Dry and wet combined etching method for multilayer film

A dry-wet combination and multi-layer film technology, which is applied in the manufacture/processing of electromagnetic devices, magnetic recording heads, and the manufacture of flux-sensitive magnetic heads, can solve the problem of reducing the anisotropic magnetoresistance effect of resistance strips, affecting device performance, and Corrosion of permalloy and other problems, to achieve the requirements of reducing the uniformity of large-area etching rate, high graphics quality, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Before describing the specific implementation method, first briefly introduce the instruments and devices used in the specific implementation mode of the present invention. In the specific implementation of the present invention, a magnetically enhanced reactive ion etching machine (MERIE) is used for dry etching, and its structure is shown in Figure 7 Shown; use a constant temperature water bath to control the temperature during wet etching.

[0050] A scheme of the method of the present invention, such as Figure 5 Shown as:

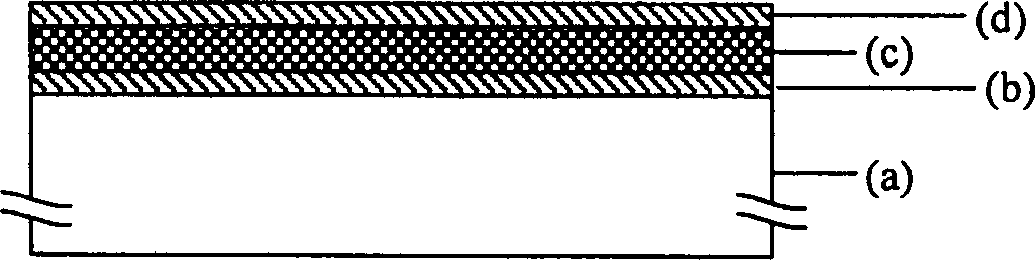

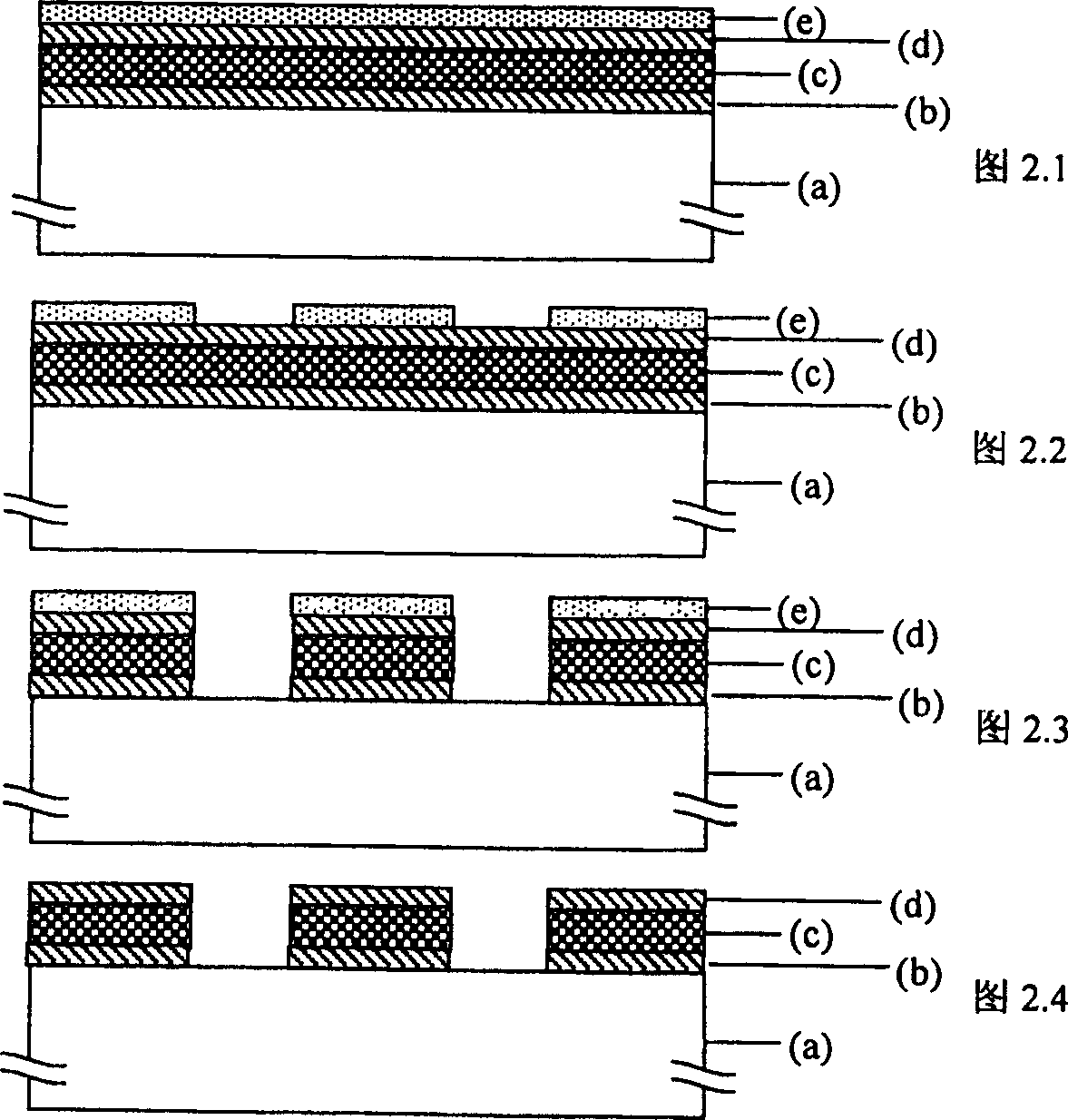

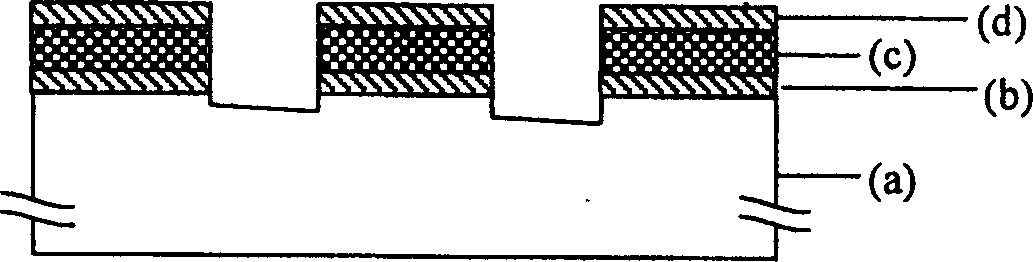

[0051] First, a photoresist mask layer is formed on an anisotropic magnetoresistance (AMR) film. Described anisotropic magnetoresistance effect (AMR) film is the multilayer film that is made up of transition layer / permalloy / protective layer, and a kind of commonly used multilayer film is tantalum (Ta) / permalloy (NiFe) / tantalum (Ta).

[0052] Next, using the photoresist mask layer as a mask, dry etching is used to etch the protective layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com