Full-automatic exposure technology

A fully automatic and high-tech technology, applied in the field of PCB exposure, can solve the problems of manual operation and low production efficiency of exposure machines, and achieve the effects of improving exposure efficiency, improving efficiency, and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

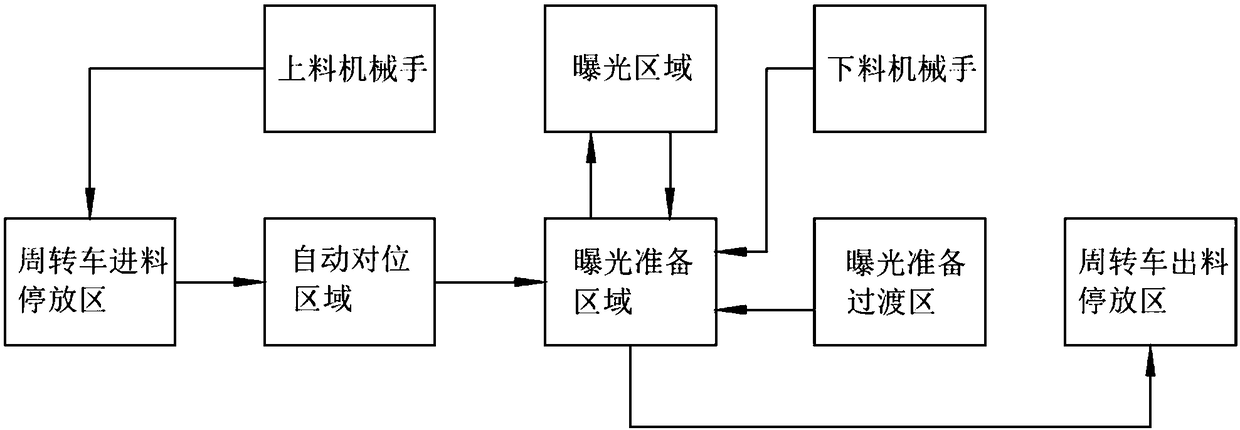

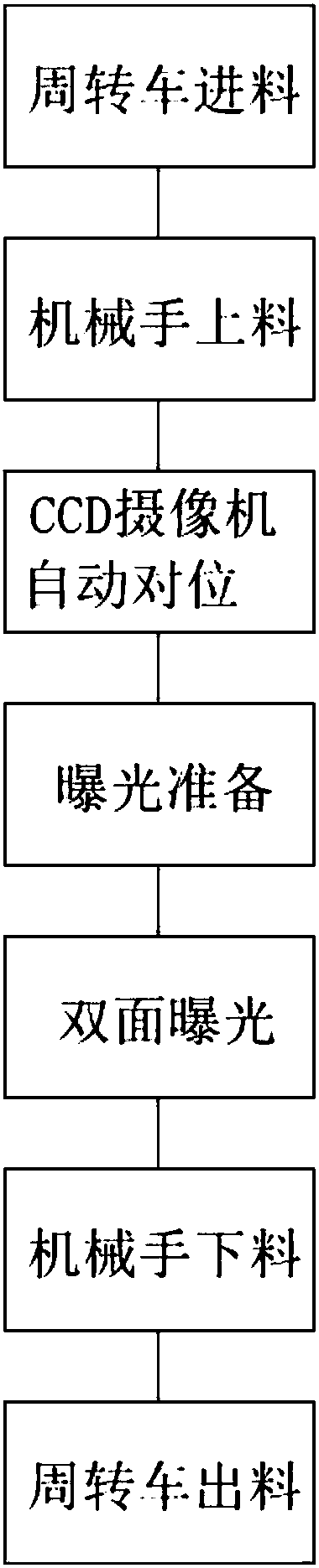

[0036] Such as figure 1 , figure 2 Shown, a kind of automatic exposure process is characterized in that, comprises the following steps:

[0037] A. Feed material: The PCB board turnover vehicle transports the PCB boards that need to be exposed from the upper process of the exposure machine, and parks them in the parking area 1 of the PCB board turnover vehicle.

[0038] B. Loading: The loading manipulator grabs the PCB boards on the PCB board turnover car to the automatic alignment area in sequence for alignment.

[0039] C. Automatic alignment: Through the CCD camera and visual alignment system, the automatic alignment of the upper film and the lower film, and the automatic alignment of the film and the PCB board are completed.

[0040] D. Exposure preparation: Grab the aligned PCB board into the exposure preparation area by the handling manipulator, complete the overlapping of the PCB board and the upper and lower negatives, and check it through the CCD camera system.

...

Embodiment 2

[0046] This embodiment focuses on the differences from the above embodiments, and the similarities will not be repeated. In this embodiment, an exposure room is provided in the exposure area of the step E, and an upper light source and a lower light source are provided in the exposure room. , for double-sided simultaneous exposure of PCB boards.

Embodiment 3

[0048] This embodiment focuses on the differences from the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, the PCB board turnover vehicle can be hauled by an AGV trolley, and the AGV trolley is an electric power supply that can be automatically charged. The driving trolley can automatically run along the planned route, and the production points of each process can automatically call the AGV trolley through the access of the calling system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com