Printed circuit etching liquid

A technology of printed circuit and etching solution, which is applied in the field of etching in the production of fine lines of printed circuit boards, can solve the problems of inability to meet the requirements of circuit refinement, inability to meet electrical performance requirements, poor stability of hydrogen peroxide, etc. The effect of stable nitric acid content, low price and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

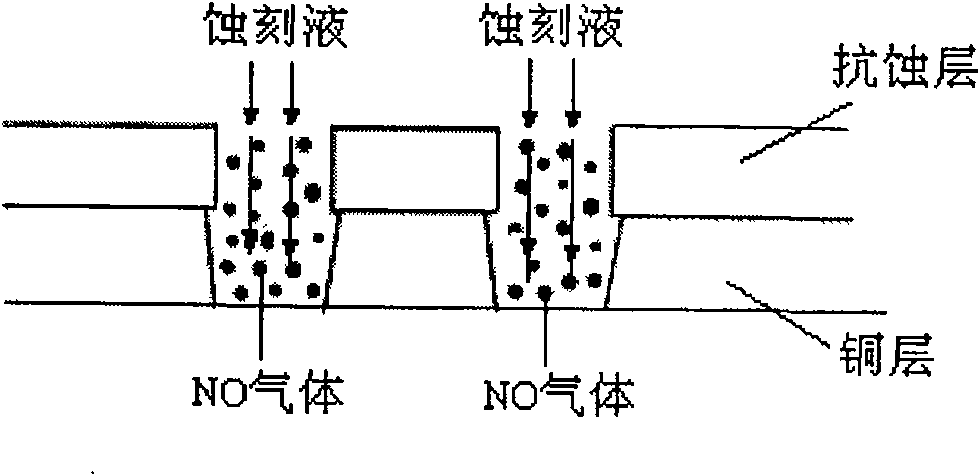

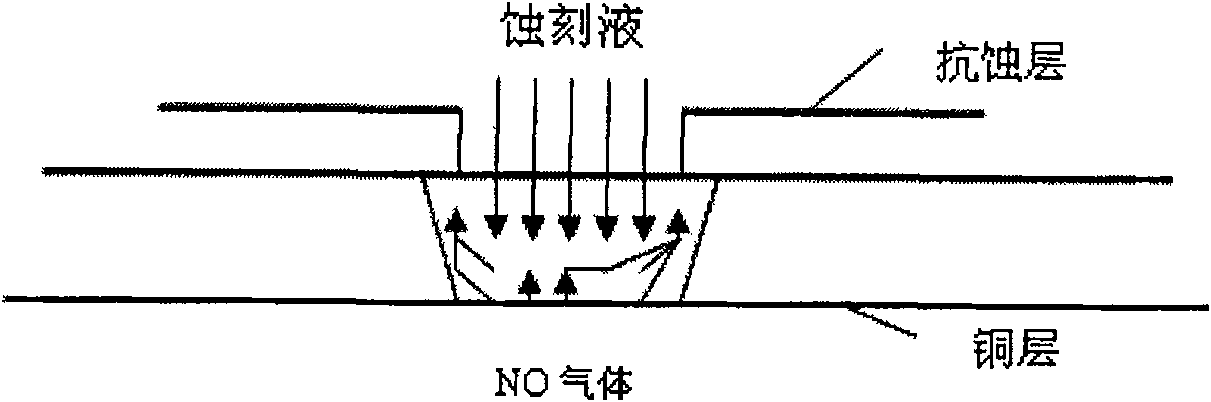

Method used

Image

Examples

Embodiment approach 1

[0056] Preparation of nitric acid etching solution:

[0057] (1) Add 100ml of deionized water into the etching tank, measure about 27.47ml of 65% nitric acid into the etching tank, and then add a small amount of deionized water.

[0058] (2) Measure about 23.19ml of 98% concentrated sulfuric acid, slowly add it into the etching tank, and stir the solution continuously during the process of adding the concentrated sulfuric acid.

[0059] (3) Add 15.90 g of anhydrous sodium sulfate into the etching tank, and stir to completely dissolve the anhydrous sodium sulfate.

[0060] (4) Add 1.00 ml of an additive with a concentration of 10%.

[0061] (5) add deionized water to 500ml, prepare 500ml nitric acid concentration and be 5%, sulfuric acid concentration is 8%, anhydrous sodium sulfate concentration is 3%, and additive concentration is the nitric acid etching solution of 0.02%.

[0062] Adjust the temperature of the etching solution to 50°C, select a copper clad laminate with a ...

Embodiment approach 2

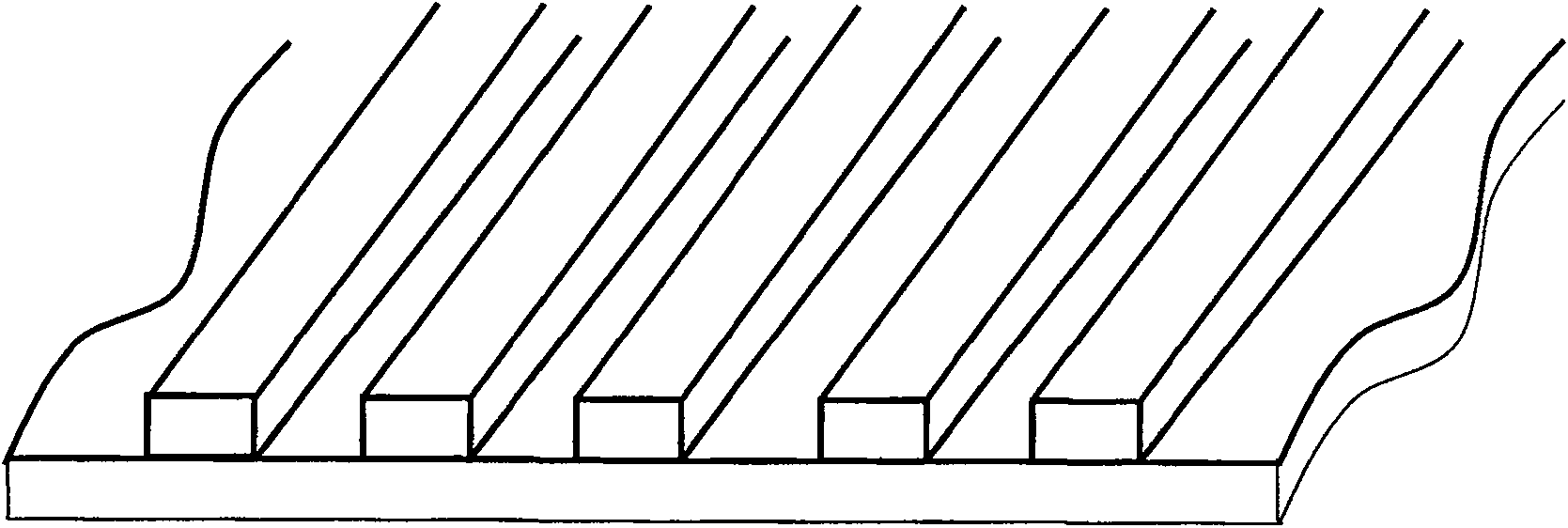

[0064] Prepare 500 ml of nitric acid etching solution with a nitric acid concentration of 7%, a sulfuric acid concentration of 12%, anhydrous sodium sulfate concentration of 3%, and an additive concentration of 0.05% according to the steps of Embodiment 1. Control the etching temperature to 60°C. Select a copper clad laminate with a copper foil thickness of 18 μm, a size of 5cmx 5cm, and a pattern transfer line width of 50 μm. Put the copper clad board into an etching tank for etching. After 15 minutes, the line etching was complete. The measured line width is 36.43 μm, and the metallographic micrograph shows that the section of the conductive line is trapezoidal.

Embodiment approach 3

[0066] Prepare 500 ml of nitric acid etching solution with a nitric acid concentration of 7%, a sulfuric acid concentration of 10%, anhydrous sodium sulfate concentration of 3%, and an additive concentration of 0.07% according to the steps of Embodiment 1. Control the etching temperature to 60°C. Select a copper clad laminate with a copper foil thickness of 18 μm, a size of 5cmx 5cm, and a pattern transfer line width of 80 μm. Put the copper clad board into an etching tank for etching. After 8 minutes, the line etching was completed. The measured line width is 74.23 μm, and the metallographic micrograph shows that the section of the conductive line is trapezoidal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com