direct-writing photoetching data processing on all output exposure graphs to obtain gray level superposition data; matching each DMD with a direct-writing precision platform, wherein the direct-writing precision platform uses an optical imaging principle to carry out gray scale splicing, and the photoetching layout is presented on an exposed substrate. In the method, N-row M-columnDMD simultaneous exposure is adopted, splicing precision is improved through splicing of gray-scale maps, possibility of segmented exposure of photoetching patterns is achieved, and productivity is improved.

Owner:HEFEI CHIP FOUND MICROELECTRONICS EQUIP CO LTD

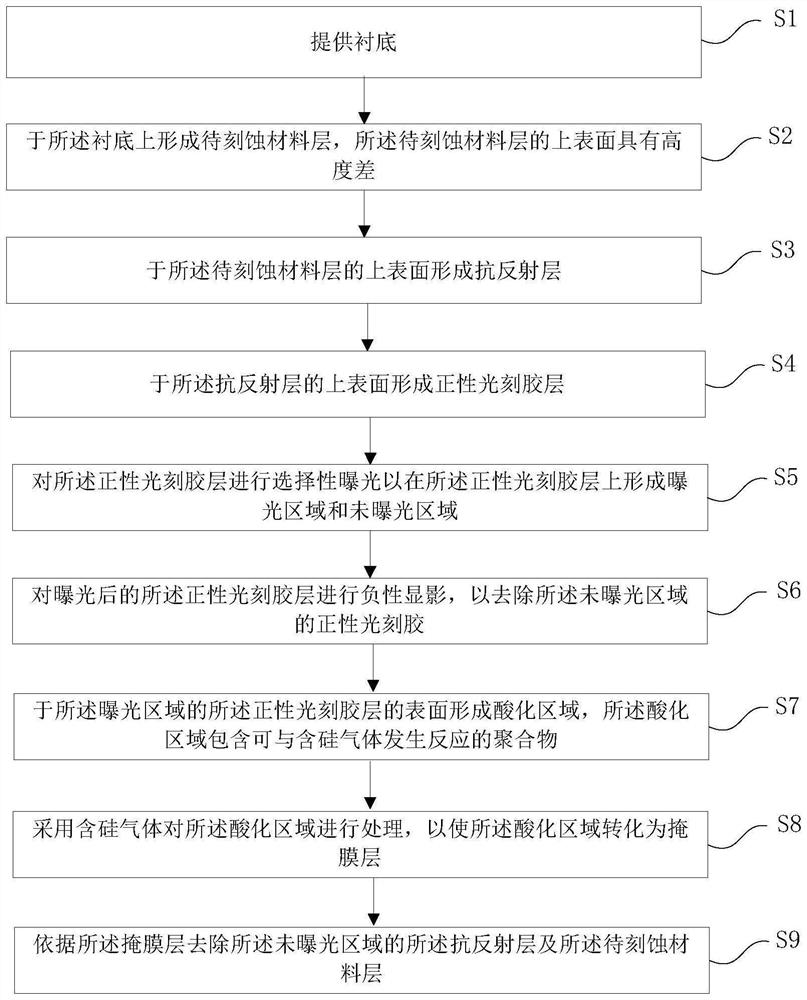

Semiconductor process method

InactiveCN111834201AReduce manufacturing difficultyGuaranteed dimensional accuracySemiconductor/solid-state device manufacturingChemistryPhotoresist

The invention provides a semiconductor process method, which comprises the following steps: 1) providing a substrate; 2) forming a to-be-etched material layer on the substrate, wherein the upper surface of the to-be-etched material layer has a height difference; 3) forming an anti-reflection layer on the upper surface of the to-be-etched material layer; 4) forming a positive photoresist layer on the upper surface of the anti-reflection layer; 5) performing selective exposure to form an exposure area and an unexposed area on the positive photoresist layer; 6) carrying out negative development to remove the positive photoresist in the unexposed area; 7) forming an acidified region on the surface of the positive photoresist layer, wherein the acidified region comprises a polymer capable of reacting with silicon-containing gas; 8) processing the acidified region by adopting silicon-containing gas to convert the acidified region into a mask layer; and 9) removing the anti-reflection layer and the to-be-etched material layer. According to the invention, the method can be effectively used for manufacturing the ultra-fine pattern with the high step difference, the size precision of a device can be guaranteed, the pattern quality can be improved, the process production yield can be improved, and the production cost can be reduced.

Owner:SIEN QINGDAO INTEGRATED CIRCUITS CO LTD

Laser interference lithography system with pattern locking function

ActiveCN103092002BLock high speedLock high precisionPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingBeam splitter

A laser interference lithography system with a pattern locking function comprises a laser, a reflector, a beam splitter, a substrate stage, a substrate and a pattern locking device. A laser beam emitted by the laser is split into an exposure beam and a reference beam by a spectroscope; the exposure beam passes through the beam splitter, and is reflected to the substrate on the substrate stage by the reflector to realize interference; the interference patterns can realize pattern record transfer by exposing the substrate; and the patterns are locked by the pattern locking device to prevent pattern drift during exposure. The pattern locking device includes a null phase meter, an electronic signal processing component, a controller, a driver and a phase modulation executing, wherein the null phase meter is used for measuring pattern phase drift; the pattern phase drift is fed back to the controller through the signal processing component; and the controller controls the phase modulation executer to realize phase locking through the driver. The laser interference lithography system provided by the invention has the advantages of simple structure, high pattern locking accuracy and the like, and is a key system for realizing large-area high-accuracy grating fabrication.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com