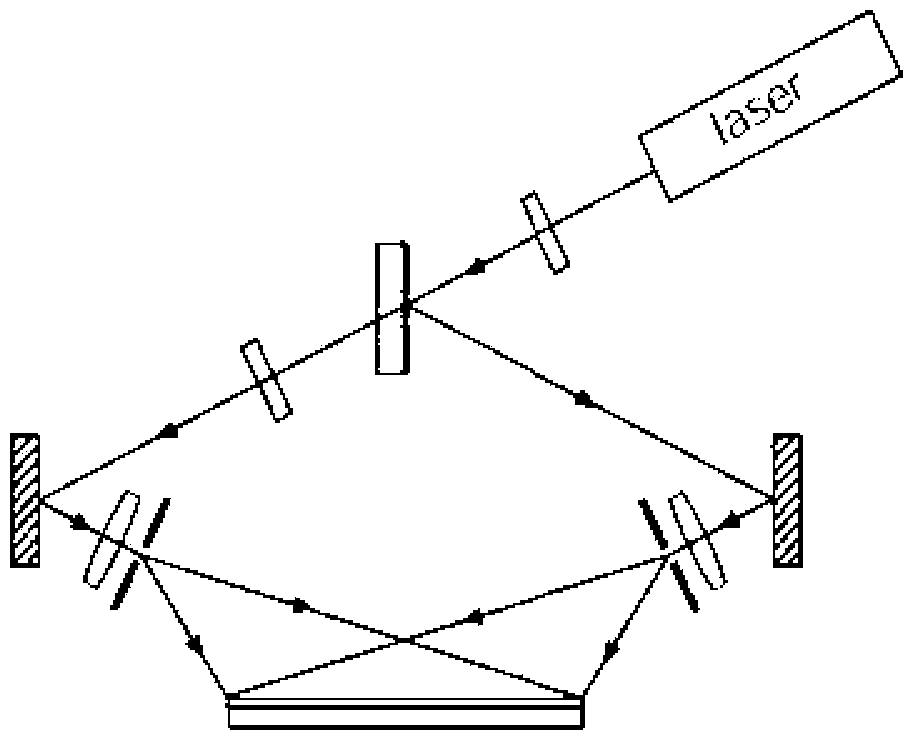

Transmission-type spectro-grating and interference lithography system

A spectroscopic grating and transmissive technology, applied in the field of lithography, can solve problems such as manufacturing difficulty and cost increase, poor graphic quality, limited lithographic format, etc., and achieve the effect of pixelation control, graphic quality improvement, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

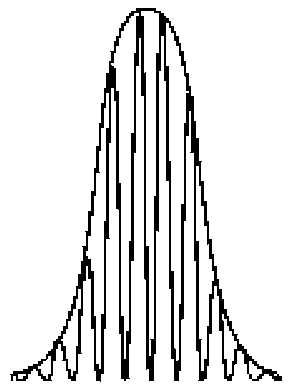

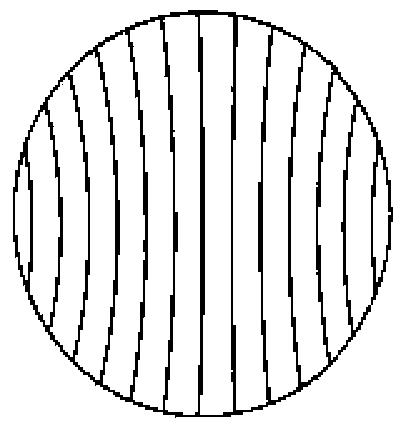

[0054] As mentioned in the background technology, in the existing interference lithography process, when a diffraction grating is used as a spectroscopic device, due to the defects of low diffraction efficiency of the diffraction grating and insufficient suppression of useless diffraction orders, the interference image during exposure has irregular fringes. Issues with sharpness and edge distortion.

[0055] Therefore the object of the present invention is to propose a kind of transmission type spectroscopic grating applied in the interference lithography process and the interference lithography technology using the spectroscopic grating, the transmission type spectroscopic grating can improve the ±1st order diffraction efficiency of the diffraction grating, Suppressing the diffracted light energy of other orders, especially the efficiency of 0-order light and ±2-order light, makes the ±1-order diffraction efficiency of the grating reach more than 92%, which is obviously better...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com