Flexible substrate MEMS technology-based electroencephalogram dry electrode array and preparation method thereof

A flexible substrate and electroencephalogram technology, applied in microstructure technology, technology for producing decorative surface effects, decorative art, etc., can solve the problem of limited fastness of solder joints, electrodes without connectors, and electrodes that cannot be connected And other problems, to achieve the effect of high mechanical strength, low impedance, high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

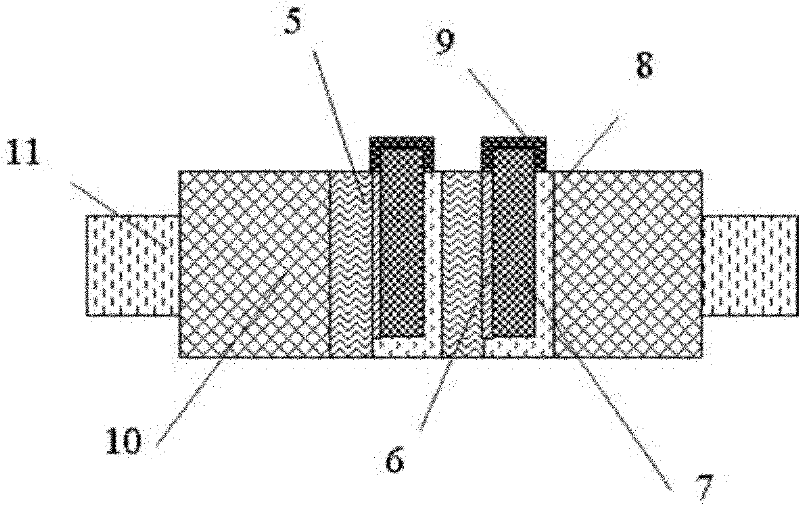

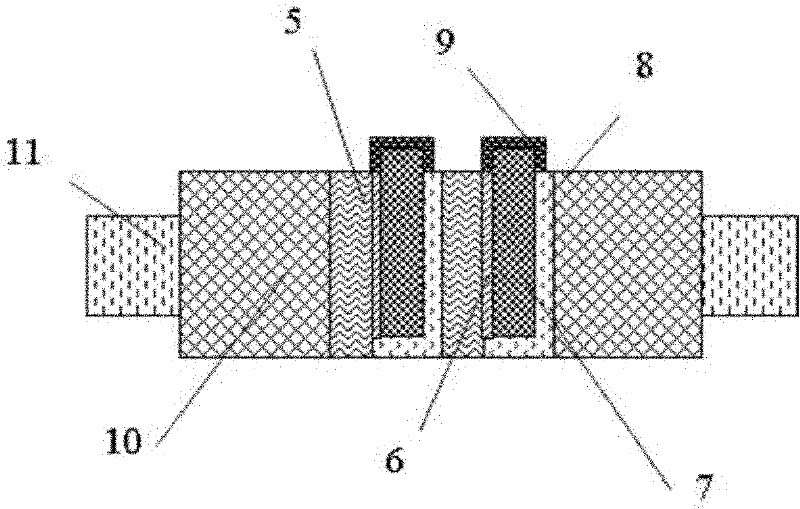

[0038] Structural parameters of EEG dry electrode array: glass substrate, polydimethylsiloxane adhesive layer thickness 50 μm, total biological microelectrode thickness 55 μm, nickel electrode microneedle and circuit layer thickness 28 μm, line width 50 μm, microneedle length 200 μm , the needle tip ratio is 1:1, the thickness of the gold protective layer is 0.5 μm, it is assembled in 10 layers, the clamp is combined, and the diameter of the nylon screw is 1.5 mm.

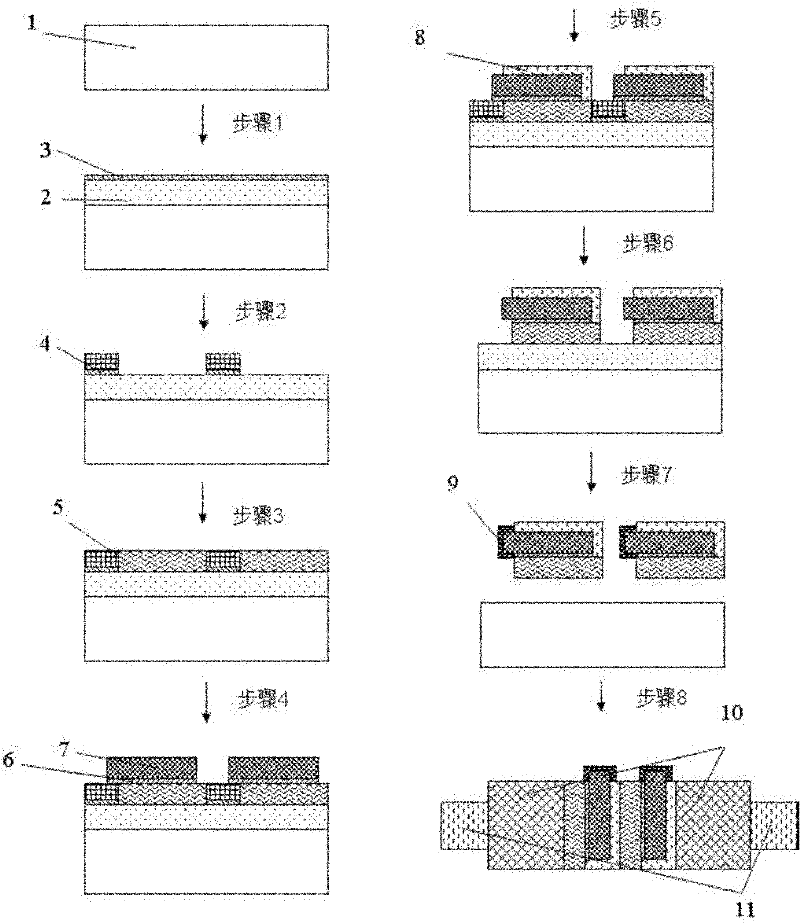

[0039] Such as figure 1 As shown, the preparation process of this embodiment is as follows:

[0040] (1) Substrate treatment and preparation of polydimethylsiloxane adhesion layer

[0041] A glass sheet with a thickness of 2mm was used as the substrate 1, and the substrate was firstly treated: ultrasonically cleaned with calcium carbonate powder, acetone, alcohol and deionized water, and dried in an oven at 180°C for 3 hours. Then, a polydimethylsiloxane adhesive layer 2 with a thickness of 50 μm was coated on th...

Embodiment 2

[0057] Structural parameters of biological microelectrode array: glass substrate, polydimethylsiloxane adhesive layer thickness 200μm, total biological microelectrode thickness 100μm, nickel electrode microneedle and circuit layer thickness 48μm, line width 100μm, microneedle length 300μm, needle tip The ratio is 1:1.5, the thickness of the gold protective layer is 1μm, and it is assembled in 8 layers. The fixture is integral, and the diameter of the nylon screw is 2mm.

[0058] like figure 1 As shown, the preparation process of this embodiment is as follows:

[0059] (1) Substrate treatment and preparation of polydimethylsiloxane adhesion layer

[0060] A glass sheet with a thickness of 2mm was used as the substrate 1, and the substrate was firstly treated: ultrasonically cleaned with calcium carbonate powder, acetone, alcohol and deionized water, and dried in an oven at 180°C for 3 hours. Then a polydimethylsiloxane adhesive layer 2 with a thickness of 200 μm was coated on...

Embodiment 3

[0076] Structural parameters of biological microelectrode array: silicon substrate, polydimethylsiloxane adhesion layer thickness 100μm, total biological microelectrode thickness 120μm, nickel electrode microneedle and circuit layer thickness 68μm, line width 200μm, microneedle length 500μm, needle tip The ratio is 1:2, the gold protective layer is 1.5μm, and it is assembled in 4 layers. The clamp is combined, and the diameter of the nylon screw is 2.5mm.

[0077] like figure 1 As shown, the preparation process of this embodiment is as follows:

[0078] (1) Substrate treatment and preparation of polydimethylsiloxane adhesion layer

[0079] A silicon wafer with a thickness of 0.5 mm was used as the substrate 1, and the substrate was firstly treated by ultrasonic cleaning with deionized water, and drying in an oven at 180° C. for 3 hours. Then a polydimethylsiloxane adhesive layer 2 with a thickness of 100 μm was coated on the substrate at a rotation speed of 1000 rpm, and cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com