Universal film material graphics method

A thin-film material, graphic technology, applied in metal material coating process, gaseous chemical plating, process for producing decorative surface effects, etc. High-quality, easy-to-promote, and uncomplicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Main material:

[0049] Substrate: 3 mm thick optical glass substrate

[0050] Disposable Planar Micromold Material: Photoresist (AZ4620)

[0051] Film material: polyimide (Beijing Bomi Technology Co., Ltd. ZKPI-305II glue)

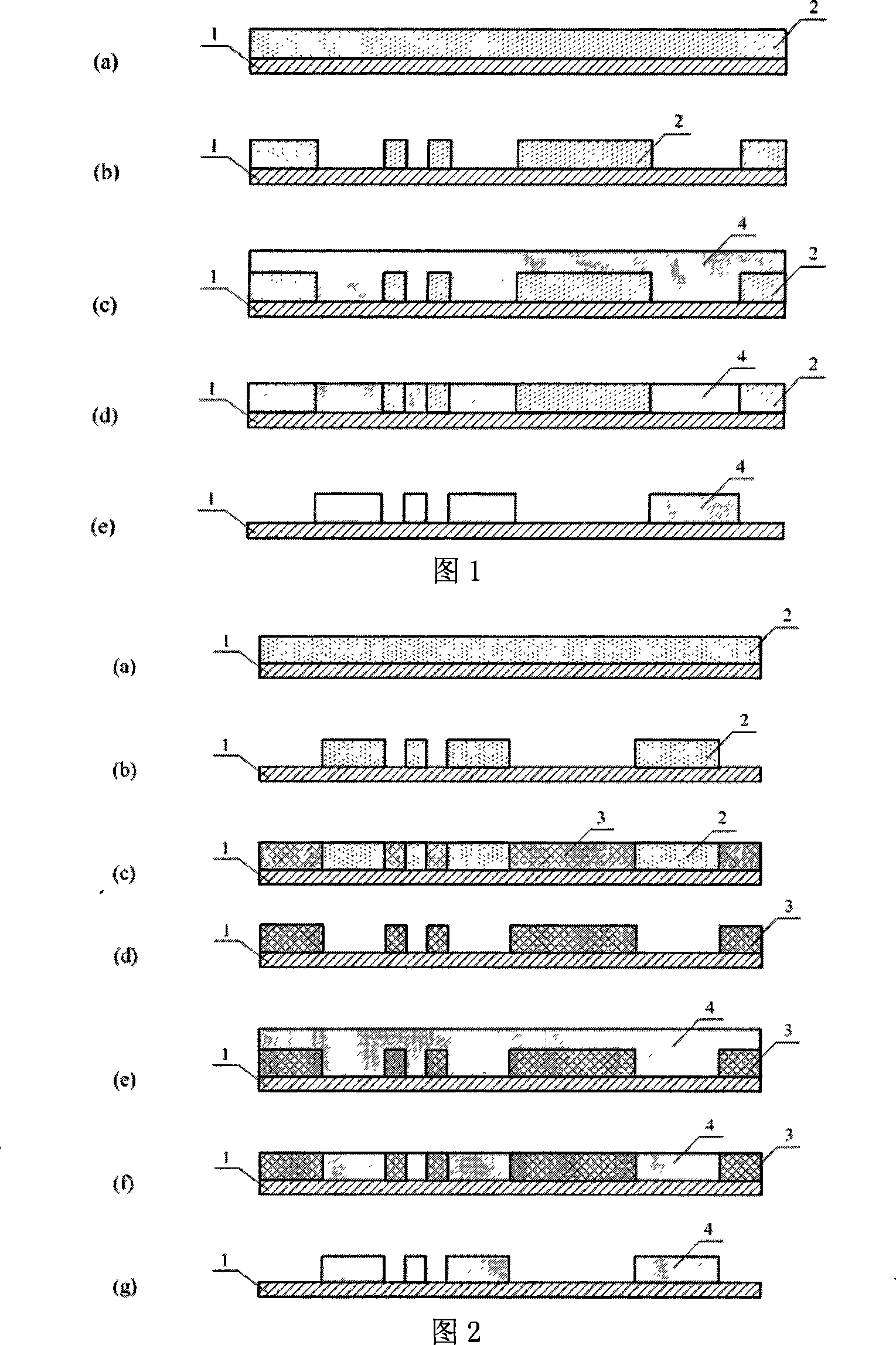

[0052] As shown in Figure 1, the optical glass substrate 1 is first cleaned sequentially with acetone and deionized water. After drying and drying, the AZ4620 photoresist 2 with a thickness of 22 microns is spin-coated, and a disposable planar micro-surface is formed by conventional ultraviolet lithography and development. The pattern of the mold, the gap of the pattern is a rectangular shallow groove array with a length of 60 microns and a width of 20 microns, which is the position of the microstructure of the film to be formed.

[0053] The polyimide film 4 is deposited by spinning to fill up the voids of the micro-mold. After the deposition of the polyimide film is completed, at first grind the surface of the substrate covered by polyimide wi...

Embodiment 2

[0057] Main material:

[0058] Substrate: 3 mm thick optical glass substrate

[0059] Disposable planar micromold material: metallic copper

[0060] Film material: polyimide (Beijing Bomi Technology Co., Ltd. ZKPI-305II glue)

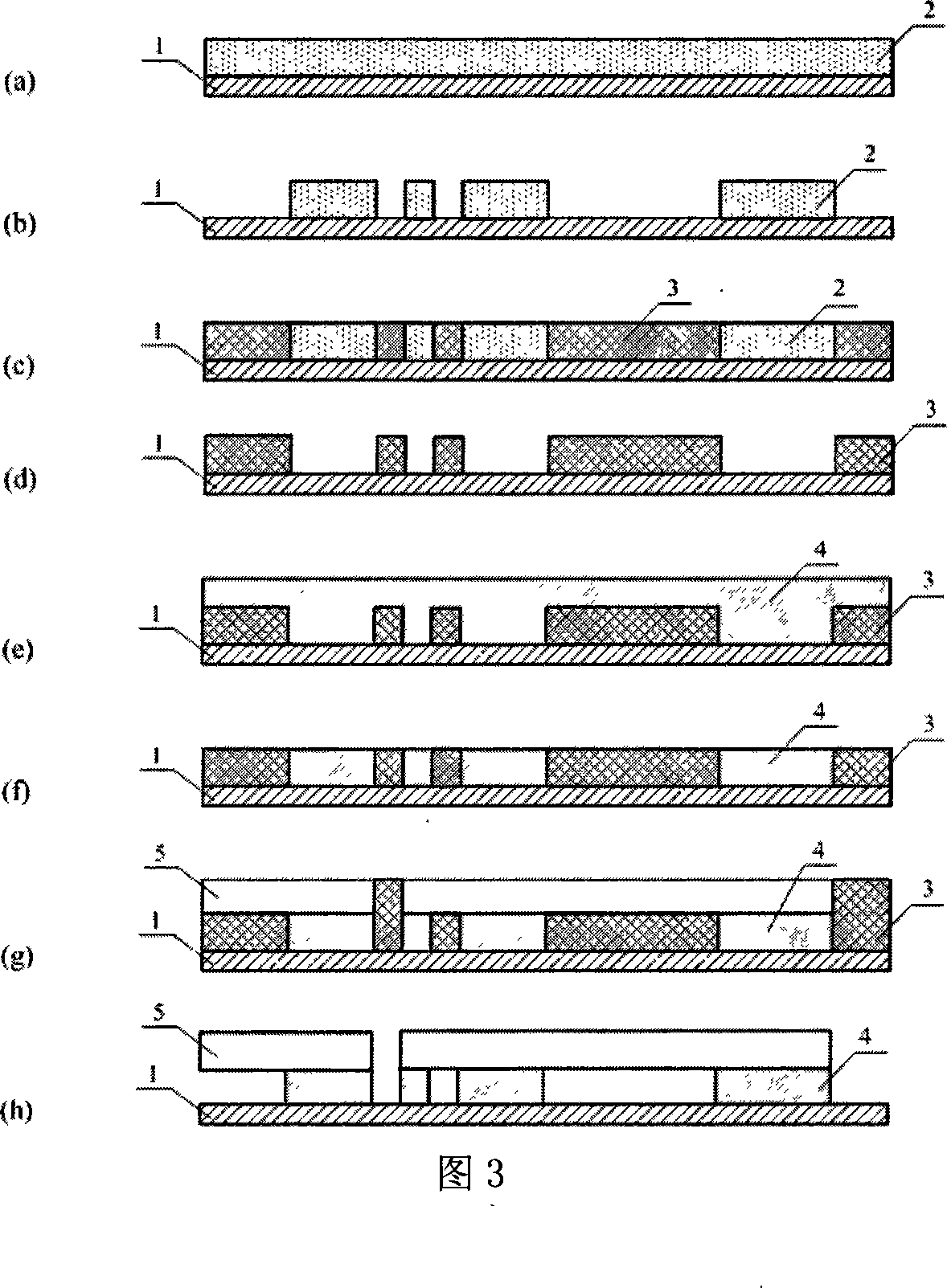

[0061] As shown in FIG. 2 , firstly, the optical glass substrate 1 is cleaned sequentially with acetone and deionized water, and after drying, the Cr / Cu seed layer is sputtered. AZ4620 photoresist 2 is spin-coated with a thickness of 22 microns, and a mask used for electroplating is formed by conventional ultraviolet lithography and development, that is, a photoresist rectangular array with a length of 60 microns and a width of 20 microns (same as the final microstructure pattern made ).

[0062] Use a high-dispersion copper sulfate plating solution to perform mask electroplating on the patterned substrate after photolithography, and grow a 22-micron thick metal copper plating layer 3 on the photolithographically exposed seed layer, flush with the ph...

Embodiment 3

[0069] Main material:

[0070] Substrate: 2 mm thick optical glass substrate

[0071] Disposable planar micromold material: metallic copper

[0072] Film material: polyimide (Beijing Bomi Technology Co., Ltd. ZKPI-305II glue), carbon nanotubes (Shenzhen Nanoport Co., Ltd. SMWNTS-2040)

[0073] As shown in FIG. 2 , firstly, the optical glass substrate 1 is cleaned sequentially with acetone and deionized water, and after drying, the Cr / Cu seed layer is sputtered. AZ4620 photoresist 2 is spin-coated with a thickness of 22 microns, and a mask used for electroplating is formed by conventional ultraviolet lithography and development, that is, a photoresist rectangular array with a length of 60 microns and a width of 20 microns (same as the final microstructure pattern made ).

[0074] Use a high-dispersion copper sulfate plating solution to perform mask electroplating on the patterned substrate after photolithography, and grow a 22-micron thick metal copper plating layer 3 on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com