Optical proximity effect corrective modeling method and generating method of test pattern

A technology of optical proximity effect and test pattern, which is applied in the field of photolithography, can solve the problems of poor photolithography quality of optical proximity effect test pattern, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

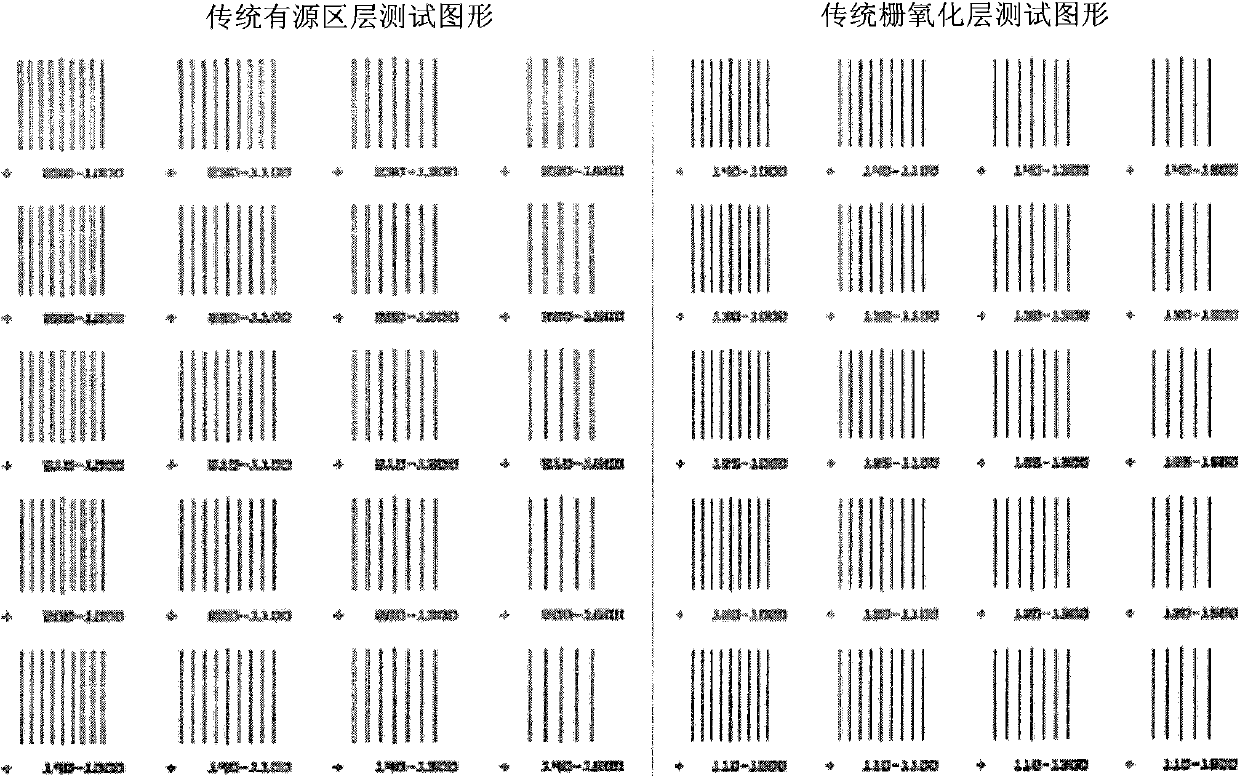

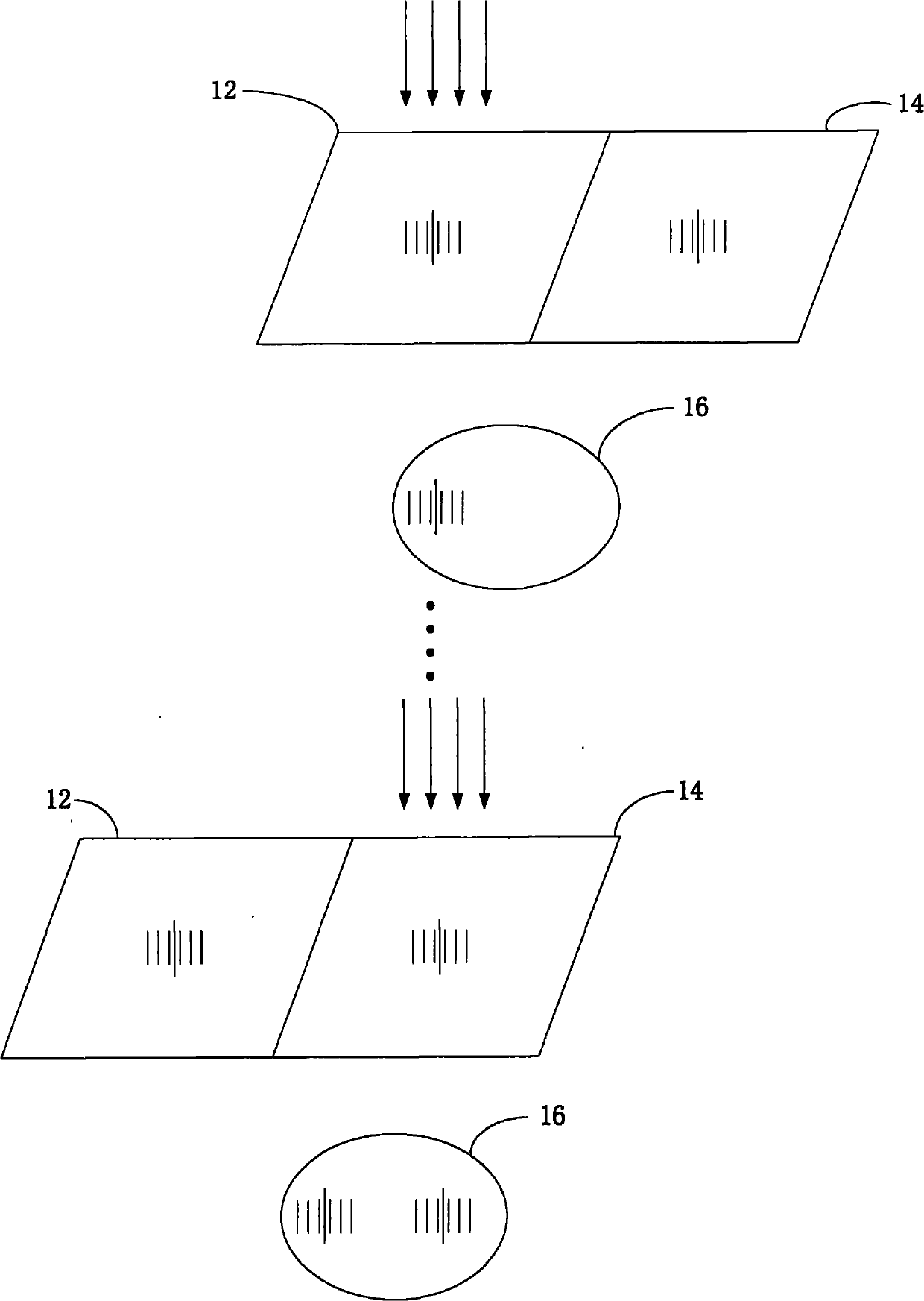

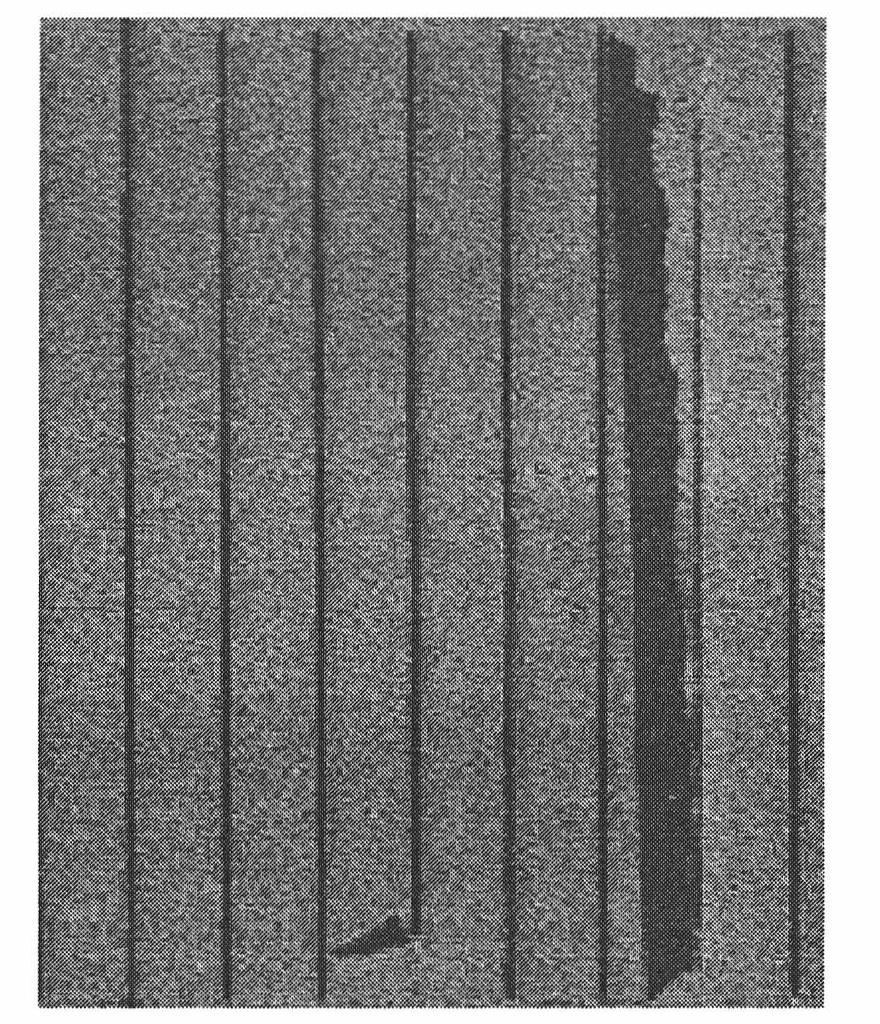

[0024] The method for forming the optical proximity effect test pattern in the preferred embodiment of the present invention is to regenerate a group of enlarged patterns on the basis of the original test patterns of each traditional level. The enlarged pattern is obtained by enlarging one or several groups of test patterns in the original test patterns, such as Figure 4 shown. In this way, after photoetching the optical proximity effect test pattern of the preferred embodiment of the present invention onto the mask plate, each layer of the test pattern has two areas, the original pattern area and the enlarged pattern area.

[0025] The present invention will be clearly and completely described below by taking the active region layer and the gate oxide layer as examples. The purpose of generating enlarged graphics is to simulate the real circuit layout situation. After photoetching the optical proximity effect test pattern of the active region layer onto the wafer, the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com