Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154results about How to "Improve exposure efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital X-ray machine automatic exposure control method and device

ActiveCN104146724AImprove image qualityImprove Exposure StabilityX-ray apparatusRadiation diagnosticsTime delaysExposure control

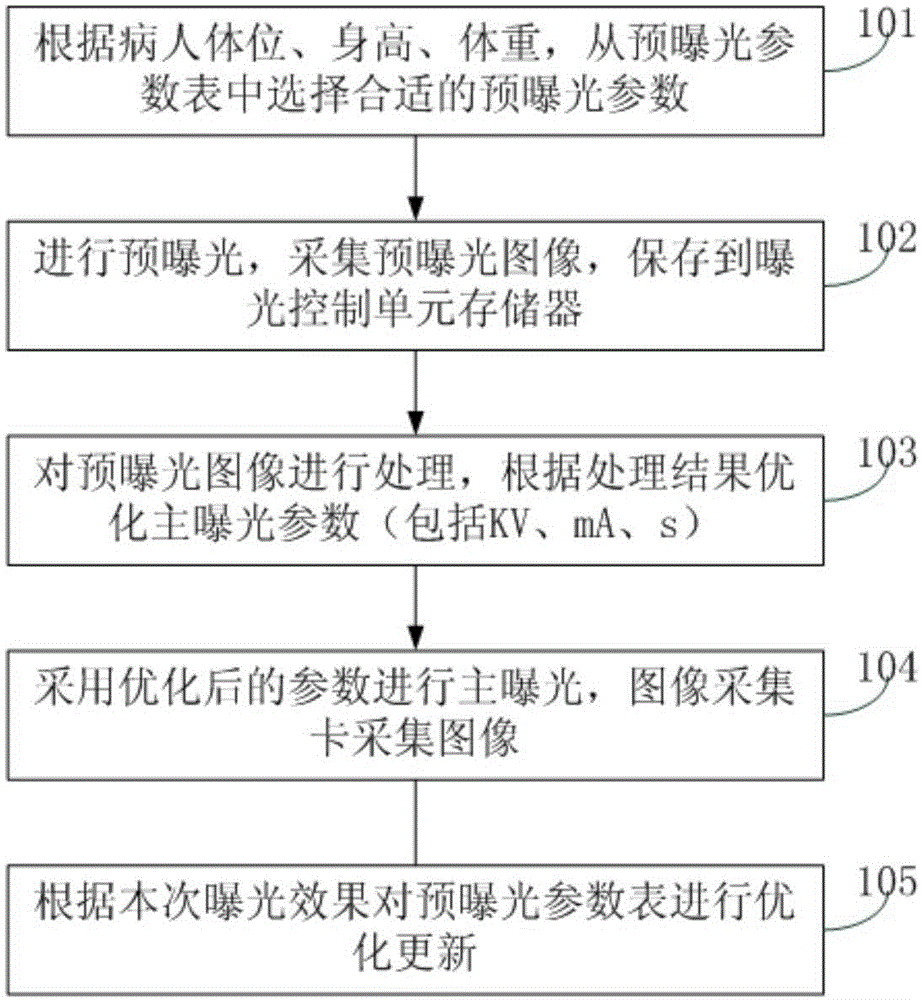

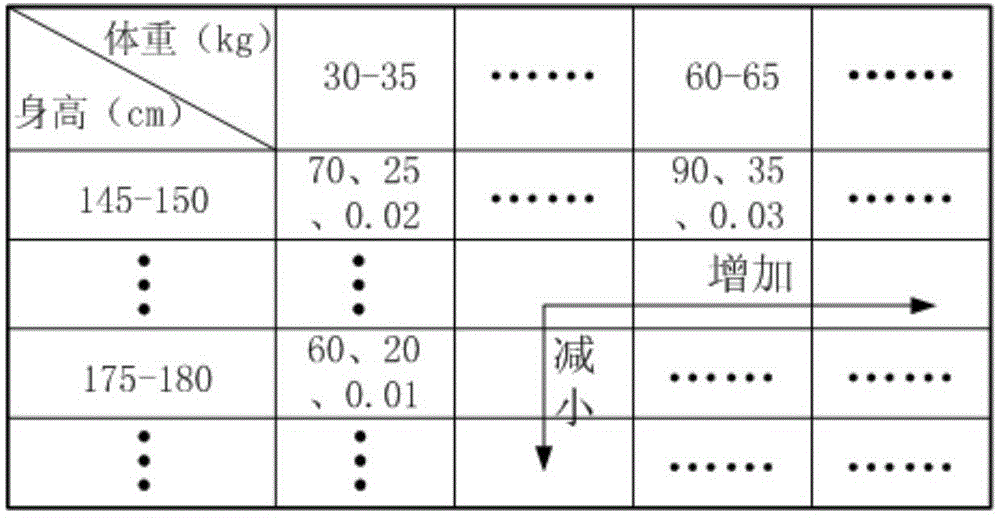

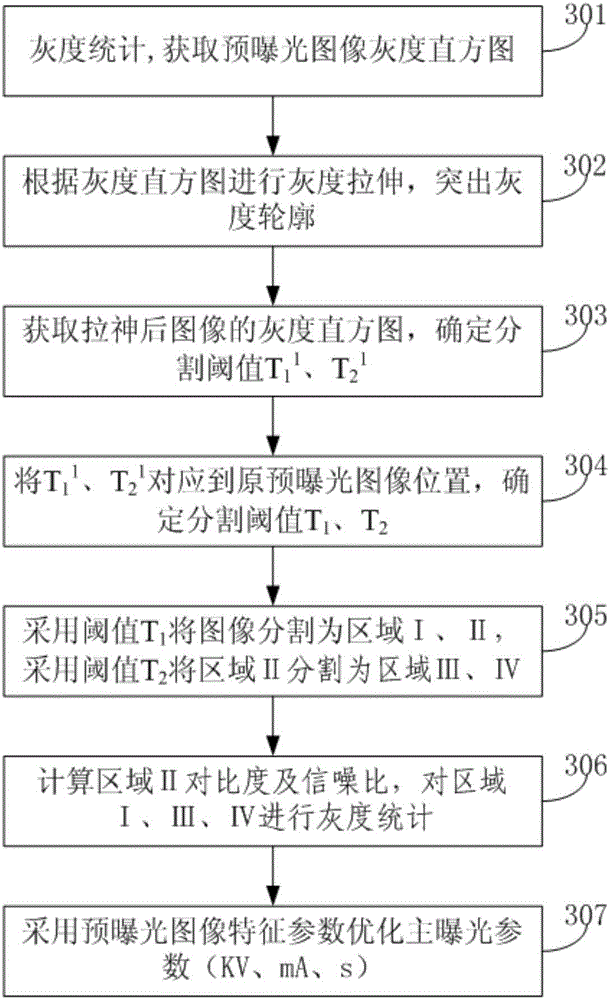

The invention relates to a digital X-ray machine automatic exposure control method and device, and belongs to the technical field of digital radiography. The method mainly includes the steps of processing a pre-exposure image in secondary exposure and optimizing exposure parameters in a self-adaptive mode. The optimal threshold value is correspondingly found according to positions through gray stretch of the pre-exposure image, the image is divided into different areas, areas of interest with different components are extracted, the average gray level, the signal to noise ratio and the contrast ratio are calculated respectively, and then the main exposure parameters (mA, s and KV) are optimized in the self-adaptive mode; the precise time sequence is provided for the exposure process and data acquisition through a synchronous control unit, and the imaging effect is prevented from being influenced by time delay or antedating reaction. By the adoption of the multiple components, multiple target areas and multiple image standards, the exposure parameters are adjusted through a self-adaptive algorithm, and the top-quality image can be obtained through a small exposure dose when exposure is conducted under the synchronous control.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

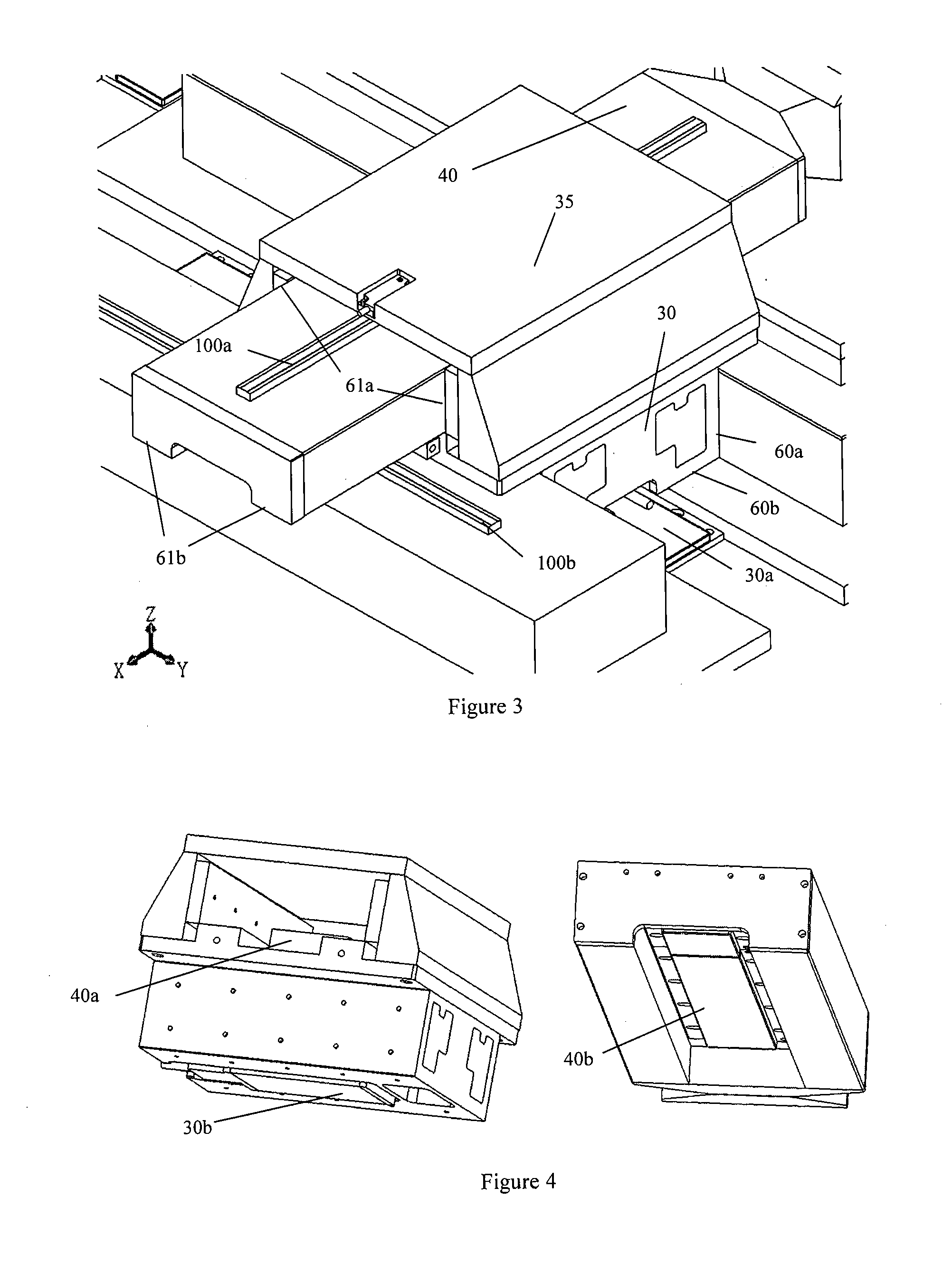

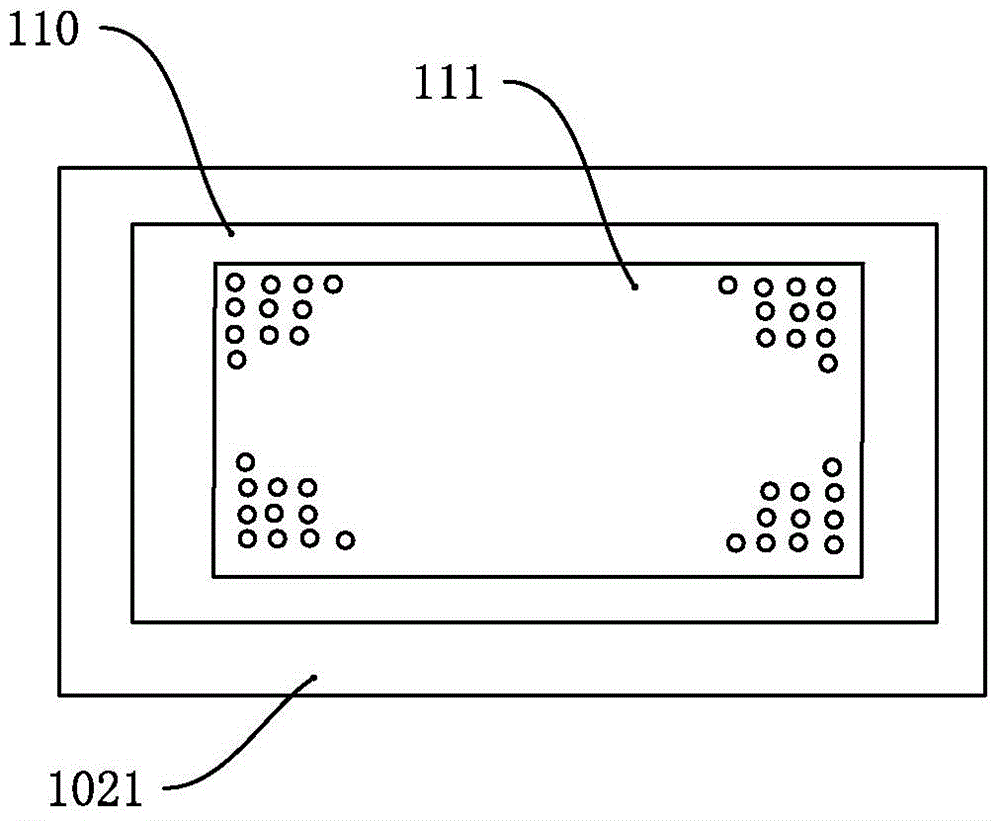

Dual platform switching system for mask aligner silicon slice platform using conveyer structure

InactiveCN101201555ASave time at workAvoiding problems with precision dockingSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringSilicon chip

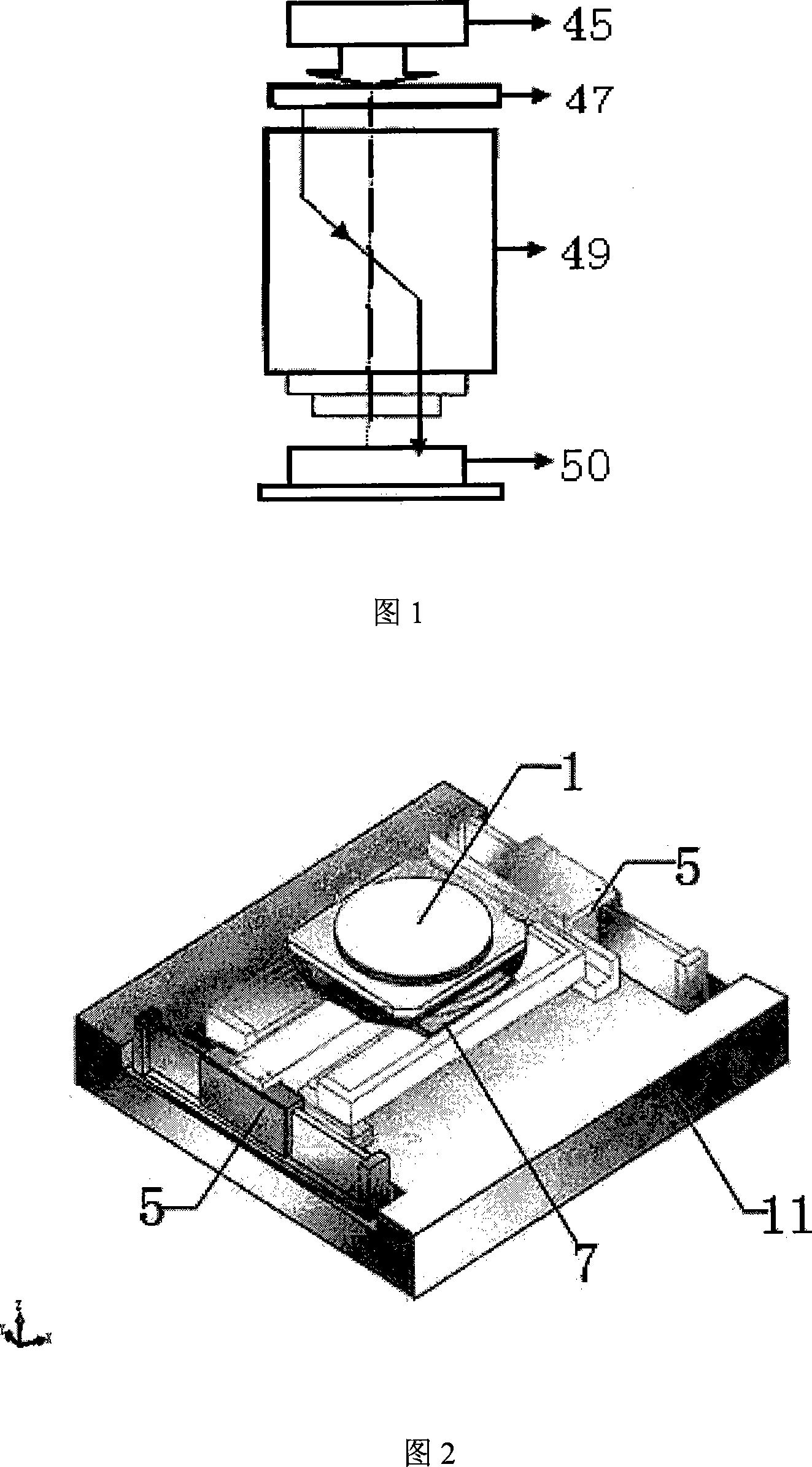

The invention provides a double-platform exchanging system for a photoetching machine silicon chip platform with a conveyor belt and belongs to the technical field of the manufacturing equipment of a semiconductor. The invention comprises a silicon chip platform operated on a pretreatment station and a silicon chip platform operated on an exposure station; the pretreatment station and the exposure station are respectively provided with a H-typed driving unit and the H-typed driving unit consists of X-directional straight line motors on the two sides and a Y-directional straight line motor, both of which are used for driving the silicon chip platform to move along X direction and Y direction on the pretreatment station and the exposure station; the two sides of a base station are respectively provided with a conveyor belt in the system and a butt slide block is fixed on and connected with the lateral side of the conveyor belt; with the conveyor belt and the butt slide block, the transition of the silicon chip platform 1 from the pretreatment station to the exposure station can be realized. As the invention adopts the conveyor belt structure, the invention effectively avoids the problem of accurate abut joint of the guide rail of the patent ZL03156436.4 double-platform exchanging system and has the characteristics of simple operation and small size of outline, etc.

Owner:TSINGHUA UNIV

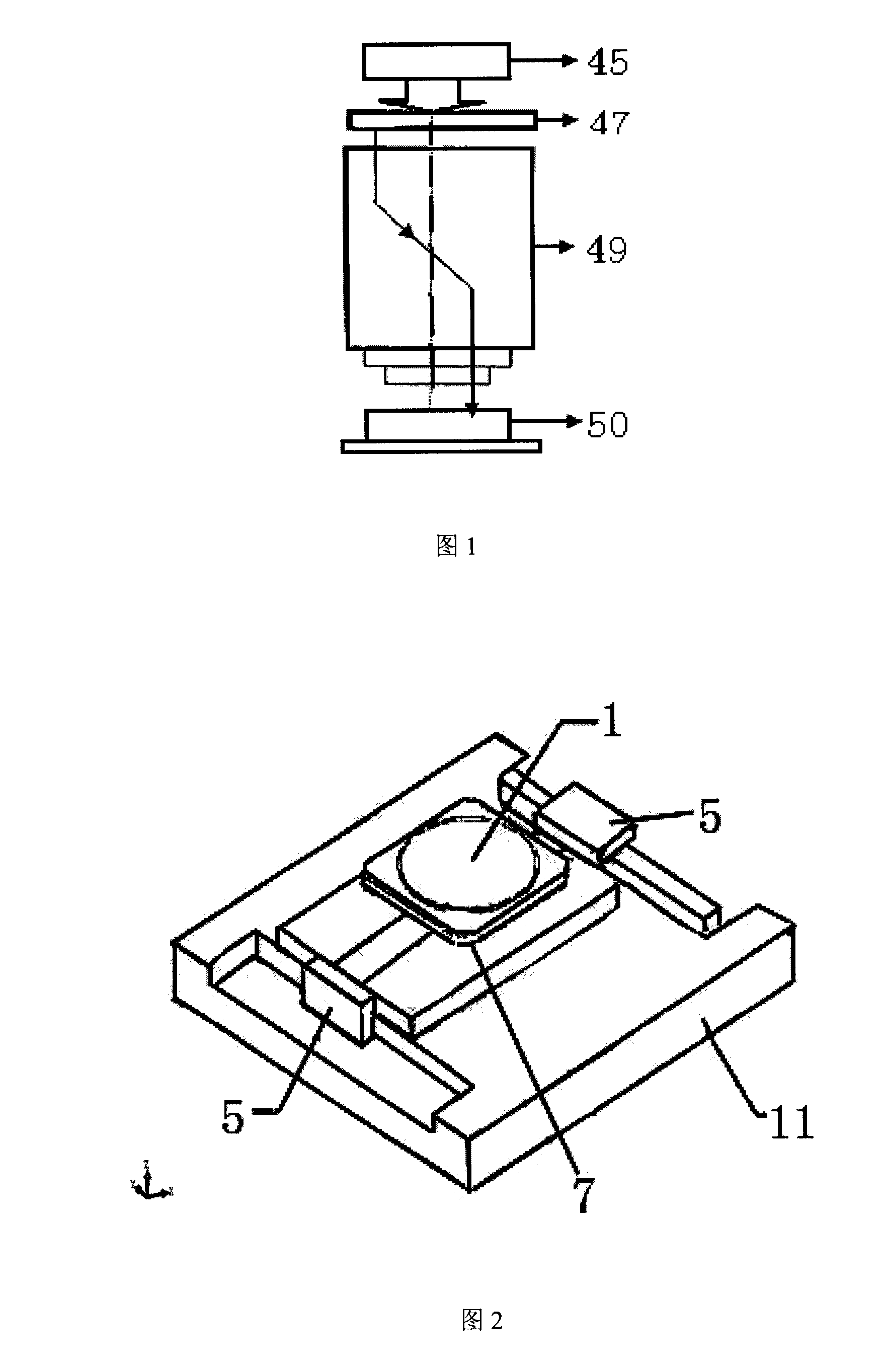

System for switching benches of photo-etching machine silicon slice benches by transition continue device

ActiveCN101231471ASave time at workAvoiding problems with precision dockingSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringLinear motor

The invention provides a double stage exchange system adopting transition devices for wafer stages in a photoetching machine, which belongs to the technical field of semiconductor manufacturing equipment. The invention comprises a wafer stage running in the pretreatment position, a wafer stage running in the exposure position, and H-shaped driver units arranged in the pretreatment position and the exposure position respectively. The H-shaped driver units each consists of an X-axis linear motor and a Y-axis linear motor and are used for driving the wafer stages to move in the X-axis and Y-axis directions in the pretreatment position and the exposure position respectively. The technical proposal of the invention is that two transition devices are arranged between the stages and provided thereon with friction wheels. When the H-shaped driver units are aligned with the transition devices, the wafer stages are transferred from the pretreatment position to the exposure position under the frictional force of the friction wheels. The invention ensures the accurate connection of guide rails and reduces the complexity of the system structure.

Owner:TSINGHUA UNIV +1

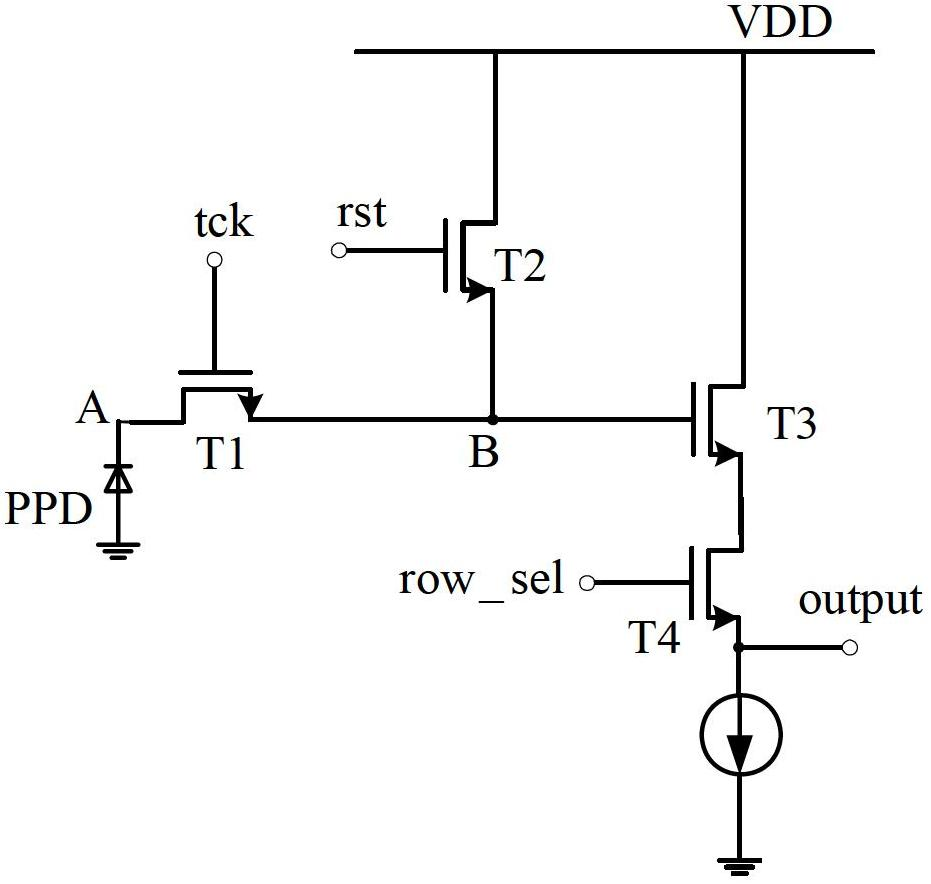

CMOS image sensor and exposure control method thereof

ActiveCN102695004AImprove exposure efficiencyTelevision system detailsColor television detailsCMOSNumber times

The invention discloses a CMOS (Complementary Metal Oxide Semiconductor) image sensor and an exposure control method thereof. The method comprises the following steps: aiming at a pixel array, first row-to-row exposure and second row-to-row exposure are executed to obtain first image data and second image data, the exposure time interval of the same row of the first row-to-row exposure and the second row-to-row exposure is longer than a half light intensity period of change by odd number times; and image data in the same row of the first image data and the second image data is compound to obtain an output image. The CMOS image sensor comprises an exposure time sequence control circuit, row selecting circuits, a pixel array, a reading circuit and an image compound circuit, wherein the row selecting circuit executes the first row-to-row exposure and the second row-to-row exposure for the pixel array, the exposure time interval of the same row of the first row-to-row exposure and the second row-to-row exposure is longer than a half light intensity period of change by odd number times, and the image compound circuit compounds the first image data and the second image data to form an output image. By adopting the CMOS image sensor and the exposure control method thereof, yellow bands or light and shade strips in an image are eliminated.

Owner:BRIGATES MICROELECTRONICS KUNSHAN

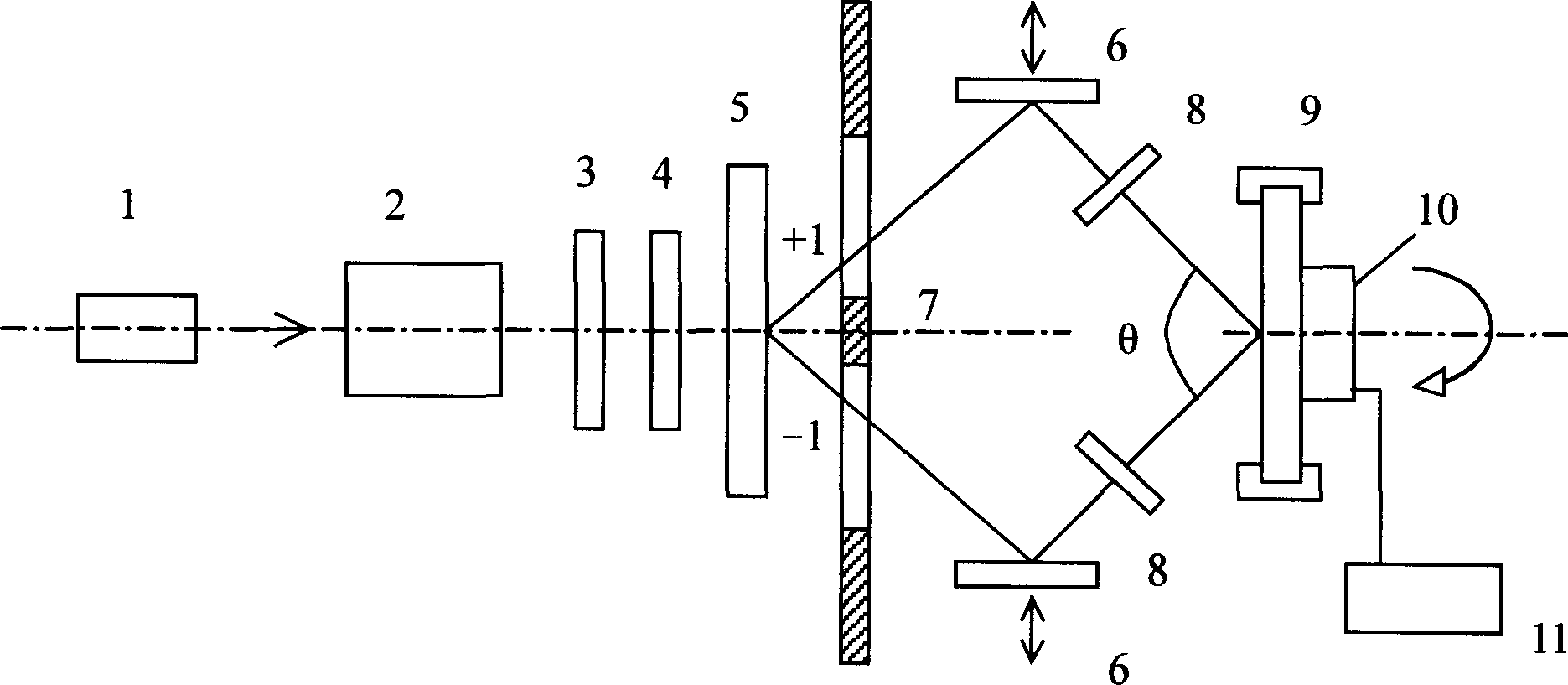

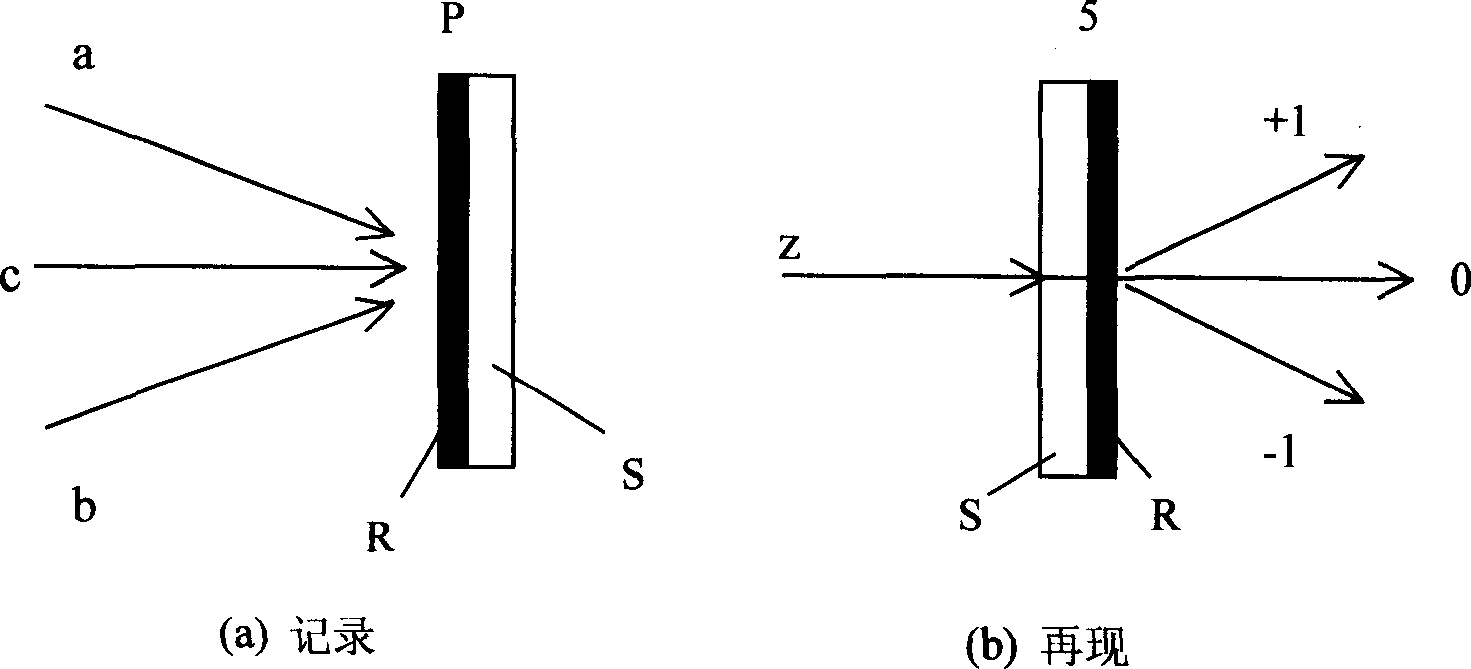

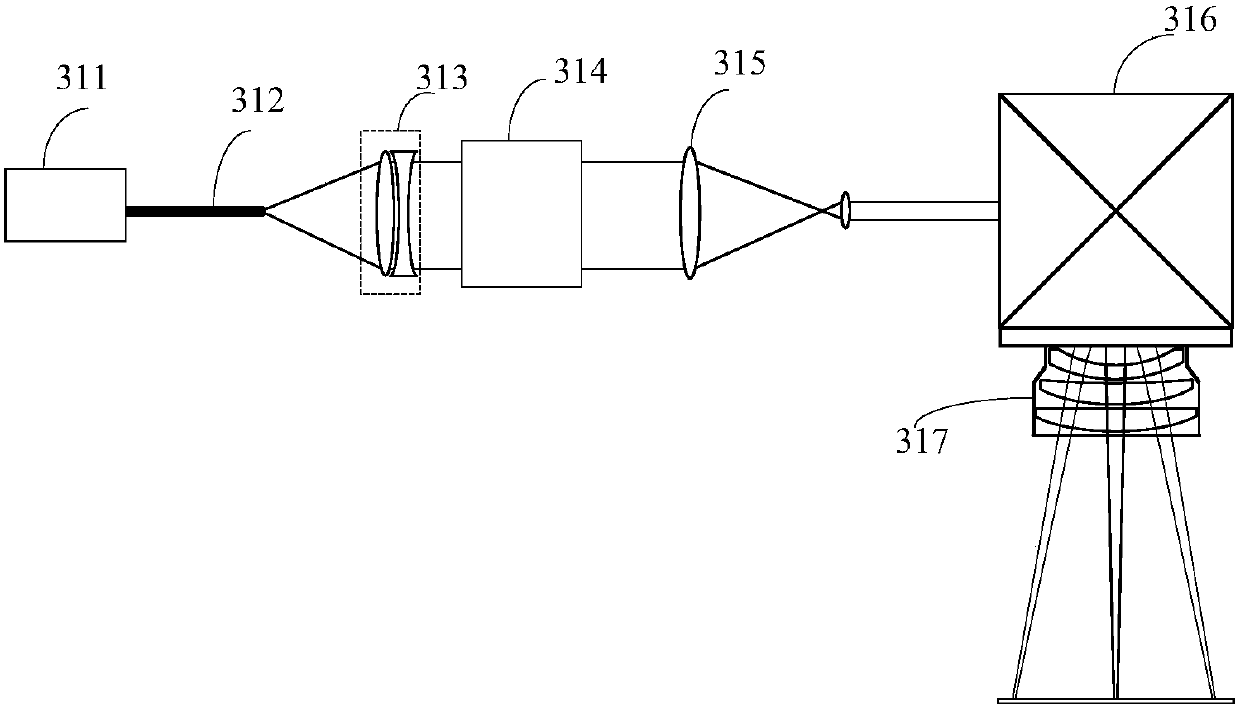

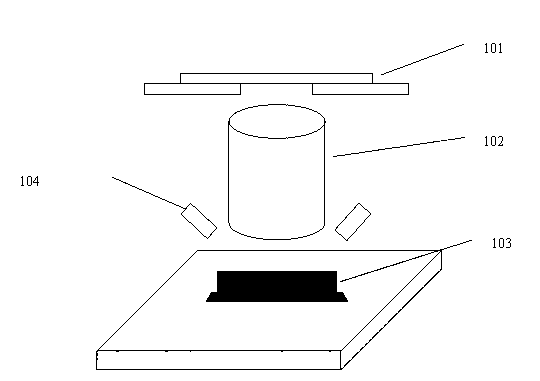

Laser interference photo etching method adopting holographic optical elements and photo etching system

InactiveCN1690857AEasy to manufactureImprove adaptabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingWavelength

The laser interference photo-etching method with holographic optical element is characterized in that: use holographic optical element as beam amplitude division element to divide the laser beam to two beams of almost equal strength and angle divided; reflect to make them intersect; on the intersect overlap area, expose the resister basal plate to produce high resolution grating, form minuteness interference image; holographic optical element is element that can produce tri-beam, quad-beam, or quint-beam, or holographic image produced by computer, or diffraction optic element; laser interference photo-etching system realized aforementioned method comprises a laser of ª™-wave, beam expand collimating device, timer shutter, variable density neutral color filter, holographic optical element, adjustable diaphragm, holophote, optical attenuator, basal plate and electric control roller. As the preparation of holographic optical element is easy, with light weight, and can made with low cost according to different angle to adjust different needs, this invention can decrease size, weight and cost of the system, of far reaching importance and application future.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

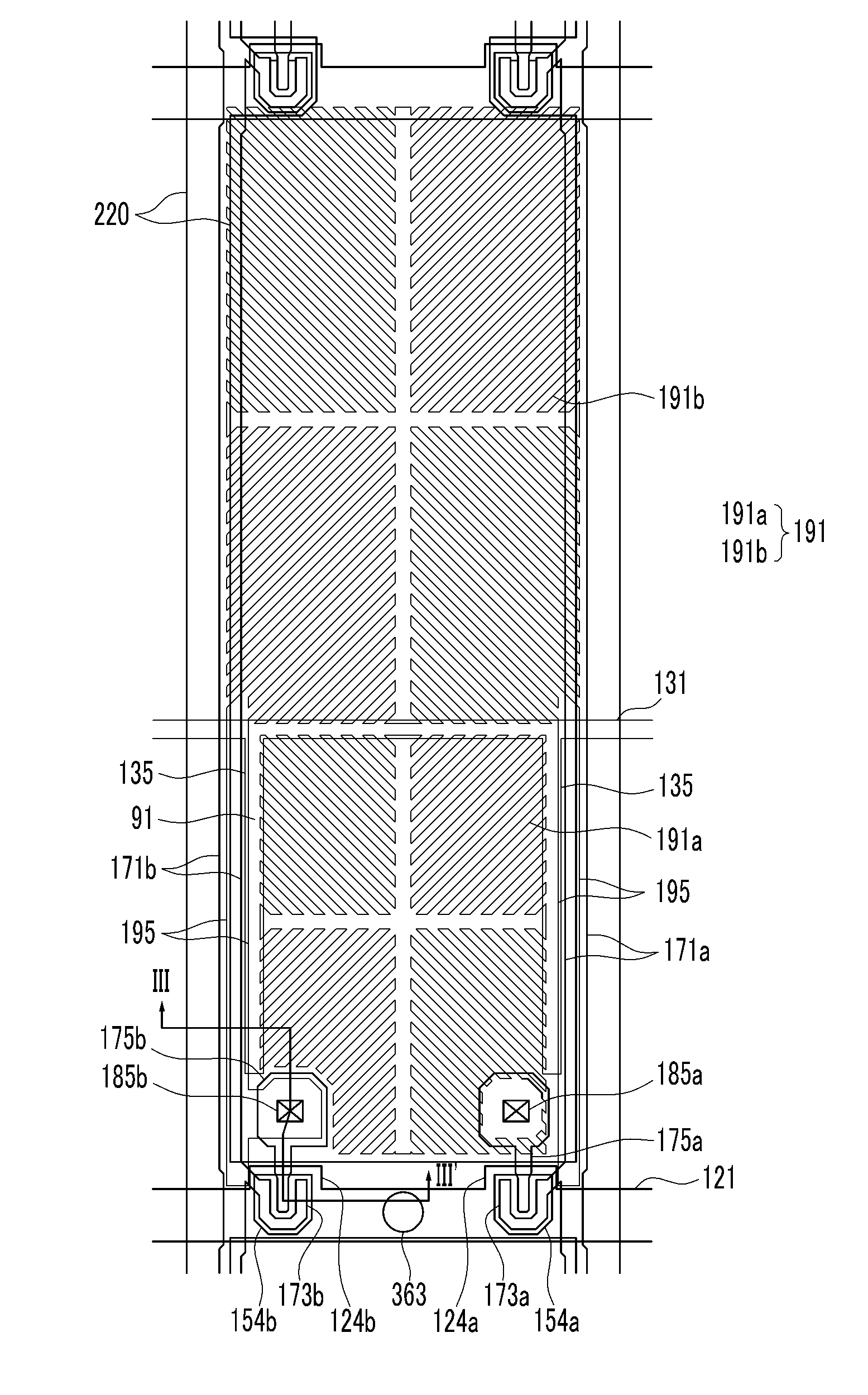

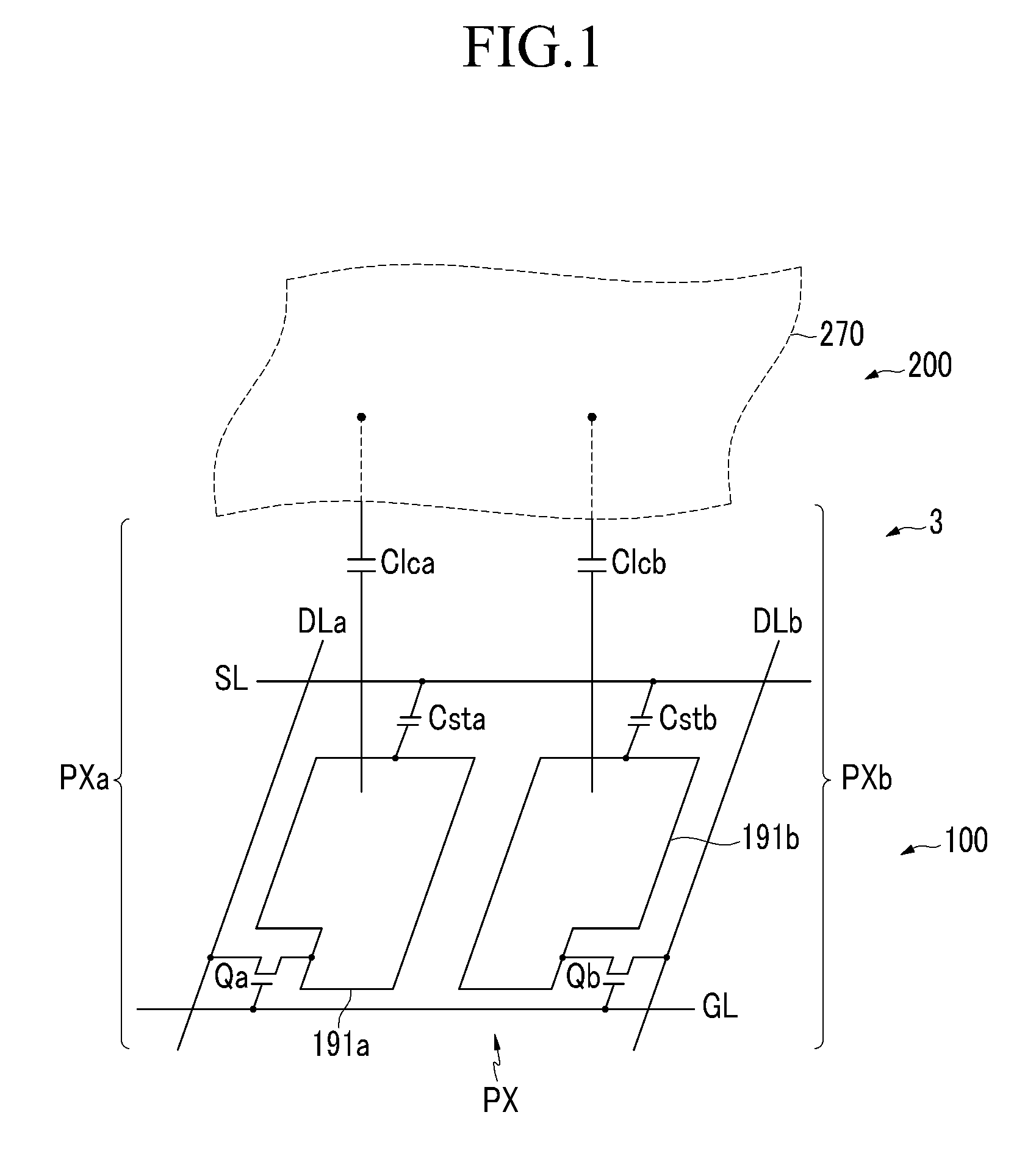

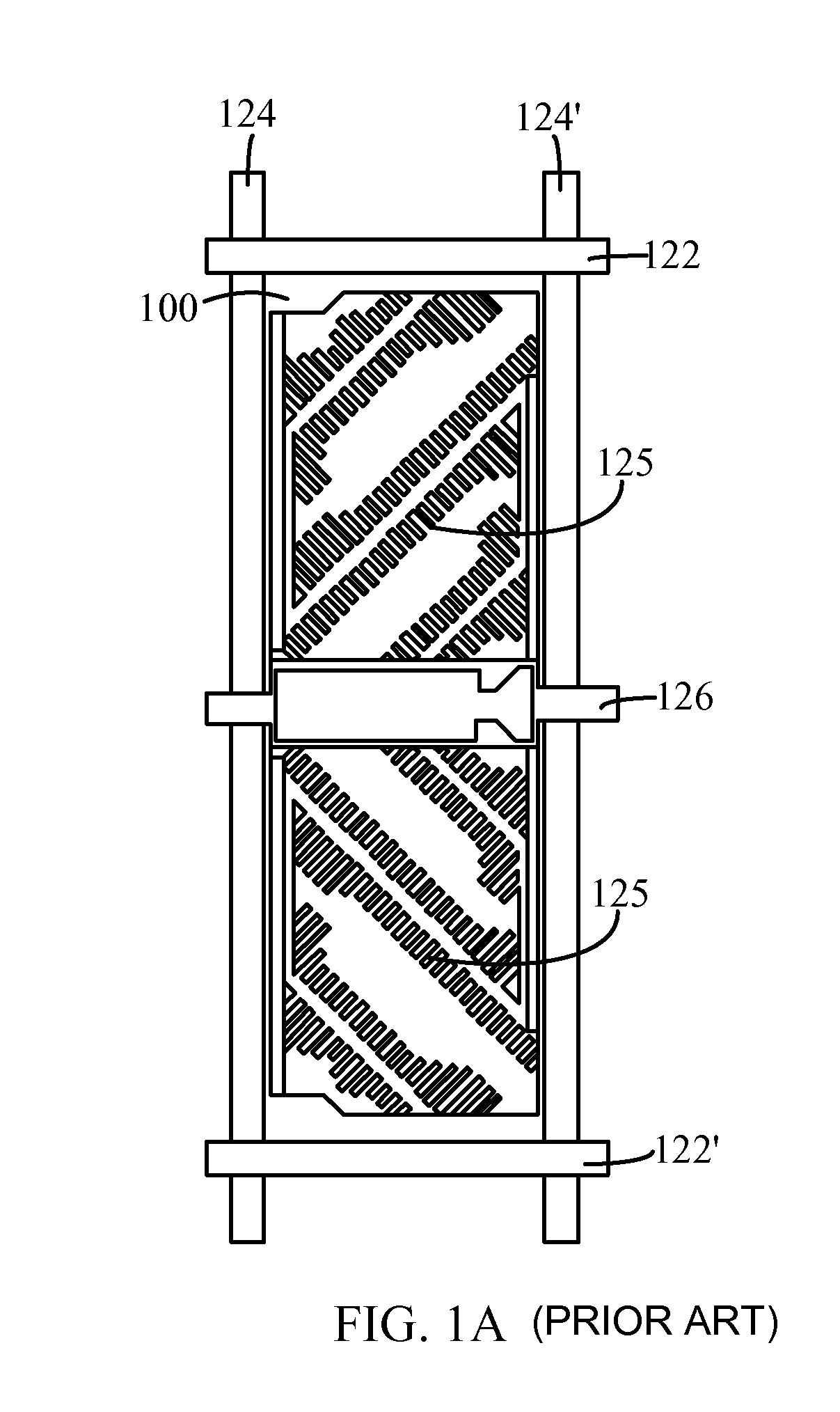

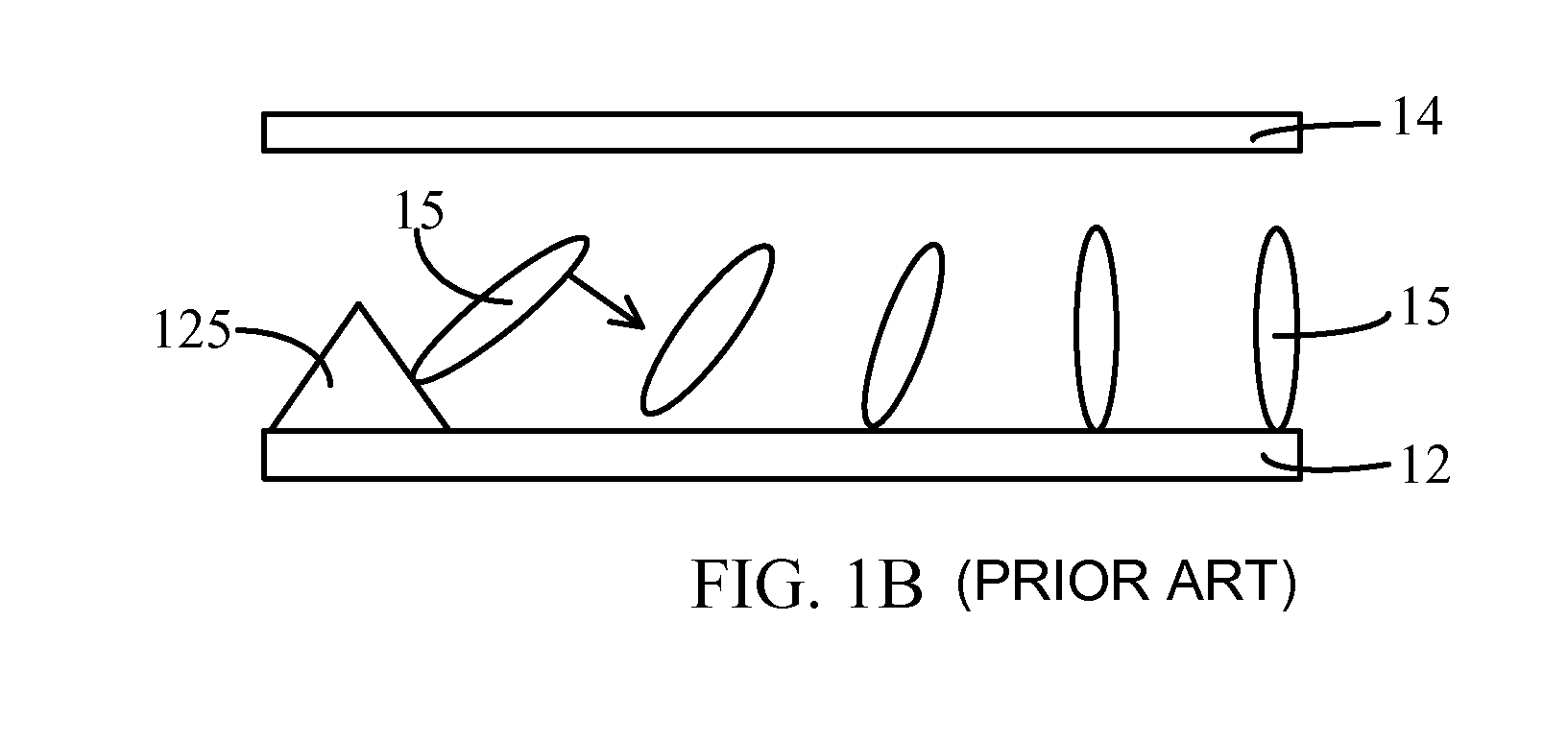

Liquid crystal device and manufacturing method of the same

InactiveUS20110051065A1Prevent deterioration of voltage hold ratioInhibit deteriorationLiquid crystal compositionsVessels or leading-in conductors manufactureEngineeringLiquid crystal devices

A liquid crystal display and a manufacturing method are provided. A liquid crystal display according to an exemplary embodiment of the present invention includes a first substrate, a second substrate facing the first substrate, a field generating electrode disposed on at least one of the first substrate and the second substrate, an alignment layer disposed on the field generating electrode, and a liquid crystal layer interposed between the first substrate and the second substrate, including liquid crystal molecules and a second alignment polymer, wherein the first alignment polymer is formed by light-irradiating the alignment agent and the first alignment aids and the second alignment polymer is formed by light-irradiating the liquid crystal molecules and the second alignment aids, and the first alignment aids and the second alignment aids include a mesogen and a photo-polymerizable group coupled to the mesogen.

Owner:SAMSUNG DISPLAY CO LTD

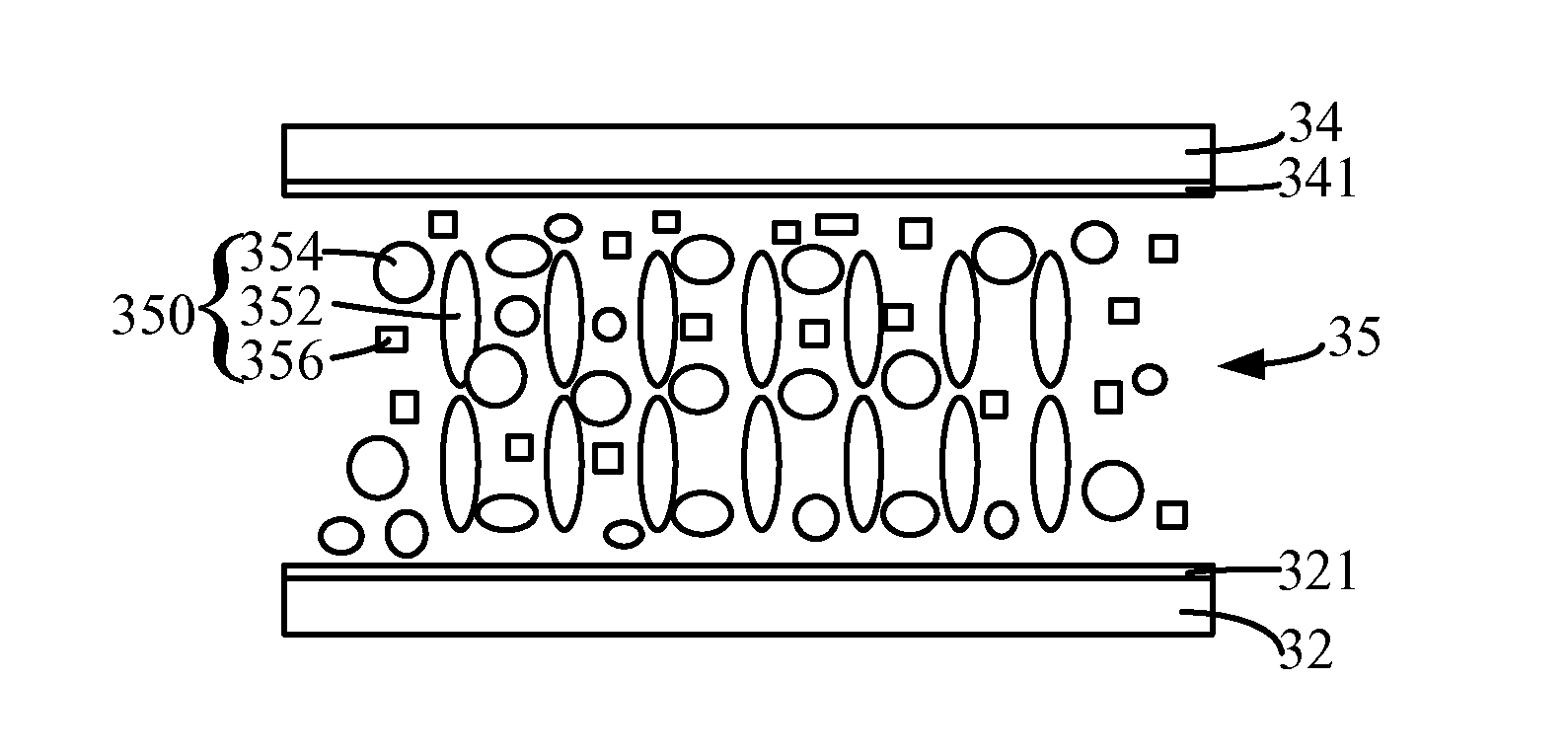

Liquid crystal alignment process

InactiveUS20120081652A1Improve efficiencyShorten the timeLiquid crystal compositionsNon-linear opticsCrystallographyMonomer

A liquid crystal alignment process comprises steps of: providing a first substrate and a second substrate to form a liquid crystal accommodating space therebetween; pouring a liquid crystal composition into the liquid crystal accommodating space, the liquid crystal composition comprising liquid crystal molecules, a first monomer material, and a second monomer material; applying a voltage difference to the first and second substrates for arranging the liquid crystal molecules at a pre-tilt angle; and exposing the liquid crystal composition by mixed multi-spectrum rays for polymerizing the first monomer material and the second monomer material to form at least one type of liquid crystal alignment polymer on opposite surfaces of the first and second substrates. The liquid crystal alignment process is capable of improving the efficiency of exposure procedure, reducing time to manufacture products, and is capable of solving the problems of high costs and waste pollution.

Owner:CHUNGHWA PICTURE TUBES LTD

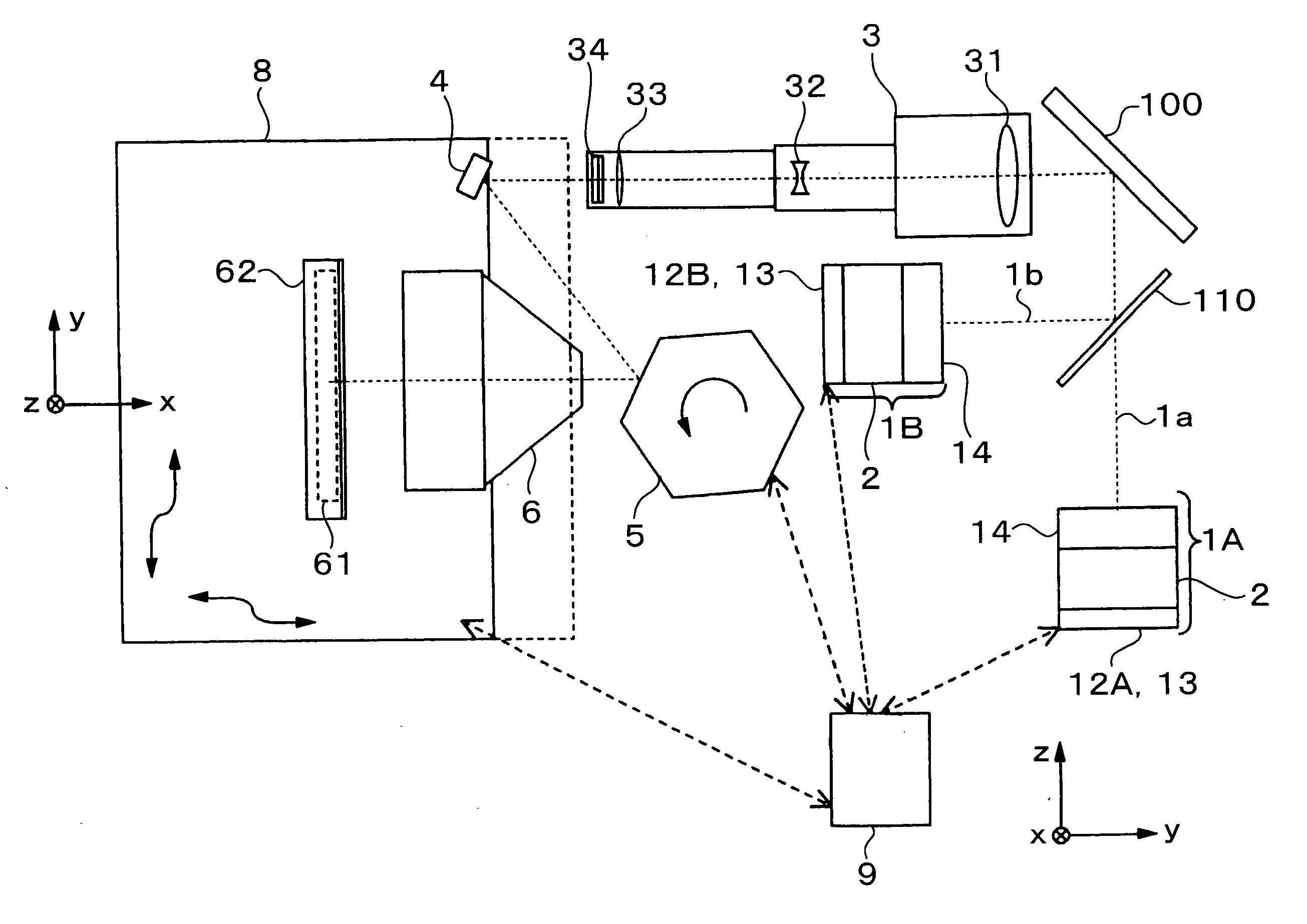

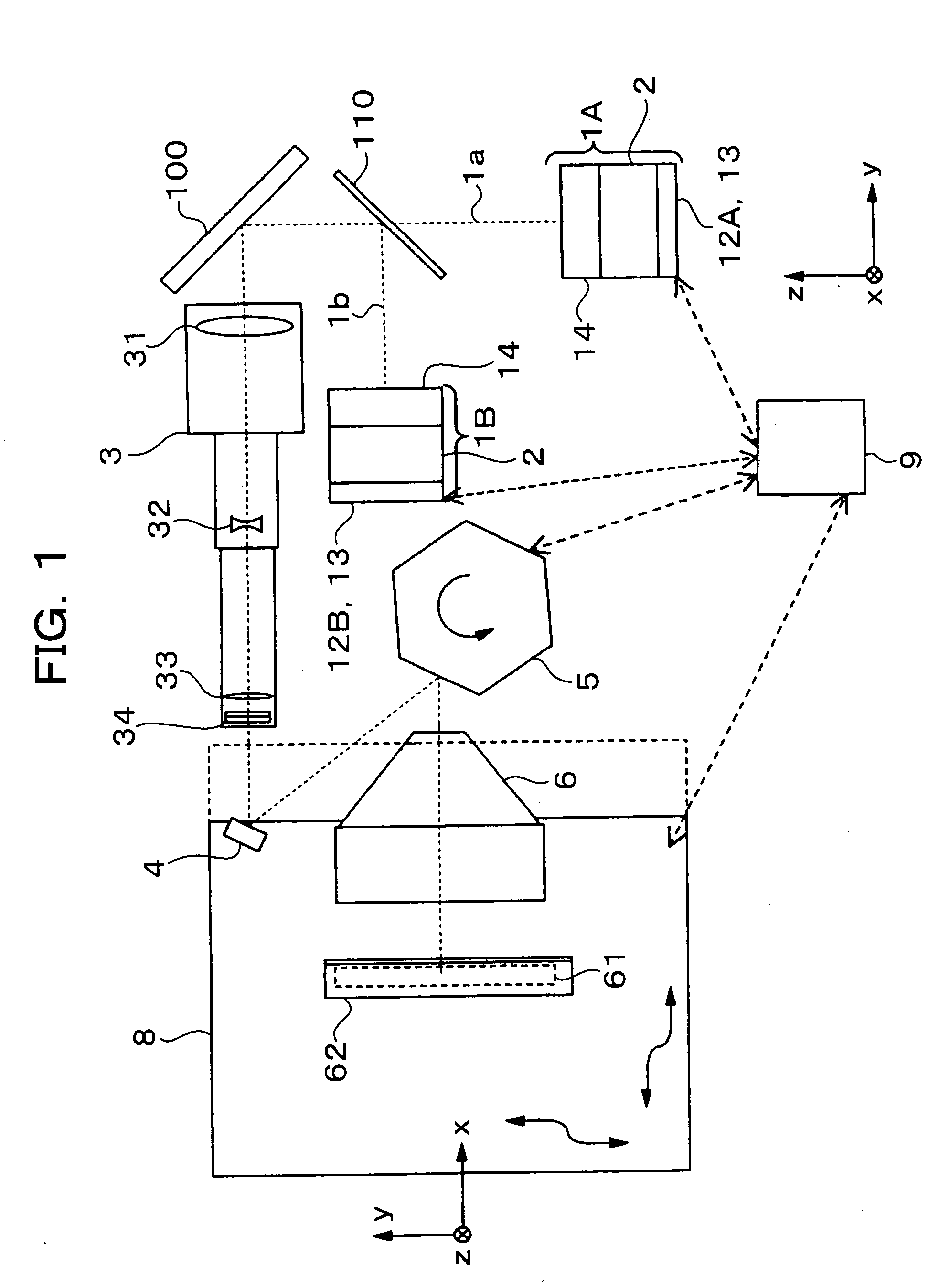

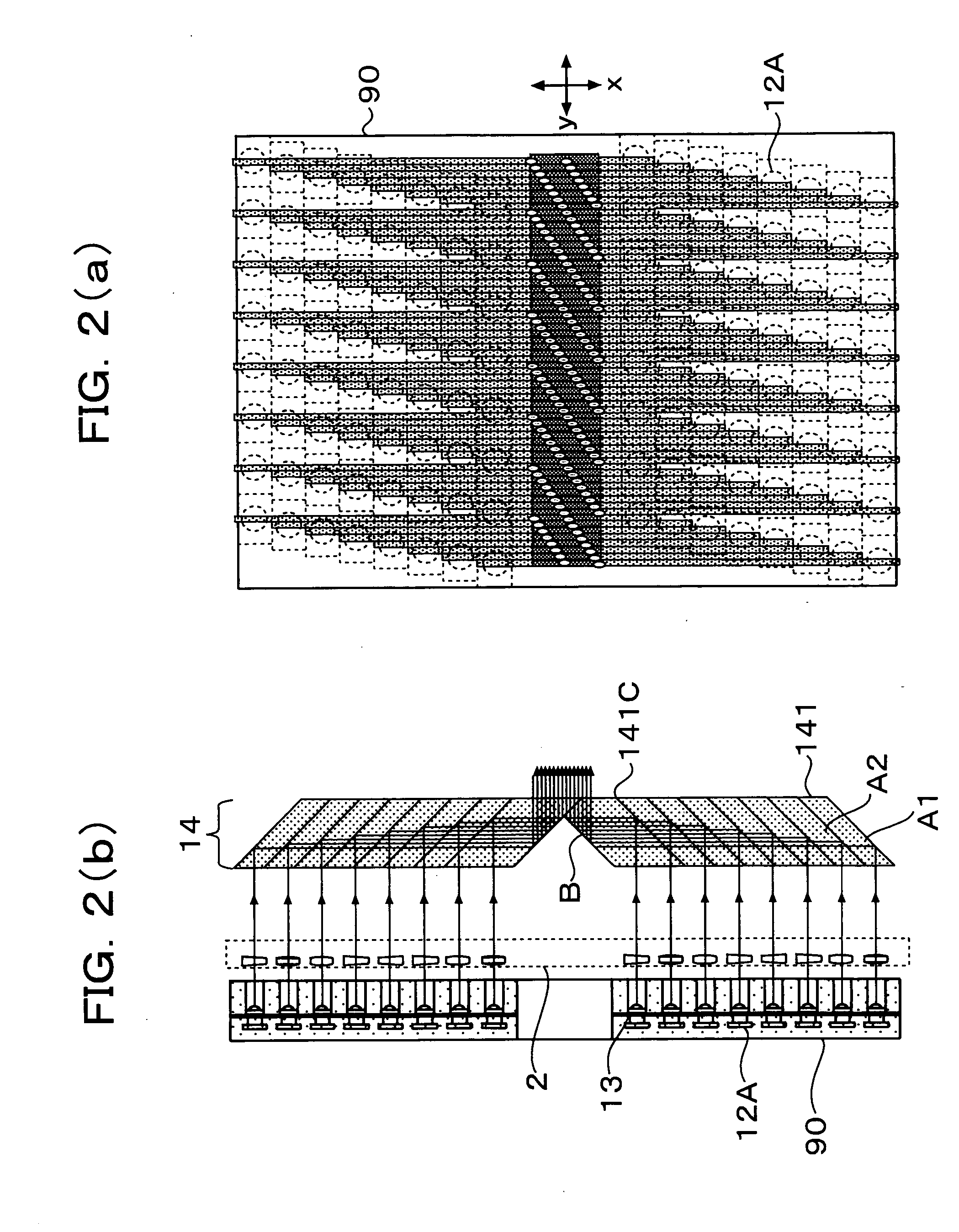

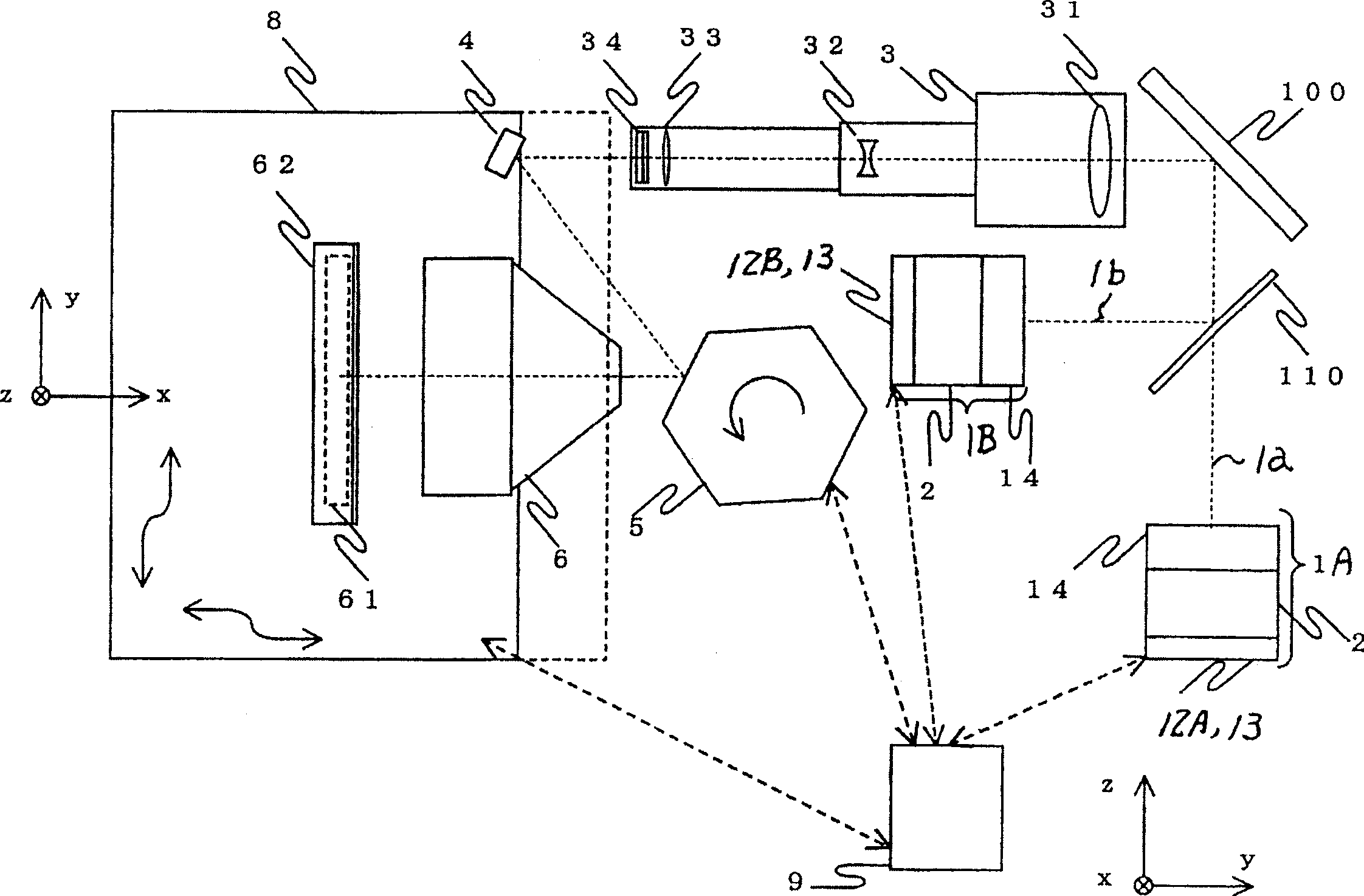

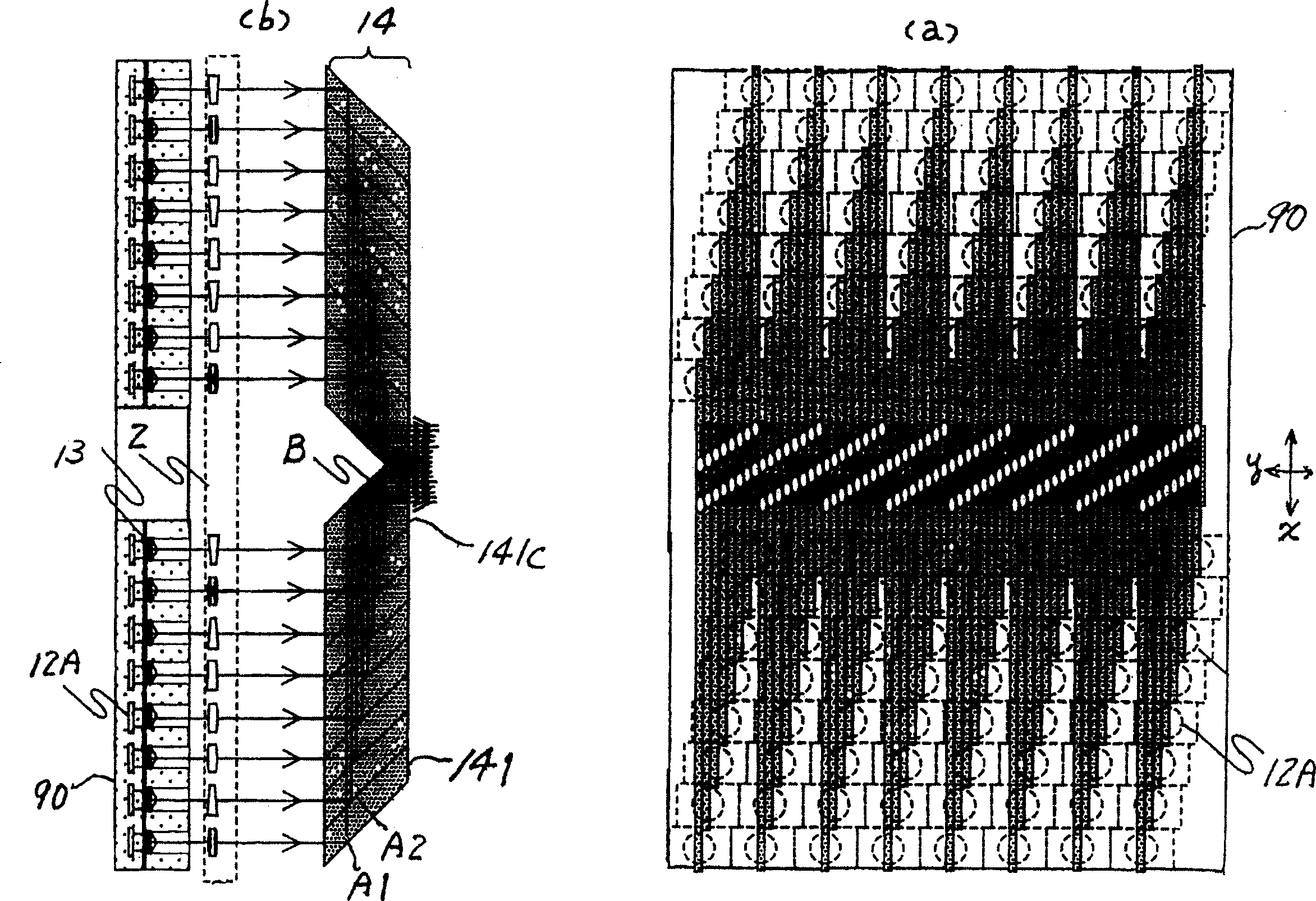

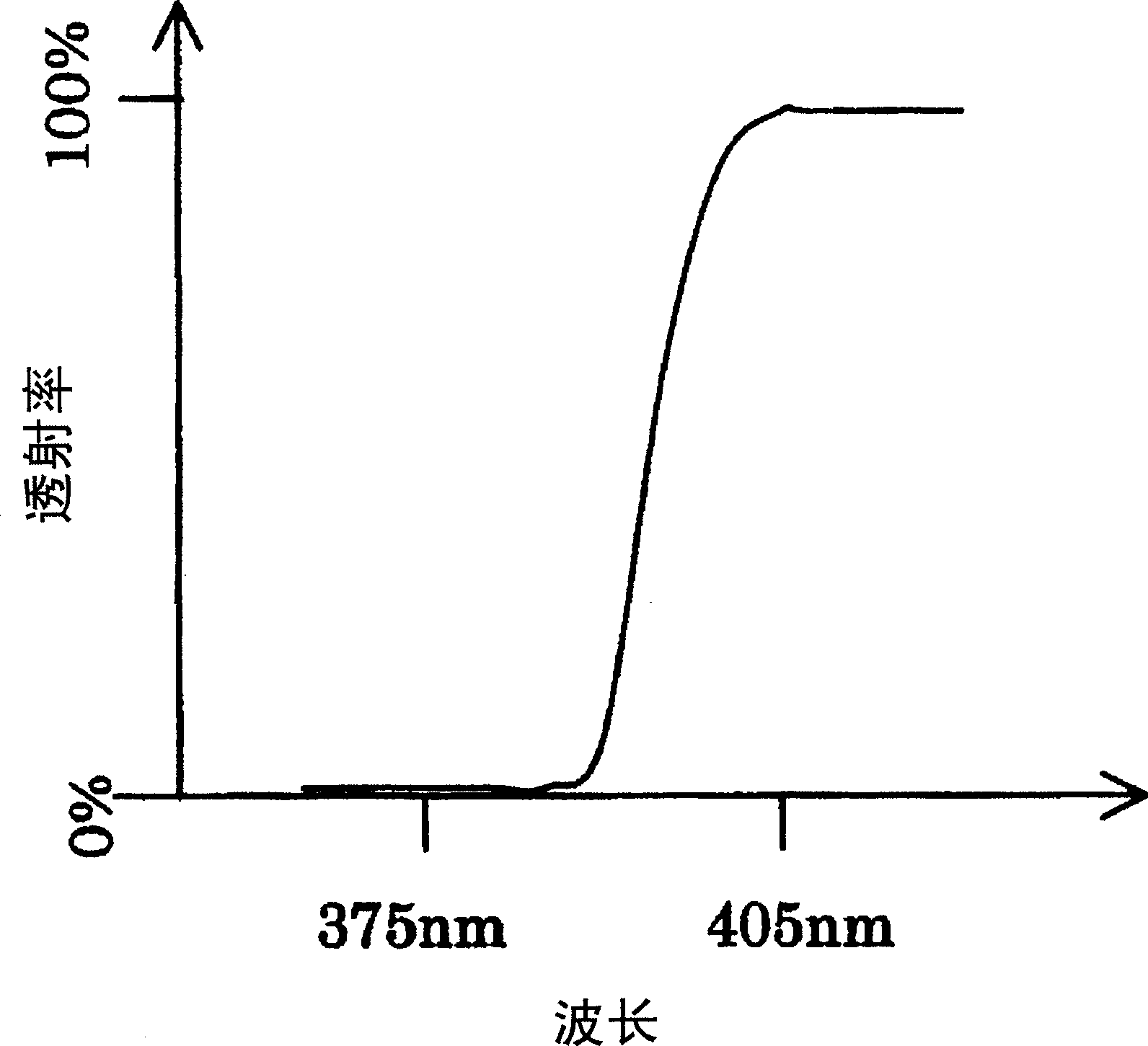

Pattern exposure method and apparatus

InactiveUS20060215139A1Efficient executionImprove exposure efficiencyPhotomechanical apparatusPolarising elementsResistOptical axis

A maskless exposure method and a maskless exposure apparatus in which maskless exposure can be performed efficiently with high-directivity illumination light, while the exposure efficiency of solder resist can be improved. Blue-violet semiconductor lasers 12A emitting laser beams 1a with a wavelength of 405 nm and ultraviolet semiconductor lasers 12B emitting laser beams 1b with a wavelength of 375 nm are provided to irradiate a substrate 8 with the laser beams 1a and 1b whose optical axes are made coaxial. In this event, one and the same place on the substrate 8 is irradiated with the laser beams 1a and 1b a plurality of times. Thus, the variation in intensity of the laser beams 1a and 1b is averaged.

Owner:HITACHI SEIKO LTD

Pattern exposure method and apparatus

InactiveCN1837962AImprove exposure efficiencyEfficient exposureSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistOptical axis

A maskless exposure method and a maskless exposure apparatus in which maskless exposure can be performed efficiently with high-directivity illumination light, while the exposure efficiency of solder resist can be improved. Blue-violet semiconductor lasers 12 A emitting laser beams 1 a with a wavelength of 405 nm and ultraviolet semiconductor lasers 12 B emitting laser beams 1 b with a wavelength of 375 nm are provided to irradiate a substrate 8 with the laser beams 1 a and 1 b whose optical axes are made coaxial. In this event, one and the same place on the substrate 8 is irradiated with the laser beams 1 a and 1 b a plurality of times. Thus, the variation in intensity of the laser beams 1 a and 1 b is averaged.

Owner:HITACHI SEIKO LTD

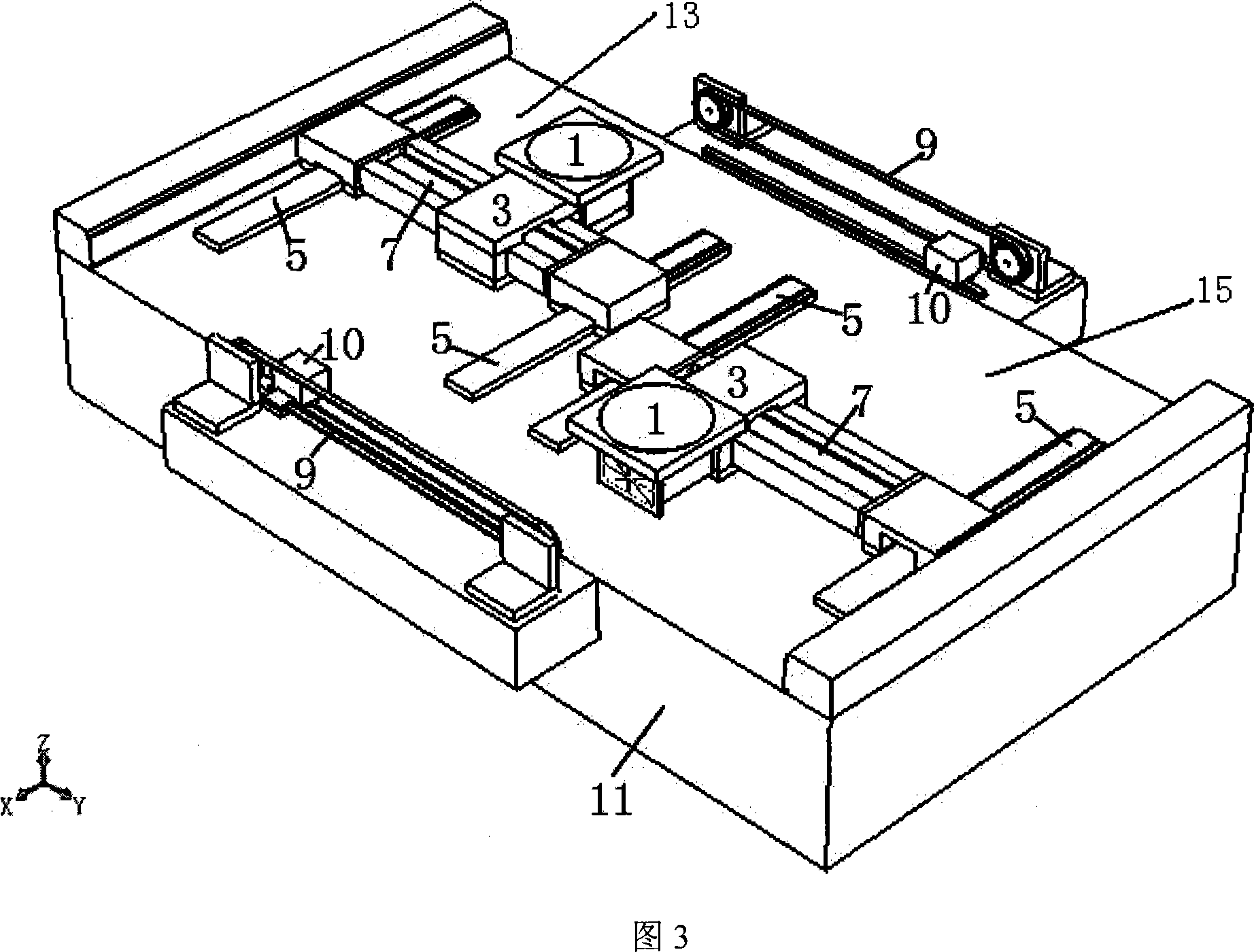

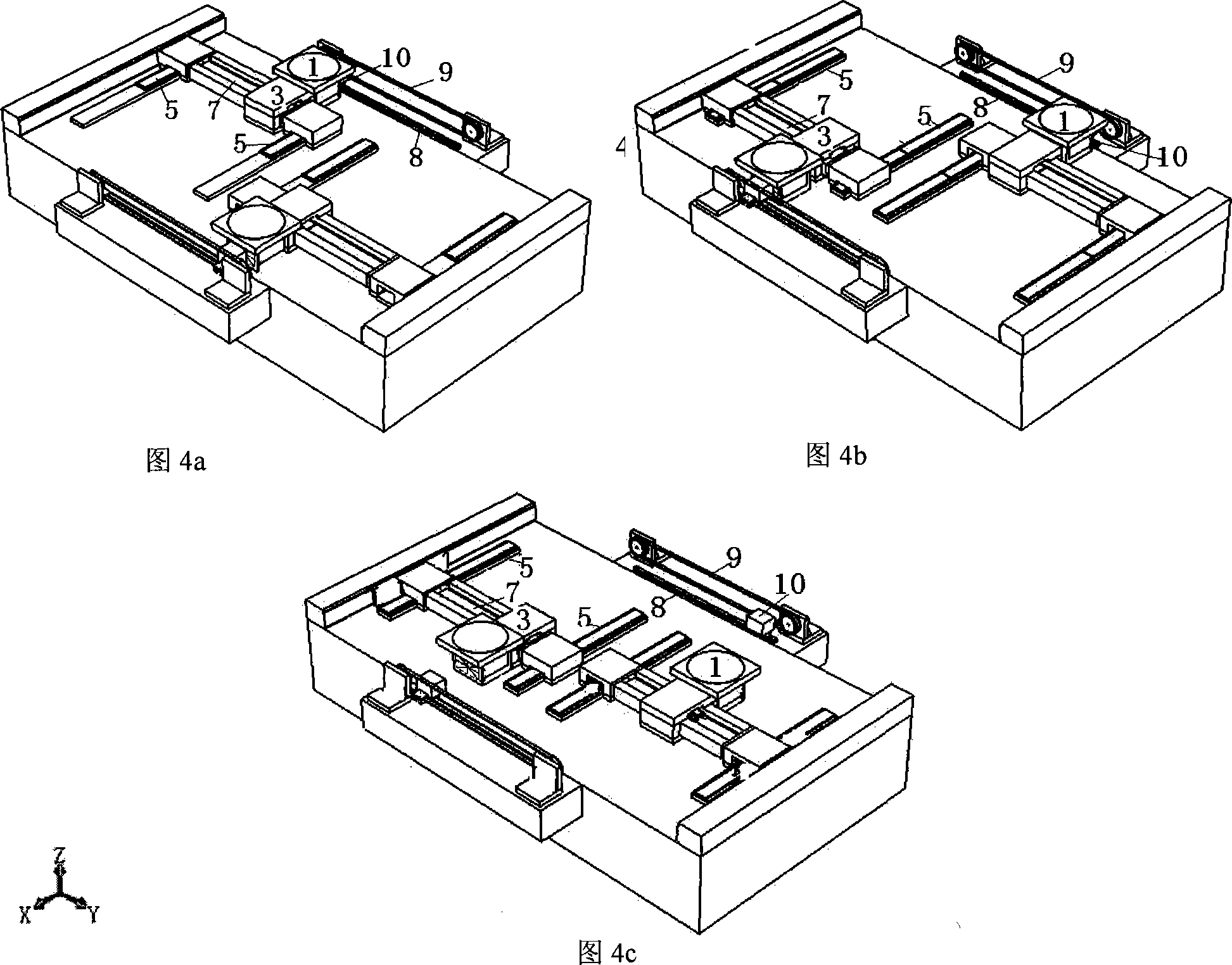

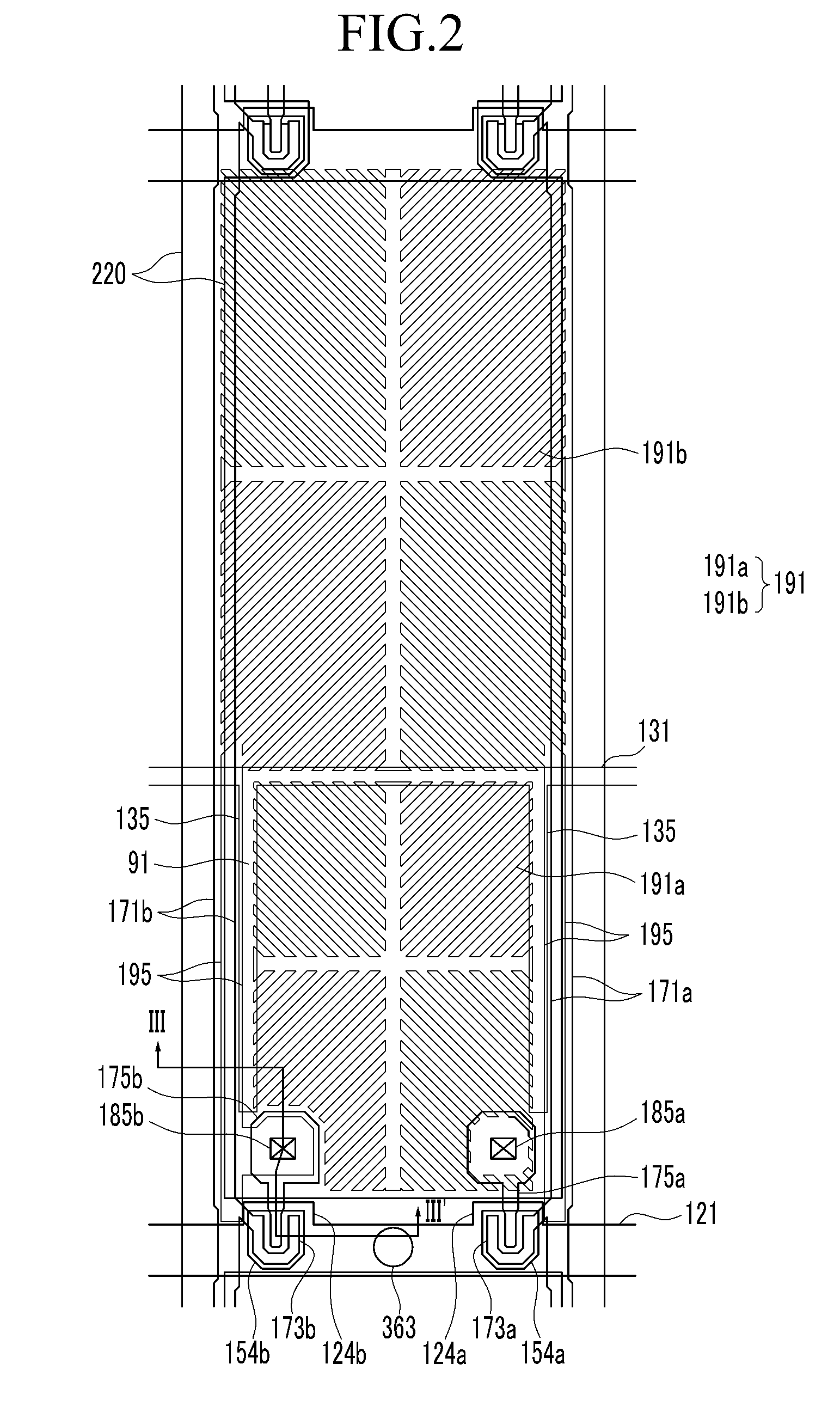

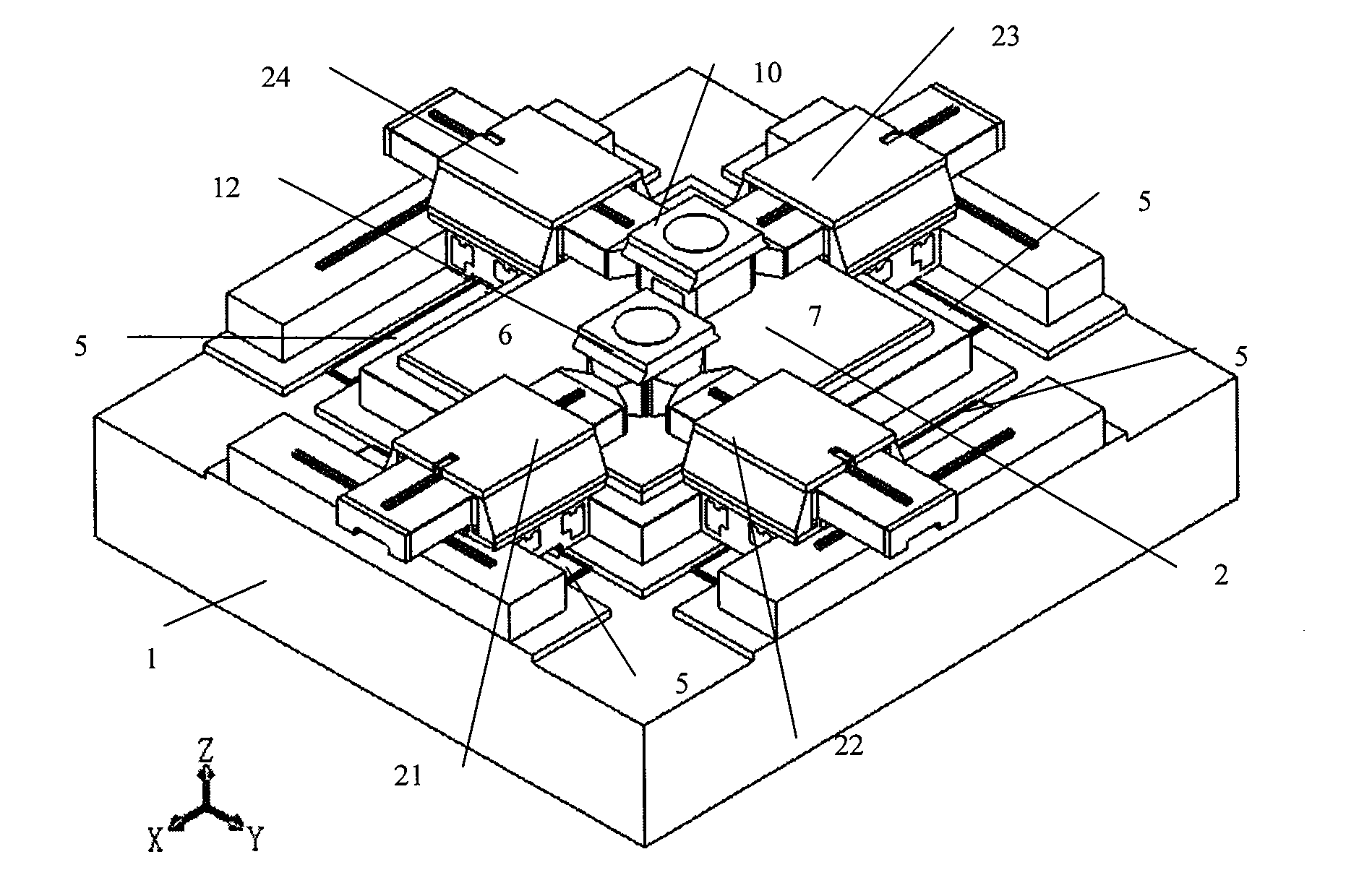

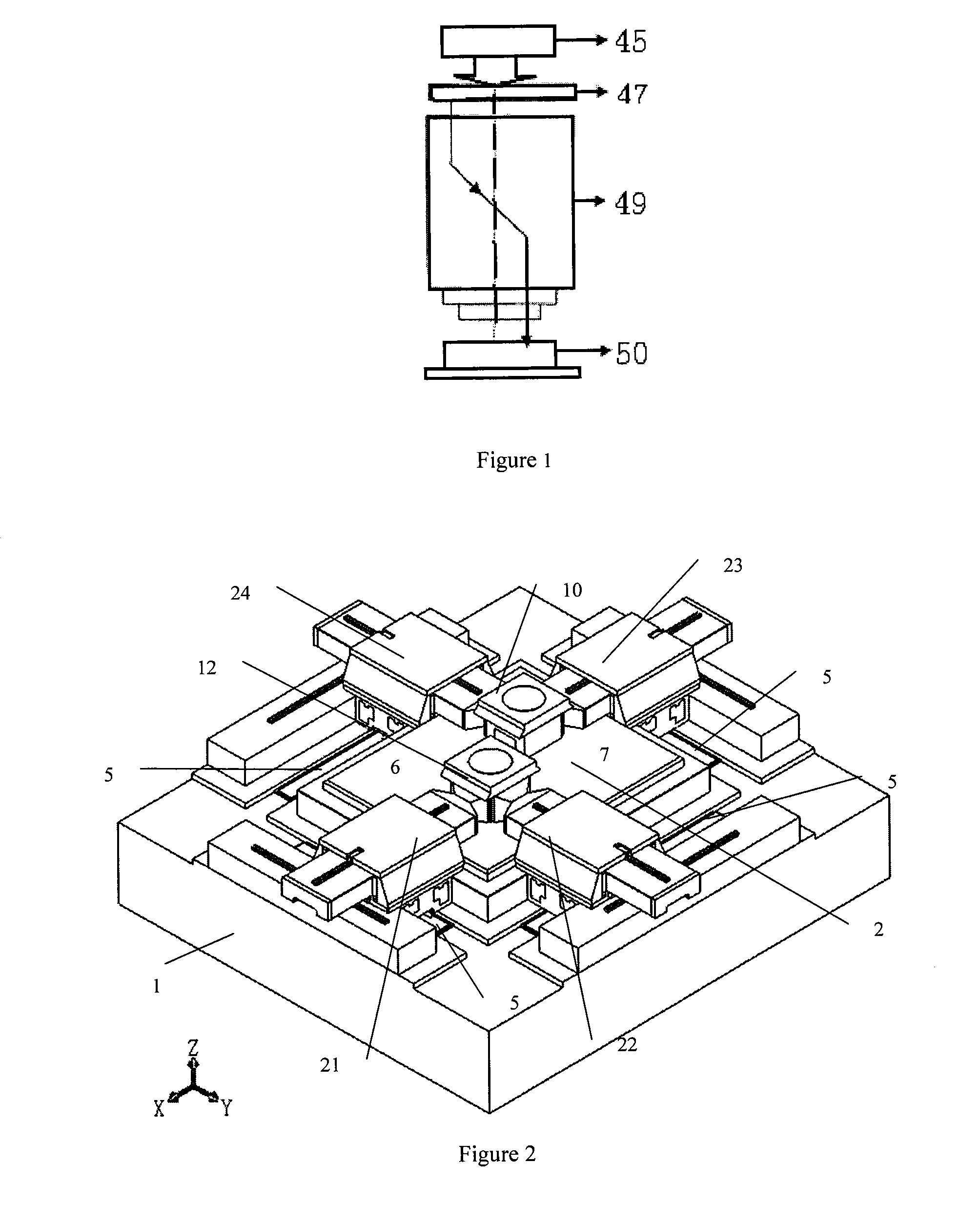

Dual-stage switching system for lithographic machine

ActiveUS20100208227A1Complex structureSimple system structurePhotomechanical apparatusPhotographic printingAir bearingDual stage

A dual-stage switching system for lithographic machine includes a wafer stage to be operated in an exposure station and another wafer stage to be operated in a pre-processing station. The two wafer stages are provided on a base, with four 2-DOF driving units capable of moving along X direction and Y direction being provided along the edge of the base, and the wafer stages being disposed in a space surrounded by the four 2-DOF driving units and suspended on an upper surface of the base by air bearings. Each of the 2-DOF driving units includes upper and lower linear guides and a guiding sleeve, with the upper and lower linear guides being installed vertical to each other in their corresponding guiding sleeve. Two adjacent 2-DOF driving units cooperatively drive the wafer stage) to move in the X direction and Y direction.

Owner:TSINGHUA UNIV

Exposure device and method

ActiveCN107664924AImprove exposure efficiencyImprove Exposure AccuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusControl systemEngineering

The invention discloses an exposure device and an exposure method. The device comprises a flexible substrate and a reel-to-reel transmission system, wherein the reel-to-reel transmission system is used for transmitting and fixing the flexible substrate; the exposure device also comprises a frontal-surface exposure system and a back-surface exposure system which are symmetrical about the axial direction of the flexible substrate, measurement systems which are corresponding to the frontal surface and the back surface of the flexible substrate respectively, and a master control system which is connected with the reel-to-reel transmission system, the frontal-surface exposure system, the back-surface exposure system and the measurement systems respectively. Through arranging the frontal-surfaceexposure system and the back-surface exposure system, the frontal surface and the back surface in the flexible substrate are exposed respectively; not only is the exposure efficiency improved; but also two different exposure systems are arranged respectively in the frontal-surface exposure system and the back-surface exposure system at the same time to realize the coarse exposure and the correction exposure on different exposed graphs on the flexible substrate; the exposure device can adapt to different deformation amounts and the exposure precision is greatly improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

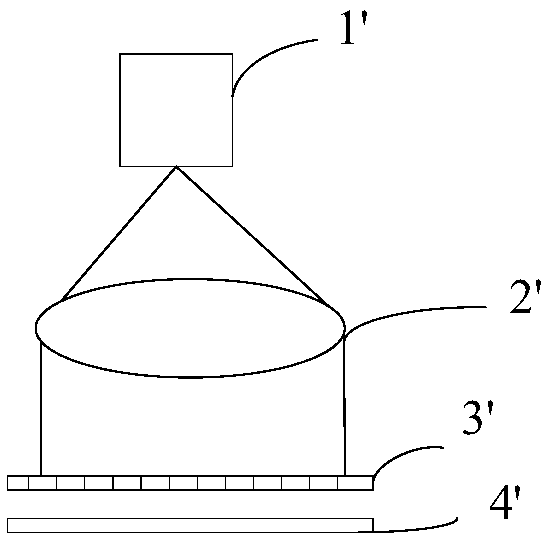

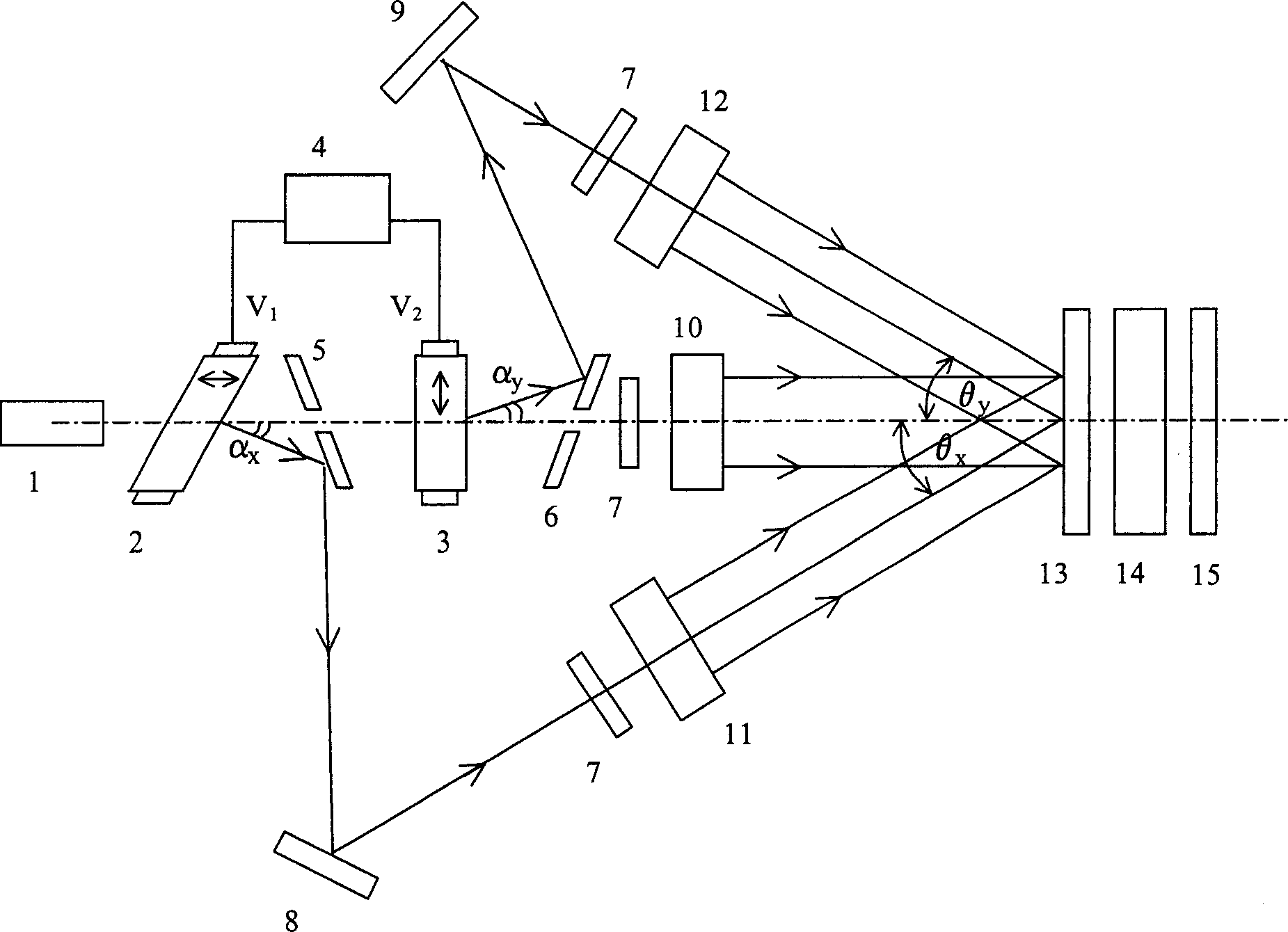

Imaging interference photo etching method using two quadrature acousto-optic modulators and photo etching system

InactiveCN1731283ANo influence of mechanical vibrationNo image alignment issuesPhotomechanical exposure apparatusMicrolithography exposure apparatusResistEtching

The invention relates to an image interference etching method and the etching system which uses two quartered acoustic-optic modulators and which is characterized in that it uses two quartered acoustic-optic modulators to bend the laser beam from the laser, when the acoustic-optic modulator dose not have the supersonic power, the laser can directly through the acoustic-optic modulator; when the acoustic-optic modulator have the supersonic power, the laser generates a first-order diffraction light witch can provide the illumination of level direction and vertical direction.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

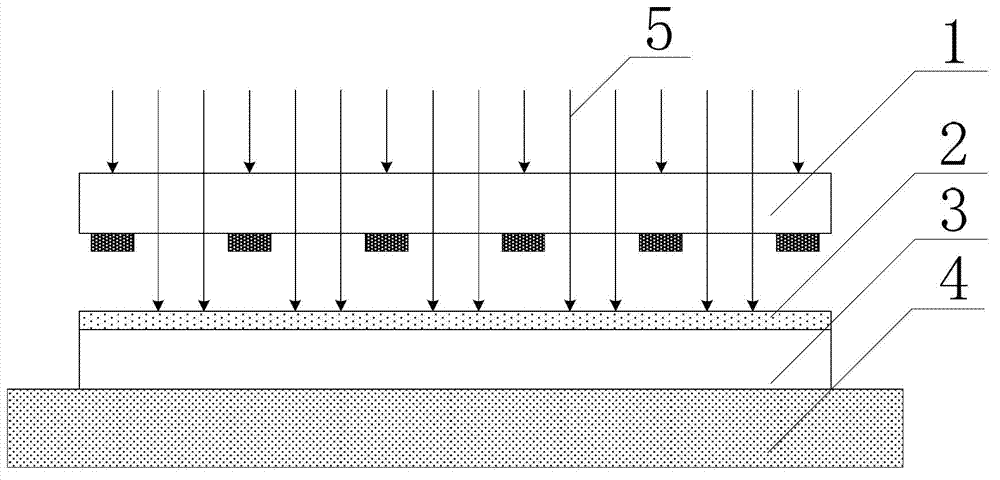

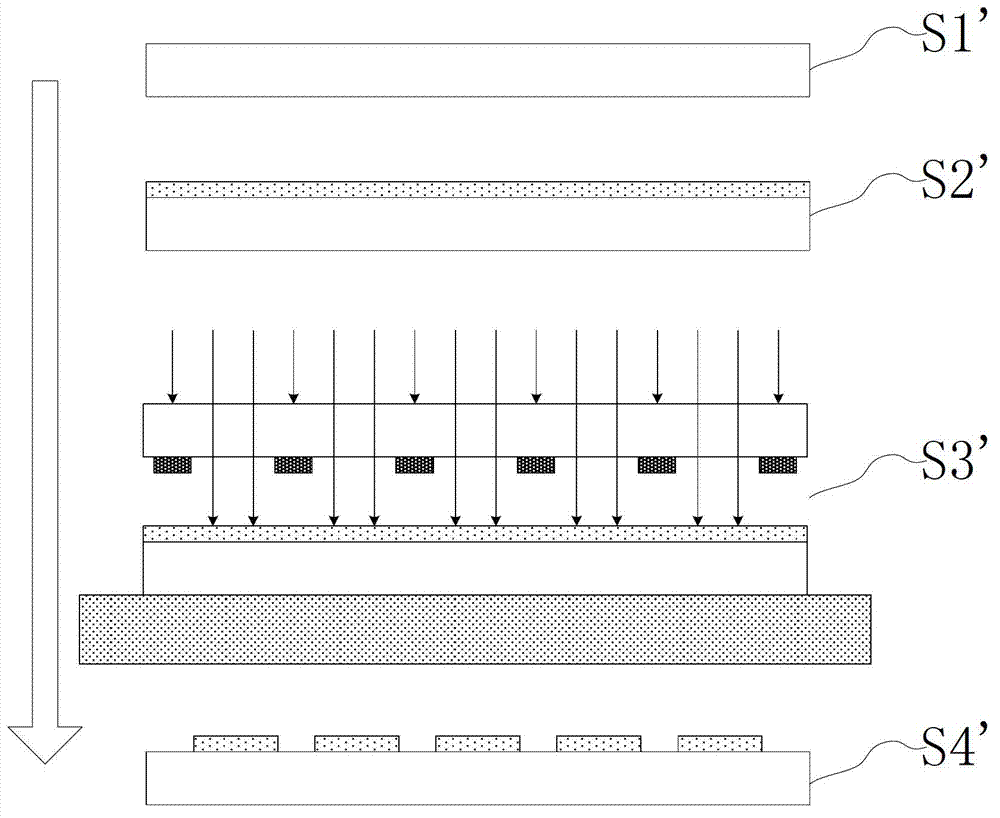

Exposure method and exposure apparatus

InactiveCN103207529AReduce in quantityImprove exposure efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusPhotoresistEnergy consumption

The invention relates to the technical field of display, in particular to an exposure method and an exposure apparatus for implementing the exposure method. A plurality of substrates coated by photoresist are arranged under one mask, parallel exposure light is adopted to irradiate the masks vertically; the photoresist of the top substrate is exposed by the parallel exposure light, the parallel exposure light penetrates the top substrate to continuously expose the photoresist of the substrates under the top substrate, and so on, till the exposure processes of the photoresist of all the substrates are completed. Since the photoresist of a plurality of substrates can be exposed synchronously, exposure efficiency is effectively improved; and meanwhile, since the number of the used masks is greatly reduced, exposure cost is reduced considerably; and since the same exposure light is fully utilized, energy consumption is reduced, and exposure cost is further reduced.

Owner:BOE TECH GRP CO LTD +1

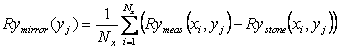

Workpiece platform position error measurement and pre-compensation method

ActiveCN103293865AEliminate errorsThe result is trueUsing optical meansPhotomechanical exposure apparatusPosition errorEnvironmental geology

The invention discloses a workpiece platform position error measurement and pre-compensation method comprising the following steps of: measuring at multiple positions, calculating the influence on the height and the incline of the workpiece platform caused by fluctuation of a support platform according to the measuring results, calculating the influence on the angle of inclination of the workpiece platform caused by the shape of a reflecting surface at the side face of the workpiece platform, and compensating the workpiece platform with the obtained error data according to the position of the workpiece.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Electron beam resist composition and preparation method

The invention provides an electron beam resist composition. Main components of the electron beam resist composition comprise a halogenated acrylate copolymer and a photo-acid generator, wherein the halogenated acrylate copolymer is a copolymer of a halogenated acrylate monomer unit and an aromatic acrylate or aromatic alkene monomer unit. Side chain-substituted halogen atoms and rigid aromatic rings are introduced and a proper combination of monomer units is selected. The copolymer in the composition provided by the invention has higher sensitivity and corrosion resistance. Besides, the composition also contains the photo-acid generator which can accelerate the pyrolysis of the copolymer in the composition, effectively improves exposure efficiency and further improves the sensitivity of the electron beam resist.

Owner:儒芯微电子材料(上海)有限公司

Double-sided exposure machine and double-sided exposure method

ActiveCN108873622AImprove time utilizationImprove exposure efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMechanical engineering

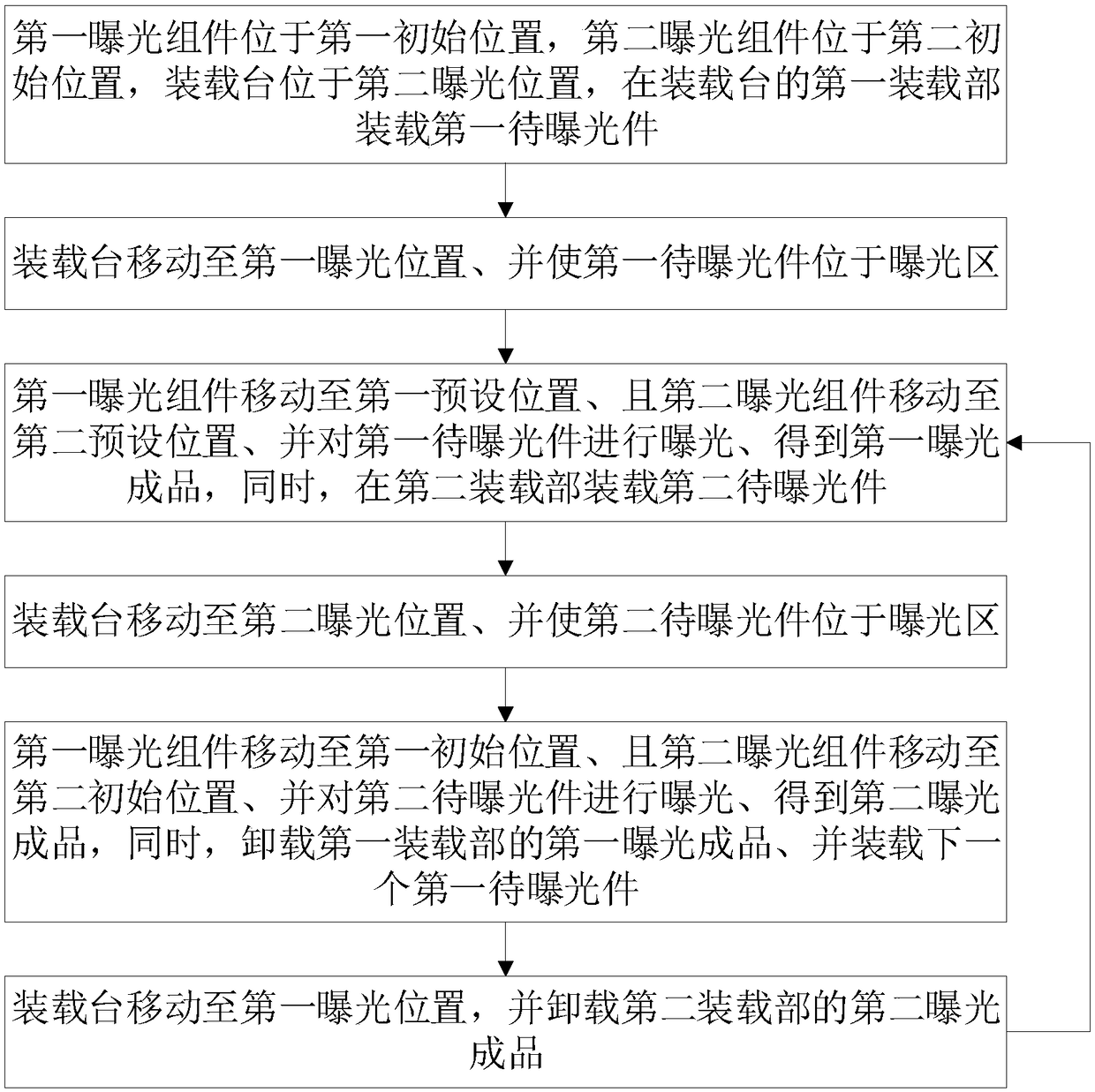

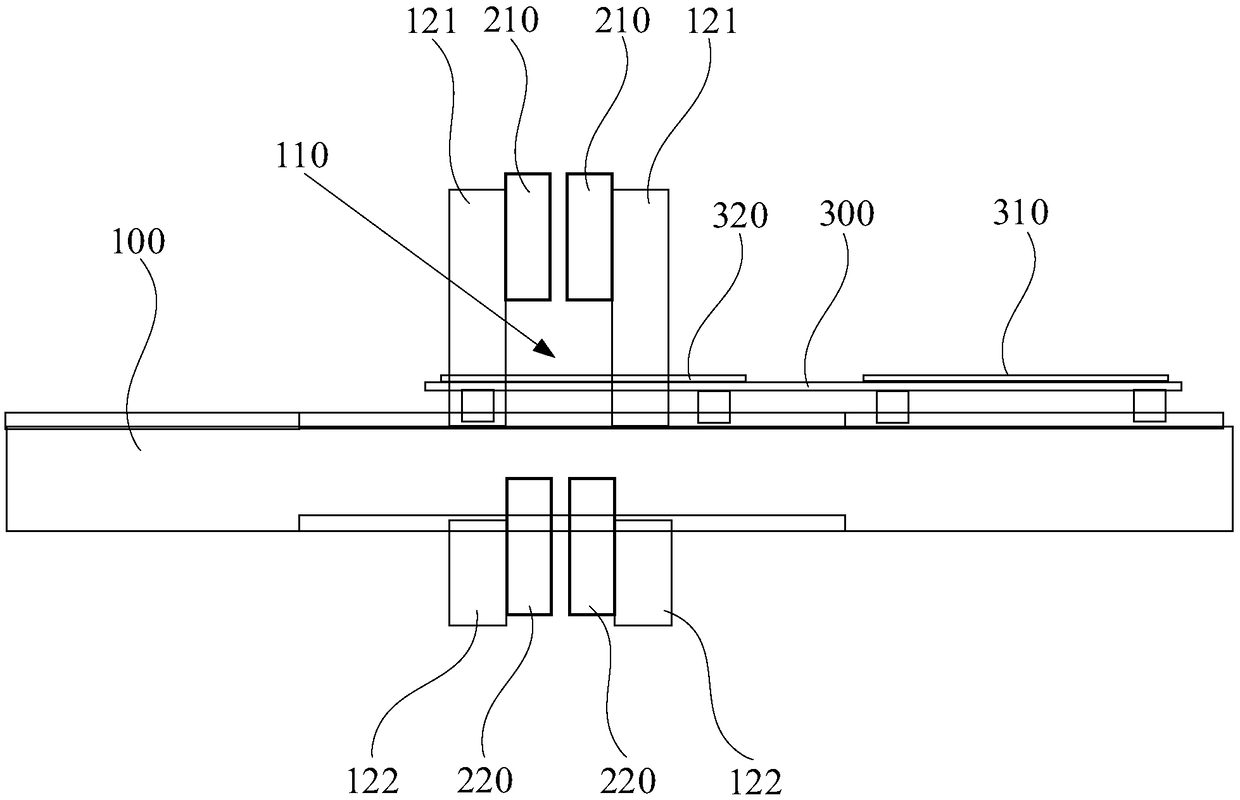

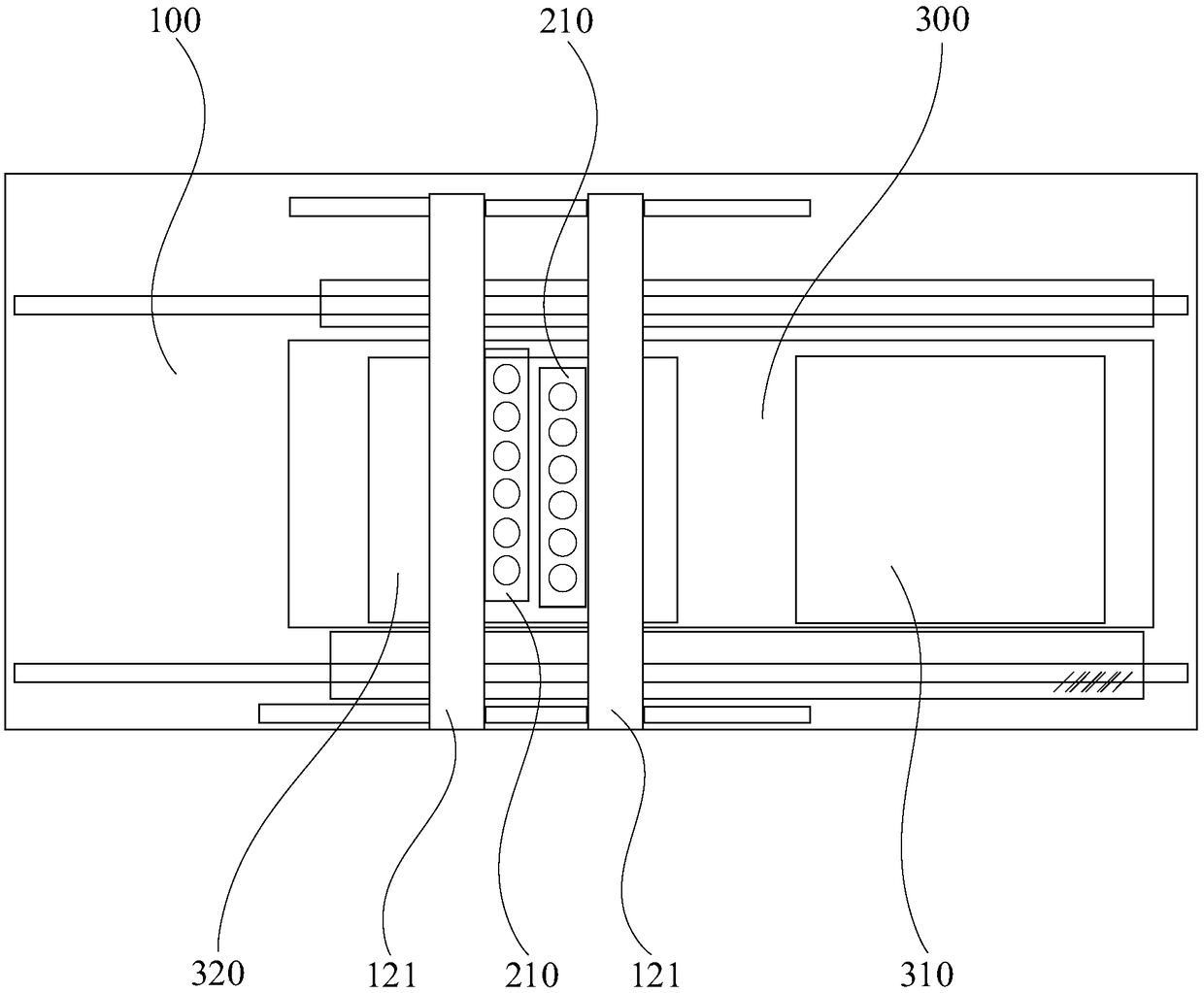

The invention relates to a double-sided exposure machine and a double-sided exposure method. The double-sided exposure machine comprises a worktable; the exposure machine comprises a first exposure component and a second exposure component each capable of movingalong the worktable, and forms an exposure area on the worktable; the loading machine comprises a loading platform; a first loading part and a second loading part are disposed on the loading platform, and the first loading part and the second loading part are disposed at a pitch; the loading platform is movable along the worktable and moves the first loading part or the second loading part to the exposure area. According to the arrangement of the movable first exposure component and second exposure component, the loading platform ismoved to the preset position during exposure, so that the first loading part or the second loading part is located in the exposure area, and then the first exposure component and the second exposurecomponent move toexpose the corresponding first component to be exposed or the second component to be exposed. Due to the simultaneous double-sided exposure, operations such as flippingare avoided, the exposure process and alignment are reduced, and the exposure efficiency and the exposure precision are improved.

Owner:ZHONGSHAN AISCENT TECH

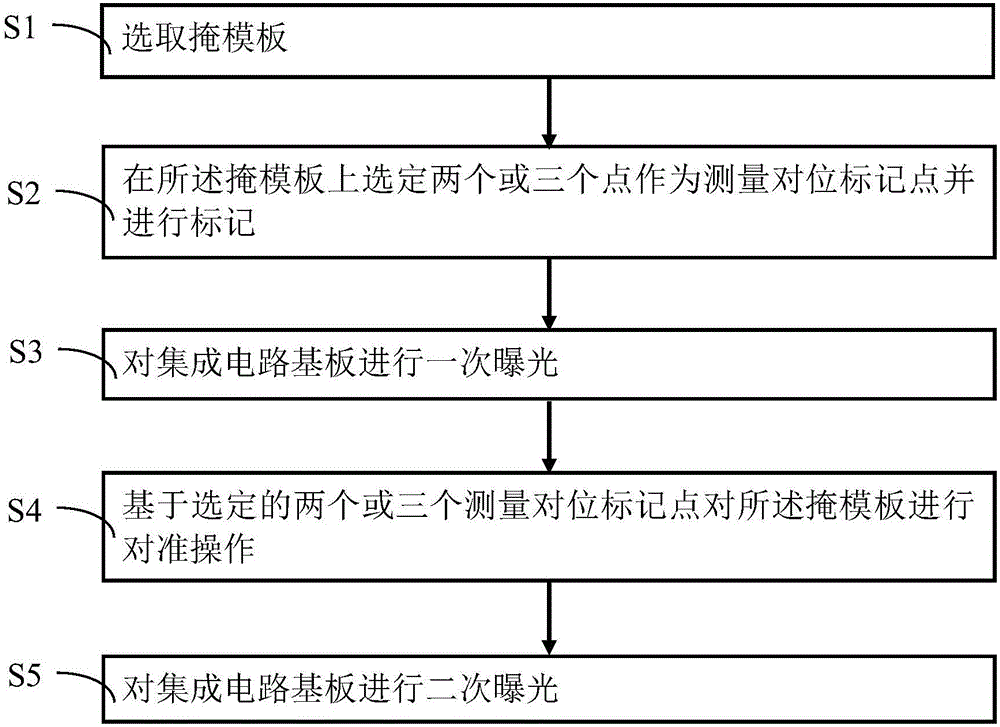

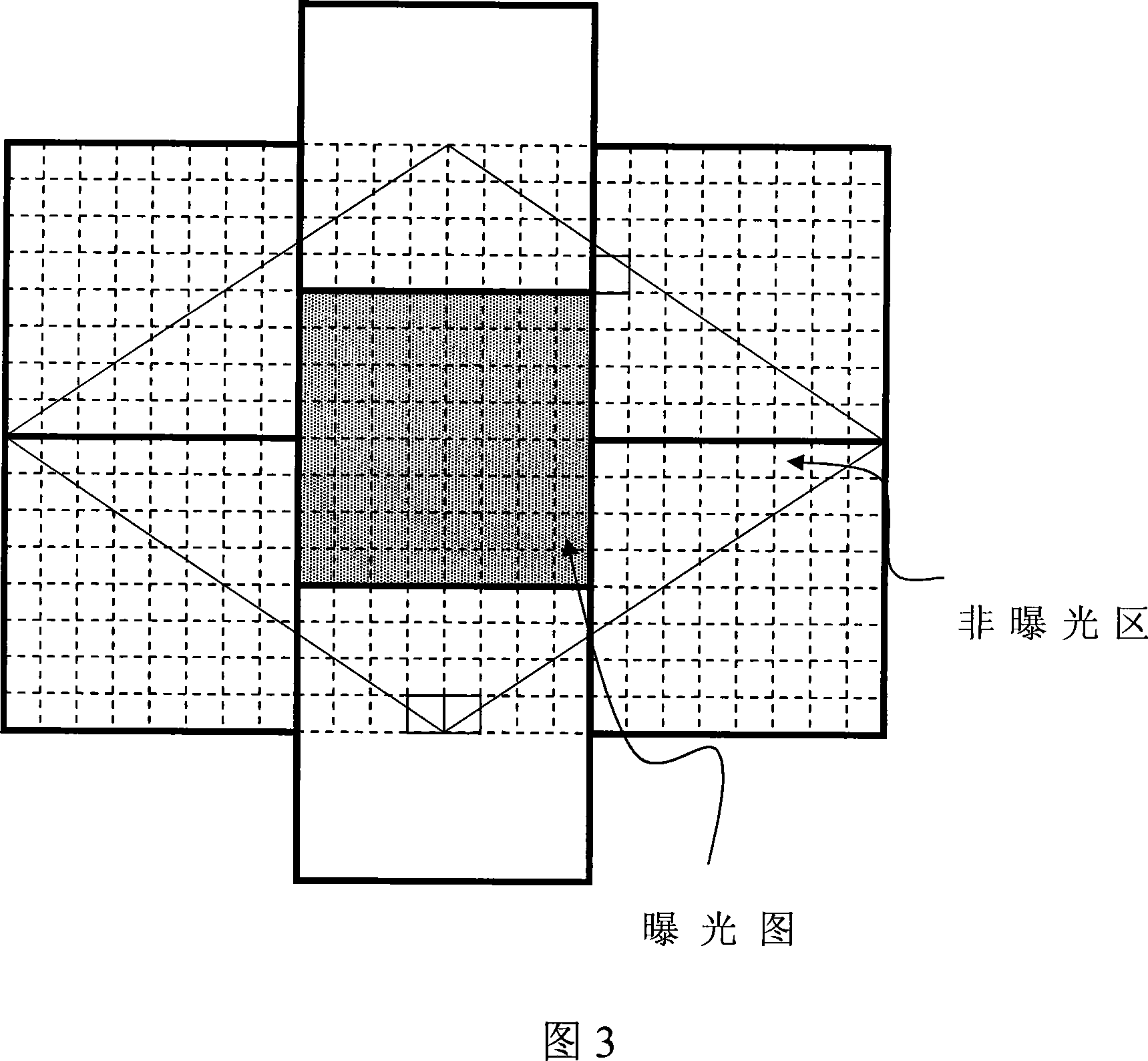

Mask plate-based secondary exposure method for integrated circuit substrate

ActiveCN106154768AShorten the timeImprove exposure efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusIntegrated circuitEngineering

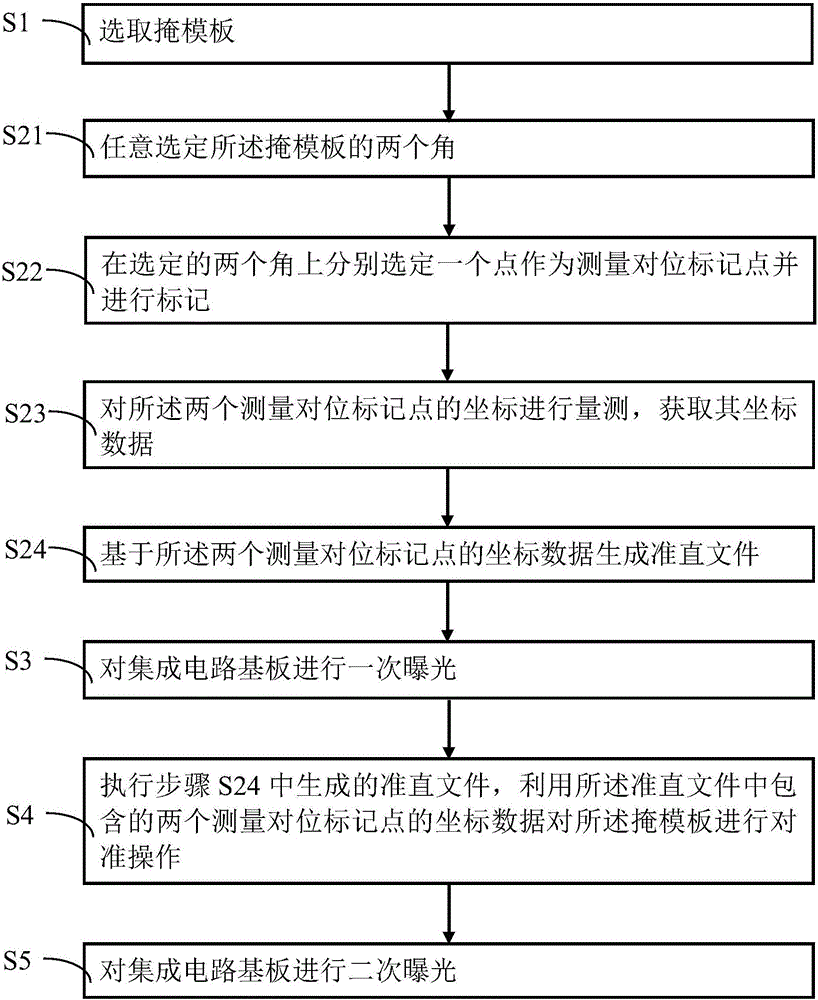

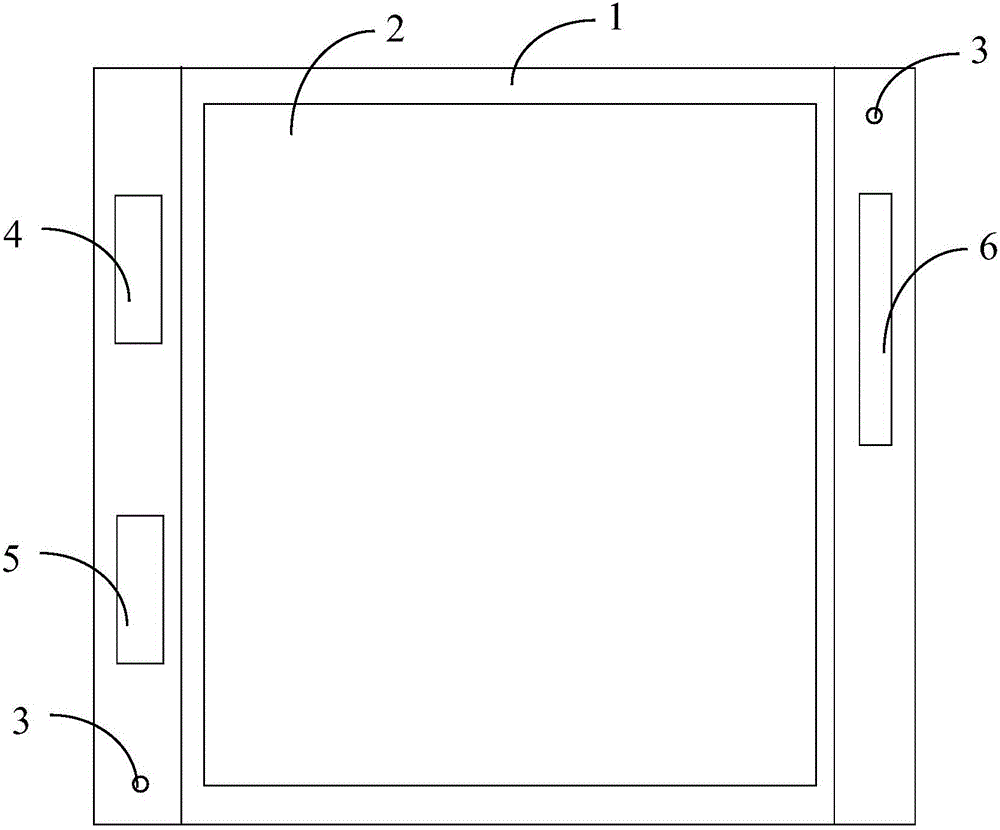

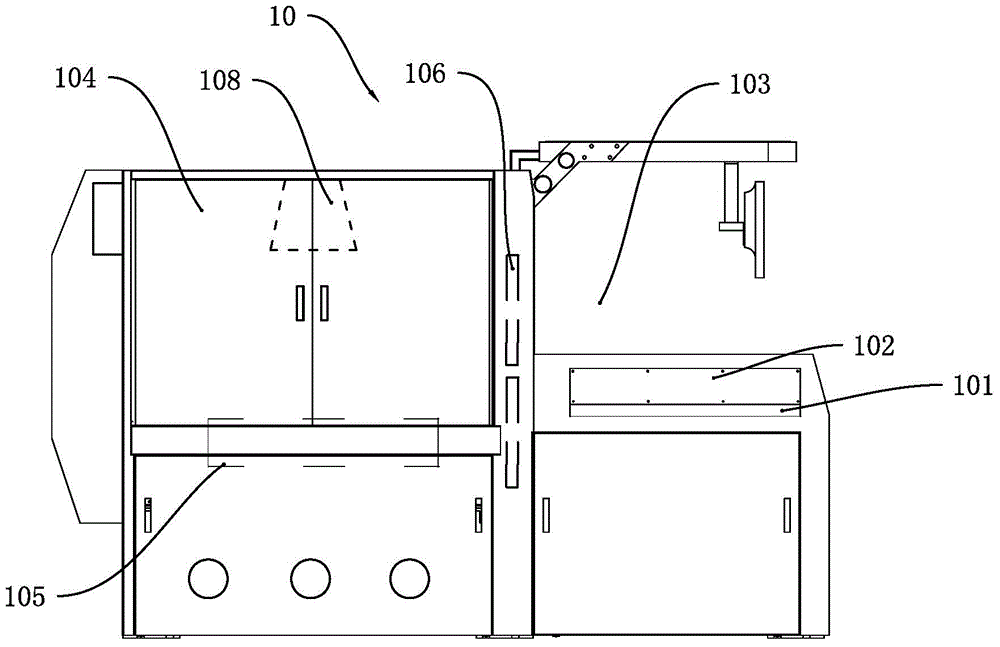

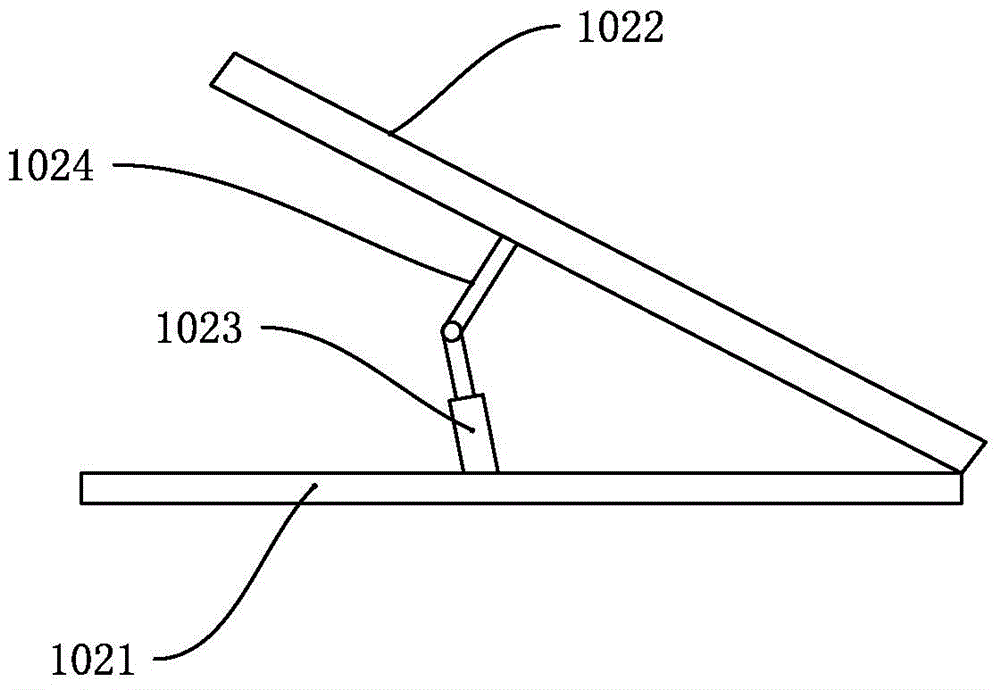

The invention belongs to the technical field of semiconductors and discloses a mask plate-based secondary exposure method for an integrated circuit substrate. The method comprises the steps of S1, selecting a mask plate; S2, selecting two or three points on the mask plate to serve as measurement alignment mark points and performing marking; S3, performing primary exposure on the integrated circuit substrate; S4, performing alignment operation on the mask plate based on the selected two or three measurement alignment mark points; and S5, performing secondary exposure on the integrated circuit substrate. According to the method, the alignment operation is performed according to alignment based on obtained coordinate data after the integrated circuit substrate is subjected to the primary exposure, and then the integrated circuit substrate is subjected to the secondary exposure, so that the alignment operation time in the secondary exposure process is effectively shortened, the exposure efficiency is improved, and the production capacity is increased.

Owner:WUXI ZHONGWEI MASK ELECTRONICS

TFT (thin-film transistor) processing technique for thin-film transistor liquid crystal display

InactiveCN106158590AReduce sheddingImprove exposure efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesMarket potentialChemistry

The invention discloses a TFT (thin-film transistor) processing technique for a thin-film transistor liquid crystal display. After washing with water and with ultrasonic wave, it is possible to remove impurity and oil stain on the surface of glass; by determining a temperature and humidity for photoresist application, adhesive can be well pasted to the surface of the glass, the problems of shedding and graphic defects are lessened for the glass; by starting an aerator to carry out preheating stabilization with ultraviolet before exposure, aeration efficiency can be improved for the glass; an acid solution that is a mixed solution of HCl and HNO3 may corrode and remove ITO (indium tin oxide) film without damaging the glass and photoresist; by determining etching temperature and time, it is possible to improve etching effect. The TFT for the thin-film transistor liquid crystal display processed by using the processing technique has the advantages of high production efficiency and high opening rate, and has great market potential and promising prospect.

Owner:HEFEI JIARUILIN ELECTRONICS TECH

Semi-automatic alignment and exposure device of printed circuit board (PCB)

InactiveCN105629670AAccurateThe alignment mechanism is automatic and accuratePhotomechanical exposure apparatusMicrolithography exposure apparatusControl systemSemi automatic

The invention discloses a semi-automatic alignment and exposure device of a printed circuit board (PCB). The semi-automatic alignment and exposure device comprises an alignment chamber and an exposure chamber, wherein an upper slipway and a lower slipway are respectively arranged in the alignment chamber and the exposure chamber and are in parallel, an upper alignment platform is arranged in the upper slipway and comprises a first working table, a first upper cover and an alignment mechanism, the first working table can slide along the upper slipway, the first upper cover is hinged with the first working table, a signal acquisition device is arranged above the first working table and can slide along the alignment chamber, the exposure chamber comprises an exposure device, the exposure device can do vertical movement along the exposure chamber, a lower alignment platform comprises a second working table, a second upper cover and an alignment mechanism, the second working table can slide along the lower slipway, the second upper cover is hinged with the second working table, the first working table and the second working table do movement relative to each other by a driving device, the semi-automatic alignment and exposure device also comprises a control system, and the control system controls opening and closing of a partition plate, controls the first working table and the second working table to do movement relative to each other and controls the alignment mechanism to automatically align. The semi-automatic alignment and exposure device has the advantages of positioning accuracy and high positioning efficiency.

Owner:永天机械设备制造(深圳)有限公司

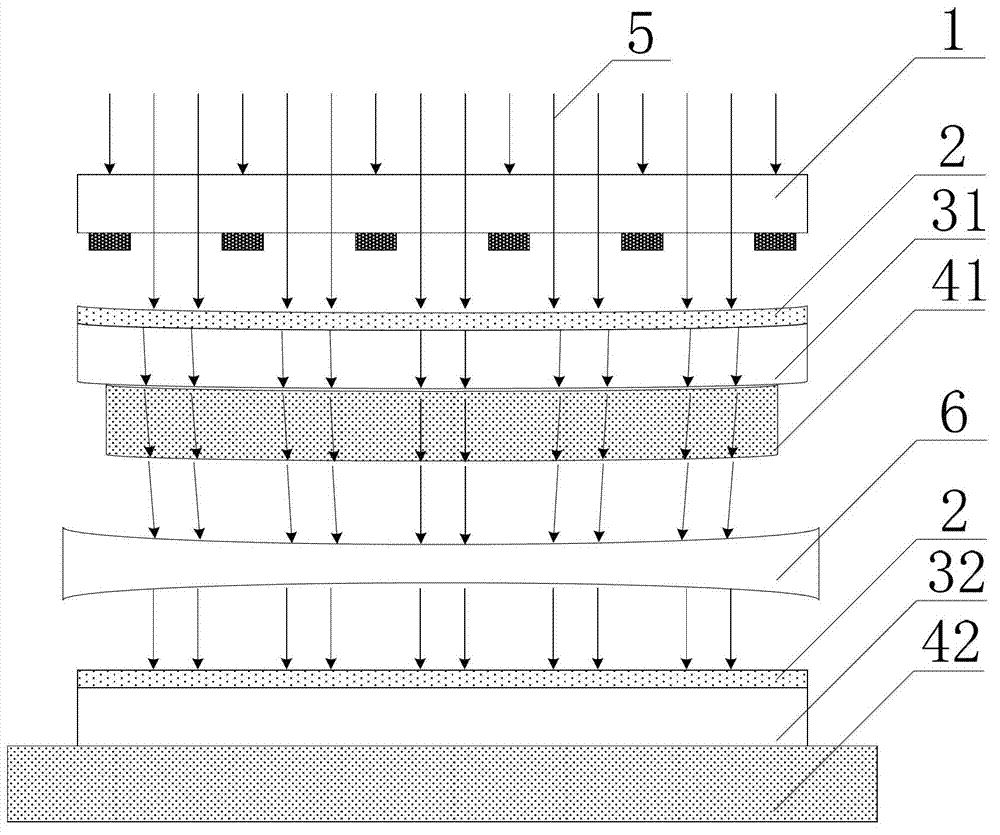

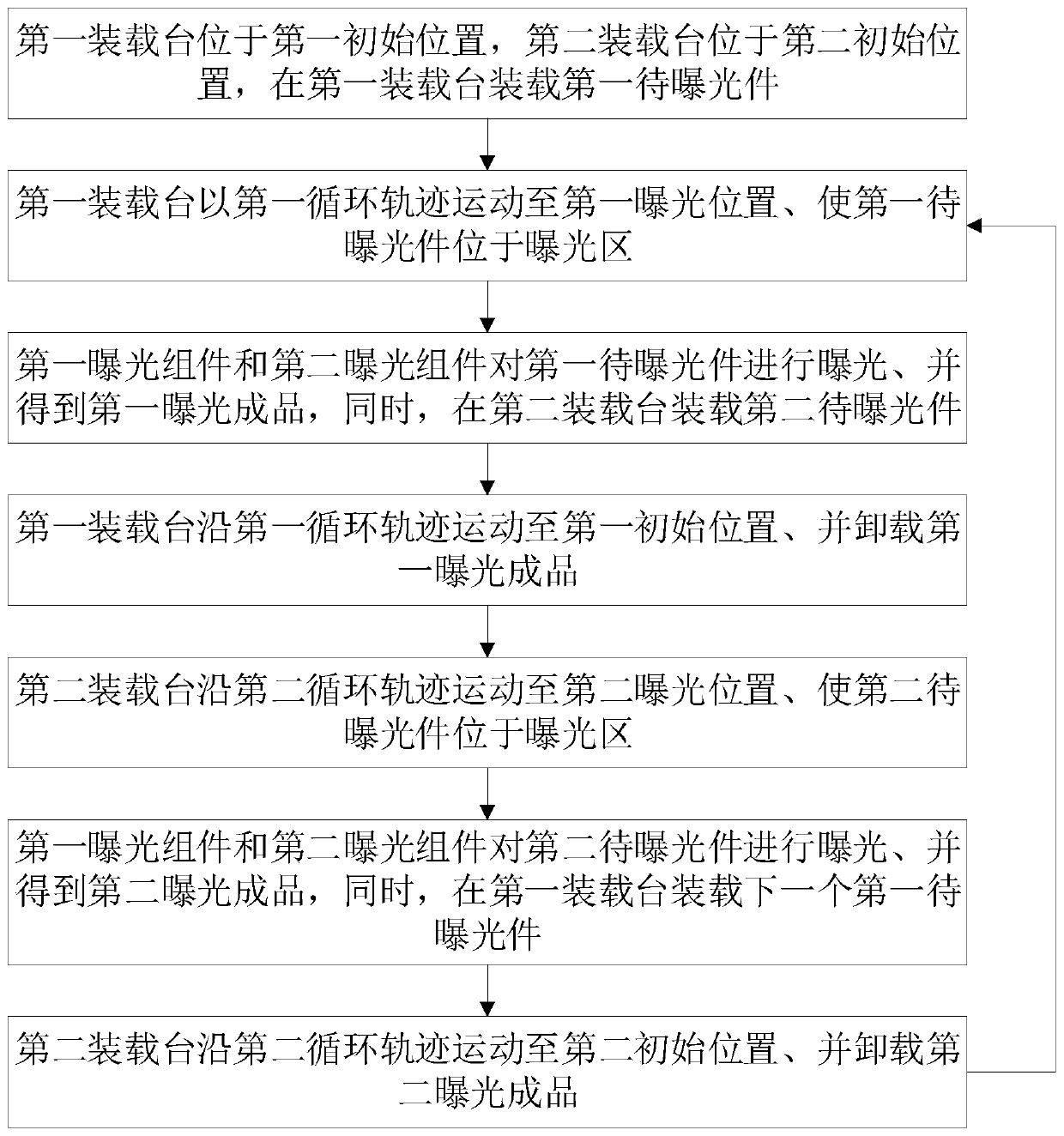

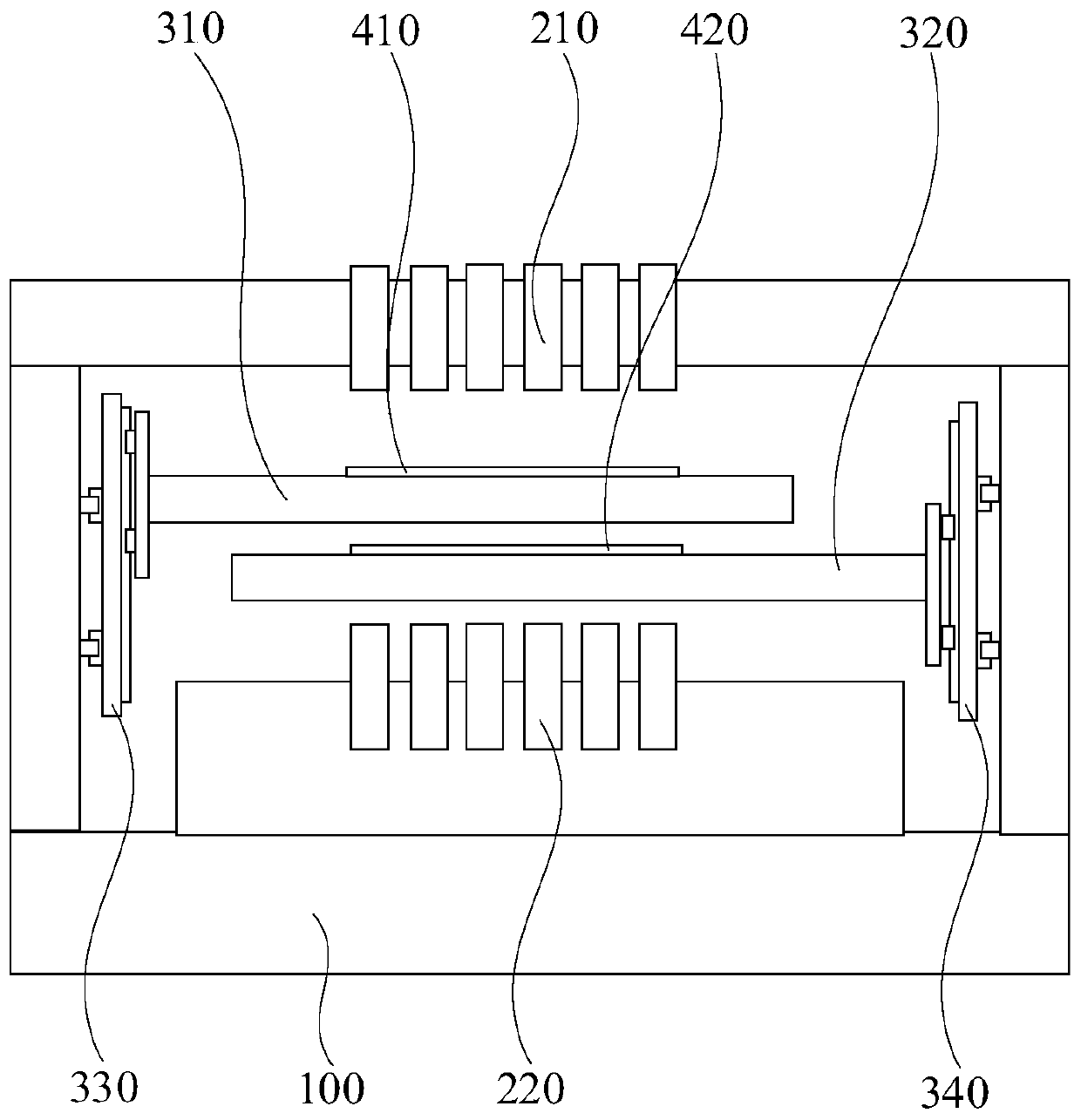

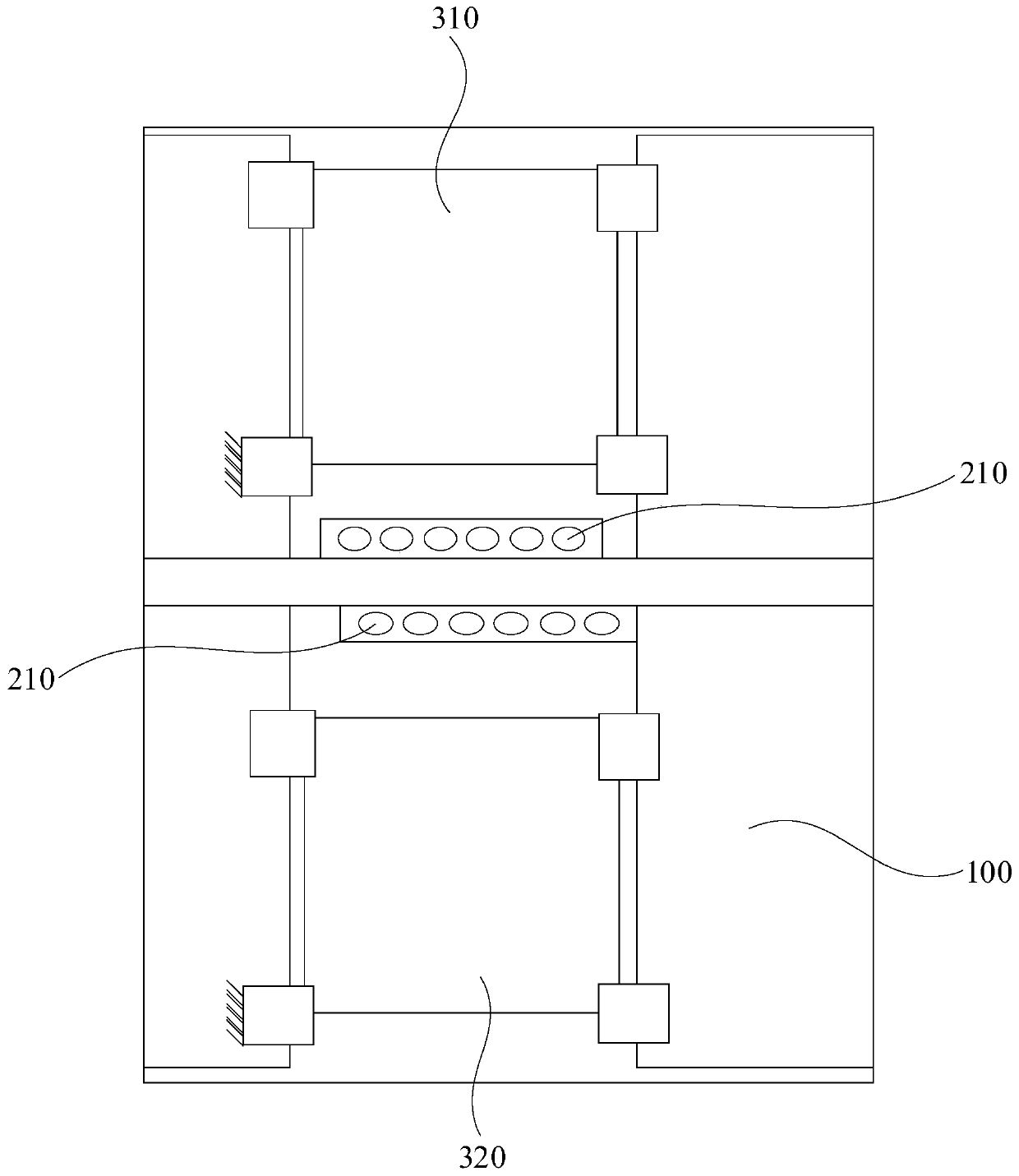

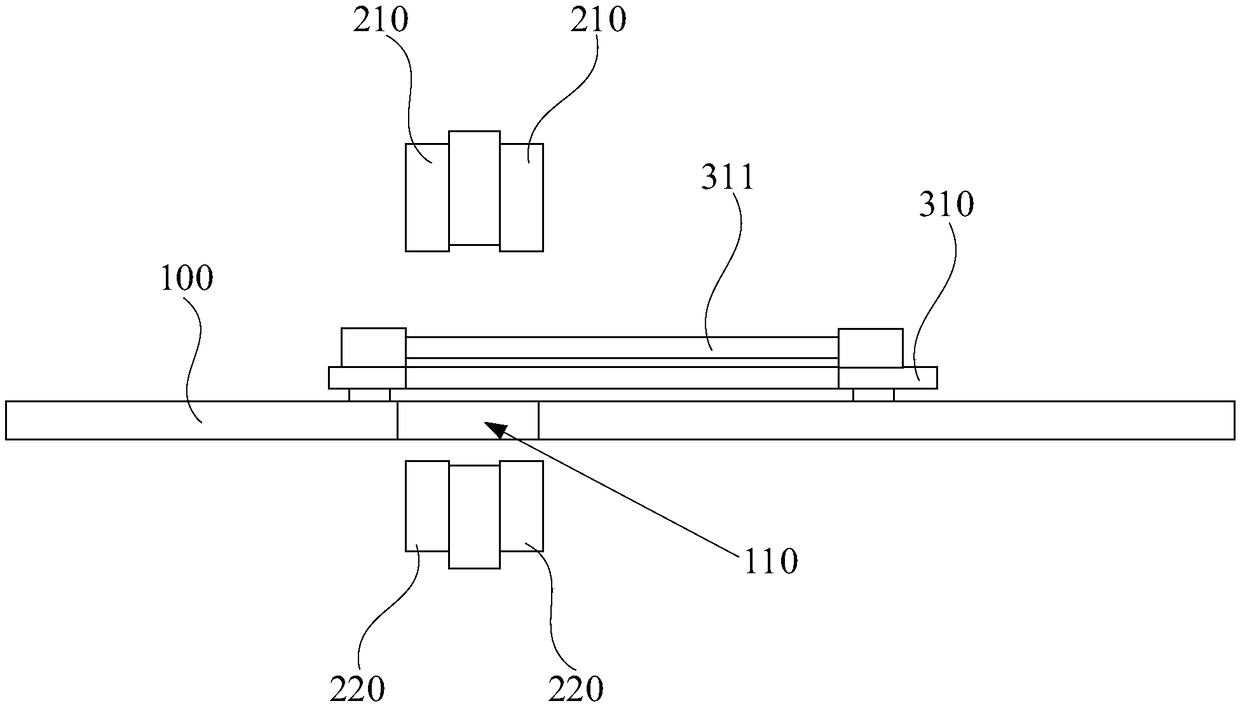

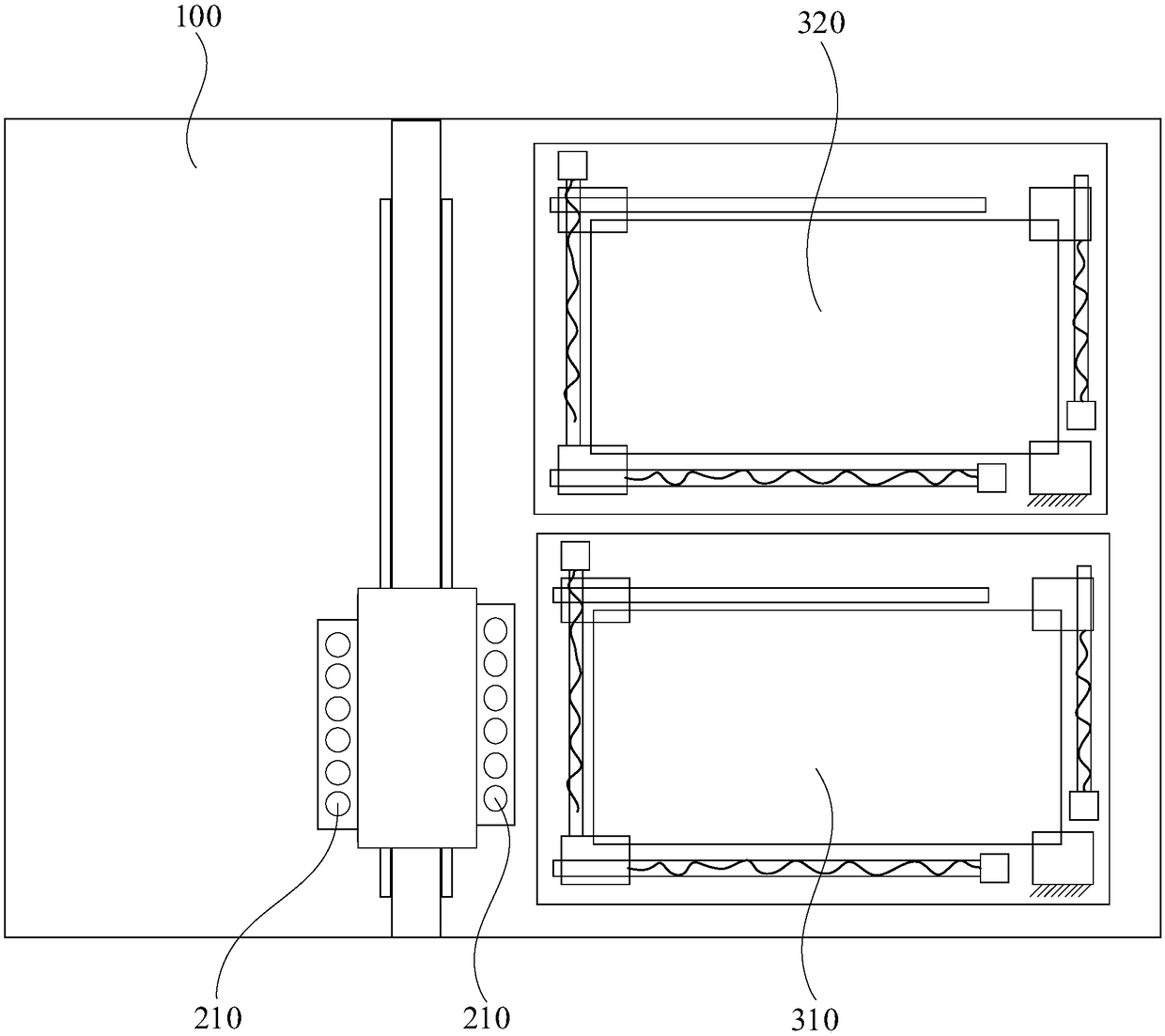

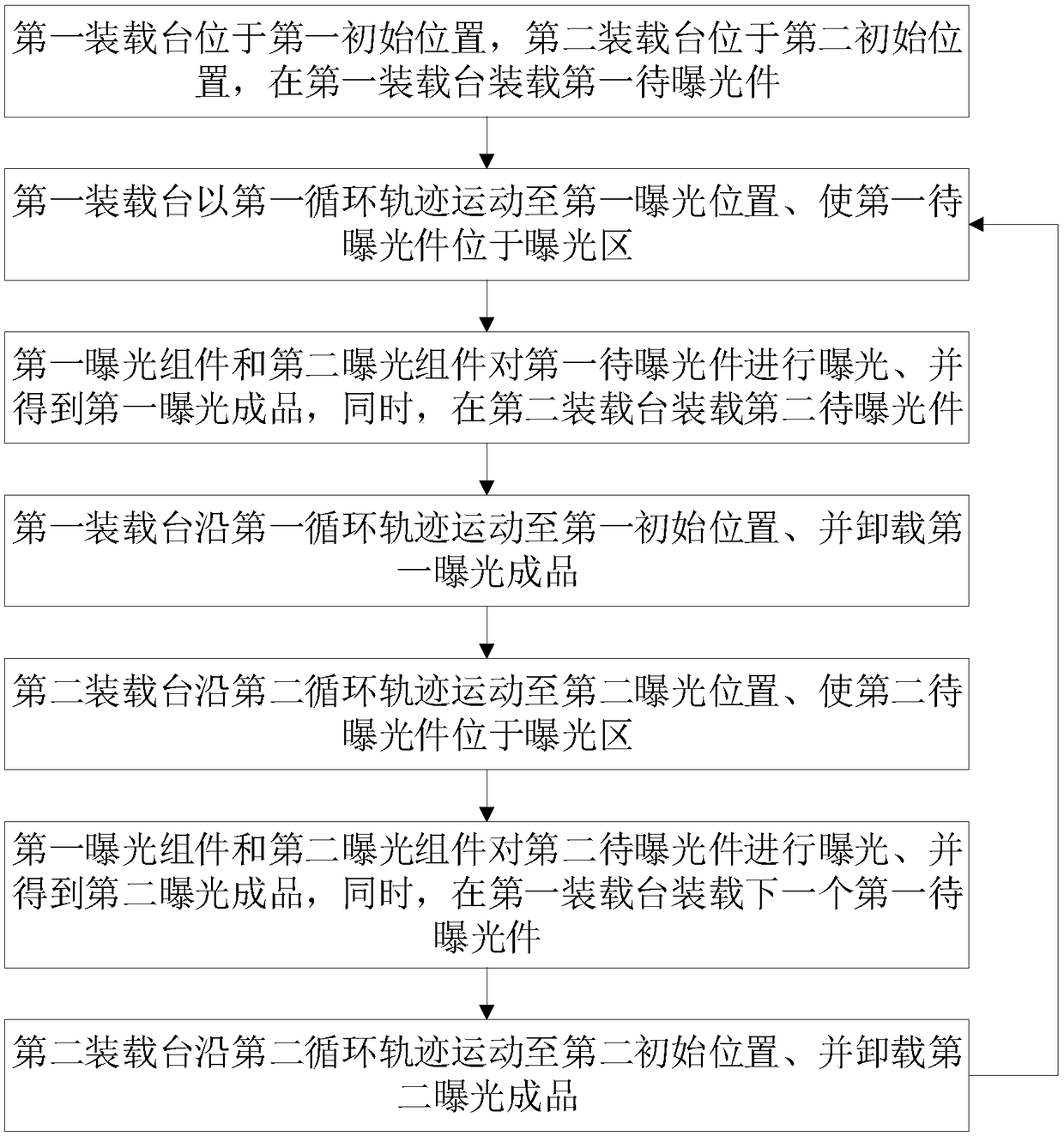

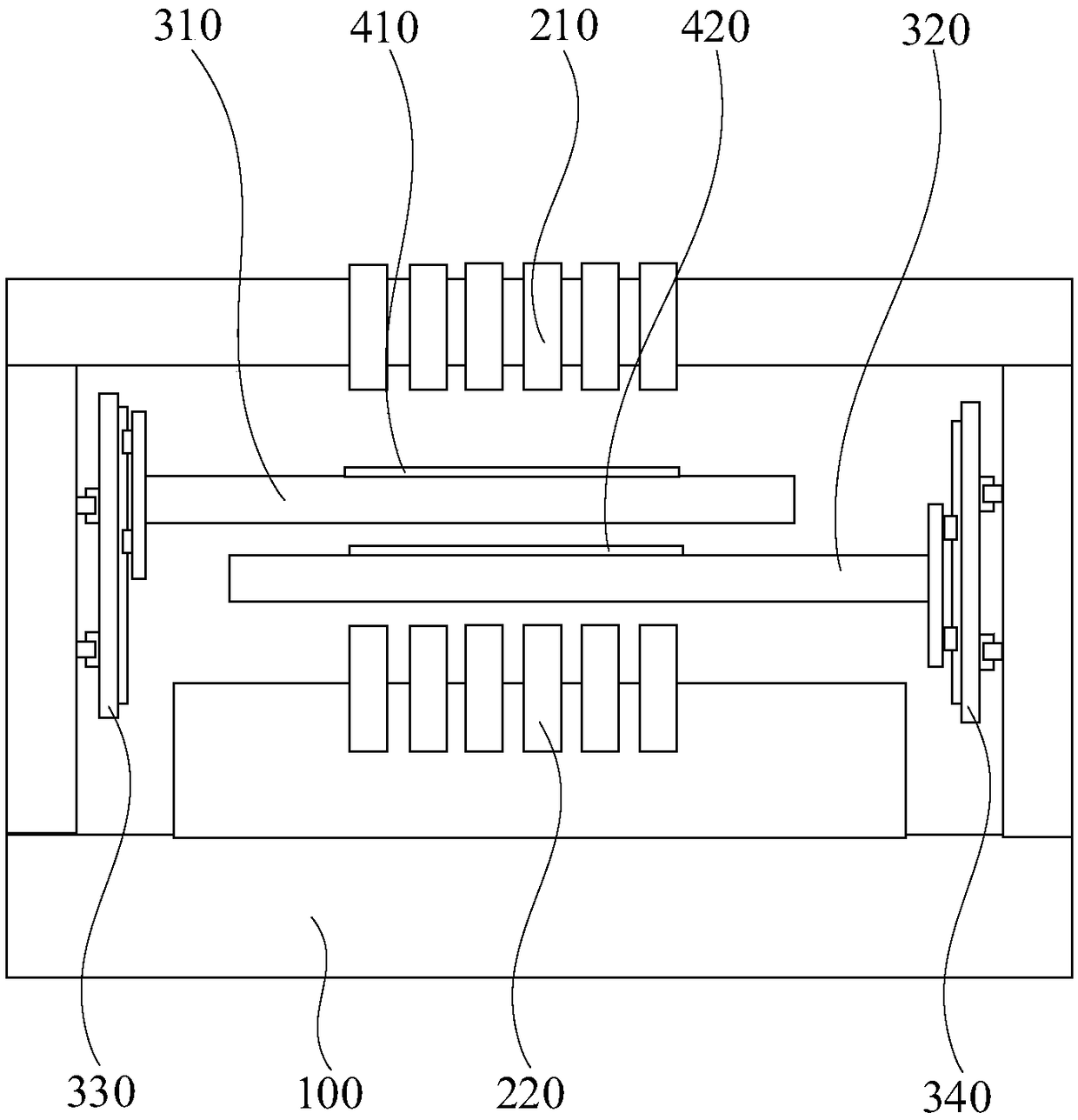

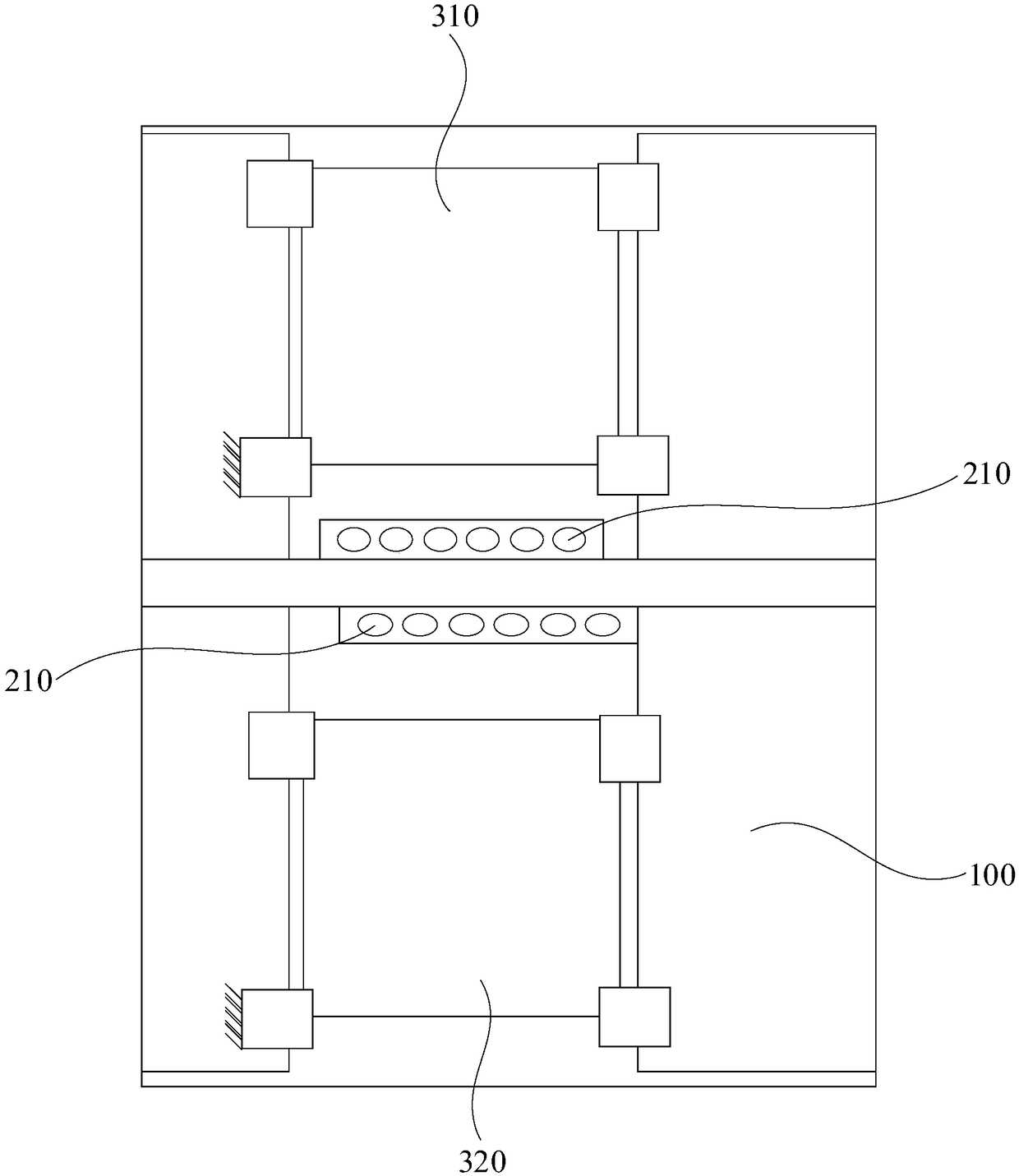

Double-side exposure machine with cantilever-type double-tables and double-side exposure method

ActiveCN108873621BImprove automationImprove time efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusExposureCantilever

Provided are a double-sided exposure machine and a double-sided exposure method. The double-sided exposure machine comprises: a mounting frame; a first exposure component (210) and a second exposure component (220) provided at two sides of the mounting frame, respectively; a first loading table (310) and a second loading table (320); and a driving mechanism, the driving mechanism comprising a driving assembly, the first loading table (310) and the second loading table (320) passing through an exposure area in a first motion state and a second motion state, respectively. During exposure, the first loading platform (310) moves along a first circular path and passes through the exposure area in the first motion state, so as to expose a first member to be exposed (410), and the second loading platform (320) moves along a second circular path and passes through the exposure area in the second motion state, so as to expose a second member to be exposed (420). Both the first loading platform (310) and the second loading platform (320) are in circular motion, and while said second member (420) is being exposed, the unloading of a first exposed finished product or the loading of a next first member to be exposed can also be performed, thereby having high exposure efficiency. Compared with the traditional double-sided exposure method by means of flipping, the present invention has high exposure precision.

Owner:ZHONGSHAN AISCENT TECH

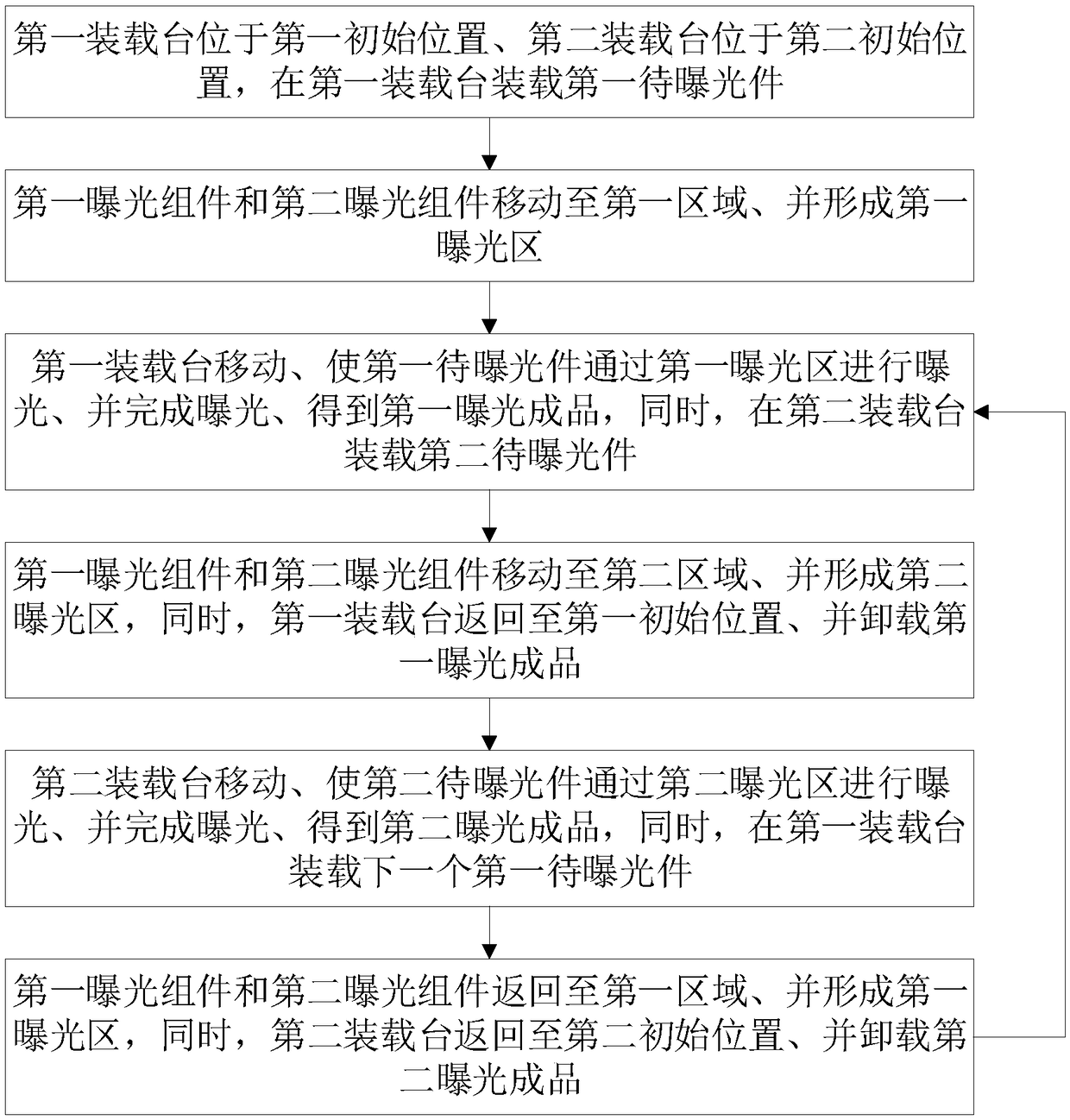

Double-side exposure machine and double-side exposure method

InactiveCN108897197AImprove exposure efficiencyImprove Exposure AccuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineering

The invention relates to a double-side exposure machine and a double-side exposure method. The double-side exposure machine comprises: a mounting frame; first and second exposure components arranged oppositely and capable of moving along the mounting frame; first and second stages capable of moving along the mounting frame. The double-side exposure method is applied to the double-side exposure machine. The first exposure component and the second exposure component form a first exposure zone in a first moving state; the first stage moves in the first exposure zone and performs exposure on a first part to be exposed; the second stage carries a second part to be exposed and forms a second exposure zone when in second moving state; the second stage moves in the second exposure zone and performs exposure on the second part to be exposed, and meanwhile, the first stage unloads or loads a next first part to be exposed; front and back exposure can be achieved with no need for reversing, and inaddition, the time of an exposure process is fully utilized, exposure efficiency is improved, and automatic operation can be achieved.

Owner:ZHONGSHAN AISCENT TECH

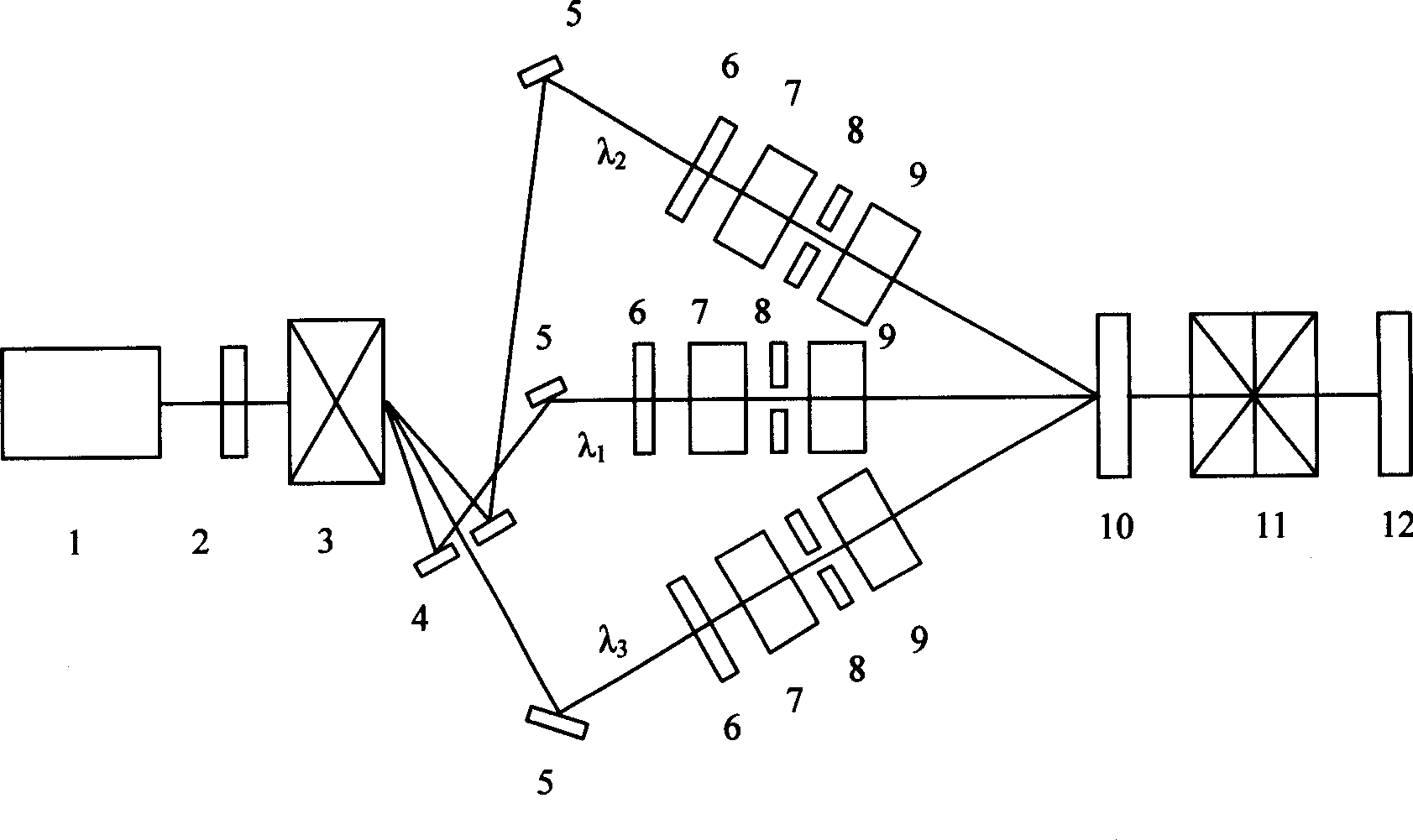

Method and system for imaging interference photoetching adopting white laser

InactiveCN1786822AEasy to adjustNo alignment issuesSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistLaser light

The invention relates to an imaging interference photoengraving method and the system that adopts white laser. The feature is that is contains plural wave length of white laser light source and light splitting components, and three beams of laser with different wave length are separated from the splitting component to supply illumine on plumbing masking direction, X direction and Y direction. The system needs not any adjusting components in the exposal process. It is benefit for the application of imaging interference photoengraving technology.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

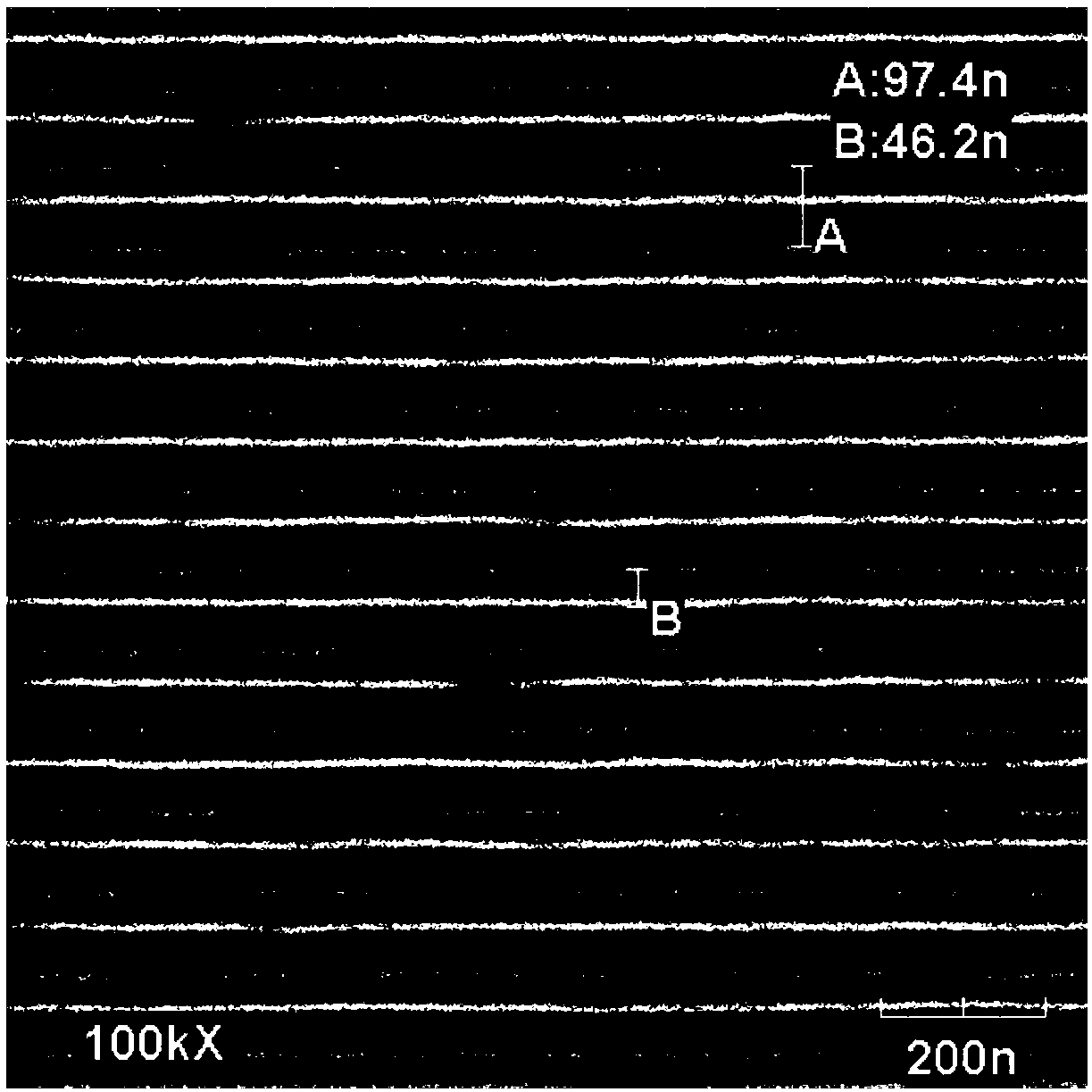

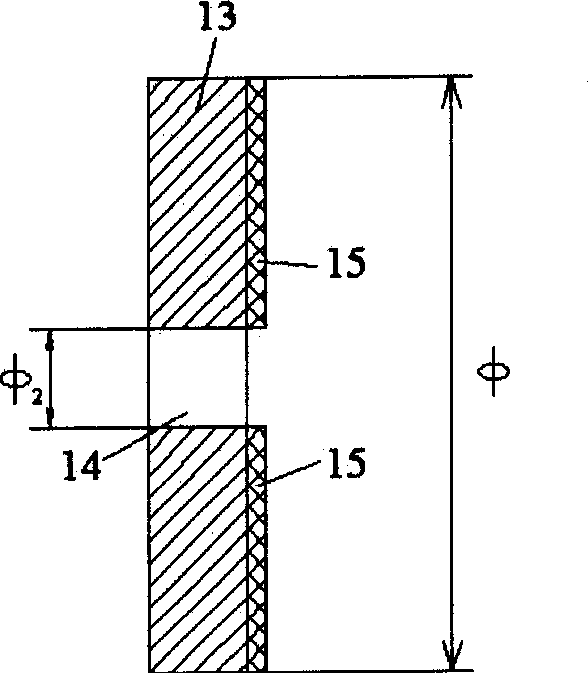

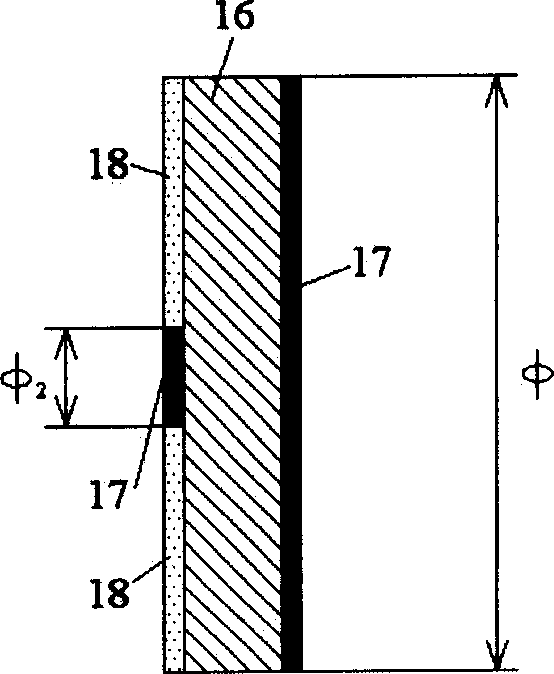

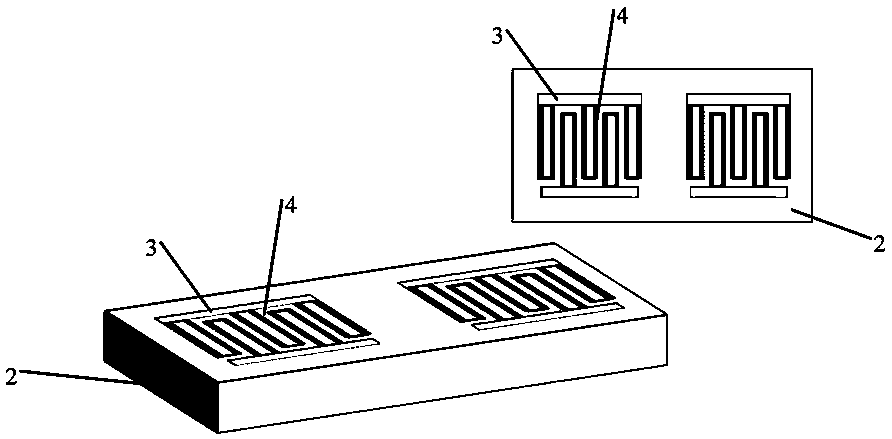

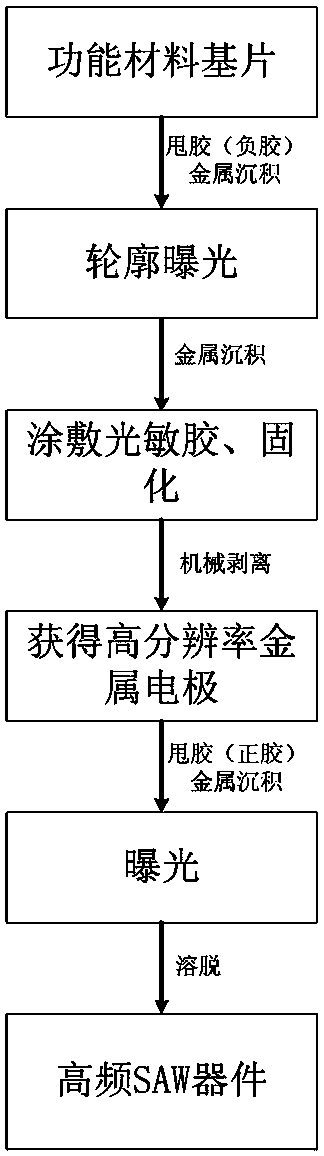

Fabrication method of high-band surface acoustic wave device electrode

ActiveCN107910438AImprove yieldEfficient preparationPiezoelectric/electrostrictive device manufacture/assemblyElectricityMetallurgy

The invention discloses a fabrication method of a high-band surface acoustic wave device electrode. The fabrication method comprises the steps of S1, exposing a profile of an interdigital electrode inan electrode to be fabricated on a substrate of a piezoelectric functional material by employing negative glue; S2, performing metal deposition after exposure and developing to obtain a metal coatinglayer with an interdigital electrode profile pattern; S3, mechanically stripping a redundant metal layer outside the profile pattern to obtain a final intensive pattern corresponding to the interdigital electrode; S4, performing exposure and metal deposition on a convergence bar and a bonding pad in the electrode to be fabricated by employing positive glue; and S5, stripping the redundant metal layer from the metal layer after being deposited by employing a solution removal process to obtain an electrode pattern corresponding to the convergence bar and the bonding pad so as to complete electrode fabrication. By the fabrication method, a nanoscale SAW device electrode compatible with a high-resolution intensive pattern and a large-size pattern can be obtained, and the fabrication method has the advantages of low cost, high fabrication efficiency, high yield, high SAW electrode quality, good universality and the like and is simple to implement and operate.

Owner:NAT UNIV OF DEFENSE TECH

Double-side exposure machine and double-side exposure method

ActiveCN108873621AImprove automationImprove time efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusCircular motion

The invention relates to a double-side exposure machine and a double-side exposure method, wherein the double-side exposure machine comprises a mounting frame, a first exposure assembly and a second exposure assembly arranged on two sides of the mounting frame respectively, a first loading platform and a second loading platform, and a driving mechanism. The driving mechanism comprises a driving assembly, and the first loading platform and the second loading platform pass through the exposure area in a first motion state and a second motion state respectively. When exposed, the first loading platform moves in a first circular track and passes through the exposure area in the first motion state to expose a first to-be-exposed part; and the second loading platform moves in a second circular track and passes through the exposure area in the second motion state to expose a second to-be-exposed part. The first loading platform and the second loading platform are in circular motion, and whenthe second to-be-exposed part is exposed, unloading of a first exposure finished product or loading of the next first to-be-exposed part can be carried out; the exposure efficiency is higher, and theexposure precision is higher compared with a traditional mode adopting overturning double-side exposure.

Owner:ZHONGSHAN AISCENT TECH

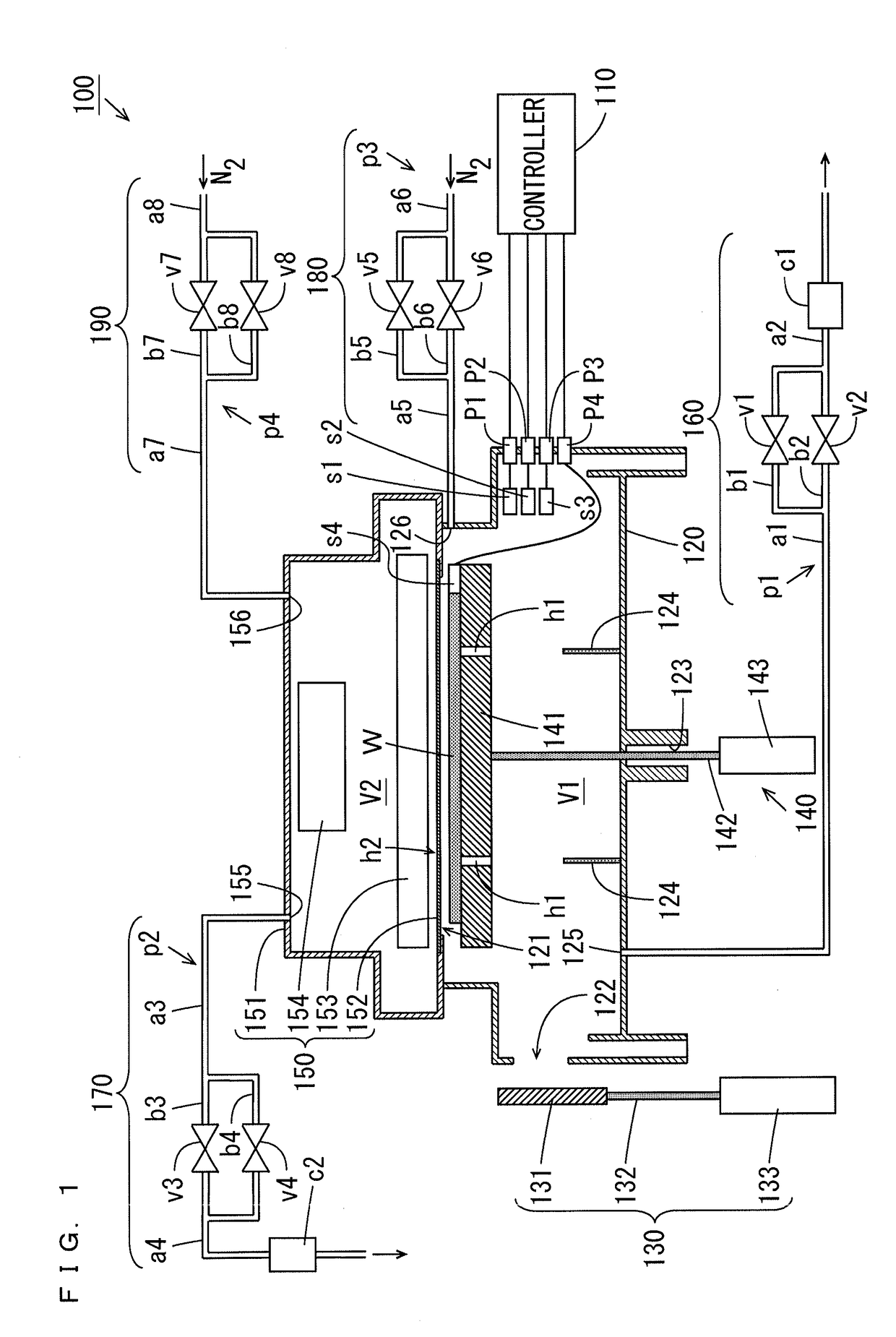

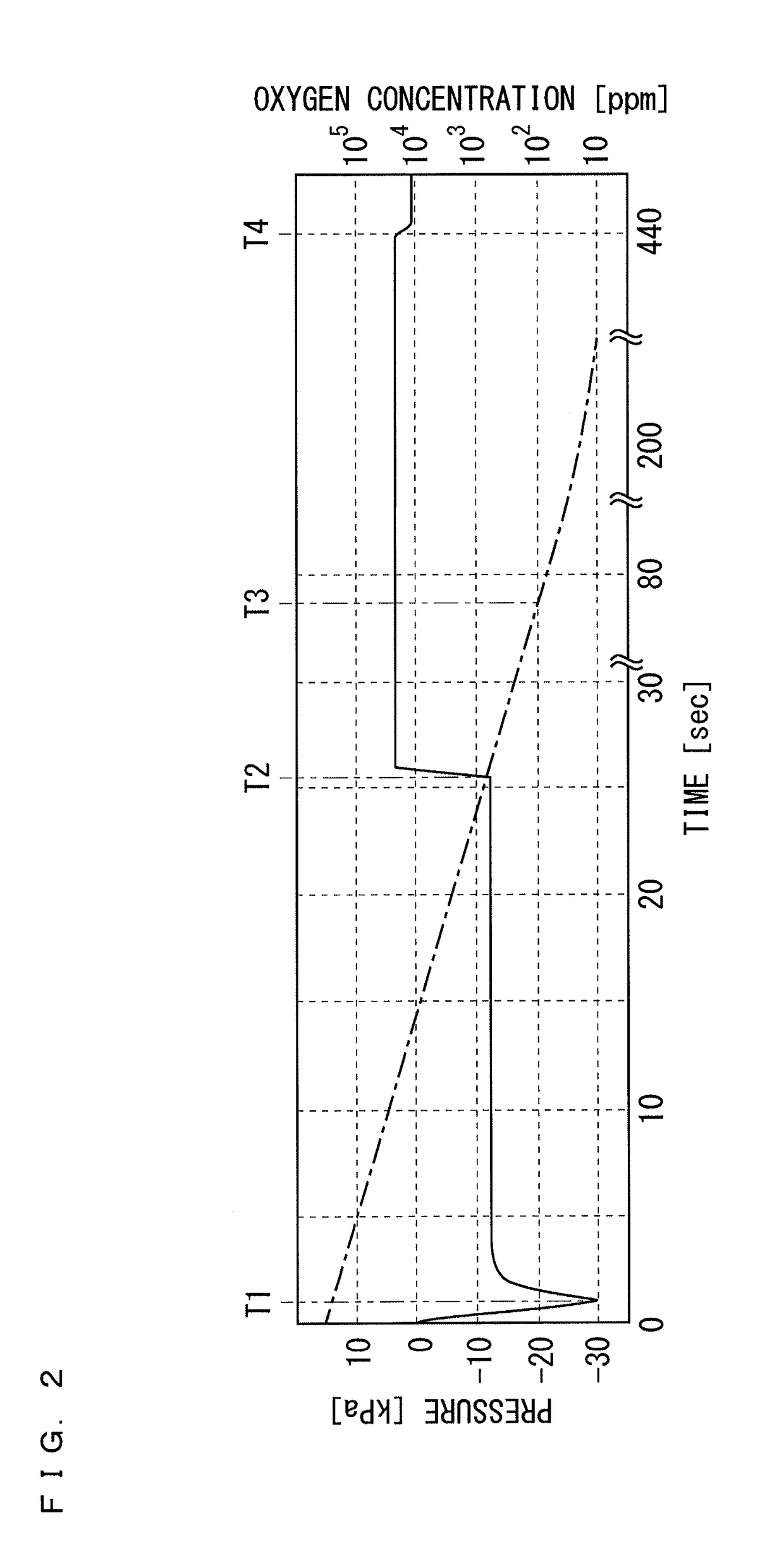

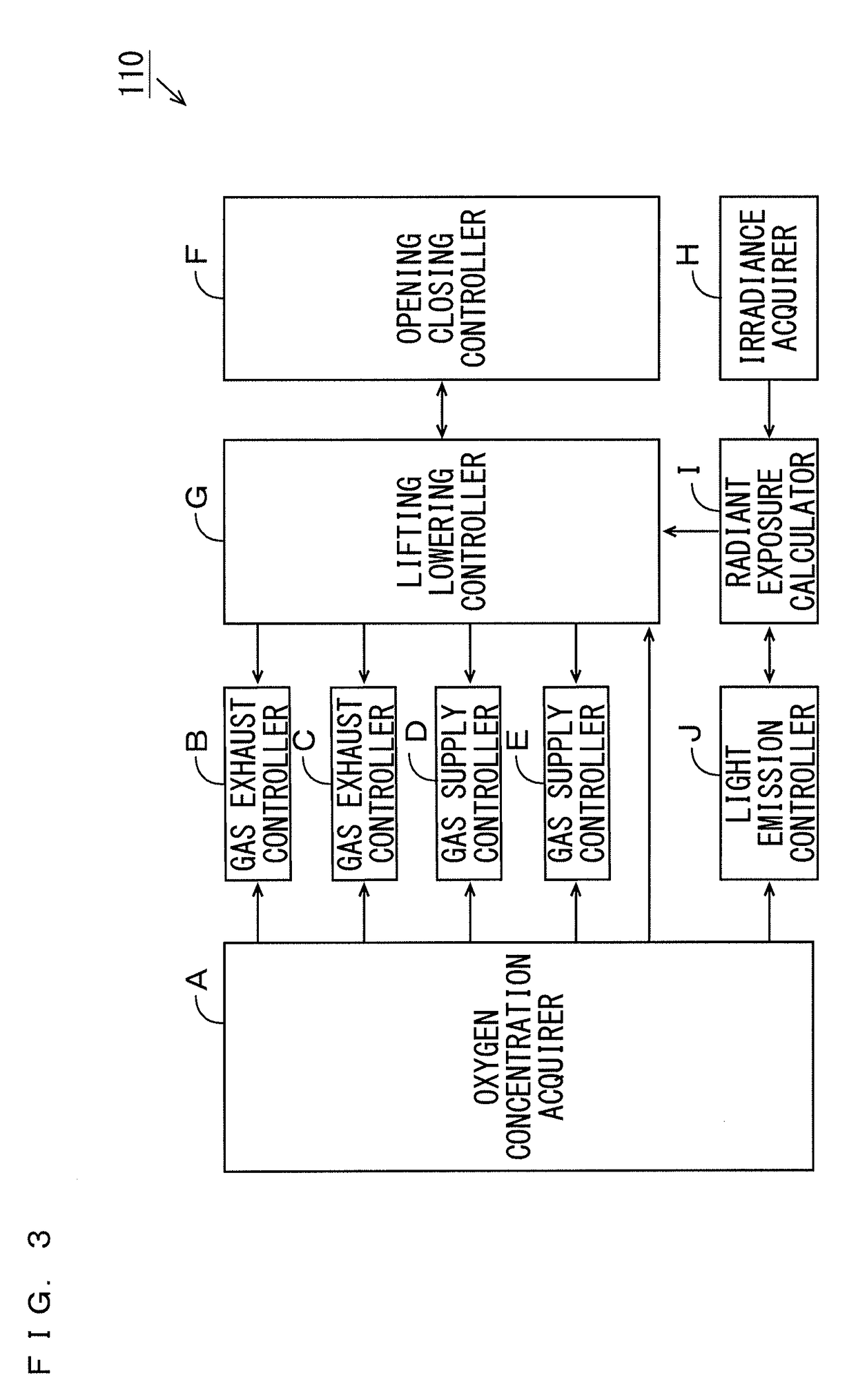

Exposure device, substrate processing apparatus, exposure method and substrate processing method

ActiveUS20190086808A1Low efficiencyImprove exposure efficiencySemiconductor/solid-state device manufacturingPhotomechanical coating apparatusUltravioletEngineering

Exhaust of gas in the processing chamber is started by a gas exhaust section, and supply of an inert gas into the processing chamber is started by a gas supply section after a predetermined time length has elapsed since the exhaust of gas is started. Alternatively, the gas in the processing chamber in which a substrate is stored is exhausted by the gas exhaust section, the inert gas is supplied into the processing chamber by the gas supply section, and the pressure in a light emitter that has a light-transmitting plate is allowed to match or be close to the pressure in the processing chamber. The substrate in the processing chamber is irradiated with vacuum ultraviolet rays by the light emitter with an oxygen concentration in the gas in the processing chamber lowered to a predetermined concentration. Thus, the substrate is exposed.

Owner:DAINIPPON SCREEN MTG CO LTD

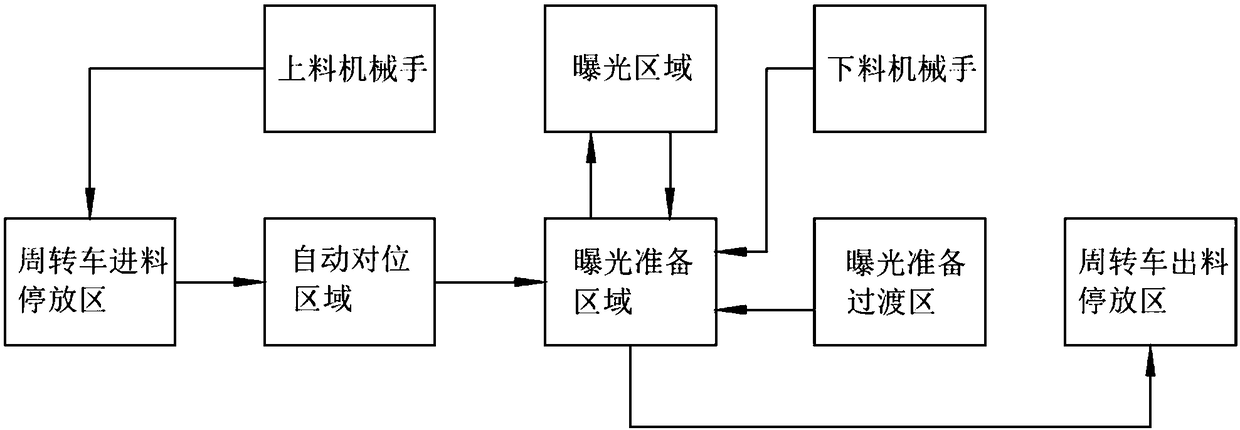

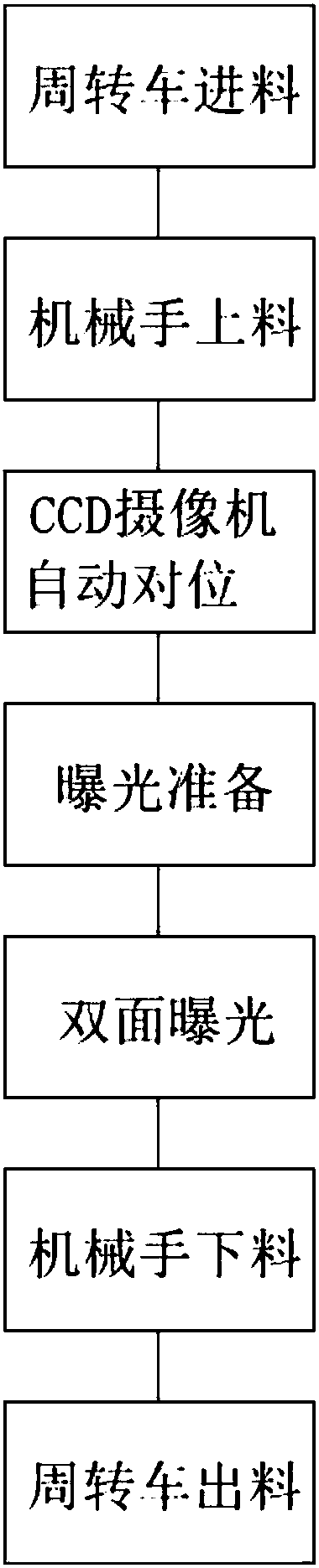

Full-automatic exposure technology

InactiveCN108319114ARealize fully automatic unmanned processingSave human effortPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringCcd camera

The invention discloses a full-automatic exposure technology and belongs to the technical field of PCB exposure. The full-automatic exposure technology comprises the following steps: A, feeding a material: a PCB transfer vehicle conveys PCBs to be exposed; B, loading the material: a material loading manipulator grabs the PCBs on the PCB transfer vehicle to an automatic aligning area to be aligned;C, automatic alignment: a CCD camera and a visual aligning system can finish automatic alignment between an upper negative film and a lower negative film, and the negative films and the PCBs are automatically aligned; D, exposure preparation: a carrying manipulator can grab the aligned PCBs to an exposure preparation area, and overlapping between the PCBs and the upper and lower negative films isfinished and is checked by a CCD camera system; E exposure: the aligned and checked PCBs are sent into the exposure area to be exposed by a lead screw guide rail platform of the exposure preparationarea, and after exposure is finished, the PCBs are automatically returned to the exposure preparation area; F, discharging the material: a discharging manipulator grabs the exposed PCBs to the PCB transfer vehicle. The full-automatic exposure technology disclosed by the invention can achieve unmanned automatic processing in the whole process.

Owner:CHENGDU KAIJING INTELLIGENT EQUIP CO LTD

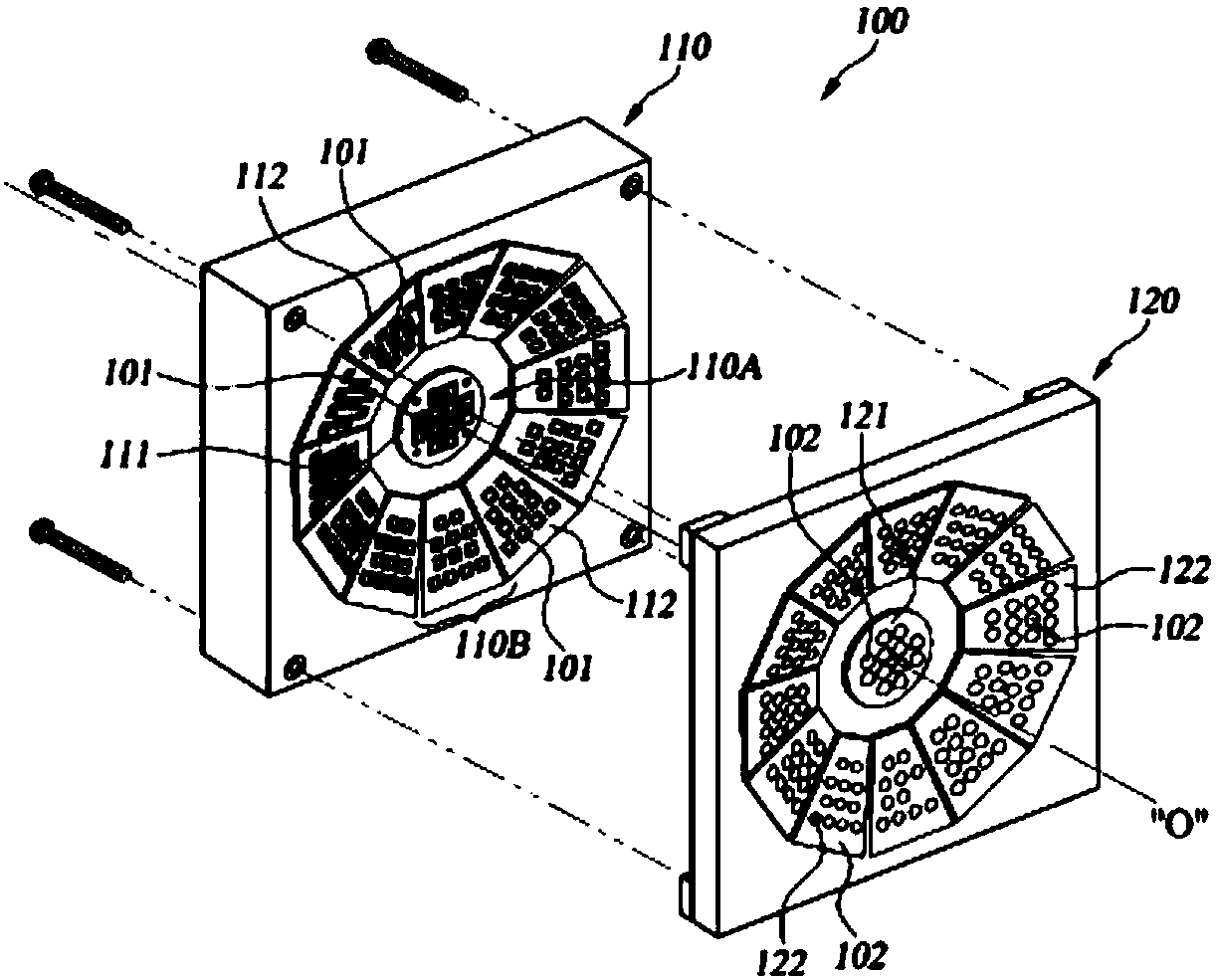

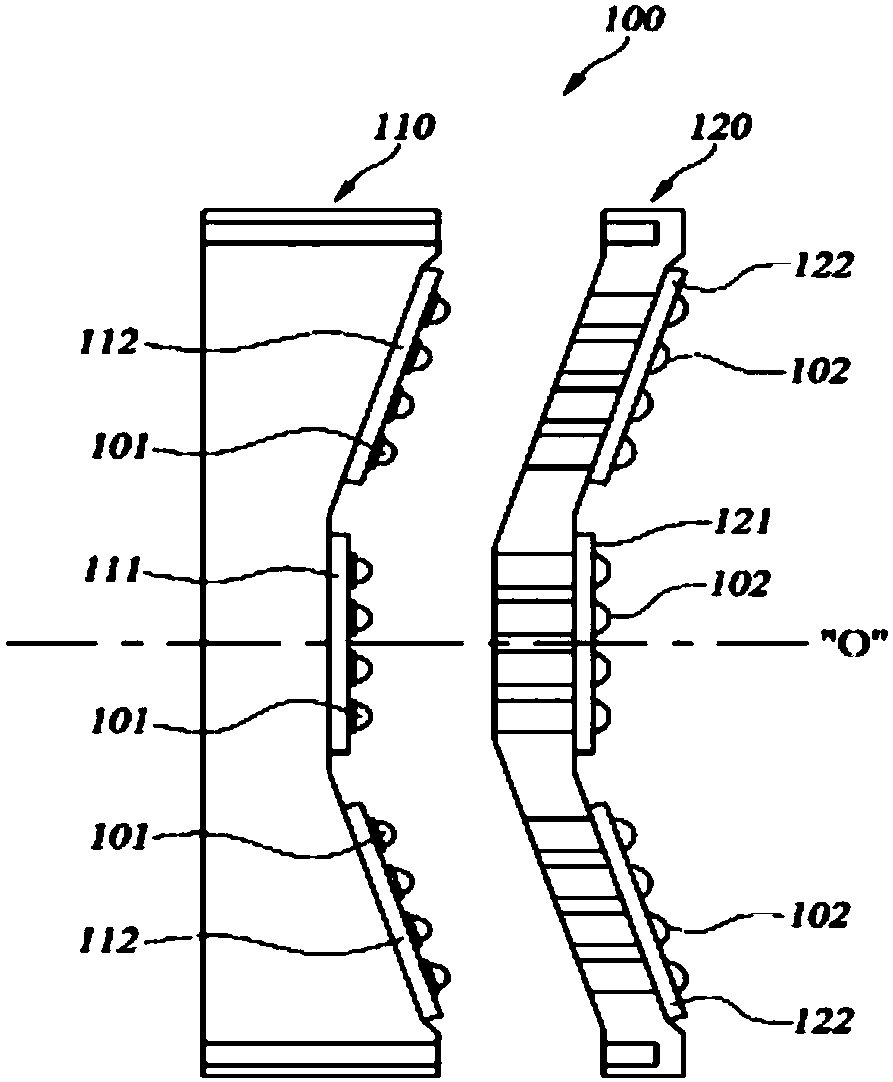

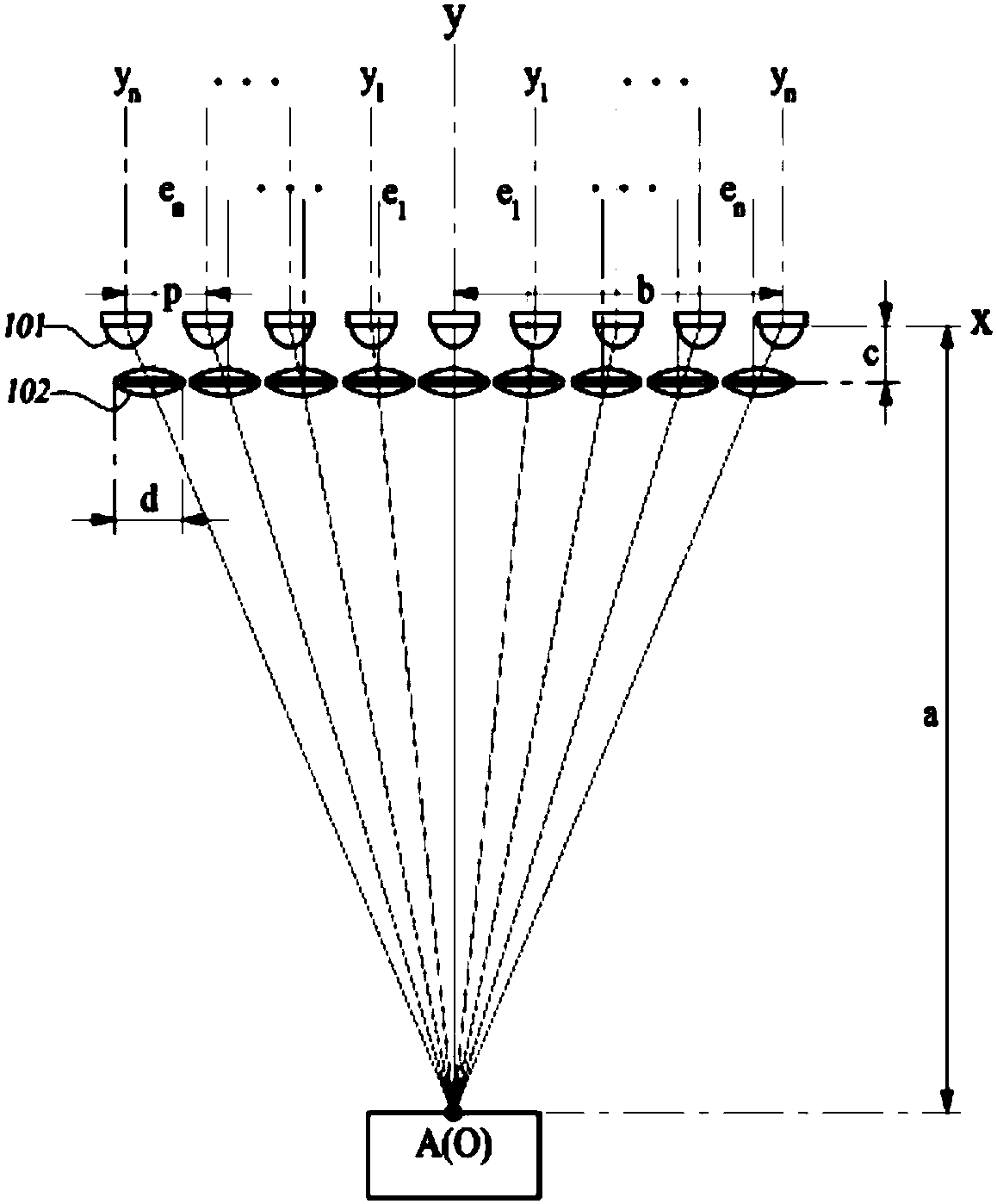

Light source module unit for exposure and exposure device having light source module unit

ActiveCN107924134ALight source replacement costs reducedAchieve resolutionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusMicrofabricationImage resolution

The present invention provides an integrated light source module unit for exposure and an exposure device having the light source module unit, which can ensure exposure performance capable of dramatically improving the microfabrication and the resolution of exposure patterns and, at the same time, has been improved so as to be economically substitutable for the light source of a conventional exposure device since low power consumption and, particularly, ultraviolet (UV) lights having a high-efficiency and high-output single wavelength and short wavelength are ensured by maximizing light outputpower by a combination of modules each comprising: a center light source part comprising a light source panel formed by mounting a plurality of unit UV light emitting diodes (LEDs) on a circuit boardin a matrix array structure, and an optical panel formed by providing a plurality of unit condensing lenses on the optical panels, which are arranged at light-emitting sides of the LEDs to face the light source panel, in a matrix array structure in a state in which the condensing lenses are eccentric toward a random reference center axial line, which passes the center of a UV LED array on the light source panel, with respect to a major optical axis at the positions respectively corresponding to the LEDs; and a plurality of peripheral light source parts radially and equally arranged in an inclined state so as to face a major light-emitting axis of the unit UV LED of the center light source part.

Owner:赵南稙

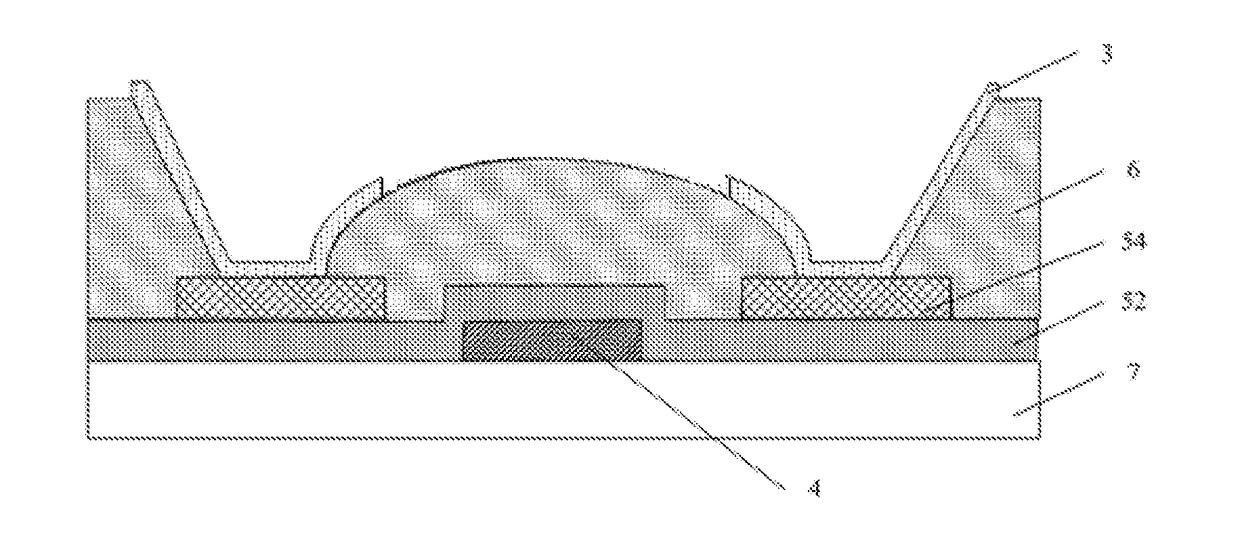

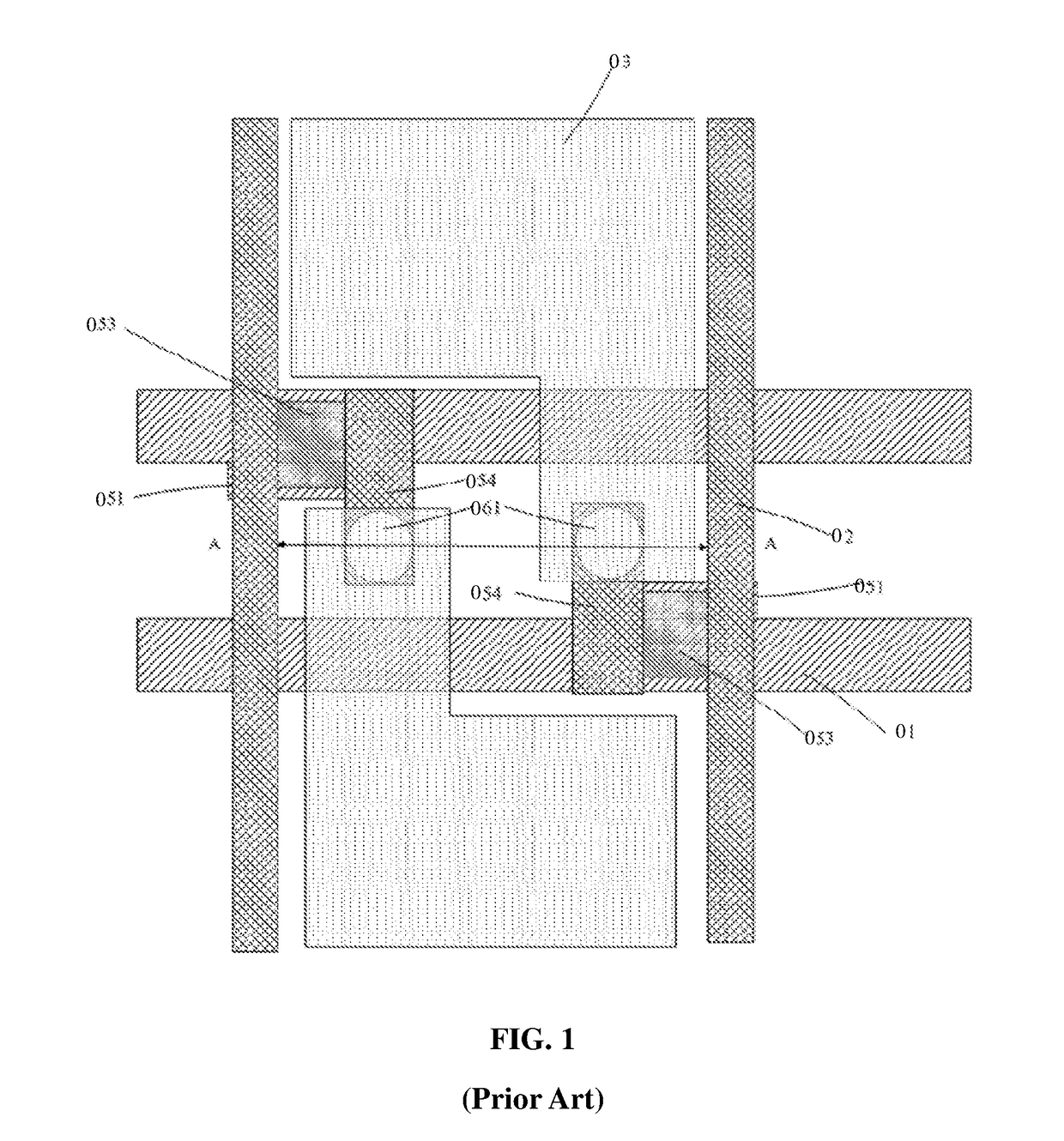

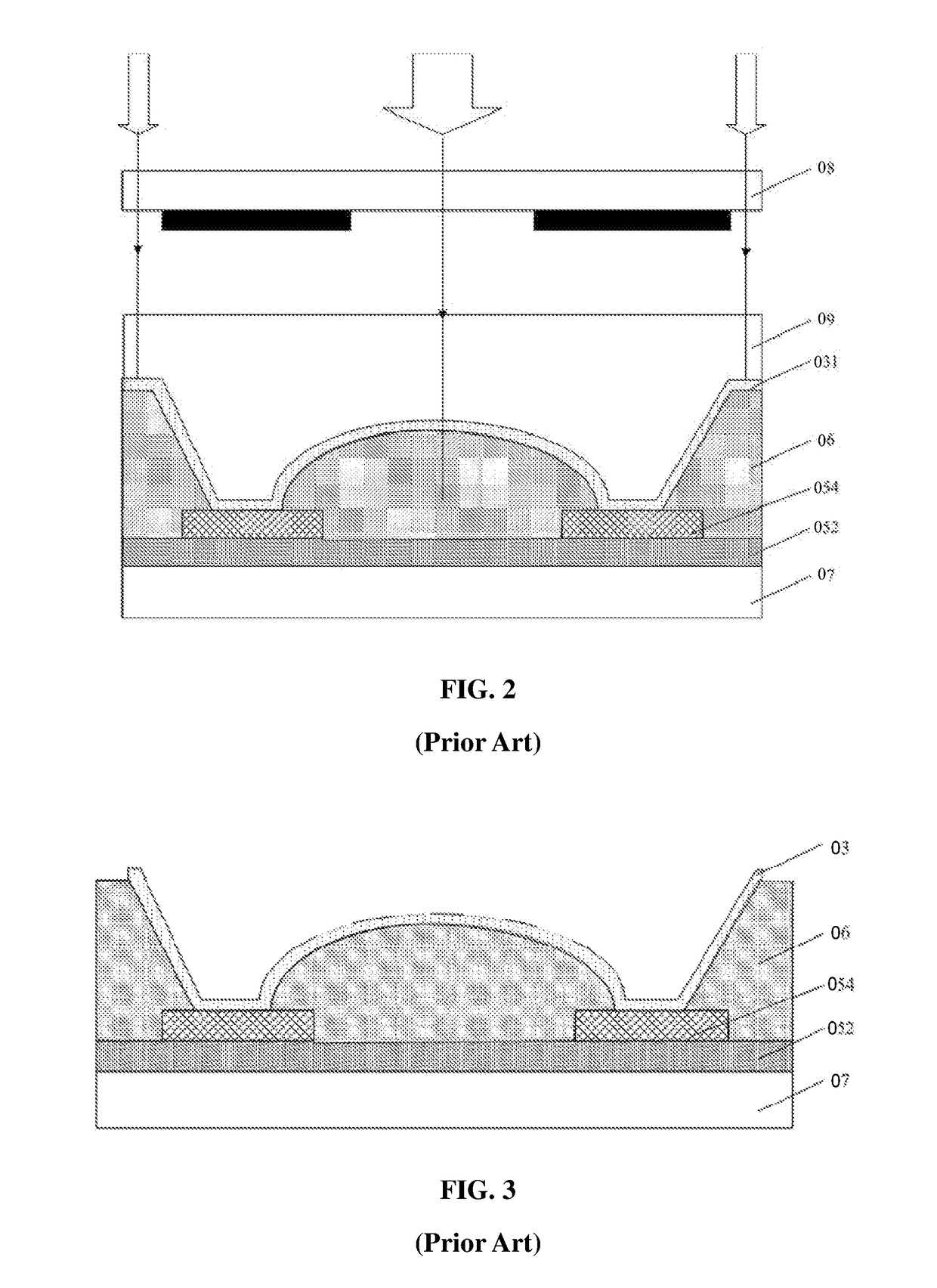

Array substrate and fabrication method thereof, and display device

An array substrate, a fabrication method of the array substrate, and a display device including the array substrate are provided. The array substrate includes a first electrode (54) including a plurality of first sub-electrodes, a second electrode (3) including a plurality of second sub-electrodes, and an insulating layer (6) disposed between the first electrode (54) and the second electrode (3). A plurality of via holes (61) are formed in the insulating layer (6), and the plurality of the second sub-electrodes are electrically connected to the plurality of the first sub-electrodes correspondingly through the plurality of the via holes (61). The array substrate further includes a light compensating structure (4) disposed under an uneven portion of the insulating layer (6) to locally improve an exposure efficiency in a photolithographic process for forming the second electrode (3).

Owner:BOE TECH GRP CO LTD +1

Integrative type direct-writing photo-etching method

ActiveCN101055424AImprove exposure efficiencySmooth graphic outlineSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusGraphicsEtching

The present invention relates to photoetching technique field, concretely is an integrative direct write photolithography method. The method includes determining the target exposal graph, direct write by steps and continuous scan etch three steps; improving the exposal efficiency by using projecting lens with different multiplying power; and gapless jointing the graphs generated by the projecting lens with changed multiplying power by using co-axial optical position detection system. The method of the invention adopts a mixing method of direct scan and minification typesetting, generates smooth graph contour outline and improves efficiency of exposal.

Owner:中夏芯基(上海)科技有限公司

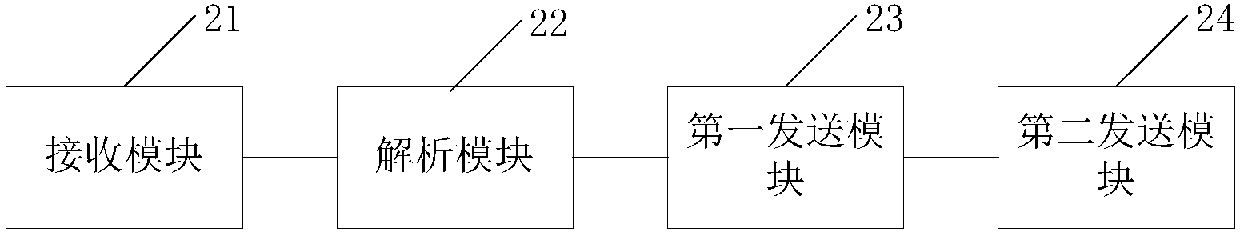

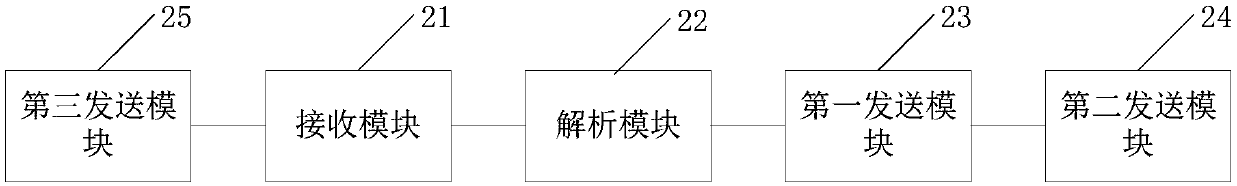

Virtual network service exposure method and device

ActiveCN107689987AMeet the needs of exposed servicesImprove exposure efficiencyTransmissionSoftware simulation/interpretation/emulationIp addressVirtual machine

The invention provides a virtual network service exposure method and device. The method comprises the steps that when a server sends a second access service request to a port of a virtual machine, source IP address information of an outer network terminal is taken as a mark and is added to the second access service request; the virtual machine is enabled to obtain a service data packet corresponding to the second access service request; the source IP address information is taken as the mark, is carried in the service data packet and is returned to the server; and the server sends the service data packet to the outer network terminal according to the source IP address information as the mark. According to the embodiment of the invention, the source IP address information of the outer network terminal is taken as the mark and is added to the second access service request and the corresponding service data packet, so a true IP mode is prevented from being employed when the IP and port ofthe physical server are mapped to or bridged with the port of the virtual machine, the true and available IP and port of the physical server are expanded, the demand of virtual network exposure service can be satisfied, and the virtual network service exposure efficiency is improved.

Owner:NEUSOFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com